How Much Does 40 mil HDPE Liner Cost?

How to buy the best HDPE liner, reservoirs, or industrial water storage starts with knowing the price of various thicknesses, and one of the most popular choices for its good balance between strength and low price is a 40 mil HDPE liner. Prices for the same product can differ depending on the quality, size of the roll, installation method, as well as the location. We clarify the 40 mil hdpe liner cost, describe the factors that determine the price, and assist you in budgeting for water storage projects that can be either small or large-scale, in this handbook.

1. Introduction to 40 mil HDPE Liner

The 40 mil hdpe liner is a high-density polyethylene geomembrane whose thickness is 40 mils (1 mil = 0.001 inch), which is equal to 1.0 mm. This is an engineering material primarily used in containment systems because it is waterproof, resistant to wear, and also resistant to chemicals and UV rays. The hdpe pond liner is made from top-grade polyethylene resins which are subjected to polymerization processes like slurry, gas-phase, or solution methods to get the right mix of strength and flexibility. The 40 mil thickness compromises between the two (performance and price) and thus, can be used in medium-duties such as pond liners, water storage in agriculture, and industrial settings as the second level of containment. Compared to thicker variants (e.g. 60 mil), 40 mil hdpe geomembrane is of less weight thus, are less labor-intensive when installing, yet they still can be used for leak protection as well as UV and weather resistance.

2. 40 mil HDPE Liner Key Product Characteristics

40 mil hdpe pond liner represent a combination of features that make the product workable in a variety of settings and situations:

2.1 Chemical Resistance

HDPE is an inert material in relation to a large number of chemicals that are acids, alkalis, and industrial effluents, hence, it is a material of choice over time, even in corrosive environments.

2.2 Mechanical Strength

With the same high tensile and puncture resistance, High density polyethylene pond liner can handle mechanical stresses of a moderate nature, for example, soil movement or machine contact.

2.3 Flexibility and Adaptability

Polyethylene pond liners automatically adjusts to any surface that has irregular shapes, the creativity of installers can therefore be limitless when dealing with slopes or curved basins that require them to work with complex geometries.

2.4 UV and Environmental Durability

Geomembrane sheet is very resistant to UV radiation as the carbon black (2–2.5%) utilized as a UV protector is well absorbed by them making them capable of outdoor service for tens of years.

2.5 Waterproofing and Low Permeability

HDPE's tightly packed molecular structure makes it very close to zero or even fully impermeable, which is important for stopping water loss or contamination.

3. 40 mil HDPE Liner Typical Applications

The affordable price of 40 mil HDPE liner pond has made them versatile enough to be implemented in various sectors:

3.1 Water Management

Reservoirs, irrigation canals, and decorative ponds leverage hdpe geo membrane to prevent seepage and conserve water.

3.2 Agriculture and Aquaculture

Pits for silage, fish ponds, and irrigation ponds are all places where high density polyethylene geomembrane play a major role in water quality maintenance and soil contamination prevention.

3.3 Industrial Containment

The second layer of containment for carbon tanks, storage of chemicals, and basins for wastewater treatment process, is made possible through the use of 40 mil high density polyethylene liner that come at low costs.

3.4 Mining and Landfills

While the use of lining hdpe that are thicker (e.g., 60 mil) is a must for landfills' primary hdpe geomembrane liner, the 40 mil geomembrane pond liner is used for doing such things as capping or serving as temporary containers'at mining operations.

3.5 Infrastructure Projects

In civil engineering, these hdpe geomembrane sheet act as waterproofing layers for tunnels, bridges, and foundations.

4. 40 mil HDPE Liner Cost Price Range and Market Overview

A 40 mil HDPE liner cost of 40 mil is determined by the cost of raw materials for the production, the quantity of the order, as well as manufacturer requirements. To illustrate, here is the information obtained from Alibaba suppliers:

4.1 Bulk Orders

The price varies from $0.30 to $0.69 per square meter for 100 m² and more.

4.2 Large-Scale Projects

In excess of 10,000 m² costs are about $1.29–1.31 per square meter, and this is the price most of the time inclusive of installation support or technical guidance.

4.3 The pricing is influenced by the following:

4.3.1 Fluctuations of the Raw Material

The HDPE prices are based on the prices of the ethylene as well as on the supply chain.

4.3.2 By the Nature of the Product

The texture of the surface (i.e., double-faced for slope stability) or the application of additives (i.e., UV inhibitors) may make the price rise.

4.3.3 Location

In Asia, the manufacturers especially in China can offer very competitive rates because of low production costs. On the other hand, suppliers in North America or Europe can charge high prices for the products, which are in compliance with strict regulatory standards.

5. Comparison with International Counterparts

When comparing 40 mil HDPE liners cost from global manufacturers, key distinctions emerge:

5.1 Production Technology

Western companies (e.g., in the U.S. or EU) often employ advanced processes like Unipol PE (gas-phase) or Hostalen (slurry) to produce bimodal HDPE with superior consistency and mechanical properties. In contrast, Chinese manufacturers like BPM Geosynthetics typically use cost-effective slurry or gas-phase methods, prioritizing economies of scale.

5.2 Quality Standards

International products adhere to stringent certifications (e.g., ASTM GRI GM13, ISO 9080), ensuring performance in extreme conditions. Chinese liners meet basic ASTM standards but may lag in long-term durability testing.

5.3 Customization and Innovation

Western manufacturers excel in tailored solutions (e.g., site-specific welding techniques), while Chinese brands focus on providing affordable, versatile products for broad applications.

5.4 Regulatory Compliance

In regions like the EU and North America, liners must satisfy environmental regulations (e.g., for landfill liners), driving higher costs. Chinese products are increasingly aligning with these benchmarks but remain more affordable.

6. Advantages of BPM Geosynthetics Products

BPM Geosynthetics, a well-known manufacturer in China, is able to maintain its market position because of the five major strengths:

6.1 Economical Pricing

BPM Geosynthetics is able to offer cheap 40 mil hdpe plastic liner (at a very low 0.30/m2 bulk purchase price) due to the excellent production scale working, and therefore they are quite affordable for the budget-having projects.

6.2 Complete Product Solutions

The brand is giving the users freedom of choice regarding the thickness of the 0.2 mm - 3.0 mm range, the width of 1 - 8 meters, and the texture (smooth or double-textured) of their product, to be able to meet varying needs.

6.3 Product Quality

BPM hdpe impermeable liner is in line with worldwide standards such as ASTM GRI GM13 and they have various certifications (e.g., ISO, SASO), which ensures the products are resistant to chemicals, have good tensile strength, and are stable under UV radiation.

6.4 Pre- and Post-Sales Amenities

The company extends the complete installation services, incorporating welding instruction, on-the-spot trouble shooting, thus effectively lowering the risk of the project.

6.5 International Competitiveness

BPM Geosynthetics goods are the reason for the company’s position on the world markets in North America, Europe, and Africa, where they are in competition with the international brands as far as the performance and the price are concerned.

Conclusion

The 40 mil HDPE liner is a versatile and economical solution for containment applications in water management, agriculture, and industry. Its pricing, influenced by raw material costs and order volume, remains highly competitive, with Chinese suppliers like BPM Geosynthetics offering cost-effective options without compromising baseline quality. While international manufacturers lead in advanced production technologies and tailored innovations, brands such as BPM Geosynthetics have narrowed the gap through certifications and comprehensive customer support. For projects requiring a balance between performance and affordability, 40 mil HDPE liners represent a prudent investment. As environmental regulations evolve, selecting suppliers that adhere to global standards will be crucial for ensuring long-term reliability and environmental safety.

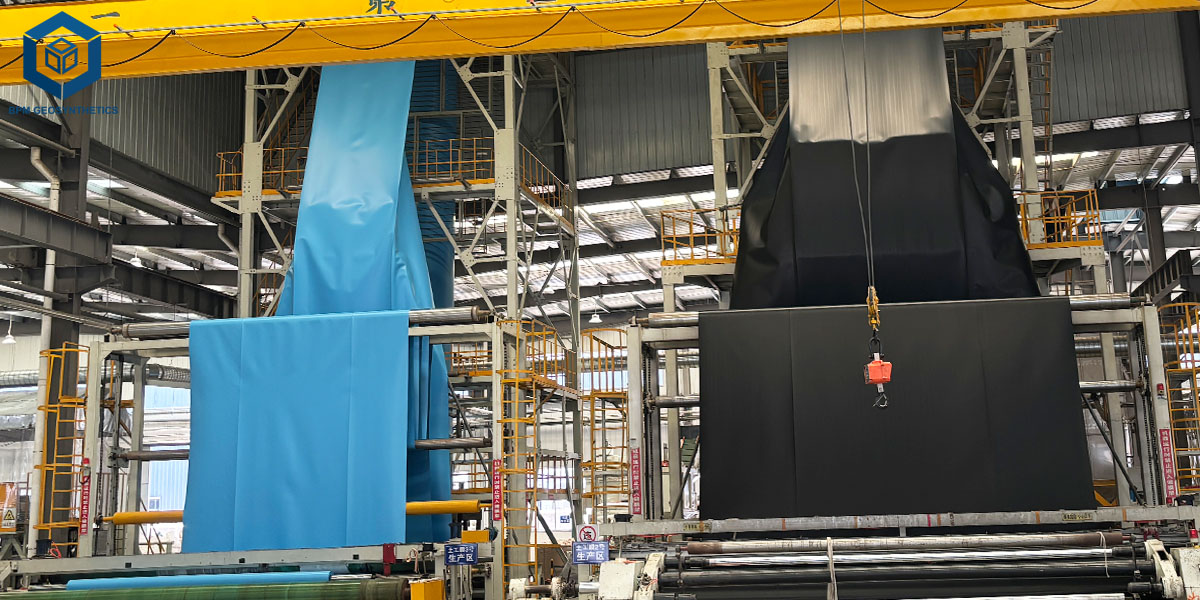

As the largest geomembrane liner companies in China, BPM Geosynthetics has more than 160 professional staff and 36,000 square meters géomembrane manufacturing factory equipped with state of the art geomembrane production lines. BPM geomembrane factory is certificated by ISO9001, ISO14001, and OHSAS18001. All BPM geomembranes have passed the certificates of the TUV, Soncap, SASO, BV and the test of SGS and Intertek etc. Product innovation, quality assurance and customer satisfaction are our long term commitment to our worldwide customers. Hope to be your partner.

The Best Project Material Co., Ltd.(BPM Geosynthetics)has provided many types of effective and state-of-the-art geomembranes and other geosynthetics to customers in over 100 countries worldwide.