HDPE Channel Lining

The HDPE Channel Lining system has become a cornerstone of modern water management, irrigation, and environmental protection projects. Made from High-Density Polyethylene (HDPE) geomembrane, this lining technology offers superior impermeability, chemical resistance, and long-term durability. As global infrastructure expands and sustainability standards rise, HDPE liners have become the preferred choice for canal, drainage, and wastewater containment applications worldwide.

HDPE Channel Lining: A Durable and Cost-Effective Solution for Modern Infrastructure

Introduction

The HDPE Channel Lining system has become a cornerstone of modern water management, irrigation, and environmental protection projects. Made from High-Density Polyethylene (HDPE) geomembrane, this lining technology offers superior impermeability, chemical resistance, and long-term durability. As global infrastructure expands and sustainability standards rise, HDPE liners have become the preferred choice for canal, drainage, and wastewater containment applications worldwide.

This article explores the market insights, cost factors, technical specifications, and installation guidelines for HDPE channel lining — providing actionable insights for B2B buyers, contractors, and project managers.

Understanding HDPE Channel Lining

What is HDPE Channel Lining?

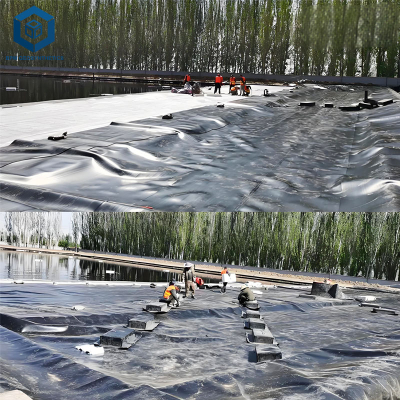

HDPE channel lining involves covering the inner surface of irrigation canals, drainage ditches, or industrial channels with HDPE geomembrane sheets. The liner acts as a waterproof barrier that minimizes seepage, soil erosion, and water loss. HDPE linings are especially popular in agriculture, mining, wastewater, and civil engineering applications.

Key Features and Benefits

High impermeability: Reduces seepage losses by up to 95%.

UV and chemical resistance: Performs effectively under sunlight and harsh chemical exposure.

Tensile strength and flexibility: Adapts to uneven terrain without cracking.

Low maintenance cost: Reduces long-term repair and operational expenses.

Sustainability: Recyclable material with a long service life exceeding 20 years.

Industry Background and Market Trends

Global Market Overview

The HDPE geomembrane market, including channel lining applications, is projected to grow at a CAGR of 6–7% between 2024 and 2030. The main growth drivers include the modernization of irrigation systems, stricter water conservation policies, and rising infrastructure investments in developing regions.

Countries in Asia-Pacific, the Middle East, and Africa are increasingly adopting HDPE channel lining systems to improve water distribution efficiency and reduce environmental degradation.

Sustainability and Innovation

Modern trends emphasize eco-friendly HDPE production, with manufacturers investing in low-carbon extrusion technology and enhanced UV stabilizers. Some projects now use textured HDPE liners to improve slope stability and bonding with concrete structures.

Factors Affecting HDPE Channel Lining Cost

The cost of HDPE channel lining varies depending on multiple parameters related to material, installation, and project specifications.

1. Thickness and Material Grade

HDPE liners are available in thicknesses ranging from 0.5mm to 3.0mm. Thicker liners provide higher mechanical strength and longer lifespan but increase cost per square meter.

0.75mm – 1.0mm: Suitable for light irrigation channels.

1.5mm – 2.0mm: Ideal for large canals or industrial drainage systems.

2.5mm – 3.0mm: Used in mining and heavy-duty containment applications.

2. Project Scale and Design Complexity

Linear projects with large surface areas benefit from economies of scale. However, channels with irregular shapes, steep slopes, or frequent bends may require custom cutting and welding, increasing labor costs.

3. Installation Method and Equipment

Professional installation involves hot wedge welding and seam testing to ensure watertight joints. Using certified welders and advanced sealing machines ensures durability but may raise initial costs slightly.

4. Site Preparation and Subgrade Quality

Proper leveling and compaction of the subgrade are essential before liner placement. Rough or rocky terrain requires geotextile underlayment, which adds to total project cost but prevents mechanical damage to the HDPE sheet.

Applications of HDPE Channel Lining

1. Irrigation and Agricultural Waterways

HDPE liners help reduce water seepage in irrigation canals, improving water use efficiency and ensuring consistent delivery to farmlands.

2. Drainage and Stormwater Management

Municipal and industrial drainage systems use HDPE channel linings to prevent erosion and contamination of groundwater.

3. Mining and Tailings Channels

Mining operations utilize HDPE linings for slurry transport channels and tailings containment, providing chemical resistance and structural integrity under heavy load conditions.

4. Industrial Wastewater and Leachate Control

In industrial sites and landfills, HDPE liners serve as secondary containment systems to protect surrounding soil and groundwater from hazardous waste seepage.

Technical Aspects and Installation Overview

Manufacturing and Quality Standards

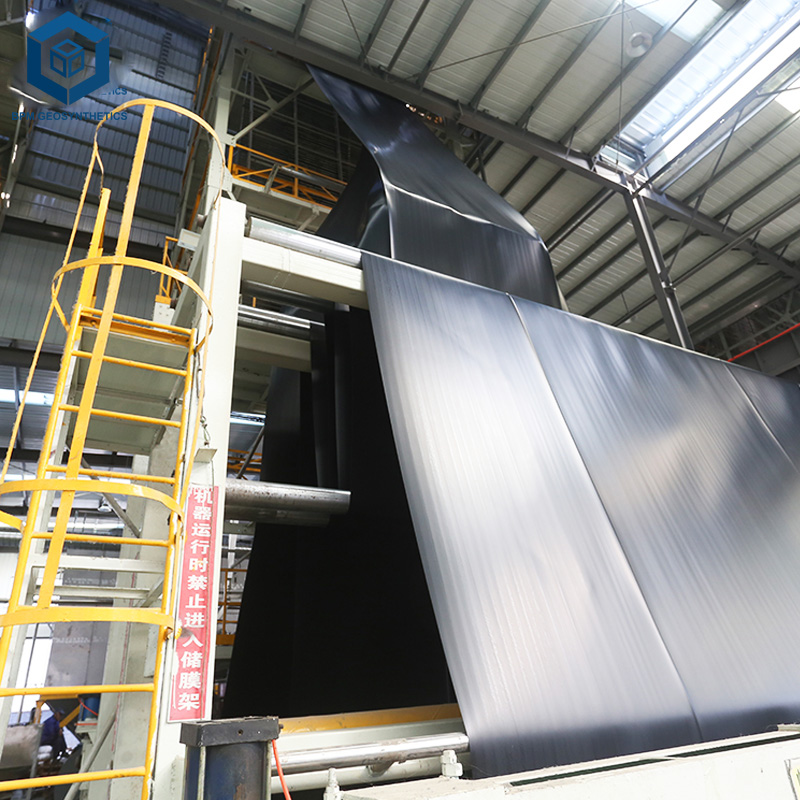

HDPE geomembranes used in channel lining are manufactured through blown film extrusion or flat die extrusion, ensuring consistent thickness and uniform molecular structure.

Quality standards such as ASTM D638, GRI GM13, and ISO 9001 are typically applied to ensure product reliability.

Installation Steps

Subgrade preparation: Leveling, cleaning, and compaction of the channel base.

Geotextile placement: Optional cushioning layer to prevent puncture.

HDPE liner deployment: Sheets are rolled out and aligned along the channel.

Seaming and welding: Joints are heat-welded using automated equipment.

Testing and inspection: Non-destructive testing ensures seam integrity.

Anchoring and backfilling: Edges are anchored into trenches for long-term stability.

Proper installation ensures that the HDPE channel lining system performs effectively over decades with minimal maintenance.

FAQs About HDPE Channel Lining

1. What is the average cost of HDPE channel lining per square meter?

Depending on liner thickness and project specifications, costs typically range from USD 2.0 to 4.5 per m², excluding installation.

2. How long does HDPE channel lining last?

A properly installed HDPE liner can last 20–30 years, even under harsh UV exposure and fluctuating temperatures.

3. Can HDPE channel liners be repaired if damaged?

Yes. Localized damage can be repaired by hot air welding or patching using HDPE material. Regular inspection ensures long-term performance.

4. What are the advantages of HDPE liners over concrete linings?

HDPE liners are lighter, more flexible, and faster to install. They also prevent seepage more effectively and require significantly less maintenance than concrete channels.

Conclusion and Call to Action

The HDPE Channel Lining system represents a modern, cost-effective, and sustainable approach to fluid containment and water management. Its combination of chemical resistance, flexibility, and long service life makes it an ideal solution for industries ranging from agriculture to mining and infrastructure development.

We provide high-quality HDPE channel lining materials manufactured under international standards, along with professional installation guidance and engineering support.

Contact us today to request technical data sheets, pricing estimates, or customized solutions for your channel lining project. Our engineering team is ready to help optimize performance and reduce long-term costs for your next infrastructure investment.