Nonwoven Filter Fabric

Nonwoven filter fabric is a high-performance fabric extensively used in filtration, drainage, and separation applications. Manufactured from polypropylene (PP) or polyester (PET), it offers great permeability, durability, and resistance to environmental factors. It is an best answer for geotechnical, industrial, and environmental tasks requiring dependable filtration and soil stabilization.

- Cost-Effective Solution:Provides lengthy carrier existence and reduces renovation costs.

- Versatile Applications:Suitable for street construction, drainage systems, landfills, landscaping, and erosion control.

- Environmentally Friendly:Made from recyclable materials, protected for soil and water systems.

- Customizable Options:Available in different weights, widths, and roll lengths to meet assignment requirements.

- Separation & Reinforcement:Prevents mixing of soil layers and will increase balance of subgrade structures.

Nonwoven filter fabric is a especially engineered geotextile manufactured from amazing polypropylene (PP) or polyester (PET) fibers, designed to supply each strength and performance in stressful environments. Unlike woven fabric that be counted on interlaced yarns, nonwoven fabric are produced the use of superior strategies such as needle-punching or heat-bonding, which create a dense but noticeably permeable structure. This special development ensures that the fabric efficiently retains soil, sand, and different pleasant particles whilst permitting managed water flow, making it an environment friendly filtration and drainage medium. In addition to its greatest filtration properties, nonwoven filter geotextile presents superb durability, chemical resistance, and adaptability to distinctive soil and climate conditions. Because of these characteristics, it has emerge as an essential fabric in geotechnical engineering, civil construction, avenue and railway projects, hydraulic works, and environmental safety structures the place soil stabilization, erosion control, and long-term reliability are critical.

1. Nonwoven Filter Fabric Key Features and Benefits

1.1 Nonwoven Filter Fabric - Efficient Filtration

Nonwoven filter fabric is designed to act as an high quality barrier, permitting water to pass by freely whilst stopping the migration of soil, sand, and first-rate particles. This ensures balance in drainage and soil separation systems, retaining the integrity of development tasks over time.

1.2 Nonwoven Filter Fabric - High Tensile Strength

Engineered from robust PP or PET fibers, the non woven geotextile fabric well-knownshows notable tensile electricity that permits it to stand up to heavy loads, soil pressure, and set up stresses. This makes it mainly appropriate for functions such as roadbeds, embankments, and landfills the place structural reinforcement is required.

1.3 Nonwoven Filter Fabric - Excellent Permeability

The special nonwoven fabric gives most desirable water permeability, permitting environment friendly drainage whilst warding off waterlogging. By making sure constant water flow, it prevents hydrostatic strain buildup and enhances soil balance in geotechnical and environmental projects.

1.4 Nonwoven Filter Fabric - Chemical and UV Resistance

Nonwoven filter material is resistant to a large vary of chemicals, acids, alkalis, and different elements frequently discovered in soil and groundwater. Its UV-resistant residences in addition make certain dependable overall performance when uncovered to sunlight, making it appropriate for each buried and uncovered applications.

1.5 Nonwoven Filter Fabric Flexibility and Easy Installation

Lightweight and exceptionally flexible, the needle punch filter fabric is handy to transport, cut, and deploy on-site. It can be tailored to irregular floor surfaces and curves barring difficulty, lowering set up time and labor costs. This makes it a sensible answer for tasks of all scales.

1.6 Nonwoven Filter Fabric Customizable Options

Available in a huge vary of weights (gsm), widths, and roll lengths, non woven geotextile filter fabric can be tailor-made to precise venture needs. Whether for small landscaping works or large-scale civil engineering projects, custom-made specs make certain superior overall performance and cost-effectiveness.

2. Nonwoven Filter Fabric Technical Specifications

2.1 Nonwoven Filter Fabric Weight Range: 100 – 1200 gsm

Nonwoven drainage fabric is manufactured in a broad vary of weights to swimsuit one-of-a-kind applications. Lighter grades (100–300 gsm) are perfect for landscaping, drainage, and small-scale separation projects, whilst heavier grades (up to 1200 gsm) are used in worrying civil engineering works such as highways, landfills, and hydraulic buildings the place larger power and sturdiness are required.

2.2 Nonwoven Filter Fabric Roll Width: 1 m – 6 m

The black polypropylene non woven filter fabric is on hand in a range of roll widths, imparting flexibility for each small and massive projects. Narrow rolls can be without problems treated and established in restrained areas, whilst wider rolls decrease overlap and set up time in substantial development works.

2.3 Nonwoven Filter Fabric Length Per Roll: 50 m – 200 m

Non woven filter roll lengths are designed to optimize managing and transportation whilst lowering the variety of joints at some stage in installation. Shorter rolls are handy for smaller jobs, whereas longer rolls provide effectivity and continuity for large-scale applications.

2.4 Nonwoven Filter Fabric Tensile Strength: 8 – 40 kN/m

Depending on the chosen grade, the non woven filter cloth affords sturdy tensile residences that enable it to stand up to heavy stresses from soil, loads, and mechanical forces. This makes it appropriate for reinforcement, erosion control, and different purposes requiring structural stability.

2.5 Nonwoven Filter Fabric Permeability: High Water Flow Rates

Engineered with a porous structure, the geotech non woven filter fabric ensures excessive water permeability whilst correctly filtering soil particles. This property permits dependable drainage and prevents water buildup, which is integral in avenue construction, protecting walls, and subsurface drainage systems.

2.6 Nonwoven Filter Fabric Customizable Options

All specs can be adjusted in accordance to venture requirements. Clients may also request personalized weights, sizes, strengths, and packaging to make sure that the material meets precise utility needs, whether or not for civil engineering, environmental protection, or landscaping projects.

3. Applications of Nonwoven Filter Fabric

3.1 Nonwoven Filter Fabric for Road and Railway Construction

Nonwoven filter material is extensively used below roads, highways, and railway tracks to stop the mixing of soil and mixture layers. By keeping apart the subgrade from the base materials, it keeps structural integrity, distributes hundreds evenly, and enhances pavement durability. This effects in longer-lasting infrastructure with decreased protection costs.

3.2 Nonwoven Filter Fabric for Drainage Systems

In drainage applications, the polypropylene non woven filter fabric material acts as an high-quality filter layer in subsurface drainage pipes, preserving walls, French drains, and trench systems. It permits water to glide freely whilst stopping soil particles from clogging the drainage system, making sure long-term effectivity and decreasing the threat of flooding or soil erosion.

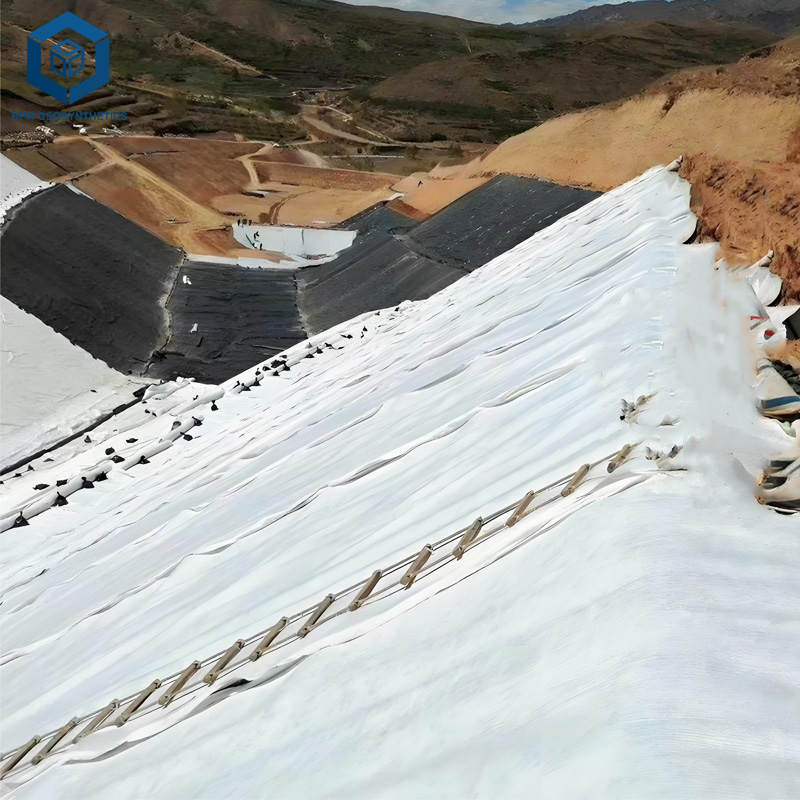

3.3 Nonwoven Filter Fabric for Landfills and Environmental Protection

Geotextile non woven filter fabric performs a indispensable function in landfill liner structures and different environmental projects. It serves as a cushioning and shielding layer for geomembranes, stopping punctures from sharp objects. Additionally, it enhances leachate series and filtration systems, assisting protected waste administration and environmental protection.

3.4 Nonwoven Filter Fabric for Landscaping and Gardening

In landscaping, the non woven fabric water filter is frequently used for soil separation, weed control, and floor stabilization. It helps preserve easy layers of soil, gravel, or sand whilst stopping weed increase besides the use of hazardous chemicals. This makes it perfect for gardens, pathways, inexperienced roofs, and leisure areas.

3.5 Nonwoven Filter Fabric for Hydraulic and Water Projects

Nonwoven filter material is necessary in hydraulic engineering works such as canals, dams, reservoirs, riverbanks, and coastal safety systems. It prevents soil erosion induced by way of water go with the flow whilst permitting suitable drainage to relieve hydrostatic pressure. This ensures the long-term balance of hydraulic buildings and reduces the danger of failure.

4. Nonwoven Filter Fabric Installation and Handling

4.1 Nonwoven Filter Fabric Lightweight and Easy to Transport

Nonwoven geotextile is lightweight, making it easy to carry, load, and dump at building sites. This reduces the want for heavy equipment and minimizes labor charges in the course of transportation and handling.

4.2 Nonwoven Filter Fabric Flexible and Adaptable

Thanks to its bendy structure, the non woven geotextile fabric material can be without problems rolled out and adjusted to match uneven floor surfaces, curves, or slopes. It adapts properly to complicated terrain besides tearing or dropping performance.

4.3 Quick Cutting and Positioning

The nonwoven geotextile fabric can be without problems reduce to the required dimensions the usage of fashionable tools, making sure correct placement and minimal waste. This lets in contractors to personalize the cloth on-site to meet unique venture requirements.

4.4 Simple Installation Process

Typically, the non woven landscape fabric is laid immediately on organized soil surfaces or between layers of aggregates. It requires minimal equipment or specialised equipment, which speeds up set up and lowers basic assignment costs.

4.5 Reduced Overlaps and Seams

With roll widths handy up to 6 meters, fewer overlaps are required, which enhances set up effectivity and ensures non-stop insurance throughout giant areas. Proper overlapping or seaming strategies stop soil intrusion and warranty long-term effectiveness.

4.6 Enhanced Long-Term Stability

When hooked up correctly, the non woven filter fabric material keeps its integrity below load and environmental stress. This ensures dependable filtration, drainage, and separation features for the duration of the lifespan of the project.

5. Nonwoven Filter Fabric Quality Assurance and Standards

To warranty overall performance and reliability, nonwoven filter fabric are manufactured in compliance with worldwide excellent requirements such as ISO, ASTM, and CE certifications. Strict satisfactory manipulate is utilized at each stage, from uncooked cloth choice to ultimate packaging, making sure regular product high-quality and lengthy provider life.

6. Why Choose Our BPM Nonwoven Filter Fabric?

We are a main geosynthetics producer with superior automatic manufacturing strains and years of export experience. Our nonwoven filter fabric are customizable to meet precise venture necessities and reachable at aggressive manufacturing facility prices. We additionally supply quickly delivery, technical support, and pattern offerings to make certain patron satisfaction.

7. Conclusion

Nonwoven filter fabric is a most economical and reliable answer for filtration, drainage, and soil stabilization throughout a extensive vary of applications. With its most desirable strength, durability, and adaptability, it has grow to be an quintessential fabric for current development and environmental projects. BPM nonwoven filter fabric is produced from top rate PP and PET fibers the usage of superior manufacturing technology, making sure super overall performance in stressful conditions. Backed with the aid of customizable specifications, strict satisfactory control, and aggressive manufacturing facility prices, BPM promises dependable geotextile options for street construction, drainage systems, landfills, landscaping, and hydraulic works.

By deciding on The Best Project Material Co., Ltd(BPM Geosynthetics), you acquire a depended on accomplice devoted to imparting excellent merchandise and expert technical assist worldwide, making sure long-lasting overall performance and brilliant fee for your investment.