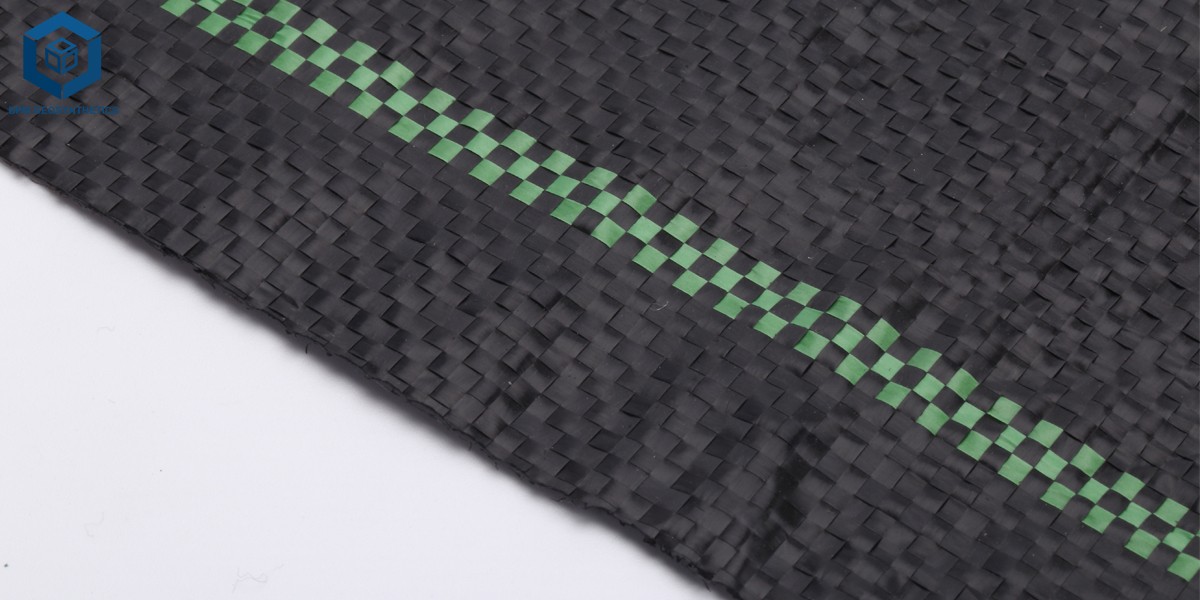

Woven Geofabric

Woven geofabric is a high-strength geotextile made by using interweaving polypropylene or polyester yarns in a uniform and secure weaving pattern. It is in most cases used for soil stabilization, separation, and reinforcement in civil engineering and development projects. The tightly woven shape offers incredible tensile strength, making it an perfect preference for functions such as roads, embankments, conserving walls, and erosion manipulate systems.

- High Tensile Strength:Provides highest quality reinforcement and load distribution for soil and combination layers.

- Durable and Long-Lasting:Resists put on from development stress, UV exposure, and environmental conditions.

- Cost-Effective:Reduces the want for over-excavation and alternative of poor-quality soil, decreasing ordinary task costs.

- Grammage & Strength Grades: From light-duty to heavy-duty fabrics (e.g., 100–600g/m²)

- Roll Widths & Lengths: Custom roll sizes to fit your project layout and reduce material waste

1. BPM Geosynthetics Woven Geofabric

Woven geofabric is a high-performance artificial geotextile made by means of weaving polypropylene or polyester yarns in perpendicular instructions to shape a strong, bendy sheet. This steady woven shape presents magnificent reinforcement, separation, and filtration capabilities, with drastically greater tensile power and minimal elongation in contrast to nonwoven alternatives. Widely used in development and civil engineering initiatives such as roadways, embankments, railways, preserving walls, and drainage systems, woven geofabric enhances soil stability, improves load distribution, and helps lengthen the lifespan of infrastructure. It is usually reachable in rolls of a range of widths and weights to meet various undertaking requirements.

2. Imported Raw Materials for Making Woven Geofabric

Woven geofabrics are specifically manufactured the use of two artificial polymers—polypropylene (PP) and polyester (PET)—chosen for their strength, durability, and resistance to environmental factors.

2.1 Polypropylene (PP) is the most many times used cloth due to its light-weight nature, amazing chemical resistance, and cost-effectiveness. It performs properly in a range of soil prerequisites and is perfect for normal civil engineering tasks such as roads, drainage systems, and embankments.

2.2 Polyester (PET), on the different hand, gives superior resistance to UV radiation and thermal degradation. This makes PET woven geofabrics in particular appropriate for long-term outside functions the place publicity to daylight and temperature adjustments is a concern. Both substances are hydrophobic, that means they do no longer take in water, which helps keep material integrity and characteristic even in moist environments.

These polymers make certain that woven geofabrics are well suited with a broad vary of soils and building materials, making them versatile and dependable factors in geotechnical design.

3. Main Applications of Woven Geofabric

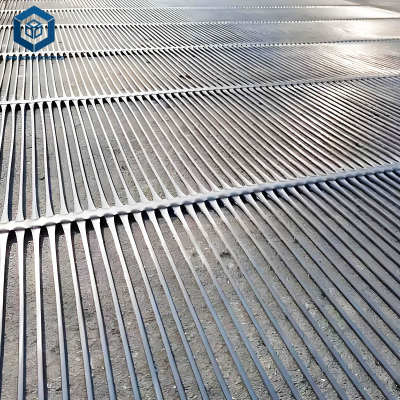

3.1 Road and Pavement Construction

Woven geofabric is extensively used under roadways and paved surfaces to enhance load distribution and minimize rutting. It acts as a separation layer between subgrade and aggregate, stopping mixing and contamination, which extends pavement existence and reduces upkeep costs.

3.2 Railway Foundations

In rail construction, woven geofabric affords critical assist through isolating song ballast from the underlying soil. This keeps the steadiness of the tune bed, reduces settlement, and enhances typical security and sturdiness of the railway system.

3.3 Retaining Walls and Slopes

Woven geofabric is many times established at the back of maintaining partitions or on slopes to beef up soil and minimize erosion. It improves the interior balance of soil masses, making it simpler to assemble steady slopes and vertical partitions in each herbal and engineered landscapes.

3.4 Subgrade Stabilization

When dealing with soft, weak, or water-logged soils, woven geofabric serves as a stabilization layer that will increase the bearing capability and reduces deformation. It approves development things to do to proceed safely and successfully even in difficult floor conditions.

3.5 Drainage and Filtration Systems

Thanks to its particular pore dimension and filtration properties, woven geofabric lets in water to bypass thru whilst keeping soil particles. This makes it appropriate for use in subdrainage systems, round basis drains, and underneath permeable pavements to manipulate water float barring clogging.

3.6 Landfills and Erosion Control

In environmental applications, woven geofabric acts as a defensive barrier in landfill liners or covers and helps manage floor erosion on slopes and embankments. It reinforces soil shape whilst permitting water to flow, minimizing the chance of washout and environmental damage.

4. Woven Geofabric Technical Specifications

| Property | Typical Value |

Material | Polypropylene or Polyester |

Tensile Strength | ≥ 20 kN/m (depending on grade) |

Elongation at Break | < 15% |

Width | 1 to 6 meters (customizable) |

Roll Length | 50 to 200 meters |

Color | Black or White |

UV Resistance | High (especially in PET variants) |

Permittivity | 0.01 – 0.3 sec⁻¹ |

*Note: Specifications can be tailored to meet specific project requirements.*

5. Choose BPM Woven Geofabric

5.1 Global Reach

BPM Woven Geofabric is relied on by means of engineers, contractors, and builders in over one hundred nations throughout the globe. Our merchandise are used in a large vary of civil and environmental engineering projects, from toll road development and railways to erosion manipulate and drainage systems. With years of worldwide experience, BPM knows the numerous technical and regulatory wishes of world markets, making sure steady overall performance and reliability in each and every region.

5.2 Certified Quality

At BPM, pleasant is at the core of each stage of production. Our woven geofabrics are manufactured below ISO9001-certified fine administration structures and meet CE and SGS standards. Each batch is carefully examined for tensile strength, elongation, permeability, and sturdiness to make sure that the closing product performs constantly beneath difficult discipline conditions. Our in-house lab and great manipulate group warranty strict compliance with global standards.

5.3 Custom Manufacturing

BPM affords tailor-made manufacturing options to meet the special necessities of one-of-a-kind projects. Whether you want geofabric in precise roll widths, customized tensile strengths, or engineered residences for specialised applications, we furnish made-to-order solutions. Our technical group works intently with purchasers to diagram merchandise that align with each structural needs and website conditions.

5.4 Reliable Delivery

BPM is dedicated to turning in tremendous merchandise on time, each and every time. We provide strong, invulnerable packaging to guard the geofabric in the course of transport and make sure protected managing on-site. Our environment friendly international logistics community lets in us to fulfill bulk orders quickly, minimizing lead instances and lowering building delays. Additionally, our responsive purchaser carrier crew is constantly equipped to supply help at some stage in your task lifecycle—from pre-sale session to post-delivery assistance.

6. Woven Geofabric Q&A

Q1: What is the difference between woven and non-woven geofabric?

A: Woven geo fabric is made by weaving fibers, giving it high tensile strength, making it ideal for reinforcement and load-bearing applications. Non-woven geofabric is needle-punched, providing better filtration and drainage but lower tensile strength.

Q2: How should Woven Geofabric be stored before installation?

A: Store rolls in a dry, shaded area away from direct sunlight, sharp objects, and chemicals. Avoid stacking heavy items on top of the rolls to prevent deformation.

Q3: Is Woven Geofabric environmentally friendly?

A: Yes. Most woven geotextile fabric is made from polypropylene or polyester, which are inert, non-toxic, and do not leach harmful chemicals into soil or water. They can often be recycled at the end of their service life.

Q4: How durable is Woven Geofabric?

A: Woven filter cloth geotextile is highly durable, resistant to UV, chemicals, and mechanical stress. Properly installed, it can last 15–25 years depending on environmental and loading conditions.

Q5: How is Woven Geofabric installed?

A: Installation involves clearing and leveling the site, laying out the geofabric without wrinkles, overlapping edges by at least 300 mm, securing edges with stakes or trenches, and covering with compatible backfill material, compacted layer by layer.

About BPM GEOSYNTHETICS – Woven Geofabric

BPM GEOSYNTHETICS is a relied on producer and exporter of top class woven geofabric, engineered to supply super strength, durability, and overall performance in a large vary of civil engineering and development projects. Our woven geofabric is produced the usage of high-tenacity polypropylene or polyester yarns interlaced in a uniform, high-density pattern, ensuing in most useful tensile power and structural stability.

Widely used for soil stabilization, separation, reinforcement, and erosion control, BPM woven geofabric is an perfect answer for infrastructure tasks such as roads, highways, embankments, keeping walls, and drainage systems. It efficaciously prevents soil mixing whilst permitting managed water flow, making sure long-term floor balance and decreased protection needs.

Our woven geotextile merchandise are handy in a range of grades, weights, roll sizes, and strengths, with customization choices which include color, labeling, and packaging to meet precise venture or branding requirements. With sturdy resistance to UV rays, chemicals, and mechanical stress, BPM woven geofabrics are constructed to operate in the most worrying web site conditions.

Backed via ISO-certified manufacturing, strict first-class control, and responsive purchaser service, BPM grants woven geofabric options that optimize price effectivity whilst bettering undertaking overall performance and lifespan.