Needle Punched Geotextile

Needle punched geotextile is a non-woven cloth made with the aid of routinely bonding polyester or polypropylene fibers via needle punching technology. This has resulted in a robust, flexible, and permeable cloth that is exceedingly appropriate for separation, filtration, drainage, and reinforcement in civil engineering and environmental applications. BPM needle punched geotextiles are typically used in avenue construction, landfills, erosion control, and drainage systems. There are a variety of GSM and roll sizes to pick out from to meet exceptional undertaking requirements.

- High permeability: Permits water to pass by via whilst stopping soil migration, making it an perfect preference for filtration and drainage.

- Excellent filtration efficiency: Maintain separation between soil layers to forestall blockages in drainage systems.

- Durable and long-lasting: Resistant to ultraviolet radiation, chemicals, and biodegradation, extending the provider existence in the wild.

- Flexible and effortless to install: Easy to adapt to floor and irregular contours, simplifying installation.

1. Needle Punched Geotextile

Needle punched geotextile is a kind of nonwoven cloth created by means of robotically bonding artificial fibers—typically polypropylene (PP) or polyester (PET)—using a system known as needle punching. In this method, barbed needles over and over penetrate and entangle the fibers to shape a dense, flexible, and long lasting mat. Unlike woven geotextiles, which are made from interlaced yarns, needle punched fabric provide most beneficial permeability and filtration capabilities, making them perfect for separation, drainage, and erosion manipulate applications.

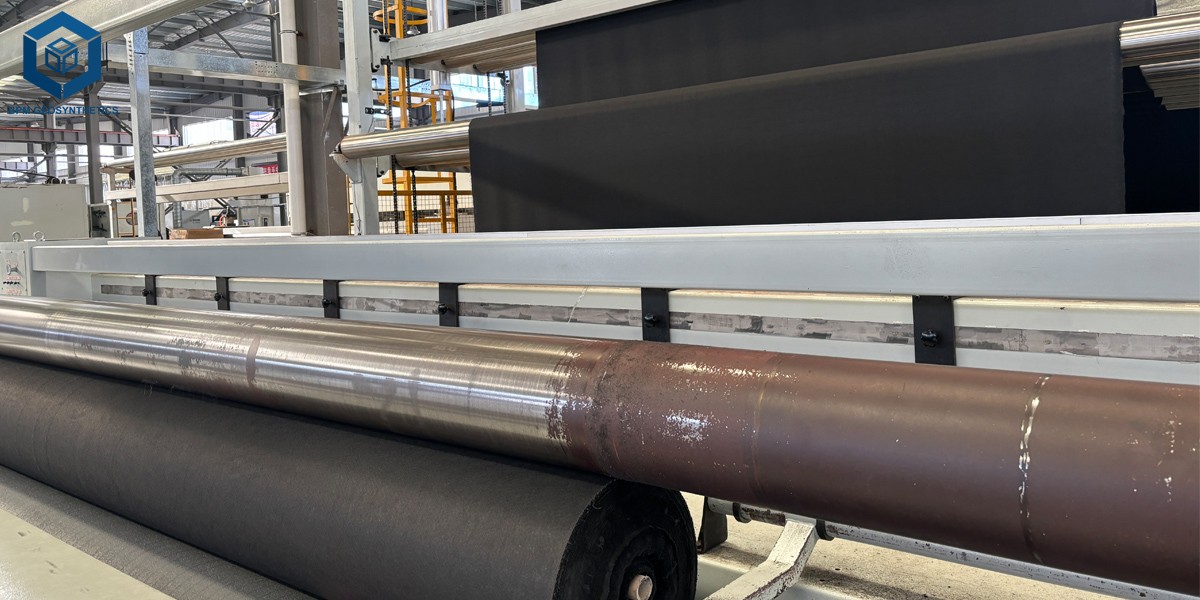

2. Needle Punched Geotextile Manufacturing Process

The manufacturing method starts with uncooked polymer fibers that are carded into a net and then consolidated thru high-speed needle punching. This creates a uniform, porous material that retains its dimensional steadiness and structural power below various load conditions. For greater performance, some variations are thermally bonded or bolstered with scrim backing relying on the supposed use.

3. Key Features and Benefits of Needle Punched Geotextile

3.1 Excellent Water Permeability

Needle punched geotextiles are designed with a porous shape that permits water to waft freely via the material whilst trapping soil particles. This attribute is integral in filtration and drainage systems, such as French drains, preserving wall backfills, and landfill leachate series systems. It helps manipulate groundwater, decrease hydrostatic pressure, and stop clogging—ensuring long-term machine performance.

3.2 High Strength and Durability

These geotextiles showcase superb mechanical properties, along with resistance to puncture, abrasion, and tearing. They are engineered to stand up to set up stress and harsh environmental conditions, which include UV exposure, chemical contamination, and microbial activity. This sturdiness makes them appropriate for each transient and everlasting installations in worrying environments like roads, embankments, and landfills.

3.3 Superior Soil Stabilization

By offering a sturdy and bendy layer between one of a kind soil sorts or between soil and aggregates, needle punched geotextiles assist distribute masses and enhance the bearing ability of susceptible subgrades. This reinforcement impact reduces agreement and rutting, making the basis extra secure and extending the lifespan of pavements, embankments, and railway tracks.

3.4 Easy to Install

Thanks to their lightweight, roll-form packaging, and bendy structure, needle punched geotextiles are convenient to handle, transport, and install on-site. They conform nicely to irregular terrain and contours, lowering installation time and labor costs. No specialised gear is required, which makes them a sensible preference for each large-scale and small projects.

3.5 Cost-Efficient

Using needle punched geotextiles can appreciably limit task fees with the aid of minimizing the want for significant excavation, extra fill materials, or commonplace maintenance. Their multifunctional role—acting as a separator, filter, and stabilizer—enhances the effectivity and durability of development systems, handing over long-term financial fee for infrastructure and environmental applications.

4. Raw Materials of Needle Punched Geotextile

Needle punched geotextiles are usually manufactured the usage of outstanding artificial polymers chosen for their strength, durability, and environmental resistance. The two most generally used substances are polypropylene (PP) and polyester (PET), every presenting special blessings for particular applications:

4.1 Polypropylene (PP)

Polypropylene is a light-weight thermoplastic polymer that is exceedingly resistant to chemical attack, organic degradation, and moisture absorption. Its hydrophobic nature makes it perfect for use in drainage and filtration systems, as it does now not take in water, permitting for higher flow-through performance. PP needle punched geotextiles preserve flexibility even in low temperatures and are least expensive for large-scale infrastructure projects. Due to its inert properties, it is like minded with a huge vary of soil kinds and development materials.

4.2 Polyester (PET)

Polyester presents most efficient tensile energy and long-term durability, making it mainly appropriate for disturbing purposes the place UV exposure, improved temperatures, or excessive mechanical hundreds are factors. PET geotextiles maintain their form and characteristic over time, even in uncovered prerequisites or intense climates. They additionally show off low elongation, which helps preserve dimensional steadiness in bolstered buildings such as embankments, protecting walls, and street foundations.

4.3 Performance Summary

Both PP and PET are chosen primarily based on site-specific needs. PP is commonly favored for subsurface drainage and separation the place cost-efficiency and chemical resistance are key. PET is best for above-ground or long-term functions the place durability, UV resistance, and structural integrity are critical. By deciding on the proper polymer type, engineers can make sure most appropriate overall performance and lifespan of the geotextile system.

5. Choose BPM Needle Punched Geotextile

5.1 Trusted Globally

BPM’s needle punched geotextiles are depended on by way of engineers, contractors, and venture managers in over one hundred nations worldwide. With a sturdy popularity for reliability and performance, BPM merchandise have been efficiently used in a large vary of infrastructure initiatives consisting of highways, landfills, railways, mining operations, and drainage systems. Our world attain demonstrates steady first-class and adaptability to distinctive environmental and regulatory conditions.

5.2 Certified Quality

All BPM needle punched geotextiles are manufactured underneath a rigorous fantastic manipulate machine and meet worldwide requirements such as ISO9001, CE, and SGS. Every roll is examined in-house for indispensable parameters like tensile strength, permeability, puncture resistance, and elongation. These certifications and inspections make sure that the product performs reliably in crucial purposes and complies with each nearby and worldwide engineering requirements.

5.3 Custom Options Available

To meet the numerous wishes of a number of projects, BPM presents a huge vary of customizable specifications. Our needle punched geotextiles are on hand in distinct GSM levels (100–1200 g/m²), widths (up to 6 meters), and roll lengths. Whether your undertaking requires light-weight fabric for landscaping or heavy-duty reinforcement for landfill capping, we tailor our geotextiles to swimsuit the technical needs and environmental stipulations of your site.

5.4 Efficient Delivery

BPM takes delight in supplying fast manufacturing turnaround and reliable international logistics. Our committed packaging and transport crew ensures that each roll is securely packed to stop harm at some point of transportation. Additionally, our responsive income and technical help groups grant ongoing help earlier than and after delivery, assisting customers resolve set up challenges and keep easy venture timelines.

About BPM GEOSYNTHETICS

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a main producer and exporter of exquisite geosynthetic products, which include geomembranes, geotextiles, geogrids, and different geosynthetic systems. Established in 2010, BPM is committed to offering complete one-stop offerings that cowl lookup and development, production, great control, and world sales. The organisation locations robust emphasis on innovation, product performance, and environmental sustainability.

BPM’s merchandise are licensed by using internationally diagnosed our bodies such as EU CE and GLP, and the agency operates below strict exceptional administration systems, such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and OHSAS 18001 (Occupational Health and Safety). These certifications make certain that each and every product delivered is constant in quality, environmentally responsible, and secure for use in disturbing applications.

With a today's manufacturing base protecting extra than 36,000 rectangular meters and outfitted with superior manufacturing lines, BPM has the potential to meet large-scale and personalized undertaking demands. The business enterprise employs over a hundred and twenty professional technical professionals and engineers who work collaboratively to supply tailor-made geosynthetic options throughout a broad vary of industries.

BPM’s product functions span key sectors such as aquaculture (pond and canal liners), landfill and waste containment, erosion control, civil infrastructure, drainage systems, water conservation, mining, and municipal engineering projects. Its geosynthetic substances have been exported to extra than a hundred international locations worldwide, incomes have confidence from consumers via regular quality, expert service, and on-time delivery.

Looking forward, BPM GEOSYNTHETICS stays dedicated to non-stop improvement, increasing its international presence, and partnering with consumers and engineers to tackle complicated civil and environmental engineering challenges. Whether you want dependable geosynthetic substances for small-scale purposes or built-in options for giant infrastructure projects, BPM is your relied on accomplice in constructing sustainable and high-performance systems.