EPDM Pond Liner

As global water management, aquaculture, and landscaping industries expand, the demand for long-lasting and environmentally resilient waterproofing materials continues rising. Among the various geomembrane products available today, the EPDM pond liner has gained significant traction due to its exceptional elasticity, UV resistance, and performance stability in extreme climates. This article examines the growing market demand, technical strengths, manufacturing processes, and key application areas of EPDM pond liners, providing international buyers with a comprehensive reference for procurement and project planning.

EPDM Pond Liner: A Durable and Reliable Waterproofing Solution for Global Water Projects

As global water management, aquaculture, and landscaping industries expand, the demand for long-lasting and environmentally resilient waterproofing materials continues rising. Among the various geomembrane products available today, the EPDM pond liner has gained significant traction due to its exceptional elasticity, UV resistance, and performance stability in extreme climates. This article examines the growing market demand, technical strengths, manufacturing processes, and key application areas of EPDM pond liners, providing international buyers with a comprehensive reference for procurement and project planning.

Global Market Landscape and Increasing Demand

The global geomembrane market is forecast to reach more than USD 4.5 billion by 2030, with EPDM-based materials seeing strong growth momentum. Market reports indicate that the EPDM pond liner segment is expanding at a CAGR above 6%, largely driven by:

The acceleration of aquaculture production

Expansion of agricultural irrigation facilities

Rapid development of decorative ponds and landscape engineering

Increased need for reliable waterproofing in industrial containment

Countries in Southeast Asia, the Middle East, Europe, and Africa are particularly increasing procurement volumes due to large-scale water storage and fish farming initiatives. The trend toward durable, eco-friendly lining systems places EPDM pond liners at the core of many project specifications.

What Is an EPDM Pond Liner?

An EPDM pond liner is a synthetic rubber membrane made from ethylene propylene diene monomer. Characterized by high elasticity, outstanding weather resistance, and long-term chemical stability, EPDM liners provide reliable waterproofing for ponds, reservoirs, canals, fish farms, and various outdoor containment systems.

Key Performance Features

Exceptional flexibility: Maintains elasticity even in temperatures from −40°C to 120°C

Superior UV and ozone resistance for long-term outdoor exposure

Excellent puncture resistance, suitable for uneven or rocky substrates

Non-toxic and eco-friendly, ideal for aquaculture and landscaping

High durability with service life exceeding 20–30 years

The ability of EPDM to remain pliable without cracking or shrinking is one of the primary reasons buyers prefer it over PVC or HDPE in certain applications.

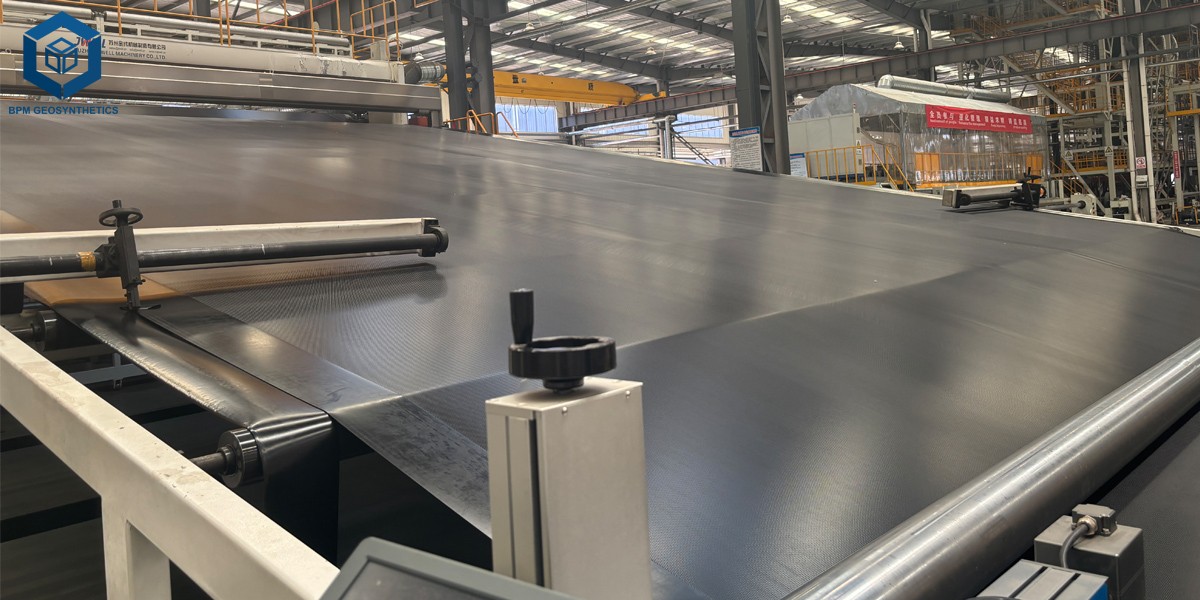

Manufacturing Process of EPDM Pond Liner

High-quality EPDM pond liners are produced through a controlled industrial process to ensure consistent thickness and material integrity.

H3: Standard Manufacturing Steps

Polymer Mixing – EPDM rubber is blended with reinforcing fillers, carbon black, curing agents, and stabilizers.

Sheet Extrusion and Calendering – The compound is processed into uniform sheets with precise thickness control, typically ranging from 0.8 mm to 2 mm.

Curing and Vulcanization – Heat and pressure permanently network the rubber molecules to enhance durability, tear strength, and flexibility.

Surface Finishing – The surface is smoothed to ensure even texture and optimal bonding performance for seaming.

Cutting, Folding, and Packaging – Liners are folded or rolled for easy transportation and installation at project sites.

Advanced EPDM pond liner production lines allow for customized dimensions, ensuring seamless installation for large-scale ponds or industrial reservoirs.

Applications of EPDM Pond Liners

H2: Aquaculture and Fish Farming

EPDM pond liners are widely used in shrimp ponds, fish culture systems, and aquaculture basins due to their non-toxic properties. The stable rubber surface prevents water contamination and supports controlled cultivation environments.

H2: Agricultural Irrigation and Water Storage

In arid regions, EPDM liners are installed in irrigation canals and farm reservoirs to reduce water loss and protect soil structures.

H2: Landscaping and Decorative Ponds

Due to their flexibility and ease of installation, EPDM liners are ideal for ornamental water features, fountain pools, and garden ponds with irregular shapes.

H2: Industrial and Environmental Containment

EPDM pond liner systems are increasingly applied in wastewater storage, chemical containment, and stormwater management facilities, where long-term waterproofing is essential.

Market Trends: Why EPDM Pond Liner Demand Continues to Grow

Rising Aquaculture Investments

Countries such as Indonesia, India, Philippines, Nigeria, and UAE are enlarging fish farming operations, creating strong demand for pond lining systems that ensure water quality.

Preference for Long-Life Waterproofing

Many construction and agricultural buyers are shifting from PVC to EPDM due to the latter’s superior longevity and reduced maintenance costs.

Sustainability and Eco-Friendly Development

Environmental guidelines in Europe and North America encourage the adoption of low-toxicity materials, boosting EPDM usage across landscaping and water management sectors.

Adaptability to Harsh Climates

EPDM pond liners are ideal for regions with extreme temperature changes, providing stable performance where plastic membranes would otherwise crack or deform.

Technical Advantages of EPDM Pond Liner

High elongation rate that prevents cracking during ground movement

Excellent tear and puncture resistance

Superior UV, ozone, and oxidation resistance

Compatibility with natural biological systems in aquaculture

Easy to install with minimal equipment required

Long-term dimensional stability with minimal shrinkage

These advantages make EPDM pond liners one of the most reliable waterproofing solutions for global buyers seeking performance durability and environmental safety.

FAQ: Common Questions from International Buyers

1. What thickness should I choose for an EPDM pond liner?

For aquaculture or landscaping ponds, 1.0–1.2 mm is typical. Industrial or rocky sites may require 1.5–2.0 mm for enhanced puncture resistance.

2. How long can an EPDM pond liner last outdoors?

With proper installation, a high-quality EPDM pond liner can last 25–30 years due to its strong resistance to UV and environmental aging.

3. Is EPDM safe for fish and aquatic plants?

Yes. EPDM pond liners are non-toxic, making them suitable for fish, shrimp, turtles, and plant-based aquaculture systems.

4. Can EPDM liners be repaired on-site?

Small punctures can be repaired using EPDM-compatible patch kits or adhesive systems, ensuring continued leakage protection.

Conclusion and Professional Call to Action

As global water management projects expand across agriculture, aquaculture, landscaping, and industrial sectors, the EPDM pond liner has become one of the most reliable and durable waterproofing materials available today. Its superior flexibility, weather resistance, and eco-friendly characteristics offer long-term performance advantages unmatched by many alternative membranes.

If you require engineering guidance, technical data sheets, or customized EPDM pond liner specifications for upcoming projects, We welcome professional inquiries. Our team can provide tailored solutions and support for procurement, design, and installation across diverse global applications.