Application of BPM Geomembranes in Landfill

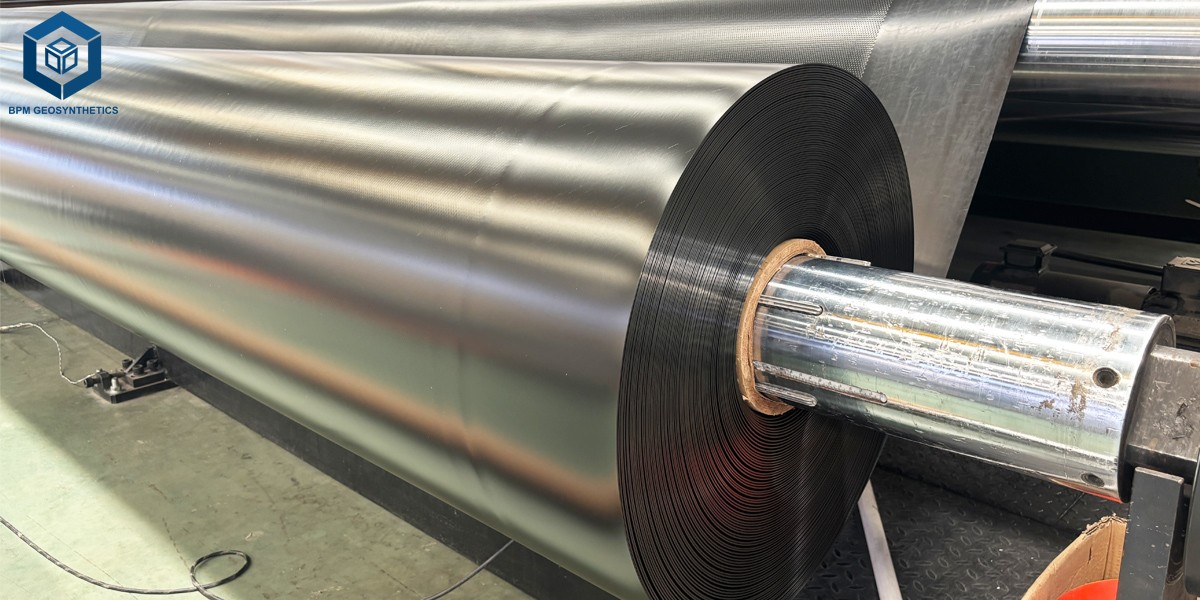

Modern landfill engineering needs high-performance containment structures that forestall environmental infection whilst optimizing long-term web site stability. BPM Geosynthetics presents superior HDPE geomembranes that shape the indispensable barrier layer in landfill base and capping systems. Engineered for chemical resistance, low permeability, and mechanical durability, BPM liners make certain dependable and sustainable waste administration in compliance with world environmental regulations.

1. Why Are Geomembranes Essential in Landfills?

1.1 Environmental Containment

Landfills naturally generate leachate—a poisonous liquid shaped when precipitation filters via layers of waste, gathering contaminants alongside the way. If no longer appropriate managed, leachate can migrate into the surrounding soil and groundwater, threatening neighborhood ecosystems and human health. BPM geomembranes supply an impermeable barrier system that plays a central function in stopping this environmental contamination.

- BPM’s HDPE geomembranes effectively isolate hazardous drinks from groundwater and soil systems

- Fully compliant with worldwide landfill layout requirements (e.g., EPA Subtitle D, EU Landfill Directive)

- Work seamlessly with geosynthetic clay liners (GCLs), geotextiles, and drainage layers to structure strong multi-barrier containment systems

1.2 Excellent Chemical Resistance

Landfill waste streams can also consist of industrial chemicals, family hazardous waste, and organic contaminants. These generate leachates wealthy in aggressive compounds such as solvents, hydrocarbons, acids, and salts. BPM’s HDPE geomembranes are in particular engineered to withstand chemical attack throughout a vast spectrum of substances.

- BPM’s HDPE geomembranes proven resistance to natural solvents, acids, alkalis, and saline compounds

- Tolerant of excessive organic undertaking and microbial degradation

- Maintain barrier feature and dimensional steadiness after long-term exposure

- Manufactured and examined in accordance with GRI-GM13 and ASTM D5322 requirements for chemical resistance

1.3 Long-Term Durability and Performance

Landfills are long-duration infrastructure projects, regularly requiring overall performance over numerous decades. BPM geomembranes are made from virgin HDPE resin, enriched with carbon black, UV stabilizers, and antioxidants to make sure high-quality longevity, even in uncovered or high-stress environments.

- BPM’s HDPE geomembranes Exceed 30 years of provider life below ideal graph and publicity conditions

- Provide excessive tensile energy and elongation, best for resisting differential settlement

- Excellent resistance to punctures, tears, and mechanical stress from overlying waste

- Suitable for use in each bottom liner systems and final closure caps

1.4 Water and Gas Management

In addition to leachate containment, geomembranes play a critical position in controlling liquid and gasoline movement inside landfill systems. When built-in with engineered drainage layers and gasoline venting systems, they assist preserve environmental manage and web site stability.

- Direct leachate effectively towards series and therapy systems

- Serve as section of fuel barrier structures to seize or vent methane and different landfill gases

- Prevent rainwater infiltration into the waste mass, lowering whole leachate quantity and enhancing landfill longevity

- Enhance slope steadiness via minimizing pore stress buildup

1.5 Cost-Efficiency in Construction and Operation

Modern landfill layout prioritizes each overall performance and monetary feasibility. Geomembranes provide faster installation, lower fabric requirements, and longer operational life, making them a low-budget answer in contrast to regular limitations like compacted clay or concrete.

- Reduced earthwork and fabric thickness = decrease set up time and labor costs

- Require minimal preservation post-installation, saving on long-term operational expenses

- Lower transportation and dealing with fees due to light-weight rolls and modular deployment

- BPM gives full technical support—from fabric resolution to QA/QC throughout installation—to maximize mission success and decrease risk

2. Main Applications of BPM Geomembranes in Landfills

2.1 Bottom Lining Systems

The backside liner is the foundation of any secure landfill. It prevents poisonous leachate from seeping into the subsoil and contaminating close by water resources. BPM geomembranes are mounted as the primary impermeable barrier, normally in aggregate with compacted clay liners (CCLs) or geosynthetic clay liners (GCLs) to create a composite containment system.

- Offers low permeability to block liquid migration

- High puncture and tear resistance, even underneath heavy waste loading

- Compatible with geonets and drainage composites to assist leachate drift towards series pipes

- Proven overall performance in municipal stable waste (MSW), hazardous, and industrial landfills

2.2 Leachate Collection and Recirculation Ponds

Leachate ponds are fundamental for briefly storing or treating accumulated leachate. Given the chemical aggressiveness of leachate, specifically in mature landfills, lining these ponds with BPM HDPE geomembranes ensures secure containment.

- Prevents leakage into the surrounding environment

- Withstands excessive concentrations of natural contaminants, heavy metals, and acids

- Compatible with aeration and recirculation structures used in leachate treatment

- Available in clean or textured finishes for structural integration with embankments

2.3 Final Closure and Capping Systems

After a landfill reaches its capacity, a closing cowl or “cap” ought to be established to seal the site. BPM geomembranes are used in these capping structures to:

- Reduce rainwater infiltration, minimizing future leachate generation

- Trap and information landfill gases towards venting structures or gas-to-energy units

- Serve as section of a multi-layer cap with soil, drainage nets, and vegetation

- Textured geomembranes decorate frictional resistance on steep slopes, enhancing slope balance and erosion control

2.4 Gas Collection and Control Systems

Landfill gases—primarily methane and carbon dioxide—are produced via decomposing natural waste. These gases need to be safely extracted to stop odor, explosion hazards, and greenhouse gasoline emissions. BPM HDPE geomembranes serve as gas-impermeable barriers, channeling gases into wells or pipes for protected extraction or flaring.

- Enable managed gasoline series for regulatory compliance

- Essential for landfills the usage of gas-to-energy conversion systems

- Integrated into each backside liners and capping systems

2.5 Cell Separation and Expansion Phases

Modern landfills are built in phases, with separate waste “cells” lined in my opinion to facilitate staged filling, monitoring, and closure. BPM geomembranes are used between adjoining cells to:

- Maintain integrity of containment at some stage in every phase

- Isolate older and more moderen waste loads to forestall cross-contamination

- Simplify enlargement planning through making sure steady liner performance

- Allow selective get entry to and closure of landfill sections based totally on operational needs

3. Practical Application Cases of BPM Geomembranes in Landfill

Case Study 1: Municipal Solid Waste Landfill – Eastern Europe

- Location: Suburban Region, Eastern Europe

- Project Area: 1850,000 m²

- Project Type: New regional landfill for municipal secure waste (MSW)

Background:

This landfill used to be designed to serve a creating metropolis populace and meet EU environmental directives. The net web page required a completely engineered bottom liner gadget with built-in leachate and gasoline administration components.

Challenges:

- Harsh wintry climate neighborhood climate with freeze-thaw cycles and immoderate soil moisture

- Regulations requiring full containment of leachate and manipulate of methane emissions

- Hilly topography with unstable slopes requiring expanded liner stability

Solution by means of BPM:

- Supplied 1.5mm textured HDPE geomembrane for the bottom liner and 2.0mm for aspect slopes

- Provided nonwoven geotextiles (500gsm) for cushioning and protection

- Offered on-site welding support, QA/QC monitoring (including spark testing, vacuum area testing)

- Integrated with drainage net and GCL for a triple-layer containment system

Outcome & Feedback:

- Installation accomplished on time desk under extreme local weather conditions

- The geomembrane maintained flexibility and weldability even in sub-zero temperatures

- Local authorities praised the system’s compliance with EU landfill Directive 1999/31/EC

- Site engineers suggested BPM for technical assist and shortly product delivery

- Zero leakage mentioned at some stage in the first two years of operation

Case Study 2: Municipal Solid Waste Landfill – Chile

- Project Location: Santiago, Chile

- Product Used: 1.5mm HDPE Smooth Geomembrane + Geotextile Underlay

- Supplied Volume: 920,000 m²

Project Background:

Santiago, Chile’s capital city, launched a large-scale municipal stable waste landfill to accommodate growing city waste and decorate environmental safety standards. The venture required a long-lasting, impermeable liner gadget to stop groundwater infection and meet Chilean environmental regulations.

Challenges:

- Seismic Activity: The area is inclined to earthquakes, requiring excessive flexibility and tear resistance from the lining system.

- Variable Soil Conditions: Uneven subgrade and excessive moisture content material introduced difficulties for liner installation.

- Strict Regulatory Compliance: The gadget wished to comply with neighborhood and worldwide requirements (e.g., GRI-GM13).

Solution:

- BPM provided 1.5mm easy HDPE geomembranes with excessive tensile and puncture strength, appropriate for seismic-prone areas.

- A nonwoven geotextile was once established beneath the liner to cushion the geomembrane from hard subgrade.

- Deployment was once assisted through BPM’s technical team, who carried out **onsite training and weld seam testing to make sure set up quality.

Customer Feedback:

"BPM supplied no longer solely top-grade geomembranes however additionally technical assist for the duration of construction. The product's overall performance beneath seismic prerequisites and throughout Chile’s wet season was once excellent."

Case Study 3: Industrial Waste Landfill – Poland

- Project Location: Silesia Region, Poland

- Product Used: 2.0mm HDPE Textured Geomembrane + GCL Clay Liner

- Supplied Volume: 585,000 m²

Project Background:

An industrial chemical business enterprise wanted to improve its present waste storage web site in compliance with EU Landfill Directive (1999/31/EC). The undertaking concerned growing a impenetrable containment gadget for hazardous and semi-hazardous industrial waste.

Challenges:

- Chemical Exposure: The web page treated corrosive substances requiring excessive chemical resistance.

- Steep Slopes: The graph covered 3:1 aspect slopes, growing threat of slippage.

- Cold Weather Installation: Installation took vicinity in late autumn, with temperatures losing beneath 5°C.

Solution:

- 2.0mm textured HDPE geomembrane used to be chosen to beautify slope steadiness and friction angle.

- BPM additionally supplied Geosynthetic Clay Liners (GCL) to act as an extra barrier under the HDPE liner.

- Welding crews used pre-heated extrusion welding techniques to make sure first-class in low temperatures.

- All substances had been licensed to EU and GRI standards, making sure sturdiness and long-term compliance.

Customer Feedback:

"The aggregate of textured geomembranes and GCL delivered tremendous containment performance. BPM’s substances had been handy to installation and surpassed all fantastic manage inspections. We layout to use BPM merchandise in future upgrades."

4. Conclusion

The design and operation of contemporary landfills closely rely on dependable containment structures that stop environmental infection and make certain regulatory compliance. BPM geomembranes furnish a exceptionally nice answer for landfill lining and capping, supplying wonderful chemical resistance, durability, and impermeability.

Backed through worldwide certifications, verified case studies, and extensive field experience, BPM geomembranes have turn out to be a relied on preference for landfill engineering initiatives worldwide.As environmental safety requirements proceed to rise, BPM stays dedicated to handing over superior geosynthetic options tailor-made to the evolving wishes of the waste administration industry.