Textured Geomembrane

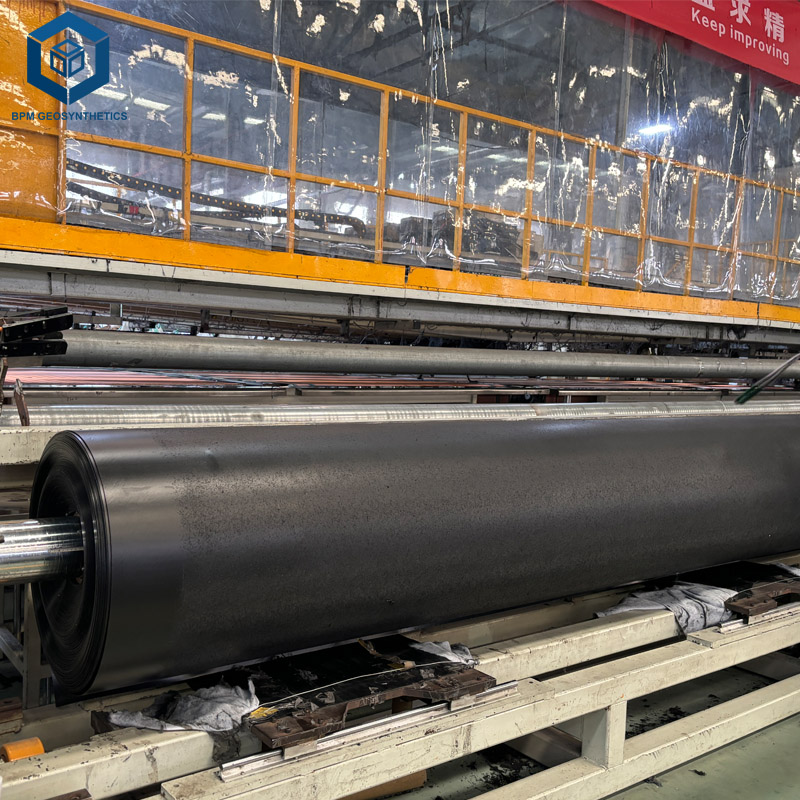

Texture geomembrane is a specialised liner designed to furnish improved frictional resistance and balance in quite a number applications. These geomembranes are made of HDPE and have a texture geomembrane that will increase grip and prevents sliding, making them an perfect desire for slopes and difficult terrains.

-Enhanced friction: The texture geomembrane affords remarkable grip and reduces the danger of sliding on slopes.

-Enhanced stability: Very appropriate for purposes involving soil masking or backfilling, making sure structural integrity.

-Improving drainage: This texture geomembrane enables advantageous water drift administration and reduces static water pressure.

-Multi purposeful application: appropriate for landfill sites, mining, and civil engineering projects.

Texture geomembrane is an superior lining designed especially for purposes that require improved friction and stability. These geomembranes are made of high-density polyethylene (HDPE) and have a special textured floor that considerably improves grip, making them best for use on slopes and in difficult environments. The extended frictional resistance helps stop sliding and ensures that the membrane stays firmly in vicinity even beneath one-of-a-kind load conditions.

These texture geomembranes are specially advisable in landfills, mining operations, and civil engineering tasks as they assist with superb drainage and aid in managing hydrostatic pressure. Their texture promotes environment friendly water drift management, decreasing the hazard of accumulation and manageable structural issues. In addition, textured geomembranes are very long lasting and can withstand ultraviolet radiation and a number chemicals, making sure long-term overall performance underneath harsh conditions. These geomembranes are handy in a variety of thicknesses and roll sizes for bendy installation, making them a dependable desire for quite a number environmental safety and sealing applications.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | D1505/D792 | 90.000kg | 0.94g/cc | ||||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 5 3 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

Textured Geomembrane Features

- Enhanced frictional resistance: The texture geomembrane affords most fantastic grip, stopping sliding on slopes and inclined surfaces.

- Increased stability: Designed to preserve structural integrity in functions involving earth cowl or backfill, decreasing the hazard of movement.

- Effective drainage management: The texture helps ultimate water flow, supporting to alleviate hydrostatic stress and end water accumulation.

- Versatile applications: Suitable for a large differ of projects, consisting of landfills, mining, civil engineering, and environmental protection.

- Durable construction: Made from high-density polyethylene (HDPE), these geomembranes are resistant to UV rays, chemicals, and environmental stressors.

- Customizable thickness: Available in a vary of thicknesses to meet unique undertaking requirements, providing flexibility in plan and installation.

- Easy installation: The texture geomembranes can be effectively hooked up in a range of configurations, making certain seamless integration into modern systems.

- Long-lasting performance: Engineered for durability, textured geomembranes grant reliable security and containment over extended periods.

Applications of Textured Geomembrane

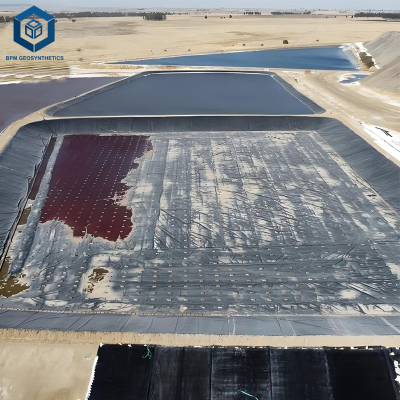

- Landfills: Textured geomembranes are in many instances used as liners to stop leachate from contaminating groundwater, imparting an advantageous barrier towards environmental pollution.

- Mining operations: These texture geomembranes are employed in tailings storage services and heap leach pads, making sure secure containment of hazardous substances and minimizing the chance of slope failure.

- Civil engineering: Used in building initiatives for maintaining walls, drainage systems, and erosion control, textured geomembranes beautify steadiness and water management.

- Water reservoirs: They serve as liners in ponds and reservoirs, supporting to maintain water whilst stopping seepage and defending water quality.

- Agricultural applications: Textured geomembranes are utilized in irrigation and storage ponds, helping in wonderful water administration and retention for agricultural practices.

- Aquaculture: In fish farming, these texture geomembranes create contained environments that defend aquatic lifestyles and make sure foremost increase conditions.

- Green roofs: Textured geomembranes can be used in inexperienced roofing systems, presenting waterproofing and drainage options whilst aiding vegetation growth.

- Wastewater therapy facilities: They assist incorporate wastewater and stop contamination, contributing to nice remedy tactics and environmental protection.

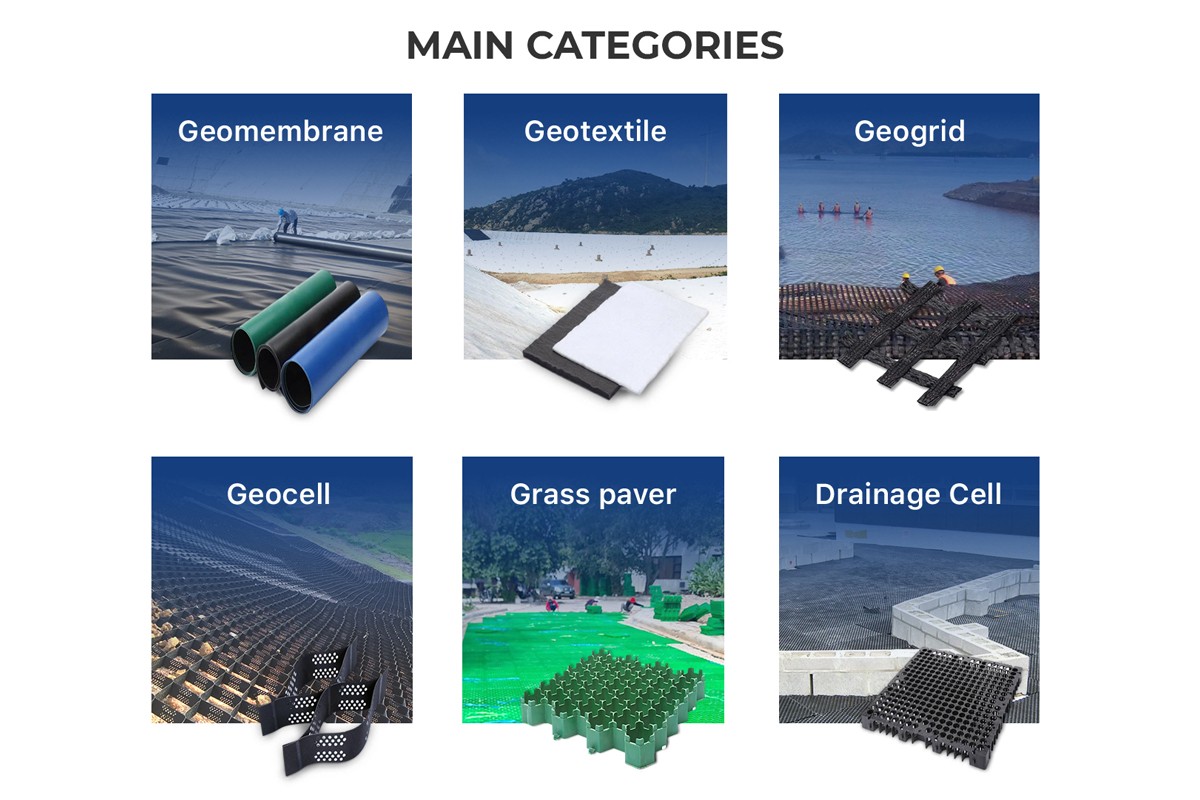

Company Profile

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, geogrids, geocells, and geosynthetic clay liners (GCL). Our products, certified by EU CE and GLP, have passed ISO 9001, ISO 14001, and OHSAS 18001 standards, and are recognized for their quality, performance, and durability.

BPM GEOSYNTHETICS has been committed to providing one-stop services for global customers in the research and development, production, sales, and export of geosynthetic materials since its establishment in 2007. The company has 120 senior technical talents specializing in geotechnical materials. The manufacturing factory covers an area of over 36000 square meters and is equipped with industry-leading automated production equipment and professional testing instruments. Product innovation, quality assurance, and customer satisfaction have always been BPM commitment to partners.

We're committed to innovation and quality, offering flexible cooperation and the best solutions for engineering projects worldwide. Our products are utilized in various sectors like aquaculture, erosion control, drainage systems, municipal engineering, mining, and landscaping. We look forward to partnering with you to solve complex challenges with our high-performance geosynthetic products.