Geogrid Mesh Retaining Wall

Geogrid Mesh Retaining Wall is a high-performance answer designed for soil stabilization, erosion control, and slope reinforcement. Constructed from long lasting polymer geogrids, it presents structural help to maintain soil and stop landslides in each civil and landscaping projects. Its light-weight but robust plan ensures convenient set up whilst preserving long-term durability, making it perfect for highways, embankments, backyard landscaping, and development sites.

- High Strength and Stability: Reinforces soil and slopes to stop erosion, landslides, and structural failures.

- Durable Material: Made from UV-resistant and corrosion-resistant polymer geogrids for long-lasting performance.

- Flexible Design: Adapts to special terrain sorts and soil conditions, appropriate for each small-scale and large-scale projects.

- Easy Installation: Lightweight and modular shape permits for speedy meeting and decreased labor costs.

The Geogrid Mesh Retaining Wall is an superior engineered machine designed to stabilize slopes, support soil, and stop erosion in a vast vary of civil, industrial, and landscaping projects. Constructed from high-strength polymer geogrids—typically HDPE (High-Density Polyethylene) or PP (Polypropylene)—these partitions combine with soil or mixture to structure a composite shape that combines flexibility, strength, and durability.

Unlike regular concrete protecting walls, geogrid mesh conserving partitions permit managed soil movement, enhance drainage, and minimize hydrostatic pressure. Their modular sketch allows adaptation to irregular terrains, steep slopes, and various soil types, making them appropriate for each city and rural environments. Additionally, their permeable shape encourages vegetation growth, mixing engineered aid with herbal aesthetics.

1. Geogrid Mesh Retaining Wall – Material Composition and Engineering Design

1.1 High-Strength Polymer Geogrid Mesh Retaining Wall

The geogrid retaining wall is made from superior high-strength polymers, generally HDPE (High-Density Polyethylene) or PP (Polypropylene), which grant first-rate tensile energy and structural integrity. These substances are UV-stabilized, making sure they preserve overall performance even after extended publicity to sunlight. Geogrid driveway are additionally resistant to chemical corrosion, consisting of acids, alkalis, and salts determined in soils, as properly as microbial degradation, which prevents weakening over time in humid or biologically lively environments. This sturdiness ensures that the protecting wall continues its load-bearing and reinforcement competencies over decades.

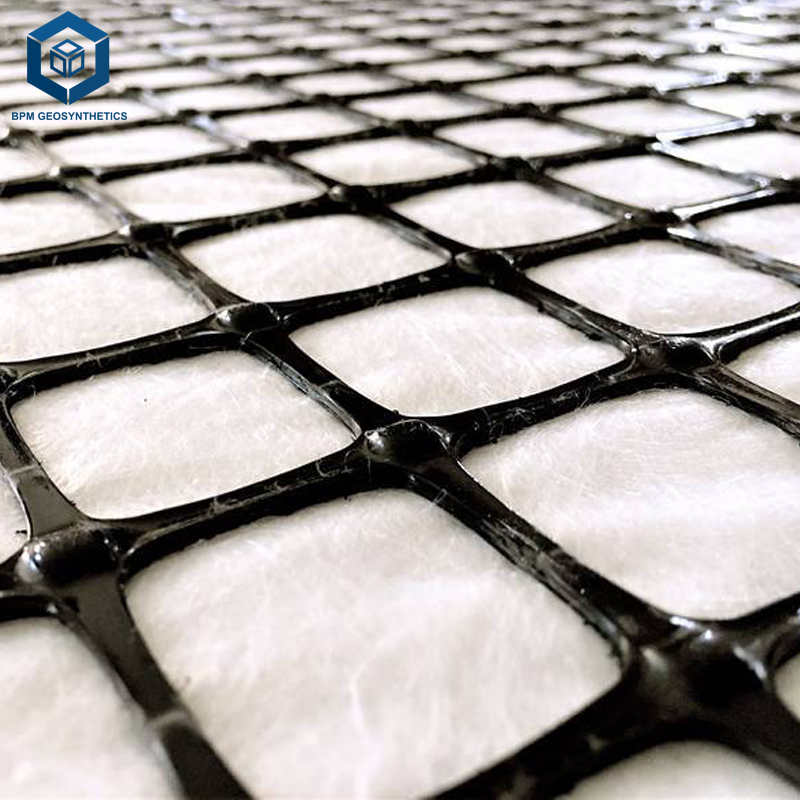

1.2 Modular Mesh Structure

The geo grid mesh elements a modular, open mesh design, with uniform apertures in particular engineered to interlock with soil or combination particles. This permits the soil to act as section of the structural system, growing a strengthened composite material. The interlocking mechanism enhances mechanical stability, distributes hundreds evenly throughout the wall, and prevents localized failures. The modular plan additionally permits customization of aperture dimension and tensile electricity to go well with unique soil types, slope angles, and undertaking requirements.

1.3 Reinforced Layering System

The wall is developed the use of a multi-layered biaxial geogrid system, the place every geogrid layer is separated with the aid of compacted soil or mixture infill. This bolstered layering transforms free or susceptible soil into a stable, load-bearing mass. The layers work collectively to withstand lateral earth pressure, limit settlement, and forestall sliding or overturning. Additionally, the layering gadget approves water to drain between layers, lowering hydrostatic strain and minimizing the chance of soil saturation, which is a frequent motive of wall failure in normal maintaining structures.

1.4 Flexible and Lightweight Design

Unlike traditional concrete or masonry walls, geogrid mesh conserving partitions are bendy and lightweight, which offers more than one advantages:

1.4.1 Ease of Handling: Individual geo grid ground grid rolls or panels can be transported to the building web page besides heavy machinery.

1.4.2 Adaptability: The bendy nature permits the wall to conform to irregular terrain, curved slopes, and variable soil conditions.

1.4.3 Simplified Installation: Reduced weight and modular elements enable for quicker set up and decrease labor costs.

1.5 Durable Lifespan

The aggregate of high-strength polymer materials, UV resistance, and strengthened composite building ensures a long-lasting lifespan, regularly exceeding 50 years beneath regular conditions. These partitions are designed to stand up to intense weather, inclusive of heavy rainfall, snow, temperature fluctuations, and freeze-thaw cycles. They additionally aid heavy load applications, such as vehicular traffic, industrial operations, and infrastructure projects, except compromising structural integrity over time.

1.6 Additional Engineering Advantages

1.6.1 Reduced Maintenance Needs: Minimal repairs required in contrast to concrete or masonry walls.

1.6.2 Environmental Integration: The open mesh and soil infill help vegetation growth, which enhances erosion manage and herbal aesthetics.

1.6.3 Seismic and Dynamic Load Resistance: The bendy layered plan absorbs vibrations and dynamic hundreds higher than inflexible structures, making it appropriate for areas inclined to seismic activity.

1.6.4 Cost Efficiency: Lightweight, modular building reduces cloth and transportation expenses whilst imparting highest quality long-term performance.

2. Geogrid Mesh Retaining Wall – Key Features and Advantages

2.1 Geogrid Mesh Retaining Wall Superior Soil Stabilization

The geogrid soil stabilization features as a reinforcement framework inside the soil, growing a composite structure that distributes masses evenly throughout the wall. By automatically interlocking with soil particles, it extensively reduces the danger of landslides, slope failure, and erosion, even in areas with vulnerable or unfastened soils. This stabilization is mainly essential in steep slopes, embankments, and areas with heavy rainfall, the place normal protecting techniques would possibly fail. Additionally, the layered geogrid slope stabilization graph enhances the wall’s capacity to stand up to lateral and vertical pressures, imparting long-term structural reliability.

2.2 Geogrid Mesh Retaining Wall Drainage Optimization

The open mesh graph of the geogrid erosion control approves for environment friendly water infiltration and drainage, stopping the buildup of hydrostatic strain at the back of the wall—a frequent motive of maintaining wall failure. Water can go freely via the soil and geogrid material layers, minimizing soil saturation and lowering the probability of erosion or wall deformation. This self-draining property additionally prevents frost heaving in less warm climates and ensures balance in areas with heavy rainfall or excessive groundwater levels.

2.3 Geogrid Mesh Retaining Wall Customizable Design

Geo grid wall mesh preserving partitions are exceedingly adaptable to project-specific requirements. The modular gadget can be designed for:

Variable slope angles, from mild embankments to steep hillsides.

Different heights, from small backyard terraces to giant civil engineering projects.

Multiple soil types, together with clay, sand, silt, rocky soils, or combined compositions.

This flexibility lets in engineers and designers to optimize the wall for most performance, regardless of website constraints or environmental conditions.

2.4 Geogrid Mesh Retaining Wall Eco-Friendly Construction

By decreasing the reliance on heavy concrete, steel, and different inflexible materials, gravel geogrid mesh preserving partitions supply an environmentally sustainable solution. The shape permits for herbal vegetation growth, which now not solely improves aesthetic integration with the panorama however additionally enhances erosion protection. Furthermore, the usage of lighter, modular aspects reduces building electricity consumption and lowers the normal carbon footprint of the project.

2.5 Geogrid Mesh Retaining Wall Long-Term Durability

Retaining wall grid mesh holding partitions are designed for many years of maintenance-free operation. The substances used are:

UV-resistant, stopping degradation from long-term daylight exposure.

Chemically stable, resisting injury from acids, alkalis, and salts in soil.

Biologically resistant, stopping microbial or insect-related deterioration.

This sturdiness ensures that the wall continues structural integrity and overall performance over time, even beneath harsh environmental stipulations or heavy load applications, such as highways or industrial sites.

2.6 Geogrid Mesh Retaining Wall Cost-Effective Solution

Compared to common protecting walls, plastic geogrid structures provide full-size price savings:

Lightweight and modular building reduces transportation and set up costs.

Faster meeting minimizes labor and equipment requirements.

Reduced protection desires decrease long-term operational expenses.

Material effectivity capacity much less use of concrete, steel, or heavy development machinery.

This makes geogrid mesh retaining wall maintaining partitions a high-performance, in your price range answer for a vast vary of applications.

2.7 Geogrid Mesh Retaining Wall Versatility

Geogrid wall conserving partitions are appropriate for various projects, including:

Civil infrastructure: highways, railways, bridge embankments, flood manipulate levees.

Municipal landscaping: parks, playgrounds, city inexperienced spaces, riverbanks.

Residential landscaping: backyard terraces, ornamental slopes, driveways, holding small hillsides.

Industrial and industrial applications: manufacturing facility or warehouse maintaining structures, heavy load platforms, and erosion manipulate for development sites.

This versatility, blended with the wall’s structural, environmental, and monetary advantages, makes it an perfect answer for almost any soil stabilization and slope reinforcement project.

3. Geogrid Mesh Retaining Wall – Typical Applications

3.1 Geogrid Mesh Retaining Wall for Civil Infrastructure

Geogrid for soil stabilization maintaining partitions play a imperative position in large-scale civil engineering initiatives due to their capability to stabilize soil, manipulate loads, and forestall erosion:

3.1.1 Highways, Railways, and Bridge Embankments

These partitions grant critical reinforcement for roadway embankments and railway tracks constructed on slopes or tender soils. By integrating geogrid layers with the backfill, they enhance load distribution, minimize settlement, and forestall lateral soil displacement. Retaining wall grid are in particular advantageous in high-traffic areas the place vibration and dynamic hundreds are common.

3.1.2 Flood Control Levees and Riverbank Reinforcement

Geogrid mesh conserving partitions defend integral infrastructure from flooding by using stabilizing riverbanks and levees. The modular mesh machine permits for managed water flow, reduces erosion, and continues slope integrity all through heavy rainfall or excessive river discharge events.

3.1.3 Highway Slope Stabilization and Cut-Fill Embankments

When highways or roads traverse uneven terrain, geogrid driveway partitions help reduce slopes and fill embankments, stopping landslides and slope failures. The layered geogrid shape distributes weight efficiently, making sure long-term security and durability.

3.2 Geogrid Mesh Retaining Wall for Environmental and Municipal Projects

Polyester geogrid preserving partitions are exceptionally valued in city and ecological tasks for their environmental compatibility and structural reliability:

3.2.1 Retaining Walls for Parks, Playgrounds, and Urban Landscapes

The bendy and modular format permits for aesthetically appealing protecting partitions that combo into natural landscapes. These partitions help terracing, seating areas, playground structures, and public areas whilst offering soil steadiness and erosion control.

3.2.2 Erosion Control on Coastal Areas, Reservoirs, and Riverbanks

Coastal and riparian zones are susceptible to soil erosion due to water currents and tidal activity. Retaining wall geo grid partitions support these areas by using stabilizing soil, permitting for vegetation growth, and lowering sediment loss, supporting to hold ecological balance.

3.2.3 Landfill and Waste Containment Slope Stabilization

Slopes round landfills and containment web sites can be bolstered with plastic geogrid mesh partitions to forestall soil slippage and waste contamination. The drainage homes of erosion control geogrid structures decrease water accumulation and hydrostatic pressure, improving the structural integrity of containment slopes.

3.3 Geogrid Mesh Retaining Wall for Industrial and Commercial Projects

In industrial and industrial settings, hdpe geogrid driveway protecting partitions make certain safe, reliable, and reasonable soil support:

3.3.1 Retaining Walls for Warehouses, Factories, and Parking Areas

These partitions grant structural guide for large, open areas with heavy vehicular loads. They forestall soil motion below foundations or paved surfaces, decreasing renovation fees and extending the lifespan of infrastructure.

3.3.2 Slope Stabilization Around Heavy Machinery Platforms

Industrial websites regularly require steady structures for cranes, conveyors, or different heavy equipment. Geogrid retaining wall reinforcement keeps slope stability, prevents soil displacement, and helps dynamic and static loads, making sure operational safety.

3.4 Geogrid Mesh Retaining Wall for Residential and Landscaping Applications

Biaxial polypropylene geogrid conserving partitions are increasingly more famous in residential and landscaping initiatives due to their flexibility, ease of installation, and aesthetic integration:

3.4.1 Terracing for Gardens and Hillside Properties

Ideal for developing a couple of terrace ranges on sloped gardens or hillsides, geogrid partitions stop soil erosion whilst offering stage planting areas.

3.4.2 Reinforced Planters and Decorative Slopes

They guide ornamental slopes, raised backyard beds, and planter structures, permitting house owners to sketch practical and visually attractive landscapes.

3.4.3 Walkways, Driveways, and Recreational Area Support

Geo grid material partitions support paths, driveways, patios, and out of doors leisure areas by means of stabilizing soil and stopping agreement or erosion. The lightweight, modular graph allows rapid set up except heavy equipment.

4. Geogrid Mesh Retaining Wall Technical Specifications (Typical Range)

Parameter | Specification |

Material | HDPE / PP Polymer Geogrid |

Tensile Strength | 30–150 kN/m (depending on model) |

Aperture Size | 25–100 mm |

Thickness | 3–8 mm |

Color | Black (standard), Customizable |

Temperature Resistance | -40°C to +80°C |

UV Resistance | ≥ 5000 hours |

Lifespan | 50+ years in standard environmental conditions |

5. Geogrid Mesh Retaining Wall – Installation Process

5.1 Installation Process

Step 1: Site Preparation

Proper website training is vital for making sure the long-term balance and overall performance of the keeping wall. This includes:

- Clearing Debris: Remove rocks, vegetation, roots, and any free soil from the development area. Ensure a easy floor for the wall foundation.

- Leveling the Base: Excavate and stage the basis to grant a stable, flat floor for the first layer of geogrid. A compacted base reduces uneven contract and will increase wall stability.

- Slope Excavation: Excavate the slope in accordance to the sketch specifications, retaining the deliberate slope attitude and dimensions. Ensure that soil is steady and free from extra moisture earlier than proceeding.

- Drainage Considerations: Install preliminary drainage channels or perforated pipes if the website is susceptible to water accumulation, as suitable drainage is key to stopping hydrostatic stress at the back of the wall.

Step 2: Geogrid Placement

- Horizontal Layering: Lay the geogrid stabilization panels horizontally alongside the slope, beginning from the base. Ensure every panel is tight and flat in opposition to the soil.

- Proper Overlap: Overlap adjoining geogrid sheets in accordance to the manufacturer’s specs (usually 0.3–0.5 meters) to make sure non-stop structural reinforcement.

- Anchoring: Secure the geogrid ends or edges the usage of stakes or soil pins the place necessary, mainly on steep slopes, to forestall displacement in the course of backfilling.

- Alignment Check: Make positive the geogrid is aligned with the layout slope angle, and affirm that there are no wrinkles or folds that may want to compromise soil interlocking.

Step 3: Soil or Aggregate Infill

- Material Selection: Use compactable soil, gravel, or mixture with excellent particle dimension as infill. The preference relies upon on website prerequisites and graph requirements.

- Compaction: Fill the geogrid apertures evenly, then compact in layers the usage of mechanical or guide tamping. Proper compaction ensures the geogrid ground grid and soil act as a bolstered composite structure.

- Layer Thickness: Maintain advocated infill thickness per layer (typically 15–30 cm) to stability compaction ease and structural performance.

Step 4: Layering

- Repetition of Layers: Continue putting geogrid panels and infill in alternating layers till the wall reaches the favored height.

- Quality Control: After every layer, take a look at for appropriate tension, alignment, and compaction. This ensures the wall continues uniform electricity and balance during its height.

- Slope Reinforcement: Each extra biaxial grid layer reinforces the wall in opposition to lateral soil pressure, growing normal load-bearing capacity.

Step 5: Surface Treatment

- Aesthetic Finishing: Depending on venture requirements, the wall floor can be completed with:

- Stone or brick dealing with for ornamental or city applications.

- Turfing or sod planting for herbal panorama integration.

- Shrubs or creeping flowers to beautify erosion manage and inexperienced aesthetics.

- Erosion Protection: Surface remedy additionally helps guard the pinnacle layer from rainfall impact, floor runoff, and wind erosion.

Step 6: Maintenance

- Minimal Maintenance Required: Biaxial plastic geogrid conserving partitions are designed for long-term sturdiness with very little upkeep.

- Inspection Recommendations: Periodically investigate the wall for:

- Proper drainage characteristic (no water pooling or blocked drainage).

- Vegetation growth, making sure roots do now not disrupt the geogrid structure.

- Soil contract or minor erosion alongside the wall face.

- Preventive Measures: Address any minor problems right now to preserve wall overall performance and prolong its carrier life.

5.2 Best Practices and Tips

- Follow Manufacturer Guidelines: Always adhere to geogrid reinforced retaining wall tension, overlap, and compaction specifications.

- Layer Consistency: Maintain uniform layer thickness and compaction throughout the complete wall for most structural efficiency.

- Drainage Integration: Incorporate perforated drainage pipes or gravel layers at the back of the wall if water accumulation is expected.

- Vegetation for Slope Stability: Plant grasses or shrubs on the floor to limit soil erosion and enhance environmental aesthetics.

- Professional Supervision: Complex or high-load partitions have to be designed and mounted underneath the supervision of a certified civil engineer.

6. Choose BPM Geosynthetics Geogrid Mesh Retaining Wall

- Safety: Strong reinforcement reduces the threat of slope screw ups and soil collapse.

- Efficiency: Lightweight substances and modular diagram minimize development time.

- Sustainability: Promotes vegetation increase and minimizes environmental disruption.

- Adaptability: Works for nearly all terrains and soil types, from residential gardens to massive infrastructure projects.

- Long-Term Cost Savings: Durable, low-maintenance, and extraordinarily tremendous answer for soil and slope challenges.

Summarize

The Geogrid Mesh Retaining Wall from The Best Project Material Co., Ltd.(BPM Geosynthetics)provides most beneficial soil reinforcement, slope stabilization, and erosion control. Made from long lasting HDPE or PP geogrid, it is lightweight, flexible, UV-resistant, and long-lasting. Eco-friendly and versatile, it fits highways, railways, parks, industrial sites, and landscaping. Easy to deploy and low-maintenance, it affords a cost-effective, dependable answer for cutting-edge civil and environmental projects.