Biaxial Grid

With the rapid growth of road construction, railway expansion, mining operations, and large-scale infrastructure projects worldwide, the demand for reliable soil reinforcement materials continues to increase. Among these solutions, the biaxial grid—also referred to as biaxial geogrid—has become a top choice due to its high tensile strength, reliable load distribution, and proven performance in weak soil conditions.

Introduction: The Rising Global Demand for Biaxial Grid Solutions

With the rapid growth of road construction, railway expansion, mining operations, and large-scale infrastructure projects worldwide, the demand for reliable soil reinforcement materials continues to increase. Among these solutions, the biaxial grid—also referred to as biaxial geogrid—has become a top choice due to its high tensile strength, reliable load distribution, and proven performance in weak soil conditions.

Recent industry reports indicate that the global geogrid market is projected to grow at 8% CAGR between 2024 and 2030, driven by urbanization, transportation upgrades, and the rising need for cost-efficient ground improvement. As countries invest in long-term infrastructure stability, biaxial grid reinforcement is becoming essential to meet engineering performance and economic efficiency requirements.

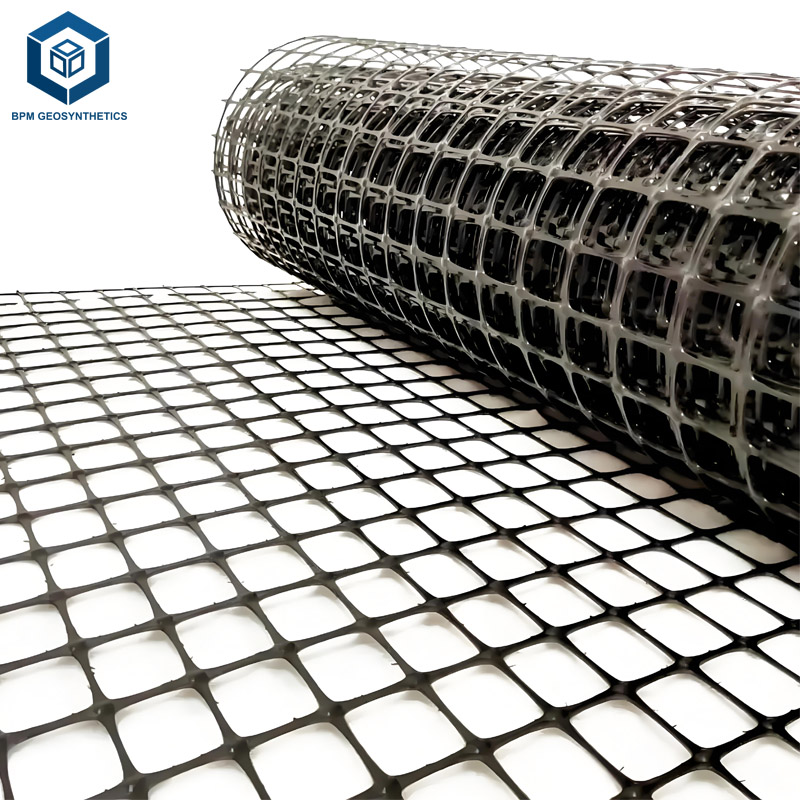

What Is a Biaxial Grid?

A biaxial grid is a geosynthetic material featuring a square or rectangular grid structure with equal tensile strength in both longitudinal and transverse directions. This dual-direction reinforcement allows it to effectively distribute loads, enhance soil interlocking, and improve the structural integrity of roads and foundations.

Most biaxial grids are manufactured using polypropylene (PP) or high-density polyethylene (HDPE), each chosen for durability, chemical resistance, and long-term mechanical performance.

Key Characteristics

High tensile strength in both directions

Excellent interlocking with aggregates

Uniform load distribution

Resistance to chemical corrosion

High durability with minimal creep

Easy transportation and installation

These advantages make biaxial grid materials widely used in highways, foundation reinforcement, parking lots, airport runways, soil stabilization, and retaining structures.

Technical Specifications of Biaxial Grid

To meet international construction standards, biaxial geogrid products typically include the following specifications:

● Tensile Strength

Common ranges: 20–50 kN/m, with higher-grade options depending on project requirements.

● Aperture Size

Optimized openings improve interlocking with crushed stone and granular fill.

● Material Composition

Polypropylene biaxial grid

HDPE biaxial geogrid

Both offer strong resistance to chemicals, soil acidity, and UV exposure.

● Elongation at Break

Low elongation ensures stable reinforcement under continuous loads.

● Roll Size

Width: 3–4m

Length: 30–100m

Large rolls improve installation efficiency for road construction and earthworks.

● Compliance Standards

Manufacturers typically follow international testing methods, including tensile strength, junction efficiency, creep testing, aperture uniformity, and environmental durability.

How Biaxial Grid Is Manufactured

The production process of biaxial grid is designed to ensure stable mechanical strength and uniformity:

1. Extrusion of Polymer Sheet

High-quality PP or HDPE resin is melted and extruded into a flat sheet.

2. Punching

The sheet is perforated to create a precise pattern of square or rectangular holes.

3. Stretching in Two Directions

First longitudinally, then transversely.

This biaxial stretching greatly enhances tensile strength and molecular orientation.

4. Cooling and Stabilization

Advanced cooling ensures structural uniformity and high junction strength.

5. Quality Control

Testing includes:

Tensile strength

Junction efficiency

Aperture consistency

Chemical resistance

UV and aging performance

This process ensures every biaxial geogrid roll meets engineering-grade requirements for demanding projects.

Global Market Analysis and Demand Drivers

● Infrastructure Expansion

Government investments in highways, rural roads, and industrial zones are increasing worldwide.

● Cost-Effective Soil Reinforcement

Biaxial grid reduces aggregate thickness, decreasing total project cost by up to 15–30%.

● Sustainable Construction Trends

As sustainable engineering becomes the norm, geosynthetic materials like biaxial grid are replacing traditional soil reinforcement solutions.

● Rapid Road Rehabilitation

Cold regions and heavy-traffic zones benefit from the ability of biaxial grid to reduce rutting, pavement deformation, and frost heave.

● Mining and Heavy Industrial Growth

Mine haul roads and platforms require high-strength reinforcement to prevent deep rutting and settlement.

Given these trends, the biaxial grid reinforcement market is expected to continue strong global growth.

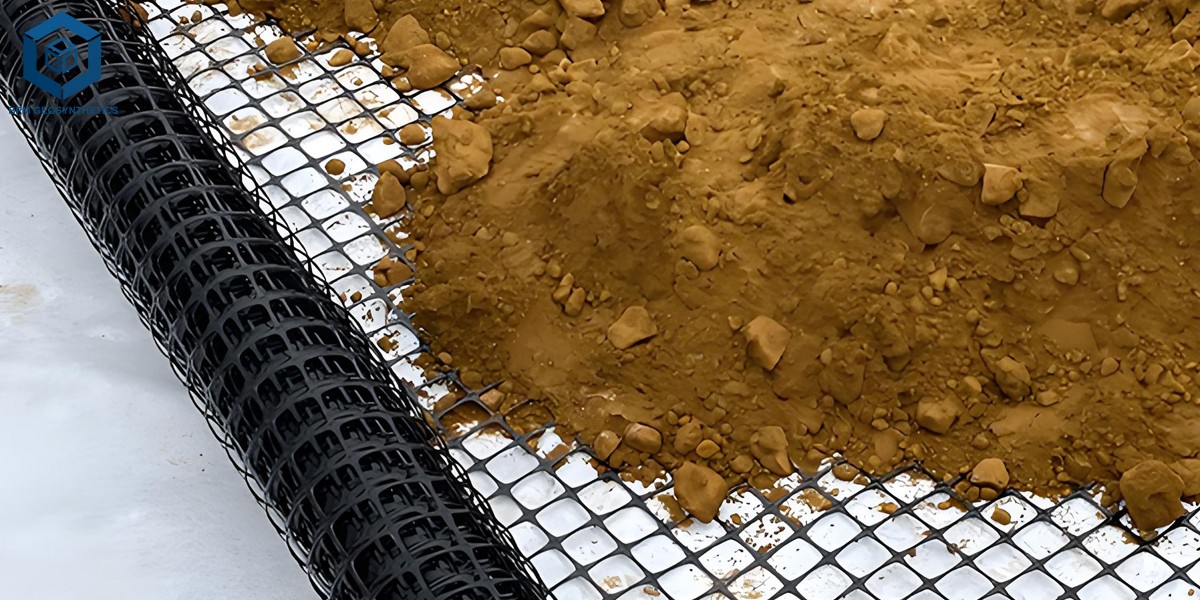

Key Applications of Biaxial Grid

1. Road Construction & Pavement Reinforcement

Improves load-bearing capacity, reduces rutting, and prevents early pavement failure.

2. Railway Track Stabilization

Enhances ballast distribution and minimizes settlement under high vibration.

3. Foundation Reinforcement

Used under embankments, storage yards, industrial platforms, airports, and container terminals.

4. Slope and Embankment Support

Provides stability in soft soil areas and prevents erosion.

5. Parking Lots & Industrial Flooring

Ensures uniform load transfer and prevents cracking of asphalt or concrete surfaces.

6. Retaining Structures & Subgrade Stabilization

Increases foundation stability for retaining walls and earth-retaining blocks.

Advantages of Using Biaxial Grid in Modern Construction

● Improved Structural Stability

Equal tensile strength in both directions ensures uniform reinforcement.

● Reduced Construction Costs

Requires less fill material and speeds up installation.

● Long-Term Durability

Resistant to chemical exposure, microbial attack, and weathering.

● Higher Load Distribution

Minimizes deformation, especially in heavy-traffic zones.

● Environmentally Friendly

Allows for reduced excavation and better use of local soil materials.

These benefits make biaxial grid a cost-efficient choice across diverse engineering applications.

Buyer Guide: How to Select the Right Biaxial Grid

When sourcing biaxial geogrid, international buyers should consider:

Required tensile strength (20kN–50kN or custom)

Soil type and subgrade conditions

Traffic load or structural load

Aperture size compatibility with fill material

Required roll dimensions

Project lifespan and environmental exposure

Compliance with engineering standards

We support buyers with engineering recommendations, sample evaluation, and technical consultation.

FAQ: Common Questions from Global Buyers

1. What is the difference between biaxial grid and uniaxial geogrid?

Biaxial grid has equal strength in both directions, ideal for soil stabilization. Uniaxial grid is stronger in one direction, used in retaining walls and slopes.

2. Can biaxial grid be used under asphalt pavement?

Yes. It reduces rutting, improves aggregate confinement, and extends pavement life.

3. Is polypropylene biaxial grid suitable for chemically aggressive environments?

Polypropylene and HDPE grids both offer excellent chemical resistance in soils with acidity or alkalinity.

4. What roll size is best for road construction?

3–4m wide rolls are standard, improving installation efficiency and reducing overlaps.

Conclusion: Biaxial Grid as a Reliable and Cost-Efficient Reinforcement Solution

As global infrastructure needs continue to expand, biaxial grid has become an essential engineering material for soil stabilization, pavement reinforcement, and foundation improvement. Its high strength, durability, and cost-saving advantages make it ideal for modern construction projects in both developed and emerging markets.

Professional Call-to-Action

If you are sourcing biaxial grid for road construction, soil reinforcement, embankment support, or heavy-duty industrial projects, our engineering team offers full technical guidance, product customization, and competitive export pricing. Contact us for specifications, samples, and expert consultation tailored to your project needs.