HDPE Pond Liner

HDPE Pond Liner is high performance geomembrane designed to furnish long-lasting, leak-proof containment for water administration projects. Manufactured from high-density polyethylene, these HDPE liner provide extraordinary chemical resistance, UV stability, and mechanical strength—making them best for aquaculture, irrigation, mining, and wastewater applications.

- High impermeability – Prevents water seepage and loss

- UV and chemical resistance – Suitable for harsh out of doors environments

- Tear and puncture resistance – Withstands soil motion and sharp objects

- Flexible set up – Easy to weld and adapt to a number of pond shapes

- Long carrier existence – Durable overall performance for 50+ years

BPM Geosynthetics gives HDPE pond liner in more than a few thicknesses and specs to meet your undertaking needs.

HDPE Pond Liner – High Performance Waterproofing Solution

1. HDPE Pond Liner Product Overview

The HDPE Pond Liner from BPM Geosynthetics is a extraordinary geomembrane designed to supply most beneficial containment in a broad vary of water administration applications. Made from High Density Polyethylene, it gives extraordinary impermeability, chemical resistance, and mechanical durability, making sure long-term overall performance even in harsh environments.

Whether used in aquaculture, agriculture, landscaping, mining, or industrial wastewater systems, BPM's HDPE pond liner affords a reliable, low-budget answer for leakage prevention and water conservation.

2. HDPE Pond Liner Key Features

2.1 HDPE Pond Liner: Excellent Waterproofing

The HDPE pond liner gives gorgeous impermeability, forming a exceedingly high-quality barrier that prevents water leakage into the surrounding soil or groundwater. Its low permeability coefficient ensures long-term water retention, making it best for lining ponds, reservoirs, canals, and different water storage systems. This greatest waterproofing potential helps preserve water, enhance gadget efficiency, and decrease preservation prices over time.

2.2 HDPE Pond Liner: Outstanding Chemical Resistance

Manufactured from chemically inert high density polyethylene, the liner resists a broad vary of aggressive substances, together with acids, alkalis, salts, and hydrocarbons. This makes it perfectly desirable for use in industrial and agricultural environments the place chemical publicity is common—such as wastewater remedy ponds, fertilizer tanks, and mining leach pads. Its resistance ensures long-term structural integrity even beneath harsh chemical conditions.

2.3 HDPE Pond Liner: UV and Weather Resistance

To make certain sturdiness in outside installations, the HDPE liner is formulated with carbon black and UV stabilizers that shield it from degradation brought on by using sunlight, heat, and weathering. This approves it to stand up to extended publicity to ultraviolet radiation besides turning into brittle, cracking, or dropping its mechanical properties. As a result, it keeps its overall performance in open-air functions for 20 years or more, even in harsh climates.

2.4 HDPE Pond Liner: High Puncture & Tear Strength

The liner well-knownshows awesome resistance to punctures, tears, and abrasions—critical facets for functions involving uneven or rocky subgrades. Its excessive tensile energy and tear resistance assist forestall injury throughout set up or from contact with sharp objects and heavy loads. This ensures the liner’s reliability in worrying environments like fish ponds, landfills, mining sites, and tailings containment systems.

2.5 HDPE Pond Liner: Thermal Flexibility

HDPE pond liner preserve flexibility and structural steadiness throughout a large temperature range. They stay pliable in freezing stipulations and withstand softening or deformation in excessive heat, making them appropriate for use in each cold alpine areas and warm barren region climates. This adaptability ensures impenetrable installation, decreased danger of cracking, and long-term overall performance regardless of environmental temperature fluctuations.

3. HDPE Pond Liner Technical Specifications (Customizable upon request)

| Property | Value Range |

|---|---|

| Thickness | 0.2mm – 3.0mm |

| Width | Up to 10 meters |

| Length per roll | Up to 100 meters |

| Tensile Strength | ≥ 27 MPa (standard HDPE) |

| Elongation at Break | ≥ 700% |

| Color Options | Black (standard), green, white |

| Certification | ISO9001, ISO14001, CE, ASTM |

4. Applications of HDPE Pond Liner

HDPE pond liner from BPM Geosynthetics are engineered to meet the wishes of a broad vary of water containment projects. Thanks to their top-quality waterproofing, chemical resistance, and mechanical strength, they are broadly used throughout the following sectors:

4.1 HDPE Pond Liner for Aquaculture Ponds

HDPE liners are drastically used in aquaculture purposes such as fish farms, shrimp ponds, crab farms, and hatcheries. They grant a safe, non-toxic, and inert environment that helps wholesome aquatic life. The liner prevents water seepage and contamination, permits higher manage over water quality, and reduces ailment dangers brought on by means of soil-based pathogens. Its clean floor additionally makes pond cleansing and renovation extra efficient.

4.2 HDPE Pond Liner for Agricultural Irrigation

In agricultural settings, HDPE liners are perfect for water storage ponds, irrigation reservoirs, and canal linings. They assist preserve water through casting off seepage losses and preserving constant water ranges for crop irrigation. These liners are resistant to agricultural chemical compounds such as fertilizers and pesticides, making sure long-lasting overall performance even in high-exposure environments. With HDPE lining, farmers can optimize water utilization and expand crop productivity.

4.3 HDPE Pond Liner for Landscape and Decorative Ponds

For garden ponds, fountains, waterfalls, and synthetic lakes, HDPE pond liners provide aesthetic flexibility alongside with durability. Their capability to be heat-welded into customized shapes approves panorama designers to create special water features. UV resistance ensures the liner stays secure and eye-catching even when uncovered to direct sunlight, whilst its impermeability ensures no leaks or erosion, retaining each shape and splendor over time.

4.4 HDPE Pond Liner for Mining & Industrial Applications

In mining and heavy industry, HDPE liner is used in integral containment structures such as heap leach pads, tailings dams, processing ponds, and chemical containment basins. They supply great resistance to cyanide solutions, acids, alkalis, and heavy metals, stopping environmental contamination. Their excessive mechanical energy ensures secure overall performance underneath heavy hundreds and sharp substrates. HDPE liners are integral for keeping regulatory compliance and operational safety in mining operations.

4.5 HDPE Pond Liner for Wastewater Treatment Systems

HDPE geomembranes are broadly utilized in municipal, agricultural, and industrial wastewater therapy systems, together with lagoons, bioreactors, sludge drying beds, and evaporation ponds. Their chemical steadiness and impermeability make certain that toxic effluents are securely contained, decreasing the chance of groundwater pollution. The liners are well matched with a variety of therapy chemical substances and resistant to organic growth, making them a dependable preference for long-term wastewater management.

5. HDPE Pond Liner Installation & Welding

Proper set up is critical to make certain the long-term overall performance and integrity of HDPE pond liners. At BPM Geosynthetics, we grant no longer solely excellent geomembranes however additionally expert assist and prefabrication alternatives to simplify the set up method and make certain leak-proof containment.

5.1 Thermal Welding Compatibility

HDPE pond liners are thoroughly like minded with superior thermal welding techniques, including:

- Hot wedge welding – Commonly used for joining long, non-stop seams. This technique creates a homogeneous bond between liner sheets, making sure most energy and leak prevention.

- Extrusion welding – Ideal for patching, element work, and seams in tight areas. It presents strong, long lasting connections and is extensively used all through repairs or round pipe penetrations and corners.

These strategies produce seam strengths equal to or increased than the liner cloth itself, putting off vulnerable factors and making sure entire watertightness throughout the installation.

5.2 Custom Sizing and Prefabrication Available

To simplify on-site set up and decrease welding time, BPM presents customized prefabrication services. Our liners can be pre-welded in our managed manufacturing facility surroundings into massive panels primarily based on your project's specific dimensions. Benefits include:

- Faster deployment on-site with much less labor

- Improved nice control, decreasing the risk of set up errors

- Less discipline welding, minimizing attainable leak paths

- Cost financial savings via decreased set up time and labor costs

Whether your pond is round, irregular, or custom-shaped, BPM can fabricate liners to suit your layout, enhancing effectivity and precision.

5.3 Installation Support and Technical Guidance

BPM presents complete technical aid for all ranges of installation. Our skilled crew can aid with:

- Project sketch session – liner selection, thickness calculation, and diagram design

- On-site education – set up procedures, welding techniques, QA/QC practices

- Testing protocols – such as air strain tests, vacuum testing, and spark exams to make certain seam integrity

- Training packages – for contractor groups or purchasers who require hands-on understanding of geomembrane coping with and installation

Our purpose is to make certain each and every task meets enterprise requirements (ASTM, ISO, etc.) and grants long-lasting, tightly closed containment.

With BPM’s exquisite HDPE pond liners and expert set up support, your venture is assured to acquire most performance, durability, and environmental compliance.

6. Reasons to Choose BPM Geosynthetics

When it comes to dependable geomembrane solutions, BPM Geosynthetics stands out as a depended on world producer dedicated to quality, innovation, and consumer satisfaction. Here's why consumers throughout industries pick BPM:

6.1 Over 20 Years of Manufacturing Experience

We deliver two many years of know-how in producing high-performance geosynthetic materials, making sure each product meets the needs of present day engineering projects.

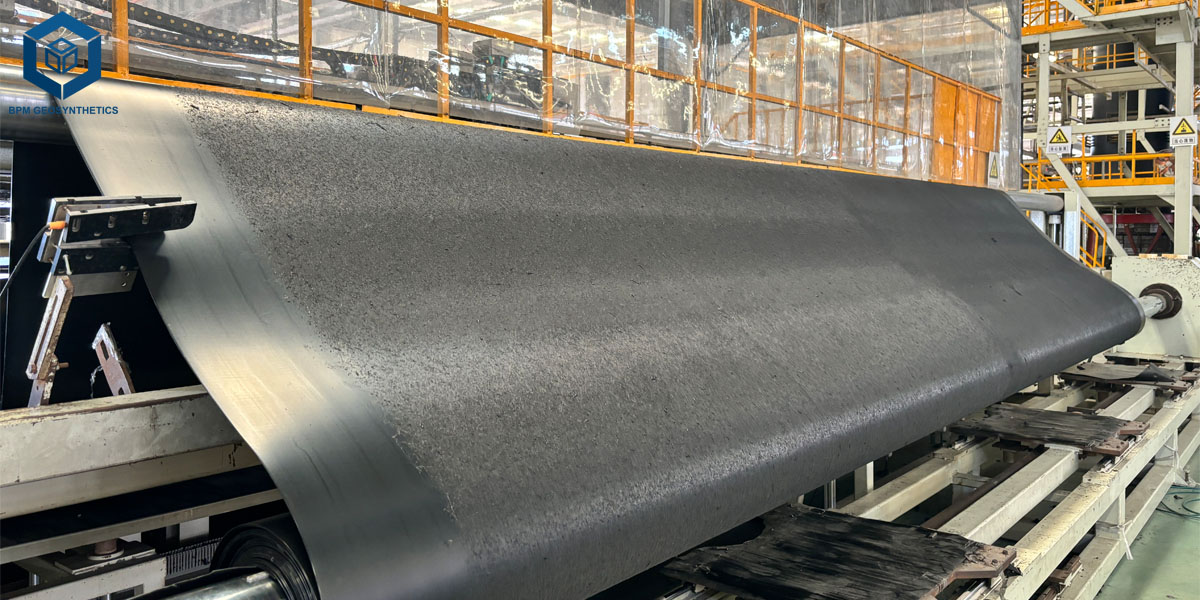

6.2 Advanced Production Lines & Strict Quality Control

Our today's manufacturing amenities are geared up with automatic strains and precision trying out systems, turning in steady excellent backed via ISO, CE, and ASTM certifications.

6.3 Global Project References in 100+ Countries

From mining in South America to aquaculture in Southeast Asia, BPM geomembranes have been correctly established in numerous environments round the world—proving our product reliability on a international scale.

6.4 Fast Delivery, Competitive Factory Pricing & Technical Support

With bendy manufacturing potential and environment friendly logistics, we provide fast turnaround times, aggressive direct-from-factory pricing, and devoted technical help in the course of your challenge lifecycle.

7. Contact Us

Looking for a durable, in your price range pond lining answer you can trust?

BPM HDPE Pond Liners are engineered for long-term performance, chemical resistance, and environmental protection—ideal for aquaculture, irrigation, mining, and more.

Reach out to BPM Geosynthetics nowadays for:

- Free product samples

- Technical datasheets

- Customized quotations

- Professional engineering support

Let’s construct a secure, sustainable solution—together.