Driveway Geocell

The global infrastructure sector has seen a rapid rise in the adoption of Driveway Geocell as project owners prioritize long-term ground stability and lower maintenance requirements. Geocell systems are used extensively in residential driveways, access roads, parking pads, logistics yards, and heavy-load platforms. With increasing land-use pressure and soil variability worldwide, geocell solutions play an essential role in improving load-bearing capacity and preventing surface deformation.

Market studies show sustained growth across North America, Europe, the Middle East, and emerging Asian regions. The shift toward permeable driveway reinforcement systems aligns with broader international trends in sustainability, stormwater management, and eco-friendly infrastructure development. These factors collectively drive greater investment in geocell technology.

Global Demand Growth for Driveway Geocell in Reinforcement Engineering

The global infrastructure sector has seen a rapid rise in the adoption of Driveway Geocell as project owners prioritize long-term ground stability and lower maintenance requirements. Geocell systems are used extensively in residential driveways, access roads, parking pads, logistics yards, and heavy-load platforms. With increasing land-use pressure and soil variability worldwide, geocell solutions play an essential role in improving load-bearing capacity and preventing surface deformation.

Market studies show sustained growth across North America, Europe, the Middle East, and emerging Asian regions. The shift toward permeable driveway reinforcement systems aligns with broader international trends in sustainability, stormwater management, and eco-friendly infrastructure development. These factors collectively drive greater investment in geocell technology.

Industry Trends and Market Drivers

Several key developments are shaping the global geocell market. First, private property owners and contractors are increasingly seeking cost-effective alternatives to deep excavation and traditional concrete reinforcement. Geocell for driveway stabilization reduces the amount of base material required while improving load distribution, resulting in significant cost savings.

Second, environmental regulations emphasizing soil erosion control and permeable ground surfaces have accelerated adoption in both public works and residential construction. A Driveway Geocell system offers high water permeability, preventing surface runoff and reducing freeze-thaw damage.

Third, growth in e-commerce logistics and outdoor construction activities has created greater demand for stabilized ground surfaces capable of supporting repetitive vehicular movement. This evolving application landscape continues to raise global geocell consumption.

Technical Specifications Required for Professional Engineering Use

To meet international engineering standards, a high-performance driveway geocell must follow strict material and structural requirements. The most critical specifications include:

• HDPE resin with high tensile strength and oxidation resistance

• Cell height options ranging from 50mm to 200mm for varying load conditions

• Cell wall thickness engineered for heavy-duty reinforcement

• Perforated or non-perforated structures depending on drainage requirements

• Seam welding strength compliant with global geotechnical guidelines

• Resistance to chemicals, UV exposure, and temperature fluctuations

These specifications support diverse long-tail applications such as HDPE geocell grid installations, load-support geocell foundations, soil stabilization geocell systems, landscaping ground reinforcement, and permeable driveway solutions.

Functional Structure and Performance Features

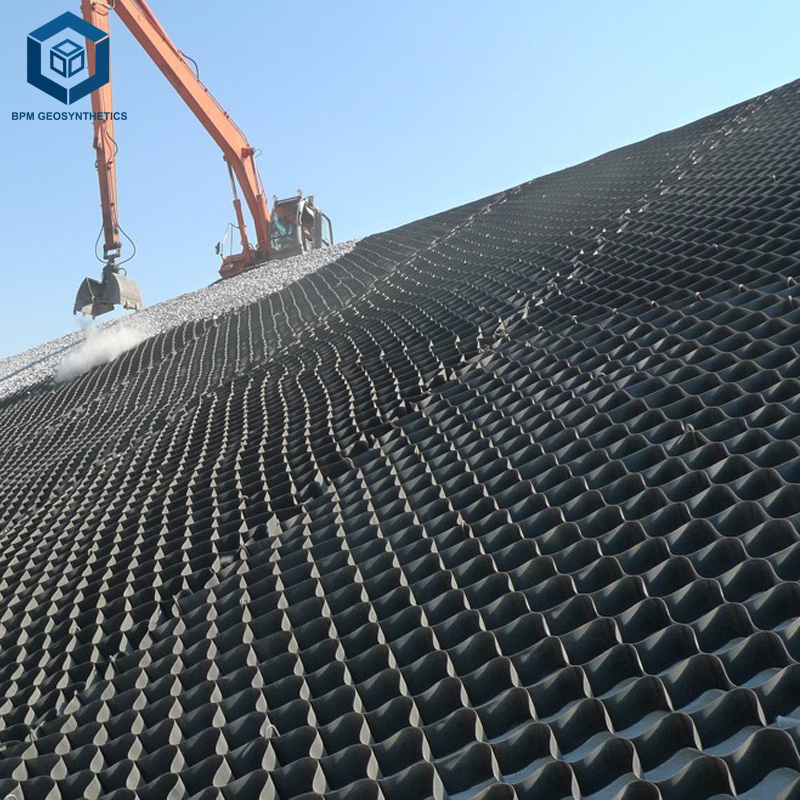

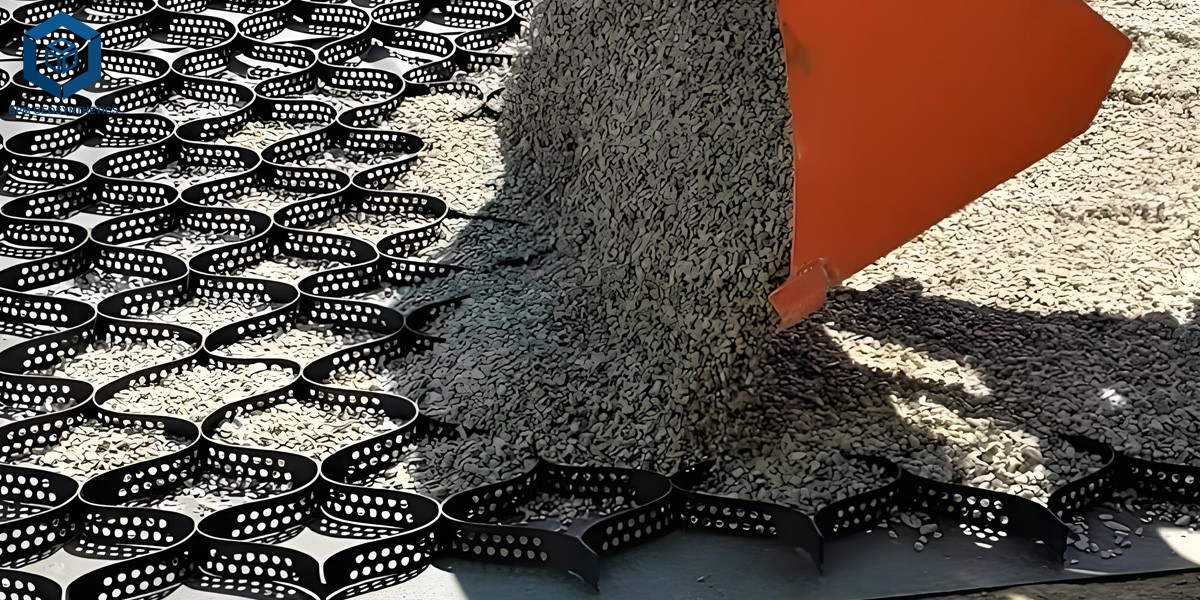

A Driveway Geocell typically consists of interconnected HDPE strips ultrasonically welded to form a honeycomb-like structure. When expanded on-site and filled with aggregate, soil, or sand, the geocell creates a semi-rigid, reinforced composite layer that distributes loads laterally rather than vertically. This reduces rutting, sinking, and surface cracking.

Key performance features include:

• Significant improvement in sub-grade modulus

• Enhanced load distribution for light and heavy vehicle traffic

• Reduced base material requirements by 30%–50%

• Effective control of soil erosion, edge failure, and migration

• Support for both soft soils and high-load industrial applications

Manufacturing Process and Quality Control System

The manufacturing of driveway geocell follows a precision-driven process to ensure consistent mechanical performance. Production includes HDPE granule selection, extrusion, strip calendering, perforation, ultrasonic welding, expansion testing, and dimensional control. Each stage requires strict monitoring to ensure cell integrity and weld strength.

Quality assurance involves multiple inspections, including tensile testing, weld peel strength evaluation, thermal aging analysis, and UV weathering simulation. International buyers commonly request detailed compliance documents to validate suitability for civil engineering and driveway reinforcement projects.

Application Scenarios and Installation Guidelines

A Driveway Geocell is widely used in private driveways, construction site access roads, RV parking pads, slope stabilization, and utility service routes. In each scenario, correct installation directly influences long-term performance and load resistance.

Typical installation steps include grading and compacting the sub-base, laying geotextile (optional based on soil conditions), expanding and anchoring the geocell, infilling with crushed stone, and compacting the surface. These steps ensure stable confinement and reduce potential deformation under repetitive wheel loads.

Compatibility with Various Filling Materials

Depending on project requirements, contractors use gravel, quarry stone, sand mixes, recycled aggregates, or soil-cement blends. The geocell’s flexible design supports multiple fill options, making it suitable for both rural and urban driveway reinforcement projects.

Buyer Preferences and Procurement Pain Points

International buyers in the geotechnical and construction sectors typically prioritize several non-negotiable factors when sourcing driveway geocell:

• High weld strength and proven structural consistency

• Detailed technical data sheets and third-party test reports

• Fast delivery time for project-based procurement schedules

• Customizable cell height, thickness, and perforation options

• Reliable packaging to minimize deformation during transport

Key pain points include inconsistent weld quality, insufficient load performance documentation, limited customization, and lack of engineering installation support. Suppliers offering complete technical guidance and project consulting tend to achieve higher conversion rates in competitive B2B bidding environments.

Global Opportunities in Residential and Industrial Construction

As global infrastructure investment continues to expand, Driveway Geocell presents a substantial opportunity for contractors, distributors, and engineering firms. Its versatility across residential, commercial, and heavy-duty applications makes it an increasingly preferred solution for ground stabilization.

The material’s longevity, performance reliability, and cost efficiency position it as a key component in modern permeable driveway systems, soil stabilization projects, and load-bearing ground reinforcement initiatives.

Conclusion: A Strategic Material for High-Performance Driveways

The rising need for durable, low-maintenance ground reinforcement solutions ensures that geocell technology will remain central to modern driveway construction. With its exceptional load distribution capability, high structural reliability, and compatibility with multiple soil types, Driveway Geocell continues to gain global market acceptance.

Engineering contractors, developers, and distributors seeking stable, long-term performance are encouraged to request full technical documentation, performance test results, and customized samples to ensure optimal project alignment.

FAQs

Q1: What cell height is recommended for residential driveway construction?

Most residential driveways use 100mm geocells, while heavier loads may require 150mm units.

Q2: Can driveway geocell be used on soft or waterlogged soil?

Yes. When combined with proper sub-base preparation, geocell significantly improves performance on weak soil conditions.

Q3: What filling material works best for driveway reinforcement?

Crushed stone or compacted gravel is recommended for optimal load-bearing capacity and permeability.

Q4: Do contractors need special equipment for installation?

No. Standard compaction and anchoring tools are sufficient for most small to mid-scale driveway projects.

For complete technical data, project consultation, custom sizing, and sample requests, contact us for a detailed quotation and engineering support.