HDPE Geocell

HDPE geocell is a third-dimensional honeycomb shape made of high-density polyethylene, designed to beautify soil and enhance ground stability. These multifunctional constructions are tremendously used in a volume of civil engineering applications, which consists of avenue construction, slope stability, and erosion control. By confining soil or aggregates indoors their units, HDPE geocells beautify bearing performance and quit soil erosion.

-Enhanced load distribution:HDPE geocell correctly distribute lots over a massive area, lowering the stress on the underlying soil and stopping deformation.

-Erosion control:Honeycomb layout helps stabilize soil and minimize erosion of slopes, channels, and embankments.

-Durability:These HDPE geocells are made of high-density polyethylene, which can face up to ultraviolet radiation, chemicals, and environmental pressure, making positive long-term performance.

HDPE geocell is a three-d expandable honeycomb shape made of high-density polyethylene, designed to furnish tremendous soil steadiness and reinforcement in a number applications. These HDPE geocells are set up by means of increasing them into a honeycomb pattern, which can be stuffed with soil, gravel, or different substances to structure a sturdy and steady surface. The special format of HDPE geocell limits the filling material, prevents lateral movement, and improves bearing capacity, making it an perfect desire for avenue construction, slope stability, and erosion control.

One of the primary blessings of HDPE geocell is its durability; They are in a position to face up to ultraviolet radiation, chemicals, and environmental pressure, making sure long-lasting overall performance even underneath harsh conditions. The light-weight traits of HDPE geocells simplify transportation and installation, lowering labor fees and mission time. In addition, their capability to promote vegetation increase and forestall soil erosion makes them an environmentally friendly preference for sustainable constructing practices. Overall, HDPE geocells grant a ordinary and advantageous answer for enhancing the balance and lifespan of a variety of infrastructure projects.

Parameter

Properties | Unit | Product type | |||

Smooth and Not Perforated | Smooth and Perforated | Textured and Not Perforated | Textured and Perforated | ||

Height | mm | 50≤H≤250 | |||

Welding Distance | mm | 330≤A≤1000 | |||

Thickness | mm | 1.0~1.4 | 1.5~1.7 | ||

Tensile Strength of Welding Points | N/cm | ≥100 | |||

Tensile Strength of Connection of Cells | N/cm | ≥120 | |||

Tensile Strength at Yield of Each Sheet | MPa | ≥20 | |||

HDPE Geocell Features

1. High durability:

HDPE geocell is made of high-density polyethylene, which can face up to ultraviolet radiation, chemicals, and environmental degradation, making sure long-term overall performance beneath quite a number conditions.

2. Lightweight design:

Its light-weight shape helps transportation and installation, lowering the managing charges and labor necessities in the course of deployment.

3. Scalable structure:

HDPE geocells can be increased into three-d honeycomb shapes and have a extensive vary of purposes in soil balance and reinforcement.

4. Load distribution:

The honeycomb plan efficaciously distributes the load over a large area, minimizing the stress on the underlying soil and stopping deformation or damage.

5. Erosion control:

By limiting the filling material, HDPE geocells assist stabilize the soil and efficiently decrease erosion on slopes, channels, and embankments.

6. Environment protection

These HDPE geocells promote vegetation growth, beautify ecological restoration, and sustainability by using offering a steady medium for plant roots.

7. Economically environment friendly solution:

The use of HDPE geocells can limit the want for tremendous excavation and extra materials, thereby reducing normal assignment costs.

8. Multi practical application:

Suitable for a number applications, consisting of avenue construction, protecting walls, army roads, and inexperienced roofs, making it a versatile preference for engineers and contractors.

These traits make HDPE geocells an necessary factor of modern-day civil engineering and environmental projects, contributing to elevated balance and sustainability.

Applications of HDPE Geocell

1. Road construction:

HDPE geocells are widely used in road engineering to reinforce roadbeds, enhance load distribution, and minimize pavement cracks. They provide a safe foundation, improving the durability and service life of roads.

2. Slope stability:

In slopes and embankments, HDPE geocells prevent soil erosion and landslides by using restricted soil or aggregates. This stability promotes the increase of vegetation and reduces the need for protection.

3. Erosion control:

HDPE geocells have high quality in controlling erosion in riverbanks, waterways, and coastal areas. By stabilizing the soil, they can prevent erosion and sediment loss related to water.

4. Application of landfill sites:

HDPE geocells are used in landfills to aid in lining structures and decorative sealing. They help control leachate and provide structural integrity for waste sealing systems.

5. Green roof system:

In inexperienced roof applications, HDPE geocells create a lightweight and supportive layer for soil and vegetation. They beautify drainage and root stability, promoting healthy plant growth.

6. Military and temporary roads:

HDPE geocells are very suitable for establishing short road entrances during offshore operations or emergency situations. They can quickly establish and reinforce fragile soils, ensuring mobility in difficult terrains.

7. Retaining wall:

HDPE geocells can be used to assemble protective walls, provide structural guidance, and improve load distribution. They help to effectively control lateral soil pressure.

8 Filling and stabilization:

In many civil engineering projects, HDPE geocells serve as a medium for filling soil, gravel, or different materials, providing stability and reducing shrinkage in the development area.

These uses demonstrate the multifunctionality and effectiveness of HDPE geocells in various fields, making them valuable assets in modern engineering and development practices.

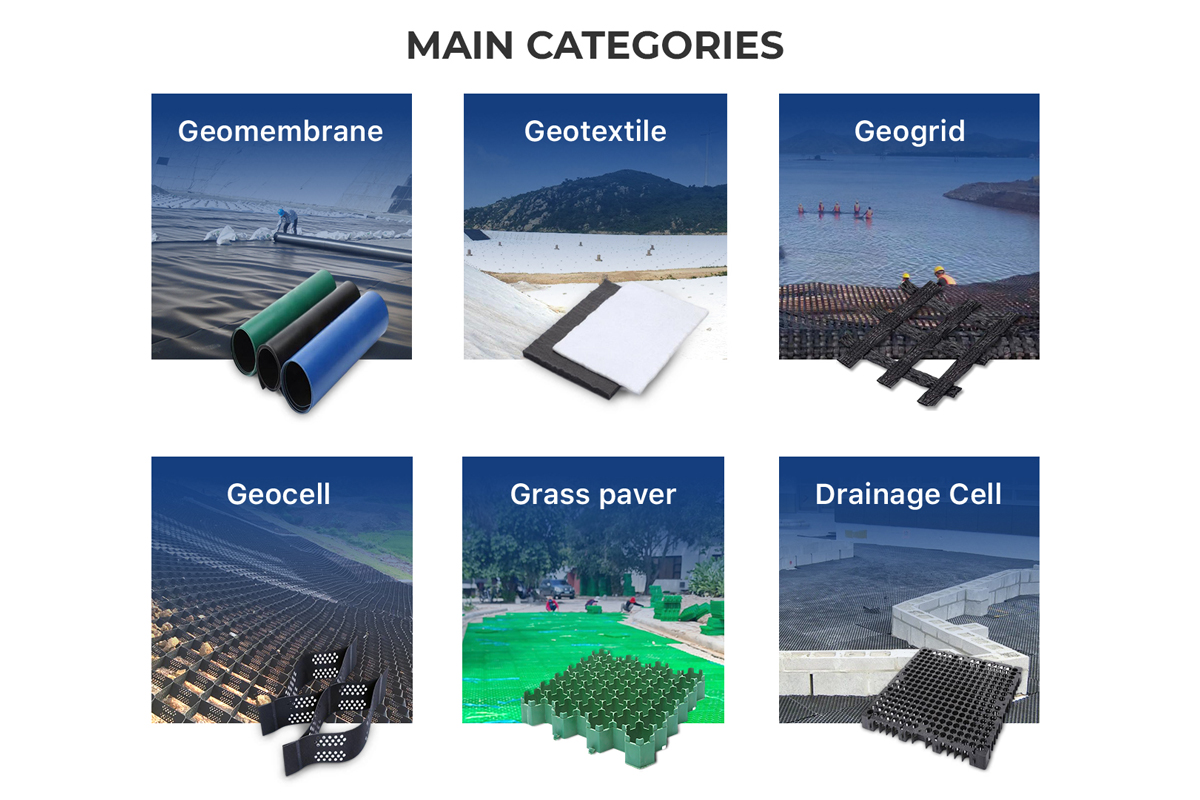

Company Profile

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, geogrids, geocells, and geosynthetic clay liners (GCL). Our products, certified by EU CE and GLP, have passed ISO 9001, ISO 14001, and OHSAS 18001 standards, and are recognized for their quality, performance, and durability.

BPM GEOSYNTHETICS has been committed to providing one-stop services for global customers in the research and development, production, sales, and export of geosynthetic materials since its establishment in 2007. The company has 120 senior technical talents specializing in geotechnical materials. The manufacturing factory covers an area of over 36000 square meters and is equipped with industry-leading automated production equipment and professional testing instruments. Product innovation, quality assurance, and customer satisfaction have always been BPM commitment to partners.

We're committed to innovation and quality, offering flexible cooperation and the best solutions for engineering projects worldwide. Our products are utilized in various sectors like aquaculture, erosion control, drainage systems, municipal engineering, mining, and landscaping. We look forward to partnering with you to solve complex challenges with our high-performance geosynthetic products.