Plastic Geocell

Plastic geocell is an modern three-d honeycomb shape made of high-density polyethylene (HDPE) or different long lasting plastics. They intention to stabilize and enhance soil, making it an best preference for more than a few civil engineering purposes such as street construction, slope stability, and erosion control.

-Load distribution:

Effectively distribute the load over a large vicinity and decrease soil deformation to the biggest extent possible.

-Erosion control:

By limiting the filling fabric and advertising stability, it helps stop soil erosion.

- Environment protection:

Support vegetation increase and beautify the environmental sustainability of building projects.

-Multi practical application:

Suitable for roads, maintaining walls, and inexperienced roofs, it has a broad vary of functions in engineering.

Plastic geocell is a three-d honeycomb confinement gadget made of high-density polyethylene (HDPE) or different long lasting plastic materials. Plastic geocells are designed to stabilize and fortify soil, and are extensively used in civil engineering and development projects. When expanding, they shape a honeycomb shape that restricts and helps filling substances such as soil, gravel, or concrete, enhances load-bearing capacity, and prevents lateral movement.

These plastic geocells are specifically high quality in functions such as street construction, as they enhance the structural integrity of roadbeds and decrease pavement cracking. In slope stability, plastic geocells assist stop erosion and similarly beautify soil steadiness through fixing the soil and promotion vegetation growth. Its light-weight sketch simplifies transportation and installation, making it an in your price range and environment friendly answer for a range of projects.

Plastic geocells can additionally face up to ultraviolet radiation, chemicals, and environmental pressure, making sure sturdiness and toughness beneath harsh conditions. Their versatility permits for a broad vary of applications, which include army tunnels, landfill stabilization, and inexperienced roof systems. By offering fantastic soil reinforcement and erosion control, plastic geocells make a contribution to sustainable constructing practices and universal resilience of infrastructure projects.

Parameter

Properties | Unit | Product type | |||

Smooth and Not Perforated | Smooth and Perforated | Textured and Not Perforated | Textured and Perforated | ||

Height | mm | 50≤H≤250 | |||

Welding Distance | mm | 330≤A≤1000 | |||

Thickness | mm | 1.0~1.4 | 1.5~1.7 | ||

Tensile Strength of Welding Points | N/cm | ≥100 | |||

Tensile Strength of Connection of Cells | N/cm | ≥120 | |||

Tensile Strength at Yield of Each Sheet | MPa | ≥20 | |||

Plastic Geocell Features

1. Durable materials:

Plastic geocells are made of high-density polyethylene (HDPE) or comparable plastics, which can face up to ultraviolet radiation, chemicals, and environmental degradation, making sure durability.

2. Lightweight design:

Its light-weight shape makes it convenient to transport and install, reduces labor costs, and allows fast deployment in a range of applications.

3. Scalable structure:

Plastic geocells can be increased into 3-dimensional honeycomb buildings and have a vast vary of functions in soil steadiness and reinforcement.

4. Payload distribution:

The honeycomb sketch efficiently distributes the load over a large area, minimizing the stress on the underlying soil and stopping deformation or damage.

5. Erosion manipulate capability:

By proscribing the filling material, Plastic geocells assist stabilize the soil and efficiently decrease erosion on slopes, channels, and embankments.

6. Environmental benefits:

They promote vegetation boom by using supplying a supportive medium for plant roots, which contributes to ecological restoration and sustainability.

7. Economically environment friendly solution:

The use of Plastic geocells can limit the want for considerable excavation and extra materials, thereby reducing usual challenge costs.

8. Multi purposeful application:

Suitable for a variety of purposes, which include street construction, maintaining walls, navy roads, and inexperienced roofs, making it an adaptive preference for engineers and contractors.

These traits spotlight the effectiveness and versatility of Plastic geocells in modern-day building and civil engineering projects.

Applications of Plastic Geocell

1. Road construction:

Plastic geocells are extensively used to give a boost to roadbeds and enhance the structural integrity of roads. They decorate load distribution, decrease avenue cracking, and lengthen the provider lifestyles of the street surface.

2. Slope stability:

In functions the place slopes are susceptible to erosion or instability, Plastic geocells hinder soil and aggregates, forestall landslides, and promote vegetation increase to enhance stability.

3. Erosion control:

Plastic geocells can correctly manage erosion of riverbanks, coastlines, and waterways. They stabilize the soil and minimize sediment loss via containing filling materials.

4. Application of landfill site:

Plastic geocells are used in landfills to assist lining structures and enhance sealing. They assist control leachate and grant structural integrity for waste manage systems.

5. Green roof system:

In inexperienced roof applications, Plastic geocells create a light-weight aid layer for soil and vegetation. They beautify drainage potential and grant steadiness for plant roots.

6. Military and Temporary Channels:

Plastic geocells are an perfect desire for constructing brief roads all through navy operations or emergency situations, which can shortly and successfully decorate mobility in difficult terrains.

7. Retaining wall:

Plastic geocells can be used to assemble conserving walls, supply structural support, and correctly control lateral soil pressure.

8. Fill and stabilize projects:

In a range of civil engineering projects, Plastic geocells are used to fill soil, gravel, or other substances to supply steadiness and decrease agreement in the building area.

These purposes display the versatility and effectiveness of Plastic geocells in enhancing the steadiness and sustainability of infrastructure initiatives in exceptional fields.

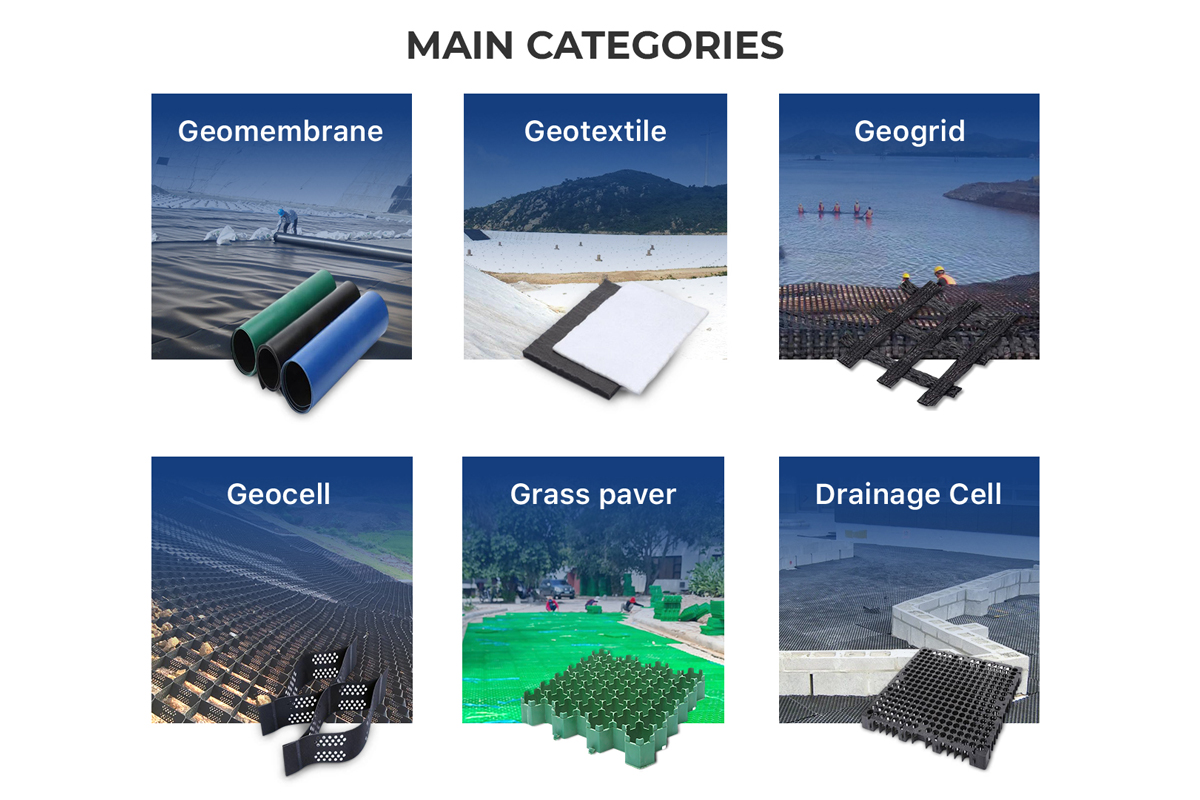

Company Profile

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, geogrids, geocells, and geosynthetic clay liners (GCL). Our products, certified by EU CE and GLP, have passed ISO 9001, ISO 14001, and OHSAS 18001 standards, and are recognized for their quality, performance, and durability.

BPM GEOSYNTHETICS has been committed to providing one-stop services for global customers in the research and development, production, sales, and export of geosynthetic materials since its establishment in 2007. The company has 120 senior technical talents specializing in geotechnical materials. The manufacturing factory covers an area of over 36000 square meters and is equipped with industry-leading automated production equipment and professional testing instruments. Product innovation, quality assurance, and customer satisfaction have always been BPM commitment to partners.

We're committed to innovation and quality, offering flexible cooperation and the best solutions for engineering projects worldwide. Our products are utilized in various sectors like aquaculture, erosion control, drainage systems, municipal engineering, mining, and landscaping. We look forward to partnering with you to solve complex challenges with our high-performance geosynthetic products.