Geo Clay Liner

In the field of environmental engineering, Geo Clay Liners (GCLs) have become a standard solution for managing water containment and preventing leakage in a variety of industries, including landfills, mining, and wastewater treatment. These geosynthetic clay liners offer a cost-effective and sustainable alternative to traditional clay liners, combining superior impermeability with enhanced durability.

Geo Clay Liner: A Sustainable Solution for Environmental Containment

Introduction

In the field of environmental engineering, Geo Clay Liners (GCLs) have become a standard solution for managing water containment and preventing leakage in a variety of industries, including landfills, mining, and wastewater treatment. These geosynthetic clay liners offer a cost-effective and sustainable alternative to traditional clay liners, combining superior impermeability with enhanced durability.

This article will provide an in-depth look at the benefits, cost factors, market trends, and applications of Geo Clay Liners, helping B2B buyers make informed decisions regarding sourcing and integration of these materials for industrial and environmental projects.

What is a Geo Clay Liner?

Definition and Composition

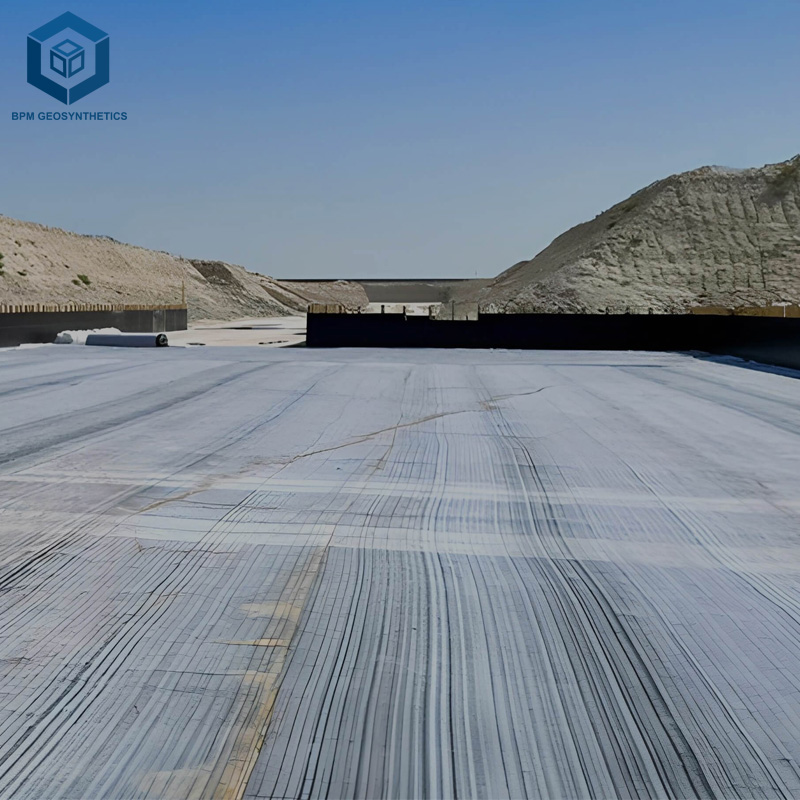

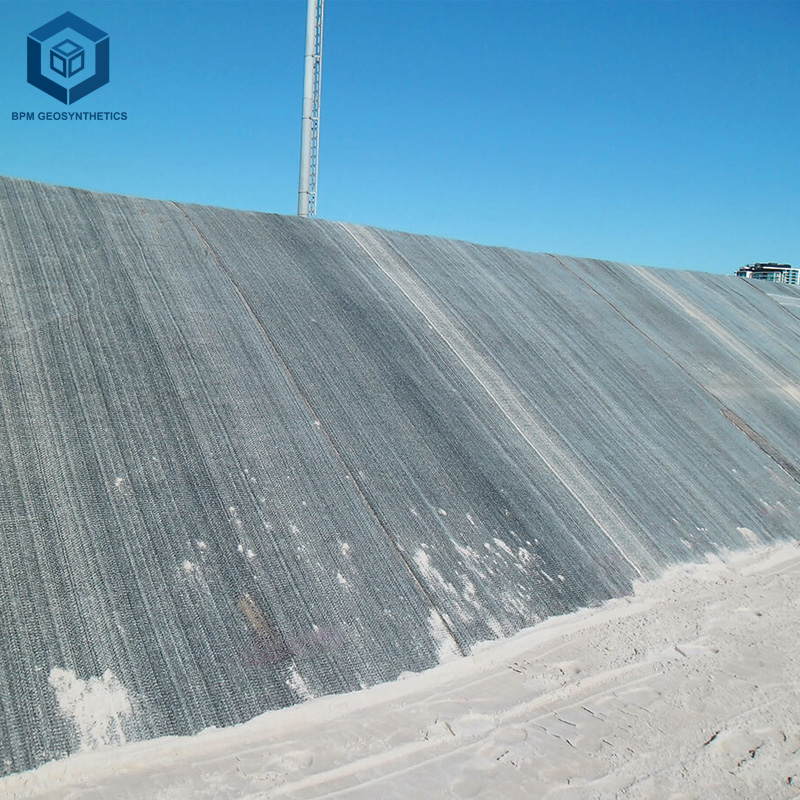

A Geo Clay Liner (GCL) is a composite material consisting of a layer of sodium bentonite clay sandwiched between two layers of geotextiles, typically nonwoven fabrics. The bentonite layer is naturally hydrated and swells when in contact with water, forming a highly effective impermeable barrier. This construction provides superior sealing capabilities, preventing the passage of liquids, which is essential in waste containment, landfill capping, and mining operations.

Key Features and Benefits

Low Permeability: GCLs have a permeability rating as low as 1 × 10⁻⁹ cm/s, offering one of the best barrier protections against water infiltration and chemical leachates.

Self-Healing: If punctured, the sodium bentonite within the liner swells to seal small holes, providing a natural self-healing mechanism.

Chemical Resistance: GCLs are highly resistant to many chemicals, including organic solvents, acids, and alkalis, making them suitable for hazardous waste containment.

Cost-Effectiveness: GCLs generally cost less than traditional clay liners due to easier installation and reduced need for maintenance.

Environmental Sustainability: GCLs are made from natural materials and are fully recyclable at the end of their lifecycle.

Market Trends and Insights

1. Increasing Demand in Landfills and Wastewater Management

As environmental regulations become stricter, the demand for Geo Clay Liners is rapidly increasing. Landfill operators and wastewater treatment facilities are adopting GCLs for containment systems to prevent groundwater contamination. GCLs are preferred due to their ease of installation, low maintenance costs, and long-term durability.

2. Growth in Mining Applications

In the mining sector, GCLs are used to line heap leach pads, tailings ponds, and other containment structures. The growth of mining activities, especially in regions like Latin America and Asia-Pacific, has led to a surge in the demand for geo clay liners as a more efficient alternative to traditional methods.

3. Shift Towards Eco-Friendly Alternatives

There is a noticeable shift towards the use of eco-friendly and sustainable materials in the construction and engineering industries. Geo Clay Liners align well with this trend, as they are made from natural, non-toxic materials and contribute to the long-term sustainability of environmental projects.

4. Technological Advancements

Technological advancements in GCL manufacturing are improving their performance, durability, and ease of installation. Manufacturers are increasingly using advanced needle-punching techniques and geotextile bonding methods to enhance the strength and reliability of GCLs. These innovations are driving the product’s adoption in more demanding applications.

Factors Affecting Geo Clay Liner Cost

1. Material Quality

The primary factor affecting the cost of Geo Clay Liners is the quality of the sodium bentonite used. Higher-quality bentonite, which offers better swelling and sealing properties, will typically increase the overall price of the liner. Bentonite sourced from specific regions may also have varying costs depending on availability.

2. Thickness and Configuration

The thickness of the liner and the type of configuration (e.g., reinforced or non-reinforced) also impact cost. For high-risk applications such as hazardous waste containment, thicker GCLs are required, which increases material costs. On the other hand, lighter-duty applications can use thinner or non-reinforced GCLs.

3. Project Size and Installation

The size and complexity of the installation project significantly influence costs. Larger projects typically benefit from economies of scale, which can lower the per-unit cost of Geo Clay Liners. Additionally, the installation process, which may require specialized equipment and labor, adds to the overall project cost.

4. Transportation and Logistics

Transportation is another important factor that impacts the cost of Geo Clay Liners. Since GCLs are typically sold by the square meter or square foot, transporting large quantities over long distances can add significant shipping costs. The availability of local suppliers and proximity to manufacturing plants can help reduce these costs.

Applications of Geo Clay Liners

1. Landfill Linings and Covers

Geo Clay Liners are widely used in landfill containment systems to provide an effective barrier against leachate seepage. In both municipal and hazardous waste landfills, GCLs are used as base liners and final covers, ensuring long-term environmental protection.

2. Mining Operations

In mining projects, GCLs are used to line heap leach pads for the extraction of metals like gold and copper. The liners are also used in tailings storage to prevent harmful runoff from contaminating nearby water sources.

3. Wastewater Treatment Ponds

GCLs are employed in the construction of wastewater treatment ponds to prevent contaminants from infiltrating the surrounding environment. Their ability to resist chemicals makes them ideal for applications involving industrial wastewater and stormwater management.

4. Agricultural and Irrigation Systems

Geo Clay Liners can be used in irrigation channels and agricultural ponds to reduce water loss due to seepage, improving water conservation and agricultural productivity.

FAQs About Geo Clay Liners

1. How long do Geo Clay Liners last?

Geo Clay Liners typically have a lifespan of 30 years or more, provided they are properly installed and maintained. The self-healing properties of GCLs help maintain their effectiveness over time.

2. Are Geo Clay Liners more cost-effective than traditional clay liners?

Yes, Geo Clay Liners are generally more cost-effective than traditional clay liners due to their ease of installation, reduced labor costs, and long-term durability. GCLs also require less maintenance.

3. Can Geo Clay Liners be used in all climates?

Yes, Geo Clay Liners are versatile and can be used in a variety of climates, including extreme heat or cold. However, proper installation is essential to ensure their performance under specific environmental conditions.

4. How do Geo Clay Liners compare to synthetic liners (HDPE)?

Geo Clay Liners offer the advantage of self-healing properties, which synthetic liners like HDPE do not possess. Additionally, GCLs are often more cost-effective and eco-friendly, while HDPE may be preferred in applications requiring very high chemical resistance.

Conclusion and Call to Action

Geo Clay Liners (GCLs) provide an exceptional, cost-effective solution for environmental containment needs across various industries. Their self-healing ability, chemical resistance, and environmental sustainability make them a top choice for applications in landfills, mining, wastewater treatment, and agriculture.

We are committed to providing high-quality Geo Clay Liners that meet international standards and ensure optimal performance. Our technical team is available to assist with material selection, project specifications, and installation guidance to ensure success in your containment projects.

Contact us today to request a detailed quote, technical specifications, or further information about how Geo Clay Liners can benefit your projects. Let us help you find the best solution for your containment needs.