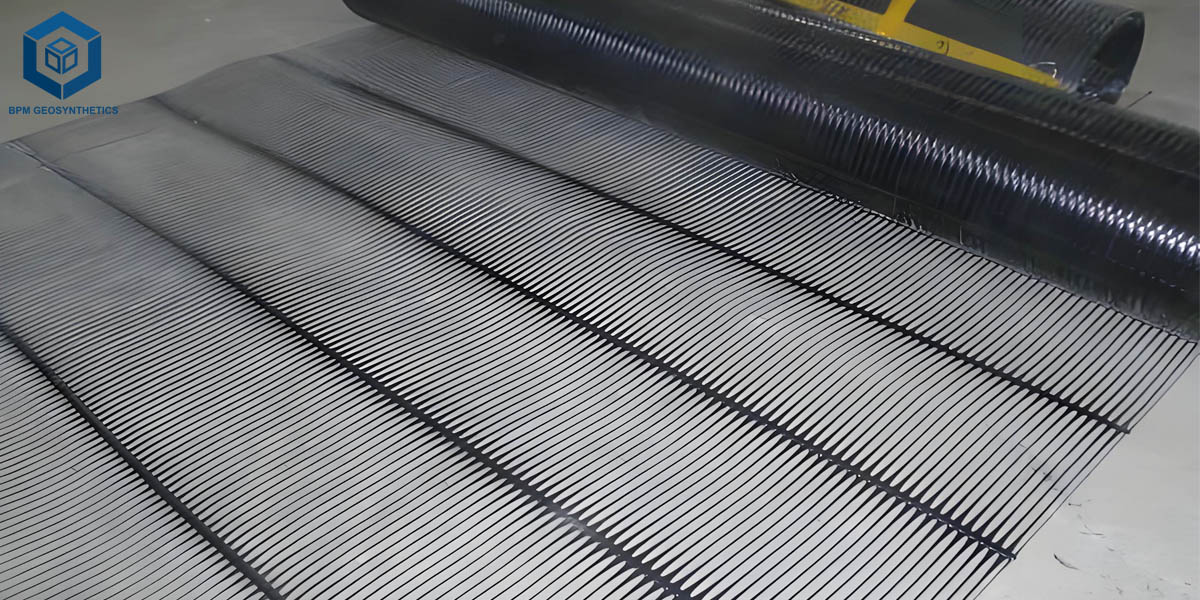

Uniaxial Plastic Geogrid

A Uniaxial Plastic Geogrid provides outstanding tensile strength, minimal creep, and excellent resistance to chemical and environmental degradation. Its high modulus-to-weight ratio ensures cost-effective reinforcement with reduced fill material requirements. The product’s ease of installation and compatibility with diverse soils make it ideal for retaining structures, slope stabilization, and embankment reinforcement. Additionally, it demonstrates long-term durability exceeding 75 years in buried conditions and consistent performance under extreme temperatures. With superior load distribution and deformation control, uniaxial geogrids deliver enhanced safety, reliability, and structural longevity in civil and environmental engineering projects.

A Uniaxial Plastic Geogrid is a high-strength polymeric reinforcement material engineered to enhance the stability and load-bearing capacity of soil structures. It is primarily used in retaining walls, embankments, steep slopes, and foundation reinforcement projects. Designed with tensile strength concentrated in one direction, this geogrid type provides superior reinforcement where stresses are unidirectional. This article presents a detailed technical overview, including its engineering principles, manufacturing standards, regulatory compliance, and best practices for installation and maintenance—optimized for both civil engineers and environmental project managers.

What Is a Uniaxial Plastic Geogrid?

A Uniaxial Plastic Geogrid is made from high-density polyethylene (HDPE) or polypropylene (PP) through extrusion, stretching, and molecular orientation. The production process aligns polymer chains in the longitudinal direction, resulting in exceptional tensile properties.

Typical Mechanical Properties:

Tensile Strength (ASTM D6637): 50–300 kN/m

Elongation at Break: < 15%

Creep Reduction Factor (ASTM D5262): < 0.5

Chemical Resistance: Excellent in acidic and alkaline environments

Service Life: > 75 years under buried conditions

These characteristics make uniaxial geogrids ideal for long-term soil stabilization and structural reinforcement applications.

Engineering Principles and Function

The primary engineering principle of uniaxial geogrids is load transfer through soil–geogrid interaction. When embedded within soil, the grid interlocks with aggregates, creating a composite material with improved shear resistance and load distribution.

Key Engineering Mechanisms:

Tensile Reinforcement: Resists lateral deformation in retaining structures.

Creep Resistance: Maintains long-term load-bearing capacity under constant stress.

Pullout Strength: Enhances frictional resistance between soil and grid ribs.

Confinement Effect: Reduces settlement and improves slope stability.

These principles align with geotechnical design theories such as the limit equilibrium method and reinforced soil structure mechanics.

Manufacturing Standards and Material Compliance

To ensure reliability and structural performance, uniaxial plastic geogrids are tested and certified according to international engineering standards, including:

ASTM D6637: Tensile properties of geogrids.

ASTM D5262: Creep testing for polymeric geosynthetics.

ASTM D5321: Direct shear strength of soil–geogrid interfaces.

ISO 10319: Wide-width tensile test for geosynthetics.

EN ISO 13431: Pullout resistance test for reinforcement applications.

Compliance with these standards guarantees mechanical integrity, environmental safety, and long-term durability in critical civil engineering applications.

Design and Application Scenarios

1. Retaining Wall Reinforcement

Uniaxial geogrids act as tensile elements to counteract active earth pressures, enabling thinner wall construction while maintaining stability.

2. Steep Slope Stabilization

Used in vegetated or rock-faced slopes up to 70°, improving resistance to sliding and erosion.

3. Embankment Construction

Enhances bearing capacity over soft foundations by distributing vertical loads uniformly.

4. Bridge Abutments and Road Subgrades

Increases structural stiffness, reduces deformation, and extends pavement life.

5. Mining and Landfill Projects

Provides reinforcement and separation in geotechnical containment systems.

Installation Guidelines

1. Subgrade Preparation

Remove vegetation, debris, and large stones.

Level the surface and compact it to design density.

2. Laying and Tensioning

Roll out the geogrid in the designed reinforcement direction.

Anchor at the start of the wall or slope and tension manually or mechanically.

3. Backfilling and Compaction

Use granular fill compatible with design specifications (e.g., angular crushed rock).

Compact in thin layers (< 200 mm) to prevent displacement.

4. Quality Control

Verify alignment and overlap (typically 300–600 mm).

Conduct field tensile tests when required by project specifications.

Performance Advantages

A Uniaxial Plastic Geogrid provides outstanding tensile strength, minimal creep, and excellent resistance to chemical and environmental degradation. Its high modulus-to-weight ratio ensures cost-effective reinforcement with reduced fill material requirements. The product’s ease of installation and compatibility with diverse soils make it ideal for retaining structures, slope stabilization, and embankment reinforcement. Additionally, it demonstrates long-term durability exceeding 75 years in buried conditions and consistent performance under extreme temperatures. With superior load distribution and deformation control, uniaxial geogrids deliver enhanced safety, reliability, and structural longevity in civil and environmental engineering projects.

Common Issues and Preventive Measures

| Issue | Cause | Recommended Action |

|---|---|---|

| Slippage during installation | Improper tensioning | Use mechanical stretchers or anchors |

| Soil movement or settlement | Poor compaction | Layered backfilling and quality control |

| UV degradation | Prolonged exposure | Bury within 24–48 hours post-installation |

| Joint failure | Insufficient overlap | Ensure minimum 300 mm overlap and secure joints |

Frequently Asked Questions (FAQ)

1. What is the difference between uniaxial and biaxial geogrids?

Uniaxial geogrids provide tensile strength in one direction, ideal for slopes and walls, while biaxial types reinforce in two directions for base stabilization.

2. Can uniaxial geogrids be used with cohesive soils?

Yes, but performance improves with granular backfill due to better interlock and friction.

3. How long do uniaxial plastic geogrids last?

Properly installed, they can perform effectively for over 75 years.

4. Are geogrids environmentally friendly?

Yes, they are chemically inert, recyclable, and reduce the need for excavation and natural aggregates.

5. What installation regulations apply?

Follow ASTM and ISO design guidelines, as well as local geotechnical codes and safety regulations.

Environmental and Safety Considerations

Ensure compliance with EPA construction site sediment control requirements.

Avoid direct sunlight exposure for long periods during installation.

Implement proper drainage systems to prevent hydrostatic pressure buildup.

Conduct post-installation inspection and documentation for project certification.

Conclusion & Professional Call to Action

A Uniaxial Plastic Geogrid represents a cost-efficient and technically advanced solution for soil reinforcement, structural stability, and long-term infrastructure resilience. It meets ASTM and ISO performance criteria, ensuring reliability across diverse civil and environmental applications.

If your engineering project requires high-tensile soil reinforcement, we can assist with technical specifications, design optimization, and material selection based on international geosynthetic standards. Contact our engineering support team today to ensure your retaining wall, slope, or embankment system achieves maximum performance, durability, and regulatory compliance.