What is Geocell Slope Protection?

Slope erosion and instability are amongst the major issues in the fields of civil engineering, construction, and environmental management. Unstable slopes may result in costly damages, risks to human lives, and environmental degradation. Typical methods for slope protection such as concrete retaining walls, riprap, or merely vegetation, are generally not up to the mark when it comes to price, durability, or ecological impact. That's when geocell slope protection comes as a modern, highly effective, and eco-friendly answer. BPM Geosynthetics is a company that focuses on advanced geocell technology aimed at ensuring long-lasting stability, erosion control, and harmony with nature.

1. Understanding Geocell Slope Protection

Geocell is a 3-dimensional, honeycomb-like structure, which is made from high-density polyethylene (HDPE), polyester, or other polymeric alloys. At the site, when fully spread out, it gives a flexible, permeable web with interconnected cells. These cells are later filled with materials like soil, sand, gravel, or recycled aggregate, resulting in a durable composite mass that acts as a single structure.

Geocell slope stabilization were originally invented by the U.S. Army Corps of Engineers in the 1970s as a means of fast stabilizing soft ground under military vehicles. The technology since then, has undergone a rapid evolution and now finds wide civilian usage in areas such as slope protection, channel lining, load support, and earth retention.

2. How Geocell Slope Protection Works?

The idea behind geocell slope protection is to use confinement. Geocell systems do slope stability and erosion control in various ways by confining the infill materials in their honeycomb-like cells:

2.1 Distributes Loads:

Geocell for slope protection spreads the forces (both vertical and horizontal) over a larger slope area. It means fewer localized stress points that otherwise may be the starting points of soil failure, slumping, or sliding. In situations of heavy traffic, rainfall, or any other type of outside stress, the even distribution of the loads makes the slope capable of remaining structurally intact.

2.2 Prevents Material Migration:

Thanks to the interconnected cell walls, the infill materials like soil, gravel, or sand are slotted tightly against each other which firmly locks them and thus prevents them from moving. Hence, the soil is not going to be washed away by rainwater or blown away by the wind. So, the slope will still be able to perform its function and at the same time, its shape will be the same, besides, it will be increasingly less likely that there will be a need for maintenance or repair.

2.3 Increases Shear Strength:

Shear strength of a slope is raised up-till a very high level when the soil that is inside the geocells is considered one big block and not as loose particles that can easily slide off each other. Hence, the slope becomes more resistant to sliding or deformation. The confined soil can support steeper slopes as well as higher loads than unreinforced fill.

2.4 Promotes Vegetation Growth:

Vegetation can grow fairly well in geocell slope filled with topsoil since, seeds and their first stages of life are safeguarded in such a miniature ecosystem. The cells protect the roots from erosion and offer structural support so that the plants may become established without any artificial assistance. In the course of time, the vegetation that is reinforced by this method will not only be a way of further stabilizing the slope but it will be a green and beautiful cover of the area which is in harmony with the natural surroundings.

3. Key Applications of Geocell Slope Protection

Our slope protection geocell is quite flexible without a doubt and are used in numerous civil, industrial, and environmental projects:

3.1 Highway & Railway Embankments:

According to the use of geocell driveway, stabilization of the slopes that are either excavated or put up alongside the roads and railway tracks is carried out. This enormously decreases the possibility of landslides, erosion, and washouts which may be caused by rain, traffic vibrations, or freeze-thaw cycles. Moreover, the maintenance of the correct shape of the slope, protection of the infrastructure, and the lowering of the costs connected with the maintenance that has to be done in the long run are all taken care of thanks to geocell for driveway.

3.2 Riverbanks & Coastal Cliffs:

Geo geocell structures serve as an effective tool for safeguarding riverbanks, estuaries, and coastal cliffs against the erosive actions of water currents, waves, and tides. Geocell erosion control achieve this by confining the soil or aggregate material, thus, not only preventing the undercutting of these areas but also reducing the loss of sediment and providing a strong, flexible structure that can easily adapt to varying water levels.

3.3 Reservoir & Canal Slopes:

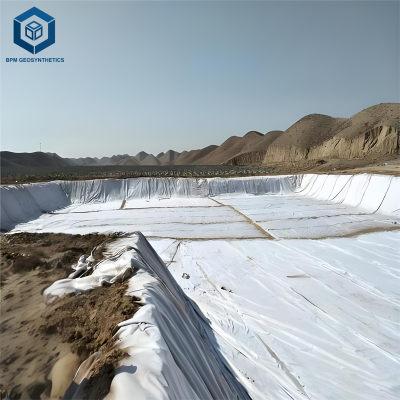

HDPE geocell is a perfect choice for irrigation canals, pond banks, and dam faces when it comes to the reinforcement of slopes and the prevention of soil erosion resulting from water seepage or surface runoff. Besides ensuring the long-lasting solidity of these water-holding structures, Geocell material use also paves the way for the growth of green, which, in turn, contributes to a more natural and harmonious environment.

3.4 Mining & Industrial Sites:

Geocell HDPE have become an integral part of the strategy to materialize the reclamation of mine tailings deposit areas by shaping the steep slopes into stable structures, defending the embankments, and enabling the transportation of heavy loads in circumstances of challenging terrains. These cells come up with a long-lasting answer to the issues of rough surroundings, thus, reducing the risk of the collapse of a slope and greatly helping in the management of a safe and sustainable site.

3.5 Landfill Capping & Civil Projects:

With their inherent ability to withstand vertical pressures and impact, geocell slope provide the perfect underpinning on which vegetated garbage necropolis caps can be built, thereby leaving no room for soil particles to be displaced and, at the same time, guaranteeing the thriving of the plant. Civilians may have also been witnesses of their usage in different landscaping and civil engineering endeavors where they have been employed for aesthetic grading, erosion control on embankments, and slope stabilization in parks, recreational areas, and urban developments.

4. Advantages of Geocell Slope Protection Over Traditional Methods

When you are switching to geocell products of BPM Geosynthetics, you are not just making a regular switch. Here is a list of many advantages that you will enjoy:

4.1 Superior Engineering Performance:

- High Structural Capacity: Our engineered polymer comes with an amazing tensile strength and is very durable, it can endure extreme temperatures and UV radiation.

- Flexibility and Durability: The system can handle ground settlement and repeated loading without any major failure, the design life is more than 50 years.

- Excellent Drainage: Being a permeable system it does not allow for pore water pressure to build up which is the most common cause of the failure of a slope.

4.2 Significant Cost Efficiency:

- Reduced Material Costs: Uses up to 80% of on-site or locally sourced material for infill which means very little of expensive imported rock or concrete is needed.

- Lower Transportation & Labor Costs: Plastic geocell weigh a lot less and are transported flat resulting in freight costs being reduced drastically, installation is very quick and needs very less equipment.

- Minimal Site Preparation: Needs less excavation and subgrade preparation when compared to the rigid structures.

4.3 Environmental Sustainability:

- Promotes Green Vegetation: A perfect substrate for the establishment of a plant system whose roots go deeply and that also controls erosion at the same time.

- Reduces Carbon Footprint: Having fewer embodied energies than concrete or steel solutions and also being more friendly for the usage of recycled materials for filling.

- Preserves Natural Hydrology: Unlike impermeable solutions, it allows for natural water infiltration and reduces runoff velocity.

4.4 Construction Simplicity and Speed:

- Easy Installation: Our solutions come with very simple connecting systems (e.g., patented zygote locks, strap systems) that allow the workers to assemble quickly and securely.

- All-Weather Application: Most of the weather conditions are suitable for installation hence projects do not get delayed.

- Minimal Skilled Labor Required: A well-organized procedure makes it possible to perform the construction with less highly specialized crews.

5. The BPM Geosynthetics Difference: Our Advanced Geocell Slope Protection

Our catalog of best geocell products is not a run of the mill. The result of the continuous R&D work by the team focused on those three aspects – performance, reliability, and user-friendliness.

5.1 Ultra-High Molecular Weight HDPE Formulations

Provide the ultimate level of resistance to creep, stress cracking, and chemical/biological degradation.

5.2 Advanced Perforation Designs

Fine-tuned cell wall perforations help in the penetration of roots; Geocell also facilitate drainage and provide a tighter interlock with the infill materials.

5.3 High-Quality Robust Connection Technology

By utilizing our own connection technologies, we are able to manufacture a monolithic mattress of extremely high strength and which can undergo tension without coming apart drastically.

5.4 Sizes and Specifications Options

We can customize your project with various cell depths, weld patterns, and sheet sizes to match exactly with the load designs and slope geometries.

6. Geocell Slope Protection Design and Installation: A Systematic Approach

Our engagement with clients starts with more than just product supply. We dedicate ourselves to the provision of thorough assistance geared towards achieving durable slope stability and efficient erosion control:

6.1 Site Assessment & Design

Our skilled engineering team performs an exhaustive study of the slope stability, looking at the soil type, gradient, hydrology, and other more or less environment-related factors. Hereafter, we design the geocell arrangement specifically for the client, we give the nod to the type of filler (soil, gravel, or topsoil) and we determine the details of the anchorage so as to ensure the performance expected in the case of load and weather conditions.

6.2 Surface Preparation

The essential precondition for the success of geocells for erosion control is the surface being well-prepared. The steps in which we explain the grading of the slope to the desired angle, how to compact the surface to prevent settlement, and, if necessary, the installation of geotextile separators so as to prevent subsurface mixing are thereby steps that establish a stable base for the perforated geocell execution and the longevity of the slope.

6.3 Geocell Deployment

The geocell layers are stretched over the slope and then firmly anchored at the top, bottom, and middle using stakes, pins, or cutting anchor trenches. It is through proper alignment and tight interconnection of cells that the team is able to create one continuous confinement system which fits the shape of the slope.

6.4 Filling and Compaction

The filling material gets distributed in layers or "lifts" which are then increasingly compacted so as to realize a maximum density and confinement in the cells. Different approaches are used according to the type of the filler: granular materials are subjected to mechanical compaction so that their structural stability is ensured whereas soil fillers for vegetated slopes are only lightly compacted so that their porosity and root growth potential be preserved.

6.5 Vegetation Establishment (if applicable)

Once the green slope projects have topsoil-packed HDPE geocells, they then get seeded or planted right after the infill material has been spread. Whether hydroseeding, hand planting or sodding is chosen depends on the state of the site. The purpose of the geocell slope protection design is to shelter the seedlings and roots so as to not only allow a speedy establishment but also to have a long-lasting natural slope reinforcement.

7. Case Study: Geocell Slope Protection Success in Action

One of the projects that were recently carried out involved a 50m-high by 45-degree embankment at a highway in an area with heavy seasonal rainfall. Due to the failure of the conventional riprap, the road was subjected to frequent closures. BPM Geosynthetics designed and supplied a deep-cell (200mm) geocell system filled with a mixture of local gravel and topsoil. The outcomes changed the game:

7.1 Zero erosion recorded after two major storm seasons:

The geocell arrangement managed to keep the infill tightly enclosed and thus there was no soil loss or slope degradation even under the downpour of the rain.

7.2 Cost savings of 40% compared to a proposed gabion wall solution:

A green geocell solution is a highly cost-effective option with reduced material, labor, and maintenance expenses without compromising stability which cuts the overall cost of problem-solving by a wide margin.

7.3 A fully vegetated, aesthetically pleasing slope established within 12 months:

The vegetation grown as a result of the combination of topsoil infill and seeding, improved the look of the slope and, at the same time brought ecological benefits such as habitat creation.

7.4 Highway remained fully operational with no maintenance interventions:

The presence of the stabilized slope reduced the number of disruptions thus the traffic was able to flow safely and continuously and the long-run maintenance requirement was low.

8. Why Choose BPM Geocell for Your Slope Protection Project?

We are more than a manufacturer; we are your technology partner in sustainable infrastructure. With decades of global experience, a certified quality management system, and an unwavering commitment to innovation, we deliver solutions that are not only technically superior but also economically and environmentally smart.

We provide:

- World-Class Technical Support: From initial concept to final installation.

- Certified, Consistent Quality: All our products meet or exceed international standards (ASTM, ISO).

- Global Supply Chain Reliability: Ensuring you get the right materials, on time, anywhere in the world.

Conclusion

Geocell slope protection represents a paradigm shift in geotechnical engineering. It successfully bridges the gap between hard armor and soft bioengineering, offering a resilient, cost-effective, and sustainable answer to the age-old problem of slope instability. As environmental regulations tighten and project budgets face increased scrutiny, the case for adopting advanced geocell technology becomes overwhelmingly strong.

Whether you are an engineer specifying materials, a contractor seeking a buildable solution, or a project owner looking for long-term value, The Best Project Material Co., Ltd.(BPM Geosynthetics)'s geocell systems provide the performance and peace of mind you require.