Geomembrane PVC

Geomembrane PVC is flexible, high-performance sheets used for containment and waterproofing applications. They provide super chemical resistance, durability, and ease of installation, making them best for landfills, ponds, reservoirs, and industrial projects.

- High Chemical Resistance: Protects in opposition to acids, alkalis, and different industrial chemicals.

- Flexibility: Easy to deal with and deploy on complicated shapes or uneven surfaces.

- Durable: Resistant to punctures, tears, and environmental aging.

- UV & Weather Resistant: Suitable for out of doors purposes with long-term performance.

- Customizable: Available in unique thicknesses and sizes to meet challenge requirements.

Geomembrane PVC is high-performance, bendy polymer sheets particularly engineered for liquid and waste containment applications. Made from polyvinyl chloride (PVC) mixed with stabilizers, plasticizers, and elective additives, they grant superb chemical resistance, durability, and flexibility. These membranes are succesful of withstanding harsh environmental conditions, consisting of UV exposure, temperature fluctuations, and chemical corrosion. Their adaptability permits them to conform to irregular surfaces and complicated structures, making them best for a large vary of industrial, environmental, and civil engineering initiatives such as landfills, ponds, reservoirs, tunnels, and chemical containment systems. With ideal set up and maintenance, PVC geomembrane provide a lengthy carrier existence and dependable overall performance for worrying containment applications.

1. Geomembrane PVC Material Composition

PVC geomembranes are chiefly composed of polyvinyl chloride (PVC) resin, mixed with:

1.1 Plasticizers

Enhance flexibility and elongation for effortless installation. Plasticizers permit the pvc liner to bend and conform to uneven surfaces besides cracking, making it appropriate for complicated shapes and diverse website online conditions.

1.2 Stabilizers

Improve thermal and UV resistance. Stabilizers assist the pvc liner pond preserve mechanical homes beneath excessive temperatures and extended daylight exposure, stopping untimely growing old or degradation.

1.3 Fillers or Reinforcements

Optional additions to enhance puncture and tear resistance. These reinforcements enlarge the 30 mil pvc liner’s mechanical strength, making it greater long lasting in the course of set up and long-term use in harsh environments.

1.4 Anti-aging Agents

Protect towards UV degradation and environmental stress cracking. Anti-aging components make certain that the 40 mil pvc pond liner retains flexibility, strength, and chemical resistance over prolonged carrier periods, even beneath intense climate or chemical exposure.

This cautiously balanced composition approves 30 mil pvc pond liner to preserve regular overall performance throughout various environmental and operational conditions, making sure long-term reliability in containment and waterproofing applications.

2. Geomembrane PVC – Physical and Mechanical Properties

PVC geomembranes are engineered to supply dependable overall performance below stress, offering each mechanical energy and flexibility for a large vary of containment applications. Key bodily and mechanical homes include:

2.1 Thickness

Typically degrees from 0.5 mm to 2.5 mm, relying on utility requirements. Thicker black pvc pond liner supply more advantageous puncture resistance and durability, whilst thinner black pvc liner provide less difficult coping with and fee effectivity for much less traumatic projects.

2.2 Tensile Strength

Provides notable load-bearing potential and resistance to stretching. High tensile electricity ensures that the pvc dam liners can face up to anxiety and exterior forces at some point of set up and operation, decreasing the danger of tears or deformation.

2.3 Elongation at Break

High elongation permits adaptation to uneven surfaces besides cracking. This property allows the membrane to take in stress brought on via soil settlement, temperature variations, or substrate movement, keeping a non-stop barrier.

2.4 Tear Resistance

Minimizes propagation of localized damage. Strong tear resistance prevents small punctures or cuts from creating into large failures, improving the long-term reliability of the lining system.

2.5 Density

Generally tiers from 1.3–1.5 g/cm³, making sure steadiness and impermeability. Proper density contributes to chemical resistance, dimensional stability, and positive containment of drinks or waste.

These bodily and mechanical traits jointly make sure long-term durability, reliability, and overall performance of plastic pond liner, even in difficult environmental and operational conditions.

3. Geomembrane PVC – Chemical and Environmental Resistance

PVC geo membranes are designed to face up to harsh chemical and environmental conditions, making sure long-term overall performance in a variety of applications. Key resistance homes include:

3.1 Chemical Resistance

Withstands acids, alkalis, salts, and many industrial chemicals. This property ensures that PVC geomembrane liner can be used in industrial ponds, chemical storage tanks, and hazardous waste containment barring degradation or loss of integrity.

3.2 UV Resistance

Stabilized towards daylight publicity for out of doors applications. UV-resistant components shield the geomembrane sheet from cracking, discoloration, and brittleness brought about with the aid of extended publicity to sunlight, extending carrier life.

3.3 Temperature Tolerance

Performs reliably throughout a vast temperature range, normally from -30°C to 60°C. This approves the geo membrane sheet to preserve flexibility in bloodless climates whilst resisting deformation or softening in high-temperature environments.

3.4 Biological Resistance

Resistant to microbial degradation in soil or water environments. PVC geomembrana can be safely used in ponds, reservoirs, and landfills besides being compromised by using bacteria, fungi, or different microorganisms.

These chemical and environmental resistance residences make impermeable geomembrane quite suitable for disturbing containment projects, offering long lasting and dependable overall performance over lengthy periods.

4. Geomembrane PVC Applications

PVC geomembranes are particularly versatile and are extensively used throughout a range of industries due to their durability, flexibility, and chemical resistance. Key purposes include:

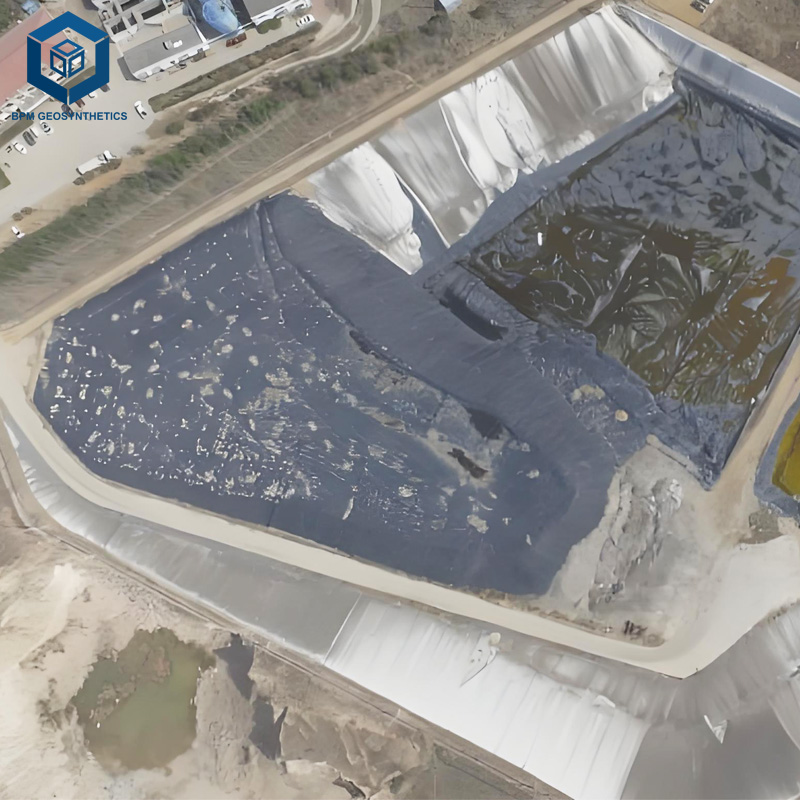

4.1 Landfills

PVC geomembrana 1mm is in many instances used for lining municipal, industrial, and hazardous waste landfills. They furnish a dependable barrier that prevents leachate and contaminants from seeping into the soil and groundwater. Their chemical resistance and sturdiness make sure long-term overall performance even beneath harsh waste conditions.

4.2 Water Retention

PVC membrane liners is perfect for reservoirs, canals, ponds, and synthetic lakes. They stop water loss via seepage and assist hold regular water levels. Their flexibility permits set up on irregular or uneven surfaces, making them appropriate for each herbal and engineered water containment systems.

4.3 Industrial Containment

PVC textured geomembrane is extensively used in chemical tanks, secondary containment systems, and procedure ponds. Their resistance to acids, alkalis, and industrial chemical compounds ensures protected storage and processing of hazardous materials, decreasing the hazard of environmental contamination.

4.4 Civil Engineering

In civil engineering projects, PVC geomembrane liner is used for tunnel liners, slope protection, and waterproofing structures. Their flexibility permits them to adapt to complicated geometries, whilst their mechanical energy ensures safety in opposition to soil pressure, erosion, and water infiltration.

4.5 Agricultural Uses

PVC impermeable geomembrane liner is utilized in irrigation canals, fish farms, and liquid manure storage facilities. They grant an impermeable barrier that prevents water and nutrient loss, protects water quality, and prevents illness of surrounding soil and groundwater.

5. Geomembrane PVC Installation Methods

PVC geomembranes provide bendy and environment friendly set up strategies to make sure long-term performance:

5.1 Welding Techniques

Hot-air welding, extrusion welding, or seam adhesives are many times used to be a part of membrane sheets. Properly done welding ensures strong, leak-proof seams, which are quintessential for containment integrity. Trained personnel and managed environmental prerequisites are integral for regular seam quality.

5.2 Surface Preparation

A smooth, clean, and compacted substrate ensures most desirable adhesion and prevents injury at some stage in installation. Removing debris, sharp objects, and uneven areas minimizes the hazard of punctures and ensures the impermeable liner conforms true to the surface.

5.3 Anchoring and Ballasting

Membranes are anchored or ballasted to stop wind uplift and hold desirable tension. This ensures balance all through set up and all through carrier life, specially for out of doors and uncovered applications.

5.4 Inspection

Seam checking out the usage of vacuum, air, or destructive/non-destructive techniques verifies the integrity of joints and the typical membrane system. Regular inspection in the course of and after set up reduces the hazard of leaks and ensures compliance with challenge specifications.

6. Geomembrane PVC - Durability and Aging Resistance

PVC polypropylene geomembrane is designed to furnish long-term containment overall performance underneath a number of environmental stresses:

- Anti-UV Additives: Special components stop degradation triggered via extended daylight exposure, decreasing brittleness and discoloration over time.

- Plasticizer Stability: Maintains flexibility except leaching over time, making sure the membrane stays pliable and capable to conform to surfaces all through its provider life.

- Chemical Stability: Resistant to corrosion, industrial chemicals, and environmental stress cracking, making PVC geomembranes appropriate for a large vary of applications, such as landfills, ponds, and industrial containment.

- Service Life: With appropriate set up and maintenance, bpm geomembrane commonly exceed 20–30 years of service, providing dependable overall performance and minimizing the want for everyday replacements.

7. Geomembrane PVC Storage and Transportation

Proper coping with of PVC geomembranes is integral to retain cloth integrity earlier than installation:

- Packaging: Rolls have to be covered with plastic movie and cardboard ends to stop scratches, punctures, and deformation all through transit.

- Storage: Store in flat, dry, shaded areas away from direct sunlight, warmness sources, and chemicals. Avoid stacking excessively to forestall everlasting deformation.

- Transportation: Care have to be taken to keep away from sharp objects, immoderate bending, or uneven stacking. Proper coping with minimizes the chance of bodily harm all through transport to the site.

8. Geomembrane PVC Maintenance and Longevity

Routine inspections and acceptable upkeep are crucial to maximize the carrier existence and overall performance of PVC geomembranes:

8.1 Inspection

Regularly take a look at for punctures, seam integrity, or floor damage, particularly after excessive climate events, heavy tools traffic, or unintended impacts. Early detection of practicable problems approves well timed intervention earlier than small troubles boost into fundamental failures.

8.2 Repairs

Minor damages, such as small punctures or seam separations, must be repaired rapidly the usage of well matched PVC patches or expert welding methods. Proper repairs repair impermeability and forestall leaks or contamination, making sure endured dependable performance.

8.3 Preventive Care

Avoid publicity to sharp, abrasive, or heavy objects that may want to puncture or tear the membrane surface. Maintain a clear and secure vicinity round the geomembrane and use defensive measures, such as geotextile cushions, in high-risk zones.

8.4 Manufacturer Guidelines

Follow encouraged methods for cleaning, chemical publicity limits, and pursuits maintenance. Adhering to producer tips ensures that the geomembrane retains its flexibility, chemical resistance, and UV stability, thereby extending its provider lifestyles and retaining standard containment integrity.

Conclusion – Choose BPM Geosynthetics Geomembrane PVC

The Best Project Material Co., Ltd.(BPM Geosynthetics)presents top rate PVC geomembranes that mix durability, chemical resistance, and flexibility for all kinds of containment projects. With strict first-rate control, worldwide certifications, and expert technical support, BPM Geosynthetics ensures reliable, long-lasting overall performance for landfills, industrial containment, water retention, and civil engineering applications. For initiatives requiring the perfect requirements in geomembrane solutions, BPM Geosynthetics is your relied on partner.