HDPE Liner Welding Machine

Ensure strong, leak-proof seams with our BPM Geosynthetics HDPE liner welding machine, designed for precision, durability, and effectivity in geomembrane installation. Perfect for landfills, ponds, reservoirs, and civil engineering projects.

Key Features:

- High Efficiency: Fast, uniform welding for giant HDPE sheets

- Reliable Seams: Ensures leak-proof, long lasting joints

- User-Friendly: Easy operation for gurus and crews

- Portable Design: Suitable for on-site and far flung projects

- Versatile Applications: Ideal for HDPE liner in water containment, mining, and waste administration

HDPE Liner Welding Machine from BPM Geosynthetics represents the pinnacle of precision, efficiency, and reliability in the area of geomembrane installation. Designed for professional use in civil engineering, mining, agriculture, and water containment projects, this computing device ensures superb seams, fast installation, and long-term durability. BPM Geosynthetics’s focal point on patron provider and technical excellence units it aside as a relied on companion for tasks worldwide.

1. Introduction to HDPE Liner Welding Machine

HDPE Liner Welding Machines are fundamental gear for putting in extraordinary geomembrane liners in various functions such as mining, landfills, agriculture, and water containment projects. BPM Geosynthetics gives superior geomembrane welding machines designed for precision, efficiency, and reliability, making sure most desirable seam integrity and long-lasting performance.

1.1 Overview of BPM Geosynthetics

BPM Geosynthetics has over 20 years of ride in manufacturing geosynthetic merchandise and associated equipment. Our HDPE geomembrane welding machines replicate our dedication to quality, durability, and purchaser satisfaction, providing tailor-made options to meet the special necessities of every project. With ISO-certified production, cutting-edge trying out facilities, and a international logistics network, BPM Geosynthetics ensures that each and every welding computing device promises constant results, whether or not used in small-scale farm ponds or massive industrial landfills.

1.2 Key Features of HDPE Liner Welding Machine

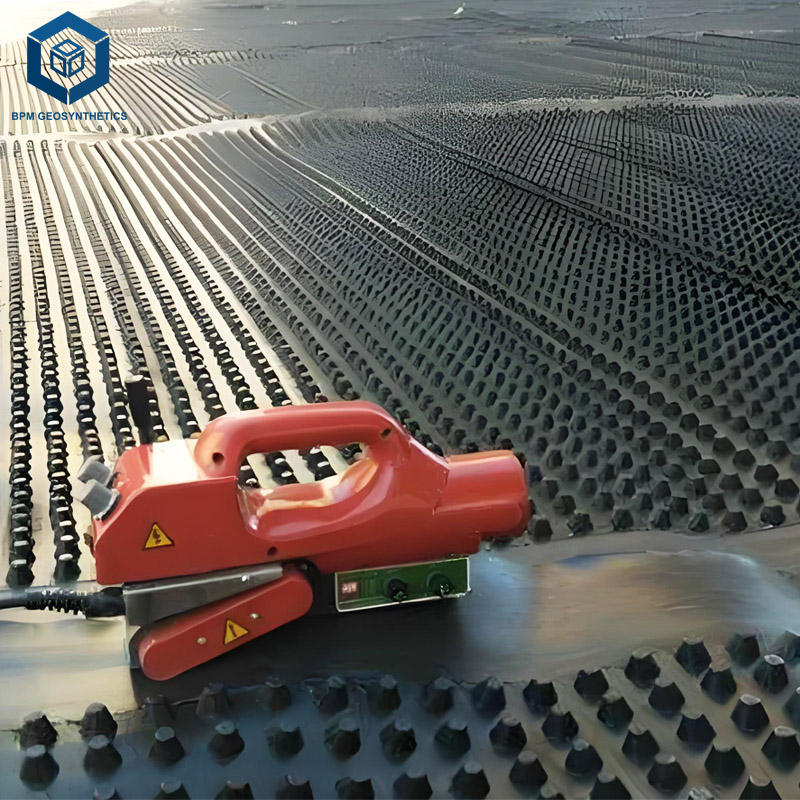

1.2.1 High Welding Accuracy

BPM geomembrane welding machine make use of unique temperature manage structures and superior heating factors to make certain uniform warmth distribution throughout the liner. This ensures strong, hermetic seams that stop leaks and lengthen the lifespan of the geomembrane. Even in thick liners up to 3mm, our machines keep constant welding performance, decreasing the hazard of seam failures.

1.2.2 Variable Speed Control

Each hdpe wedge welder is geared up with adjustable pace settings to accommodate special liner thicknesses and welding conditions. Operators can fine-tune the welding pace for skinny agricultural liners or heavy-duty industrial liners, optimizing each seam best and productivity. This flexibility ensures most effectivity throughout various venture requirements.

1.2.3 User-Friendly Interface

The manipulate panel is designed for simplicity and intuitive operation, with clear shows for temperature, welding speed, and stress settings. Operators can display the manner in real-time, lowering mistakes and fatigue. The ergonomic plan additionally ensures safer dealing with and minimal operator stress throughout lengthy welding sessions.

1.2.4 Portable and Robust Design

BPM hdpe geomembrane welding machine is engineered for on-site use in difficult environments. Lightweight but durable, they can be transported without problems throughout difficult terrains or restrained mission sites. The sturdy body and exquisite elements make sure dependable operation even beneath severe temperatures or non-stop usage, making them perfect for mining sites, reservoirs, and landfill installations.

1.2.5 Safety Mechanisms

Safety is a precedence in all geomembrane welder. Features such as computerized shutdown in case of overheating, emergency end buttons, and shielding guards stop accidents and tools damage. This lets in operators to work confidently whilst retaining fantastic welds, decreasing downtime due to tools failure or protection incidents.

2. HDPE Liner Welding Machine Applications and Use Cases

BPM pond liner welding machine is versatile, aiding a huge vary of projects. Their adaptability units them aside from traditional welding tools.

2.1 HDPE Liner Welding Machine for Mining and Industrial Waste Containment

Our dam liner welding machine is optimized for heavy-duty geomembrane welding in mining and industrial waste sites. The strong seam overall performance reduces leakage dangers and ensures compliance with environmental regulations.

2.2 HDPE Liner Welding Machine for Landfills and Waste Management

BPM hot wedge welding machine is mainly engineered to take care of landfill liners. With regular warmth distribution and unique control, they supply secure, long-lasting seams that meet global standards.

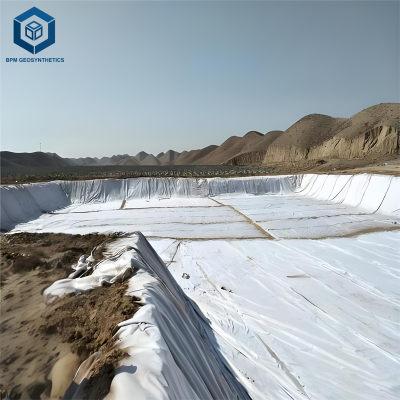

2.3 HDPE Liner Welding Machine for Agriculture and Water Containment

From irrigation ponds to water reservoirs, our machines allow fast and environment friendly set up of impermeable geomembrane liner, making sure impermeability and sturdiness in agricultural and aquaculture projects.

2.4 HDPE Liner Welding Machine for Civil Engineering Projects

Our geomembrane welding helps tasks such as canals, reservoirs, and environmental safety liners, imparting customizable welding options for large-scale constructions.

3. BPM Geosynthetics HDPE Liner Welding Machine Service Advantages

BPM Geosynthetics does now not simply provide remarkable machinery—we supply comprehensive assignment assist and value-added offerings that differentiate us from competitors. Our dedication extends from pre-sale session to post-sale support, making sure your HDPE liner set up tasks are efficient, reliable, and cost-effective.

3.1 Technical Consultation

BPM Geosynthetics presents professional technical session to assist customers pick out the most appropriate hot wedge welding machine for their particular undertaking requirements. Our engineers check elements such as membrane hdpe thickness, undertaking scale, environmental conditions, and set up web site accessibility to propose the perfect computer mannequin and settings. Additionally, we grant practise on welding techniques, seam testing, and upkeep schedules, assisting purchasers maximize desktop overall performance and make sure long-term liner integrity.

- Key benefits:

Tailored computer hints for every project.

Optimized welding parameters to minimize seam failures.

Professional recommendation to enhance set up efficiency.

3.2 Operator Training

Proper operator coaching is critical for accomplishing magnificent welds and venture efficiency. BPM gives each on-site and digital education programs, masking computing device operation, preservation procedures, troubleshooting, and seam testing. Operators research high-quality practices for exceptional polypropylene geomembrane substances and thicknesses, improving seam consistency and lowering human error.

- Key benefits:

Hands-on and interactive coaching for quicker talent acquisition.

Customized classes based totally on challenge complexity.

Long-term know-how transfer, enabling in-house groups to function independently.

3.3 After-Sales Support

BPM Geosynthetics’s dedication continues after shipping thru complete after-sales support. Our committed carrier crew is prepared to grant well timed maintenance, troubleshooting, and substitute parts, minimizing downtime and making sure non-stop undertaking progress. We additionally provide faraway technical coaching for pressing issues, making positive that each and every laptop operates at height effectivity at some stage in its lifecycle.

- Key benefits:

Fast response provider to minimize challenge delays.

Access to authentic spare components and consumables.

Remote technical aid for world clients.

3.4 Customization Options

Every assignment has special requirements, and BPM dam liner welding machine is incredibly customizable. We can alter machines for particular liner thicknesses, welding widths, environmental conditions, or exceptional undertaking constraints. This bespoke method ensures choicest overall performance and efficiency, whether or not for large-scale industrial installations, agricultural ponds, or touchy environmental projects.

- Key benefits:

Adaptation for various geomembrane hdpe thicknesses and materials.

Machine changes for intense climates or difficult terrains.

Custom options that enhance productiveness and decrease labor costs.

4. Why Choose BPM HDPE Liner Welding Machine ?

BPM welding machine for geomembrane is designed to supply unmatched performance, reliability, and fee throughout a vast vary of applications. Our dedication to engineering excellence, operational efficiency, and international assist ensures that customers can entire initiatives safely, quickly, and with long-term confidence.

4.1 Proven Reliability in Diverse Conditions

BPM geomembrane heat gun is examined to function reliably in intense temperatures and difficult environments, from freezing bloodless prerequisites to high-temperature sites. The pvc geomembrane welder is constructed with long lasting factors and precision controls, making sure regular seam integrity even underneath heavy-duty or non-stop operation. This reliability reduces renovation fees and prevents undertaking delays prompted by using tools failure.

- Key highlights:

Tested for each low- and high-temperature environments.

Robust building for long-term durability.

Consistent welding first-class below variable climate and web page conditions.

4.2 Enhanced Efficiency

Our geomembrane welder machine is designed for fast, environment friendly welding, decreasing mission time and labor costs. Adjustable pace controls and optimized heating factors permit operators to attain splendid seams rapidly besides compromising precision. This effectivity is specially treasured for large-scale tasks such as landfills, mining liners, or irrigation ponds.

- Key highlights:

Faster seam welding barring sacrificing seam strength.

Optimized overall performance for special pond liner geomembrane thicknesses.

Increased productiveness lowers ordinary challenge costs.

4.3 Precision Engineering

Every BPM hdpe geomembrane welding is crafted with superior engineering requirements to make certain long-lasting geomembrane performance. High-accuracy temperature and stress controls assurance uniform seams and leak-proof installations, minimizing the hazard of pond geomembrane screw ups over time. Precision engineering additionally simplifies computer operation and reduces the probability of operator errors.

Key highlights:

Consistent warmness distribution for hermetic seams.

High-precision welding parameters for quite a number liner geomembrane materials.

Reduced threat of seam failure ensures long-term venture reliability.

4.4 Global Logistics Support

BPM Geosynthetics offers complete world logistics and set up support, making sure that customers get hold of their machines at once and can begin initiatives besides delays. Our crew coordinates shipping, customs clearance, and on-site setup assistance, making it handy to installation machines somewhere in the world.

Key highlights:

Quick transport and international shipping.

On-site set up practise for seamless startup.

Coordinated aid to make certain assignment closing dates are met.

Conclusion

The Best Project Material Co., Ltd.(BPM Geosynthetics)’ HDPE Liner Welding Machines are industry-leading equipment designed to make certain most useful seam integrity, operational efficiency, and unmatched reliability. Backed through significant technical knowledge and complete aid services, BPM Geosynthetics empowers consumers to whole geosynthetic initiatives safely, efficiently, and with long-term durability.

Experience the BPM Geosynthetics difference—precision, performance, and expert aid for each HDPE liner installation.