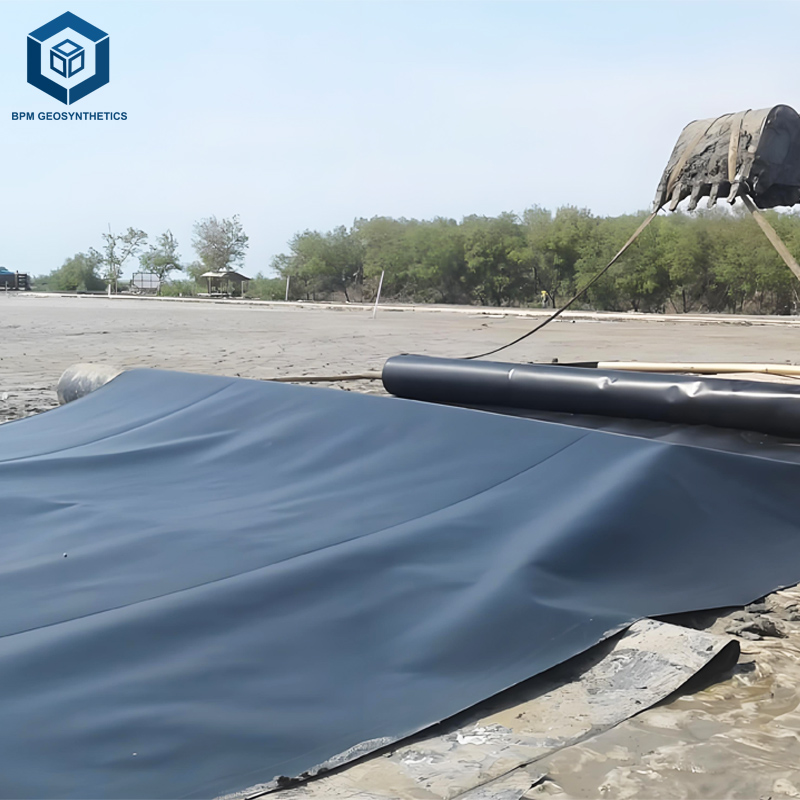

HDPE Liner

HDPE Liner is basically a metal-free fabric of the highest strength with strong resistance to chemicals. It is very often the go-to choice in the case of landfilling of solid wastes, reservoir from rivers, mining, aquaculture, and waterproofing projects. It is made from quality high-density polyethylene that gives it a very long service life, great resistance against ultraviolet rays, and superior leakage protection.

- High Performance: Proper tensile strength, puncture resistance, and impermeability of the material.

- Wide Thickness Range: From 0.2mm up to 3.0mm (8–120 mil) to be capable of handling any project.

- Custom Sizes Available: You can personalize a roll's width, length, and thickness to suit your needs.

- Surface Options:Both textured & smooth surfaces are offered

- Free Samples: Willing to give you the samples for quality inspection if you ask.

- Factory Direct Price: Affordable rates directly from the HDPE liner factory.

HDPE Liner is a top fiberglass-sheet widely applied in the fields of civil, environmental, agricultural, and industrial engineering. Its design goals include durability, resistance to chemicals, and hermetic sealing. These characteristics allow hdpe geomembrane to be the right choice for the above-ground water containers, landfills, and mining projects to name a few, where eventual leaks and seepage provide long-term problems.

1. HDPE Liner Material & Manufacturing

1.1 Premium Material

The hdpe geomembrane product is made out of high-quality, UV-stabilized HDPE resin that is non-toxic, durable, and environment-friendly.

1.2 Advanced Manufacturing

The geomembrane sheet product is made using a combination of precision extrusion and calendaring procedures to maintain an even thickness, high tensile strength, and a smooth or textured surface throughout.

1.3 Surface Options

The high density polyethylene pond liner product can either be smooth or have a textured finish, which helps increase friction, slope stability, and easy installation.

1.4 Color Choices

The standard colors of the polyethylene pond liners are black and green. However, the customer can request any color for their project.

2. HDPE Liner Technical Specifications

2.1 Thickness

HDPE liner pond is from 0.2 mm up to 3.0 mm (8–120 mil) that real-world applications provide by choosing a light or heavy use of material depending on the projects involved are varied. Thin ones are perfect for ponds, irrigation systems, etc. However, for landfills, mining pads, and industrial containment, thick ones are recommended.

2.2 Roll Width

Common width is 5.8 m and 7 m. However, for the specific layout of a project, with the help of narrower or wider widths, we can reduce the amount of the necessary seams and thus gain efficiency and time savings.

2.3 Roll Length

On one roll, you can have as many as 100 m of the material. Either short or long rolls are therefore the main determinant of installation time and seams number for a large project.

2.4 Tensile Strength

ASTM D6693 and ISO 527-based researches have been used to test this parameter. It shows how much the high density polyethylene liner material can be stretched, used, and generally handled under various environmental conditions during fixing and lifespan without breaking.

2.5 Elongation at Break

The high elongation lets the film pull without breaking, so therefore it is natural to be used for rough ground, hillside, and heat-expanding areas.

2.6 Puncture & Tear Resistance

The high density polyethylene geomembrane material could stop puncture, tear, and wear caused by the machine. This device is able to meet international levels for heavy-duty anti-leakage works which, in turn, guarantee safe storage even under bad situations.

2.7 Additional Properties

They are also protected against ultraviolet light, corrosion by chemical agents, and very hot or cold temperatures making that come long-term lasting (being able outside the developed world and in various industrial projects) possible.

3. HDPE Liner Performance Testing

To achieve a high level of performance and maintain the durability over a long period of time, the hdpe geo membrane is put through tough tests:

3.1 Tensile Strength Test

This test defines the requirement for a geomembrane pond liner to be resistant to stretching or tearing by measuring the force that causes the tear. The test also ensures that the hdpe geomembrane liner can survive the installation stress and field loads without resulting in failure.

3.2 Puncture Resistance Test

This test is concerned with determining the capability of the sheath to resist penetration caused by sharp or pointed objects, such as spikes, nails, rocks, or fragments of construction waste. The results, therefore, provide safe assurances that the sheath can be deployed in the heavy-duty sector.

3.3 UV and Weathering Test

This is a deliberate test performed to simulate long-term exposure to typical conditions in the open, such as hot sun and moisture, and cold or hot weather, and temperature drops. The purpose of the test is to prevent the gradual deterioration of the product over time.

3.4 Chemical Resistance Test

This test helps to determine the product's capabilities in terms of maintaining the properties and having a long service life when exposed to different chemicals like acids, bases, and other industrial or mining liquids. The hdpe geomembrane sheet is then suitable for use in chemical storage, tailings ponds, and wastewater storage.

3.5 Additional Quality Checks

Moreover, several other parameters such as seam strength, dimensional stability, and elongation at break are monitored in order to realize the requirements of ASTM, ISO, and other international standards.

Such performance tests promise that the high-density polyethylene (HDPE) liner is hard-wearing, sealed tightly, and has the potential to be applied in the different sectors of landfills and mining sites, aquaculture ponds, and irrigation systems, and the like.

4. HDPE Liner Customer Support & Service

We back up the sales and the installation of our high-density polyethylene (HDPE) liner with a variety of support and service options to make the customer journey smoother and easier:

4.1 Free Sample

Qualities can be checked if a sample is requested and handed over to pre-order testing. The material user can verify that an item works before ordering a large quantity.

4.2 Customization Options

The cutting of size, width, color, surface and more for the specific needs of each project is totally allowable for the smallest pond up to the landfill and mining projects of a great scale.

4.3 Fast Delivery

The timing for shipping the standard orders is between 5 and 7 days and it also available worldwide to carry out the projects on time.

4.4 Technical Support

An expert is the right person to provide the introduction of the installation, welding the seams, and taking care of the device, also giving tips on how to handle slopes, uneven ground, and nature.

4.5 OEM & Branding

The company branding or the resale side can utilize the custom logo printing, packaging, and labeling to help create a market-ready presentation that is both professional and attractive.

4.6 After-Sales Service

The plan for this service maybe entails the hosting of your project by solving problems, supplying parts, or giving extra advising for your project in order to be satisfied and have a good performance over the long term.

With all components in place, this support lineup is what essentially comprises a high-quality hdpe liner sheet. Coupled with the professional assistance at each and every phase starting from product selection and customization to installation and maintenance, clients are thus ensured of the liner quality by this complete support package.

5. HDPE Liner Case Studies & Applications

Due to their robustness, resistance to chemicals, as well as impermeability, HDPE liners are used across a wide range of industries. The following are the industrial application examples of HDPE liners:

5.1 Mining Projects

The application of 60 mil hdpe liner is featured in the installation of heap leach pads, tailings ponds, and process water containment systems, hence avoiding the leakage of leachate and resulting in the environment around the site being free from chemical contamination.

5.2 Aquaculture & Agriculture

20 mil hdpe liner take care of the water needs in irrigation ponds, fish farms, and reservoirs by providing water retention that is safe and reliable, thus aquatic life is safe, and the water loss due to seepage is kept at a minimum.

5.3 Landfills & Waste Containment

The role played by hdpe membrane sheet in the establishment of leak-proof barriers is instrumental in the case of municipal and industrial landfills, thus there is no release of dangerous substances into the soil or groundwater that can cause pollution.

5.4 Civil Engineering & Infrastructure

Among the uses of hdpe impermeable liner is slope stabilization, canal lining, embankments of highways, and reservoir protection. They help in the prevention of erosion, water leakage, and structural damage.

5.5 Environmental Protection Projects

HDPE dam liners mainly features in the ecologically safe and lasting solutions application of stormwater retention ponds, wastewater containment, and the storage of hazardous materials.

In every scenario, the use of an hdpe geomembrane pond liner is being emphasized as a multipurpose, top-performance, and very reliable problem solver in the most challenging cases. As a result, it is considered as a go-to material for waterproofing and containment-related projects that require durability and resistance to wear over time.

6. HDPE Liner Advantages

Polyethylene geomembrane bring a lot of positive points to the table that make them the most attractive option in the areas of waterproofing, containment, and environmental protection projects. They include:

6.1 Reliable Performance:

The BPM geomembrane material is able to resist structural failure due to heavy loads, extreme weather conditions, and harmful chemical exposure. This essentially means that it guarantees long-term durability and leak-free performance.

6.2 Cost-Effective:

Such a hdpe liner material product will lower maintenance and replacement costs as well as operational costs during its life cycle which is a source of great value for sizable industrial, civil, and agricultural projects.

6.3 Easy Installation:

Rolls of a light material, adjustment of the size to the work area, and residue-free welding of the joints enable rapid and efficient installation thus, in this way, the work is completed faster and the labor required is less whilst high seam integrity is maintained.

6.4 Global Standards Compliance:

This product is made according to ASTM, ISO, and other international standards of quality which in turn bring about trust worthy performance and safety in every application.

6.5 Environmental Safety:

Not only are the materials used in the fabrication of hdpe pond liner sheet non-toxic, but it is also UV-stabilized which makes it a perfect material for water storage, aquaculture, and environmentally sensitive projects.

6.6 Versatility:

It is possible to use the product in different sectors that range from mining and landfilling to irrigation, reservoir lining, slope protection, and civil engineering.

Thanks to those features, hdpe smooth geomembrane is a reliable and money-saving way in which any project involving the need for durable, flexible, and environmentally friendly geomembrane solutions can be solved.

7. HDPE Liner Q&A

Q1: What is HDPE liner used for?

A: Essentially, it is a tough geomembrane that is intended for the likes of ponds, reservoirs, landfills, mining pads, and civil engineering projects.

Q2: What thicknesses are available?

A: They range from 0.2 mm to 3.0 mm (8–120 mil) and thus, are suitable for light to heavy-duty work.

Q3: Can it be customized?

A: That is correct. You can personalize the size, thickness, color, surface type, and even logo.

Q4: Is it safe for water storage?

A: Indeed, HDPE liners are non-toxic, UV-stabilized, and environmentally friendly, just right for irrigation ponds and fish farms.

Q5: How long does it last?

A: Normally, it ranges from 20 to 30 years with the right installation and upkeep.

Summary

An HDPE Liner is a dependable, green, and budget-friendly geomembrane alternative. The blend of the properties such as strength, flexibility, chemical resistance, and long lifespan makes it the ultimate protector of water, soil, and environmental safety across various industrial sectors.

For top-notch quality and expert service, go for The Best Project Material Co., Ltd.(BPM Geosynthetics)HDPE Liner.