Plastic Dam Liners

Plastic dam liners are an modern answer aimed at enhancing the effectivity and lifespan of water sealing systems. These liners are made of long lasting substances such as HDPE, offering a dependable barrier to forestall leaks and shield the integrity of the dam structure. Plastic dam liners are tremendously appropriate for more than a few applications, such as irrigation, aquaculture, and rainwater management, contributing to fine water useful resource management.

-Leak proof: The impermeability of the plastic dam liners effectively prevents water loss and ensures the most beneficial water retention of the dam.

-Durability: These dam liners are made of sturdy materials that can face up to punctures, tears, and environmental stresses, providing long-lasting performance.

-Chemical resistance: Plastic dam liners can face up to publicity to a wide variety chemicals, making them excellent for amazing applications, consisting of these involving fertilizers or pollutants.

Plastic Dam Liners are high-performance geosynthetic sheets mainly engineered to grant dependable waterproofing, superb leak prevention, and strong soil containment throughout a extensive vary of civil engineering, water management, and environmental safety projects. Manufactured from top rate polymers such as HDPE, LDPE, or PVC, these plastic dam liner is designed to deliver long-lasting durability, exquisite flexibility, and ideal resistance to harsh environmental conditions, chemical exposure, and UV degradation. Their long lasting building ensures that they hold structural integrity even below heavy loads, moving soils, or fluctuating water levels.

These versatile liners are specially appropriate for dams, reservoirs, irrigation ponds, canals, and landfill containment, the place stopping seepage and defending surrounding soil and infrastructure is critical. In addition to their core waterproofing function, they additionally assist limit preservation costs, lengthen the lifespan of water-retention structures, and supply a not pricey choice to usual concrete or clay liners. With their mixture of strength, flexibility, and environmental resilience, Plastic Dam Liners characterize a dependable answer for engineers, contractors, and assignment managers looking for high-performance containment and long-term balance in disturbing applications.

1. Plastic Dam Liners Technical Features / Specifications

Specification | Details |

Material | HDPE, LDPE, PVC or customized polymer blends |

Thickness | Typically ranges from 0.2mm to 3mm, customizable based on project needs |

Tensile Strength | High tensile strength to resist tearing and stretching |

UV & Weather Resistance | Protects against sunlight degradation, temperature extremes, and aging |

Chemical Resistance | Resistant to acids, alkalis, salts, and other corrosive substances |

Puncture / Tear Resistance | Engineered to withstand sharp objects and ground irregularities |

Service Life | Designed for decades of reliable performance under normal conditions |

2. Plastic Dam Liners – Performance Benefits

2.1 Provides Effective Waterproofing and Containment

Plastic Dam Liners act as a enormously dependable barrier that prevents water leakage, seepage, and soil infiltration. By growing a continuous, impermeable layer, they shield reservoirs, ponds, dams, and canals from water loss and soil erosion. This ensures steady water retention and safeguards surrounding infrastructure from injury precipitated with the aid of seepage or saturation.

2.2 Long-Term Durability Ensures Minimal Maintenance

Manufactured from top rate polymers like HDPE, LDPE, or PVC, these dam lining material is resistant to UV radiation, chemical corrosion, organic degradation, and excessive temperatures. This sturdiness interprets to a long time of dependable performance, drastically lowering the frequency and value of repairs or replacements over the existence of the project.

2.3 Flexible Material Allows Easy Adaptation

The plastic dam liners is designed to be bendy and conformable, permitting them to adapt to uneven terrain, slopes, and complicated constructions except tearing or dropping effectiveness. This flexibility makes set up easier, reduces the chance of gaps or wrinkles, and ensures whole coverage, even in difficult task sites.

2.4 Offers Cost Savings Compared to Traditional Liners

Compared to ordinary concrete or clay liners, pond dam liner is furnish quicker and simpler installation, lowering labor and development time. Their light-weight diagram lowers transportation costs, and the material effectivity reduces uncooked fabric usage, making them a cost effective and sustainable choice for water administration and civil engineering projects.

3. Plastic Dam Liners – Quality Assurance & Standards

3.1 Manufactured underneath ISO, ASTM, or EN Standards

Dam on liner produced in strict accordance with global fantastic standards, inclusive of ISO, ASTM, and EN certifications. This ensures that each liner meets world engineering requirements, presenting purchasers with dependable and exceptional products appropriate for a extensive vary of civil, industrial, and environmental applications.

3.2 Rigorous Batch Testing

Each manufacturing batch undergoes complete testing, along with measurements for thickness, tensile strength, elongation, puncture resistance, and chemical durability. These checks confirm that the damliners irrigation systems hold regular overall performance and structural integrity, even beneath excessive environmental and operational conditions.

3.3 Long-Term Reliability and Compliance

Through strict manufacturing controls and fine assurance procedures, geomembrane liner provide long-term sturdiness and reliable performance. They are engineered to face up to UV degradation, chemical exposure, and bodily stress, making sure compliance with worldwide engineering and environmental safety requirements.

4. Plastic Dam Liners – Applications

4.1 Plastic Dam Liners for Dams and Reservoirs

Plastic Dam Liners furnish a durable, impermeable barrier that prevents water leakage and protects the surrounding soil from erosion. They assist hold the structural integrity of dams and reservoirs, making sure steady water storage and lowering renovation fees over the lifespan of the project.

4.2 Plastic Dam Liners for Ponds and Canals

These hdpe impermeable liner is best for irrigation ponds, fish ponds, and canals, supporting to keep water tiers successfully whilst minimizing seepage. By stopping water loss, they enhance water use effectivity and make a contribution to greater sustainable water administration practices.

4.3 Plastic Dam Liners for Landfills

HDPE dam liners act as a crucial containment barrier for landfills, stopping leachate from seeping into the soil and groundwater. Their chemical resistance ensures long-term safety in opposition to hazardous waste and environmental contamination, complying with regulatory necessities for waste management.

4.4 Plastic Dam Liners for Mining & Industrial Projects

In mining, chemical, or industrial applications, these polyethylene pond liners furnish tremendous containment for chemicals, tailings, and procedure water, whilst additionally controlling soil erosion in disturbed areas. Their chemical and UV resistance ensures dependable overall performance even underneath harsh environmental conditions.

4.5 Plastic Dam Liners for Agricultural Projects

HDPE geomembrane pond liner is extensively used in agriculture for irrigation ponds, water reservoirs, and drainage channels. They stop water loss, limit soil erosion, and assist hold steady water availability for crops, enhancing average farm productiveness and aid efficiency.

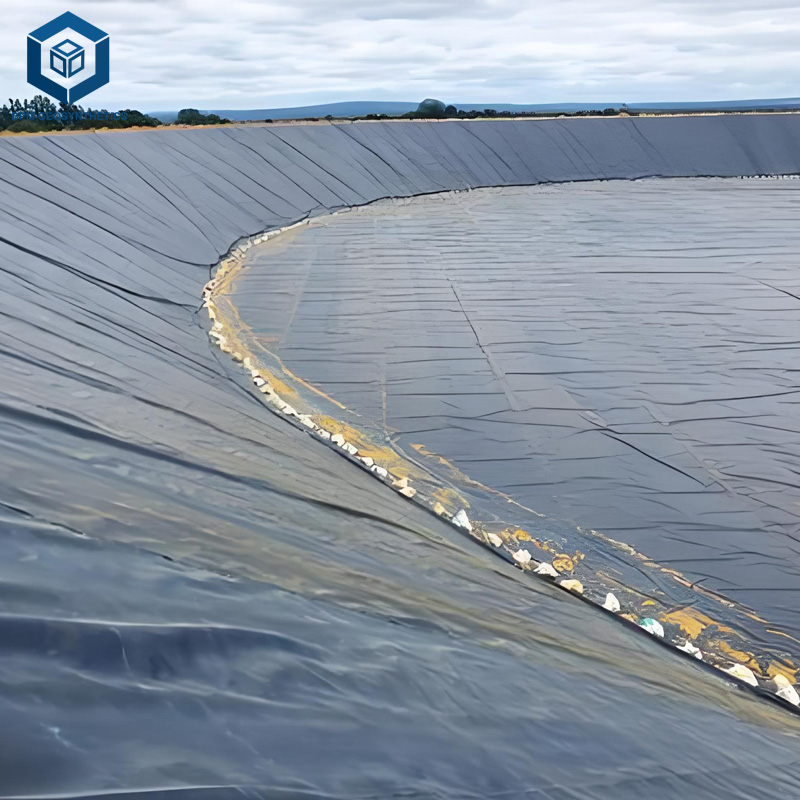

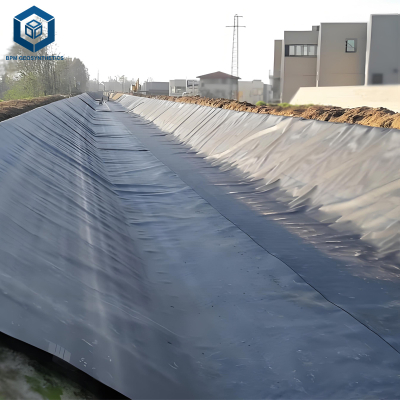

5. Plastic Dam Liners – Case Studies / Project References

5.1 Successful Applications Worldwide

HDPE liner pond have been effectively deployed in a huge range of initiatives globally, consisting of dams, reservoirs, irrigation ponds, canals, and landfill containment projects. These real-world functions exhibit the product’s versatility and reliability throughout special climates, terrains, and engineering requirements.

5.2 Proven Effectiveness

In all projects, the high density polyethylene liner have correctly avoided water seepage, soil erosion, and leachate leakage, appreciably improving the lifespan and structural integrity of dams, reservoirs, and different water-retention or containment structures. Their regular overall performance beneath traumatic prerequisites validates their suitability for each civil and industrial engineering projects.

5.3 Visual Documentation and Client Feedback

Many tasks encompass specified visible documentation, photographs, and overall performance reviews that exhibit set up strategies and last results. Additionally, nice purchaser remarks highlights the durability, ease of installation, and long-term reliability of BPM Plastic Dam Liners, reinforcing their popularity as a relied on geosynthetic answer worldwide.

6. Plastic Dam Liners – Installation Method / Guidance

6.1 Laid Flat and Overlapping at Seams

High density polyethylene geomembrane need to be laid flat on the organized surface, making sure full contact with the ground. Seams need to overlap correctly to create a continuous, impermeable barrier, stopping water leakage and retaining structural integrity throughout the complete lined area.

6.2 Welding, Adhesive Bonding, or Mechanical Fastening

Seams and joints can be sealed the use of thermal welding, adhesive bonding, or mechanical fastening, relying on challenge necessities and liner material. Proper joint sealing ensures long-term waterproofing overall performance and prevents seepage at integral points.

6.3 Minimal Equipment Required for Fast Deployment

The hdpe geo membrane is provided in light-weight rolls, which approves for convenient transport, handling, and positioning. Minimal heavy gear is required, which reduces set up time, labor costs, and typical mission complexity, making them best for each large-scale civil initiatives and smaller installations.

6.4 Follow Site-Specific Guidelines

During installation, it is essential to observe site-specific recommendations to keep away from wrinkles, folds, or punctures. Proper handling, trimming, and alignment make sure that the liner keeps its full overall performance competencies and affords a durable, long-lasting answer for water retention and containment projects.

7. Plastic Dam Liners – Packaging & Delivery

7.1 Roll Dimensions

Plastic Dam Liners are provided in popular roll widths ranging from 2m to 6m and roll lengths from 50m to 100m. Custom sizes are additionally accessible to meet particular venture requirements, permitting purchasers to pick dimensions that decrease seams and optimize set up efficiency.

7.2 Packaging

Each roll is cautiously wrapped in shielding PE movie and similarly bolstered with water resistant woven bags. This double-layer packaging ensures the liners are blanketed from moisture, dust, scratches, and different bodily harm throughout storage and transportation.

7.3 Container Loading

Rolls are strategically organized and loaded into 20ft or 40ft containers to maximize house utilization and limit delivery costs. BPM’s optimized loading techniques make certain that the rolls continue to be impervious and secure at some point of transit, minimizing the hazard of deformation or damage.

7.4 Transportation Protection

During shipment, rolls are secured with belts, area protectors, and padding to stop shifting, punctures, or floor damage. Additional shielding measures can be furnished primarily based on task size, destination, and transport conditions, making sure the product arrives in ideal condition.

7.5 Delivery Time & Logistics

Standard transport is generally 7–14 days after order confirmation, relying on order volume. BPM provides bendy logistics options, which includes sea freight, air freight, and land transport, to accommodate world purchasers and venture schedules.

8. FAQ for Plastic Dam Liners

Q1: What is a plastic dam liners?

A: In general, plastic dam liner is a waterproof, durable sheet that is made from some kind of synthetic material like HDPE (high-density polyethylene) or PVC (polyvinyl chloride), and is used not only for cleaning up the leakage of water but also for protecting the structure of the dams.

Q2: What are the main benefits of using a plastic dam liner?

A: The features main to plastic dam liners are that they stop leakages of water, water flowing can be controlled, protective layers against erosion, prolonging the lifetime of a dam, saving on maintenance budgets.

Q3: Can plastic dam liners withstand extreme weather conditions?

A: Plastic liners, if they're of good quality, can hold the sun exposure well, can also resist chemical agents, and be pretty good performers both in warm and in cold thermometers.

Q4: How long does a plastic dam liner typically last?

A: Depending on the type of the material and presence of some environmental factors, a plastic dam liner might last anywhere from 20 to 50 years. Besides, its lifespan largely depends on whether it has been installed and maintained properly.

Q5: Is custom sizing available for plastic dam liners?

A: Not only can plastic dam liners be cut to the shape of the garments, but also in different dimensions of thickness, width, and length for meeting the specific demands of your project.

Summary / Recommendation

The Best Project Material Co., Ltd.(BPM Geosynthetics) Plastic Dam Liners supply dependable waterproofing, long-term durability, and bendy set up for a extensive vary of civil, industrial, and agricultural projects. With expert technical support, pleasant assurance, and customizable options, we signify a cost effective and sustainable answer for any task requiring high-performance containment.