Dam Liners

Dam liners provide essential protection against water seepage, preserving the integrity of dams and surrounding ecosystems. Available in HDPE, PVC, and geosynthetic clay options, they offer long-lasting durability and resistance to chemicals, UV rays, and extreme weather conditions. Installation is precise, with stringent standards such as ASTM D6988 ensuring performance reliability. Regular inspection and maintenance can extend the lifespan of the liners, providing a cost-effective solution to water containment and environmental protection. With a lifespan of up to 30 years, dam liners are an essential investment for safe and sustainable water management projects.

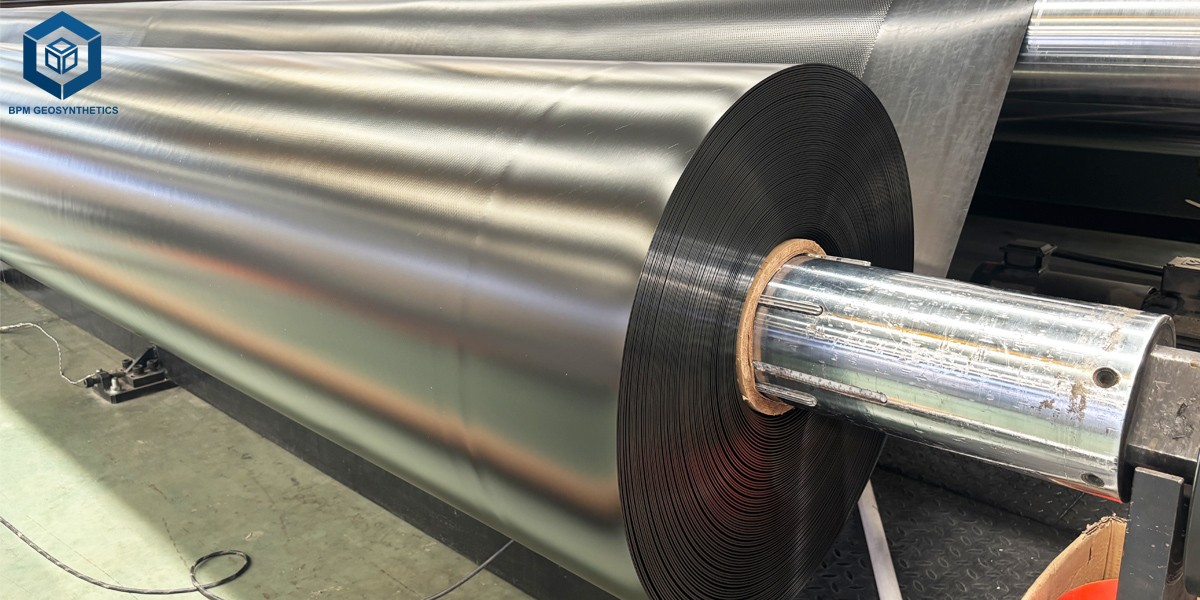

BPM Geosynthetics affords high-performance dam liners engineered from top-grade geomembrane materials, in precise designed to provide tremendous water containment, most excellent seepage control, and long-term environmental protection. These dam liners are best for use in large-scale infrastructure duties such as irrigation reservoirs, hydropower dams, mining tailings ponds, and municipal water storage systems, the region durability, impermeability, and chemical resistance are fundamental to project success. With confirmed usual overall performance in harsh environmental conditions, BPM dam liners supply a reliable and low priced reply for sustainable water management.

Dam liners are impermeable sheets used to stop water loss and shield embankments in dam structures, irrigation reservoirs, farm ponds, tailings dams, and stormwater basins. These dam liners serve as a essential barrier between water and the surrounding soil or rock, making certain structural stability and long-term sustainability.

Dam liners are crucial components in modern dam construction and maintenance, designed to prevent water seepage, protect the structural integrity of dams, and ensure the safety of surrounding environments. These liners, typically made from durable geomembrane materials, are widely used in the construction of reservoirs, water containment systems, and flood control infrastructure. This article explores the types, engineering principles, materials, and installation of dam liners, providing insight into their effectiveness and importance in dam engineering.

What Are Dam Liners?

A dam liner is a protective membrane placed in the base and sides of a dam to prevent water leakage, stabilize the structure, and maintain the integrity of the water containment system. These liners are used in a variety of dam-related applications, from hydroelectric dams to irrigation reservoirs, providing long-lasting waterproof barriers.

Types of Dam Liners:

Geomembrane Liners:

Made from high-density polyethylene (HDPE), polyvinyl chloride (PVC), or ethylene propylene diene monomer (EPDM), these liners are widely used for their impermeability and durability.Geosynthetic Clay Liners (GCLs):

These liners consist of a layer of bentonite clay between two geotextile fabrics, offering excellent sealing properties and cost-effectiveness.PVC Liners:

Lightweight and flexible, PVC liners are used in areas with lower pressure, ideal for small to medium-sized dams.

Engineering Principles Behind Dam Liners

Waterproofing:

The primary purpose of a dam liner is to prevent water from seeping through the dam structure, which can lead to erosion and weakening. Liners are engineered to create a seamless barrier that can withstand varying levels of hydrostatic pressure.Durability:

Dam liners are designed to resist degradation from chemicals, UV radiation, and extreme temperatures. For example, HDPE liners are resistant to UV rays and have excellent chemical resistance, making them suitable for both water and waste containment.Flexibility and Strength:

A good dam liner should maintain its flexibility even in extreme conditions, allowing it to conform to the shape of the dam without tearing. Geomembrane liners provide tensile strength that helps prevent punctures and tears.

Standards and Regulations

Dam liners must adhere to international standards to ensure that they provide the required durability and safety:

ASTM D6988: Standard specification for geomembranes used in water containment, outlining physical properties and testing methods.

ISO 9001: Quality management standards for manufacturers producing geomembrane and geosynthetic materials.

GCL Standardization: ASTM D5887 specifies the minimum requirements for geosynthetic clay liners in dam applications.

Environmental Regulations: Compliance with EPA and local environmental regulations for water containment and runoff management is required.

Installation Guidelines

Surface Preparation:

The substrate where the liner will be installed must be clean, smooth, and free of sharp objects to avoid puncturing the liner.Seam Welding:

For geomembrane liners, seams must be welded together using specialized equipment to ensure that the liner is impermeable. Welding quality is critical to prevent water seepage.Protection Layer:

A protective layer, such as geotextile fabric, is often placed on top of the liner to shield it from punctures, abrasion, and environmental damage during installation.Quality Assurance:

Continuous inspection and testing are necessary to ensure that the liner's integrity is maintained throughout installation. Methods such as electrical leak location (ELL) are used to detect faults.

Common Applications of Dam Liners

Hydroelectric Dams:

Used to prevent leakage in reservoirs that store water for energy generation.Irrigation Dams:

Water containment for agricultural irrigation systems, where water conservation is critical.Flood Control Dams:

Protecting areas from flooding, these dams are often lined to prevent seepage into nearby environments.Mining and Wastewater Containment:

Liners are used to prevent contaminated water from leaking into the environment in mining operations and wastewater containment facilities.

Maintenance and Monitoring

Inspection:

Regular visual inspections should be conducted, especially after severe weather conditions. Any signs of damage, such as punctures or wrinkles, should be promptly addressed.Leak Detection:

Electronic Leak Detection (ELD) methods can be used to detect hidden leaks in the liner. It's crucial to perform routine checks to prevent water loss and ensure the dam's integrity.Repairs:

Small punctures and damages can often be repaired using patch kits designed for specific liner materials. For larger issues, sections of the liner may need to be replaced.

Frequently Asked Questions (FAQ)

Q1: What materials are used for dam liners?

The most common materials are HDPE, PVC, and EPDM geomembranes, as well as geosynthetic clay liners (GCLs).

Q2: How long do dam liners last?

With proper installation and maintenance, HDPE liners can last up to 30 years or more.

Q3: Can dam liners be repaired?

Yes, small punctures or damages can be repaired using specialized patching materials, although large-scale damage may require replacing sections of the liner.

Q4: Are dam liners environmentally friendly?

Yes, modern dam liners are designed to prevent water contamination and can be made from recyclable materials, making them eco-friendly.

Call to Action

If you are planning a dam construction or maintenance project, we can provide expert consultation, quality dam liners, and professional installation services. Contact us today to discuss the best liner solutions for your needs and ensure your project meets all environmental and safety standards.