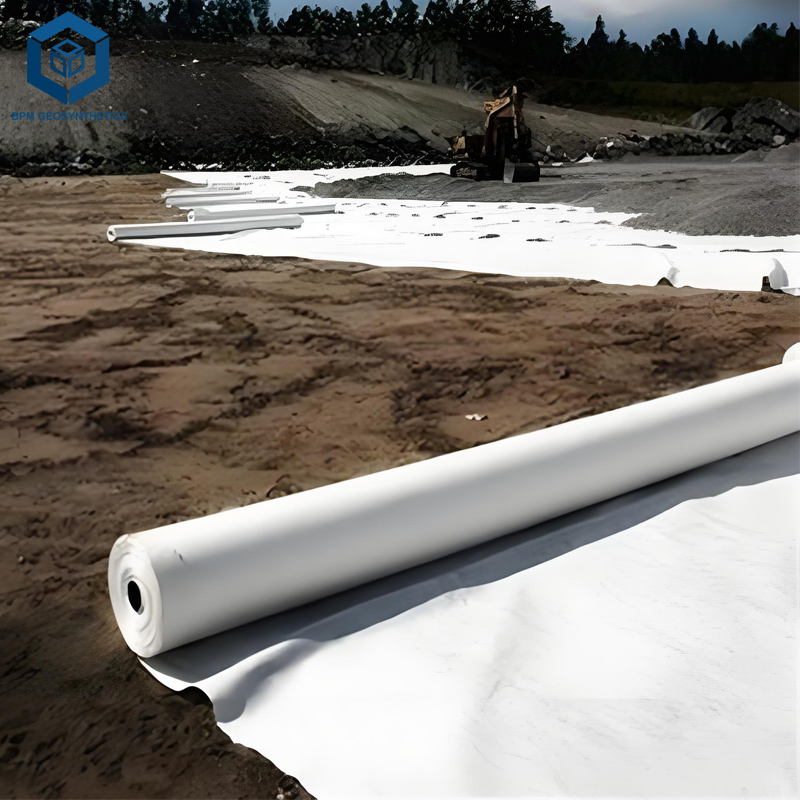

Staple Fiber Geotextile

Staple fiber geotextile is a non-woven fabric made of artificial fibers, designed specially for fluctuations in civil engineering and environmental applications. These staple fiber geotextiles furnish awesome filtering, separation, and stabilization capabilities, making them an best desire for avenue construction, erosion control, and drainage systems.

-Excellent filtration: efficaciously approves water glide whilst defending soil particles and stopping erosion.

-Multi useful application: appropriate for road, embankment, and panorama beautification projects.

-Lightweight and flexible: handy to preserve and install, lowering labor costs.

-Durable materials: resistant to ultraviolet radiation and chemicals, with a sure provider life.

Staple fiber geotextile is an revolutionary non-woven material made of artificial fibers, especially designed to meet a number wishes in civil engineering and environmental applications. These staple fiber geotextiles operate excellently in imparting simple features such as filtration, separation, and stability, making them an perfect preference for street construction, erosion control, drainage systems, and landscaping projects. They are light-weight and flexible, convenient to take care of and install, radically lowering labor prices and set up time.

Staple fiber geotextile can stand up to harsh environmental conditions, is durable, resistant to ultraviolet (UV) radiation and more than a few chemicals, making sure long-lasting performance. The special shape of these staple fiber geotextiles can successfully drain water whilst keeping soil particles, stopping erosion, and advertising soil stability. By supplying customizable options, Staple fiber geotextiles grant an cost effective and environment friendly answer that can prolong the lifespan and overall performance of building initiatives whilst contributing to sustainable engineering practices.

Parameter

ltem | Unit | BTS10 | BTS15 | BTS20 | BTS25 | BTS30 | BTS35 | BTS40 | BTS45 | BTS50 | BTS60 | BTS80 |

Mechanical Properties (MD=Machine Direction Strength/CD=Cross Machine Direction Strength) | ||||||||||||

Weight | g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 |

Weight Variation | % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

Thickness | mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3 | 3.3 | 3.6 | 4.1 | 5 |

Width Variation | % | -0.5 | ||||||||||

Break Strength (MD and XMD) | KN/m | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 12.5 | 14 | 16 | 19 | 25 |

Break Elongation | % | 25-200 | ||||||||||

CBR Burst Strength ≥ | kn | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4 |

Tear Strength(MD and XMD)≥ | Kn | 0.08 | 0.12 | 0.16 | 0.2 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 |

Hydraulic Properties | ||||||||||||

Sieve Size 090 | mm | 0.07-0.02 | ||||||||||

Permeability Coefficient | cm/s | (1.0-9.9)x(10-1~10-3) | ||||||||||

Staple Fiber Geotextile Features

-Excellent filtration capability: Staple fiber geotextiles successfully permit water to pass through whilst preserving exceptional soil particles, stopping erosion and sedimentation in drainage applications.

-Multi practical applications: These staple fiber geotextiles are appropriate for a range of purposes, consisting of street construction, embankment stability, erosion control, and panorama beautification, making them distinctly adaptable to distinct task needs.

-Lightweight and bendy design: The light-weight houses of staple fiber geotextiles make them effortless to transport and handle, facilitating quicker set up and lowering labor costs.

-High durability: These staple fiber geotextiles are made of artificial fibers that can face up to UV radiation, chemicals, and biodegradation, making sure long-term overall performance in harsh environments.

-Enhanced Strength: The material structure gives first-rate tensile energy and tear resistance, enabling staple fiber geotextiles to face up to mechanical stress at some point of set up and use.

-Customizable options: Staple fiber geotextiles are accessible in quite a number thicknesses and fabric compositions, which can be custom-made to meet precise mission necessities and overall performance standards.

-Economically environment friendly solution: By lowering the want for extra soil and maintenance, these staple fiber geotextiles furnish an inexpensive alternative for enhancing the lifespan and effectiveness of development projects.

-Environmental Protection: Staple fiber geotextiles are made from recyclable materials, which make a contribution to sustainable practices in building and land management.

Applications of Staple Fiber Geotextile

-Road construction: Staple fiber geotextiles are broadly used in street building to grant separation between roadbed soil and combination layers, beautify stability, and stop mixing from weakening road structures.

-Erosion control: These staple fiber geotextiles successfully manipulate soil erosion on slopes, riverbanks, and building web sites via imparting a protecting layer that approves for drainage whilst preserving the soil.

-Drainage systems: They are used for drainage purposes to promote water float whilst stopping sediment from clogging pipes and drainage channels, making sure environment friendly water aid management.

-Embankment stability: In embankment engineering, Staple fiber geotextiles assist to strengthen soil, enhance bearing capacity, and minimize the threat of harm induced by means of motion or settlement.

-Landfill liners: These staple fiber geotextiles act as limitations in landfill applications, stopping the migration of pollution whilst permitting for enough drainage and filtration of leachate.

-Landscape beautification: Staple fiber geotextiles are used in panorama beautification initiatives to separate soil layers, manipulate weeds, grant steadiness for plant growth, and decorate the average aesthetics and performance of out of doors spaces.

-Agricultural applications: They are utilized in agricultural environments to enhance soil management, beautify drainage, decrease discipline erosion, and promote more healthy crop production.

-Retaining structures: These staple fiber geotextiles can be used in keeping wall structures to decorate drainage and grant extra support, assisting to stop soil accumulation and make certain long-term stability.

Company Profile

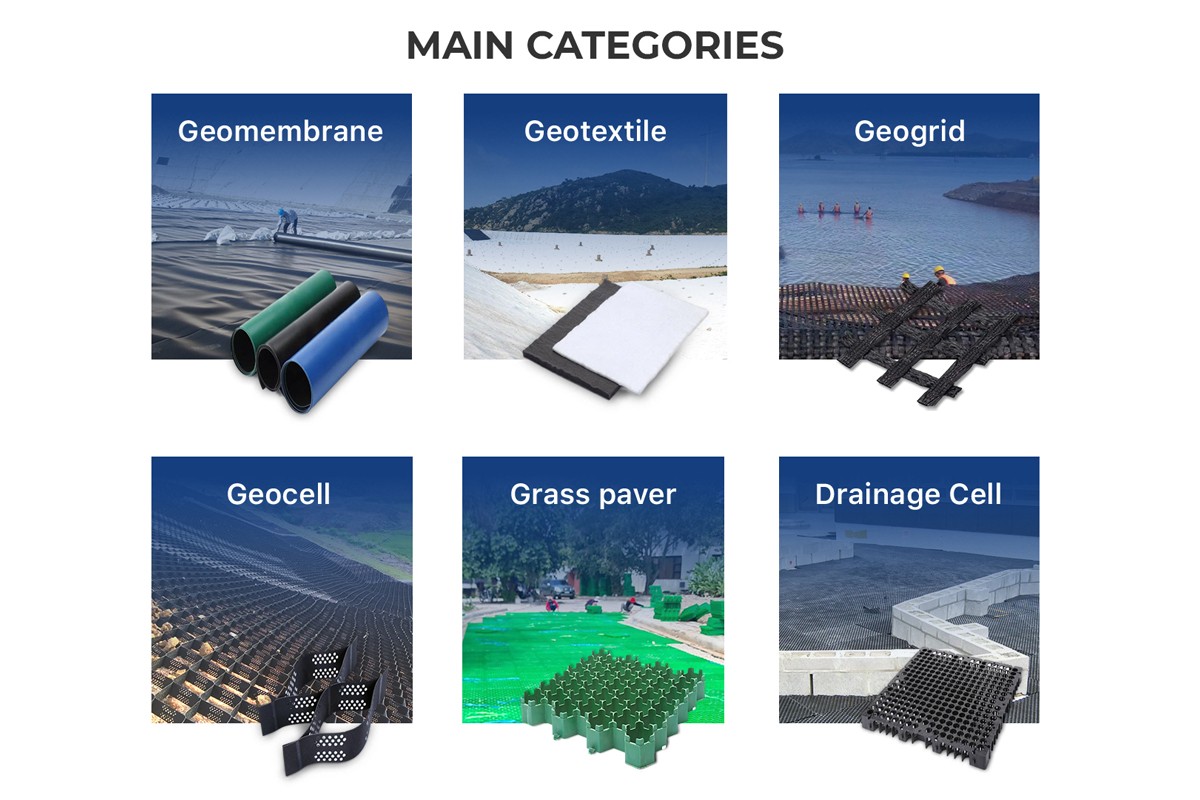

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, geogrids, geocells, and geosynthetic clay liners (GCL). Our products, certified by EU CE and GLP, have passed ISO 9001, ISO 14001, and OHSAS 18001 standards, and are recognized for their quality, performance, and durability.

BPM GEOSYNTHETICS has been committed to providing one-stop services for global customers in the research and development, production, sales, and export of geosynthetic materials since its establishment in 2007. The company has 120 senior technical talents specializing in geotechnical materials. The manufacturing factory covers an area of over 36000 square meters and is equipped with industry-leading automated production equipment and professional testing instruments. Product innovation, quality assurance, and customer satisfaction have always been BPM commitment to partners.

We're committed to innovation and quality, offering flexible cooperation and the best solutions for engineering projects worldwide. Our products are utilized in various sectors like aquaculture, erosion control, drainage systems, municipal engineering, mining, and landscaping. We look forward to partnering with you to solve complex challenges with our high-performance geosynthetic products.