Drainage Composite

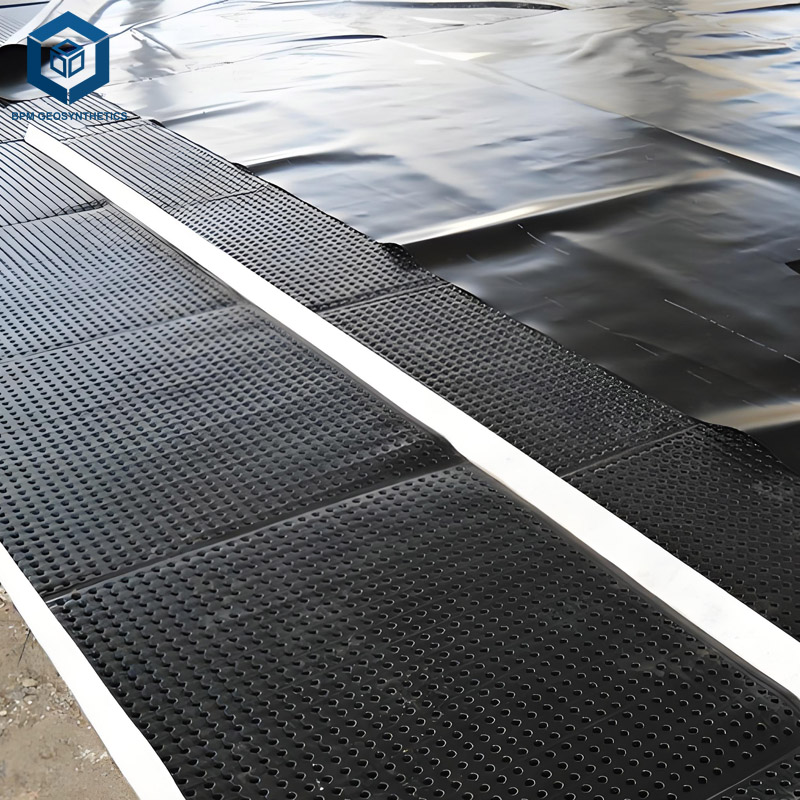

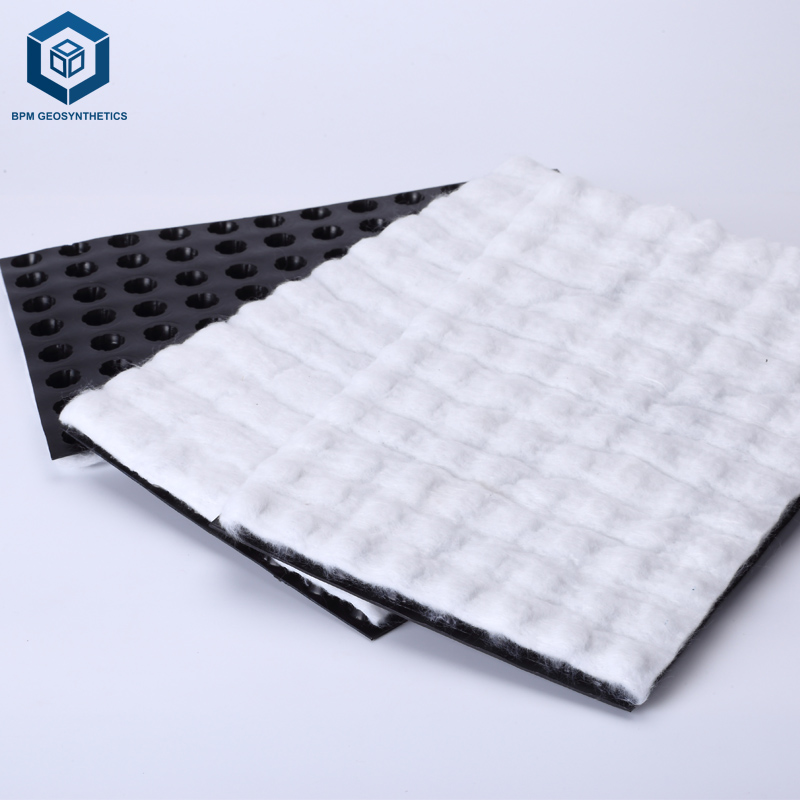

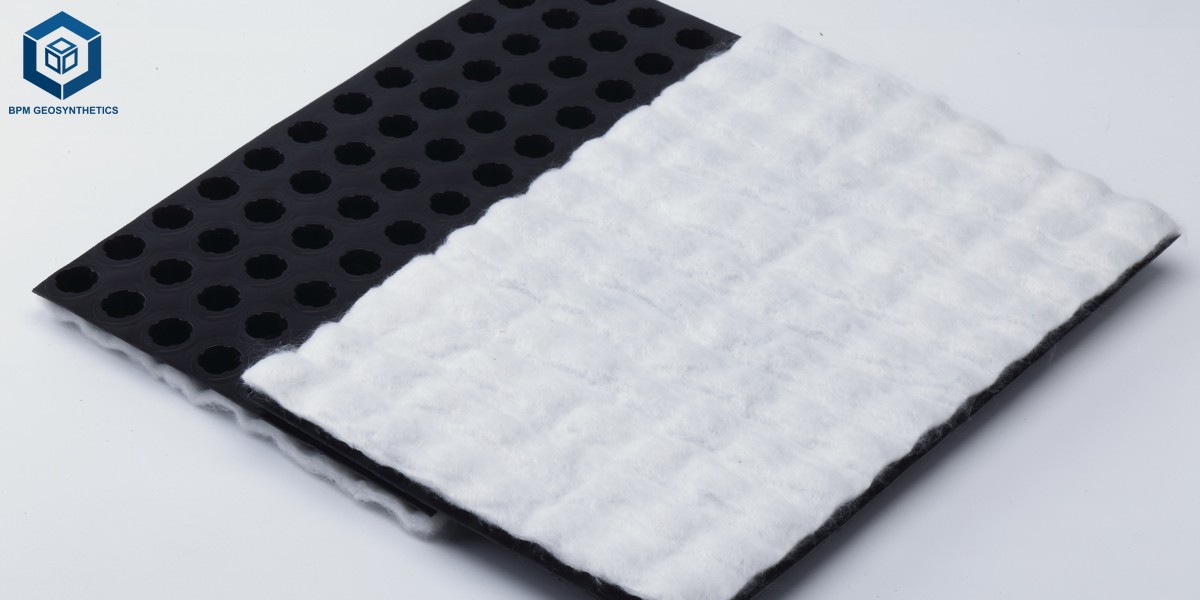

BPM Drainage Composite is a multi-layer geosynthetic cloth engineered to furnish most effective drainage, filtration, and safety in one built-in system. It generally consists of a dimpled HDPE core bonded with nonwoven geotextile material on one or each sides. This aggregate ensures excessive drift capability whilst stopping soil intrusion and defending waterproofing systems.

- Excellent Drainage Capacity: The dimpled core helps fast water flow, efficiently channeling groundwater and extra moisture.

- Integrated Filtration: Nonwoven geotextile prevents clogging through filtering out soil particles.

- Waterproofing Protection: Acts as a shielding barrier for membranes, decreasing injury all through backfill.

- High Compressive Strength: Maintains overall performance beneath soil and structural loads.

- Lightweight & Easy Installation: Reduces labor time and charges on site.

- Versatile Application: Ideal for basements, preserving walls, tunnels, plaza decks, and inexperienced roofs.

1. BPM Geosynthetic Drainage Composite

A Drainage Composite is a multi-layer geosynthetic material designed to manage water drainage and protect structures from hydrostatic pressure. It is commonly used in civil engineering, landscape, and construction applications where water drainage and soil retention are critical.

2. Select the Right Drainage Composite

Choosing the appropriate drainage composite is critical for ensuring the long-term performance and protection of your project. Each application has unique demands based on environmental, structural, and hydrological conditions. Below are the key factors to evaluate:

2.1 Site Conditions

The physical and environmental conditions of the site greatly influence the type of drainage composite required.

- Soil Type: Clay-rich soils retain more water and require a composite with higher flow capacity. Sandy soils may require better filtration performance to prevent clogging.

- Groundwater Level: In areas with a high water table, a thicker core or multi-directional flow design may be needed to manage large volumes of water.

- Load-Bearing Requirements: For sites with heavy loading (e.g., under roadways or embankments), the drainage core must have high compressive strength to resist deformation under pressure.

2.2 Application Type

The orientation and purpose of the installation define the structure and shape of the drainage material.

- Vertical Applications: For walls, basements, or tunnels, a composite with a cuspated or dimpled core helps channel water downward efficiently. Vertical uses often require good adhesion to waterproofing membranes.

- Horizontal Applications: On green roofs, decks, or roads, composites must have flat or geonet-style cores that allow for uniform water dispersal and lateral drainage.

2.3 Drainage Needs

Proper evaluation of the expected water volume and flow characteristics ensures performance over time.

- Flow Rate: Depending on rainfall, hydrostatic pressure, or irrigation load, the drainage core must accommodate adequate water flow without backup or overflow.

- Core Thickness: Thicker cores (e.g., 10–20 mm) are more suitable for high-flow environments, while thinner versions may suffice in light-duty or low-flow applications.

2.4 Compatibility

The drainage composite must integrate seamlessly with other construction materials.

- Waterproofing Systems: Ensure the composite does not compromise waterproof membranes and ideally provides added protection through cushioning.

- Soil Retention Layers: In green infrastructure or landscaping, compatibility with root barriers, planting media, or geogrids is essential to maintain system stability.

- Construction Details: Joints, terminations, and overlaps should be considered to avoid leaks or material separation over time.

3. Uses of Drainage Composite

Drainage composites are versatile geosynthetic materials used in a variety of civil, commercial, and environmental engineering projects. Their ability to manage water and relieve hydrostatic pressure makes them ideal for both vertical and horizontal installations across many industries.

3.1 Retaining Walls

- Drainage composites are installed vertically behind retaining walls to prevent the buildup of water pressure in the soil, which can cause structural failure or wall movement.

- By channeling water away from the backfill, they reduce soil saturation, preventing erosion and frost damage.

- Compared to traditional gravel backfill systems, they offer a thinner profile, saving space and reducing excavation volume.

3.2 Basement and Foundation Waterproofing

- In building foundations and basements, drainage composites are placed against exterior walls to create a continuous drainage plane.

- They collect water from the surrounding soil and guide it down to a footing drain or sump pump system, protecting the structure from leaks and moisture intrusion.

- These systems also shield the waterproofing membrane from backfill damage, acting as a protective cushion.

3.3 Green Roofs and Planter Boxes

- Drainage composites are essential in green infrastructure, where managing excess water is crucial for plant health and structural protection.

- They allow water to drain efficiently through the root zone, preventing waterlogging while retaining enough moisture for vegetation.

- In planter boxes, they help maintain soil stability and prevent drainage issues, especially in rooftop gardens or urban landscaping projects.

3.4 Tunnels and Subways

- Underground structures such as tunnels, subways, and culverts face constant exposure to groundwater infiltration.

- Drainage composites are applied around the exterior lining to collect and redirect water away from the structure, reducing the risk of seepage, corrosion, or structural compromise.

- Their flexibility and adaptability to curved surfaces make them ideal for tight, enclosed, or irregularly shaped environments.

3.5 Bridge Abutments and Roadways

- Below roads and bridge abutments, water accumulation can cause subgrade weakening, freeze-thaw damage, or pavement heaving.

- Drainage composites prevent these issues by providing a consistent drainage layer beneath or alongside the structure.

- In transportation projects, their quick installation and long service life make them a cost-effective alternative to traditional stone drainage layers.

4. Drainage Composite Features

Drainage composites operate as an integrated, multi-layer system designed to manage water flow while protecting surrounding structures. Their function is based on three key roles:

4.1 Filtration

The outer geotextile layer acts as a filter that allows water to pass through while blocking soil particles and other debris.This prevents clogging of the drainage core and ensures long-term water flow efficiency.The geotextile also stabilizes the surrounding soil and maintains the integrity of the backfill.

4.2 Drainage

The internal core—typically made of HDPE and formed into a dimpled, netted, or cuspated structure—creates continuous channels for water to move.Water is directed either vertically (in walls and basements) or horizontally (in roofs, roadbeds, or green areas) toward an outlet or collection system.This layer is responsible for relieving hydrostatic pressure and minimizing water accumulation.

4.3 Protection

In many applications, drainage composites are installed adjacent to waterproofing membranes or structural walls.The system cushions and protects these surfaces from physical damage during backfill or soil settlement.It also acts as a secondary barrier, reducing the risk of water intrusion into the building or structure.

5. Technical Specifications of Drainage Composite

While exact specifications can vary depending on the product type and intended use, most drainage composites share a standard range of key technical characteristics. These specifications are critical in evaluating performance under different environmental and structural conditions.

Core Thickness: 5–20 mm

Flow Rate: 3–20 gallons/min/ft² depending on pressure

Compressive Strength: Up to 40,000 psf

Geotextile Type: Non-woven polypropylene or polyester

Temperature Resistance: -40°C to +80°C

6. Drainage Composite FAQ

Q1: What are the main functions of a drainage composite?

Among its core functions are drainage, filtration, separation, and protection. Drainage composites essentially collect and transport water or gas. Subsequently, they lower hydrostatic pressure and a role they play is also to ensure the long-term stability of the structures.

Q2: What are the advantages of drainage composite compared with traditional gravel drainage?

Firstly, drainage composites when compared to gravel drainage layers weigh less; secondly, they are very easy to install; thirdly, less excavation work is required; fourthly, construction time is shortened and, lastly, they ensure consistent drainage performance. What’s more, they are instrumental in bringing down transportation and labor costs.

Q3: What types of drainage composite are available?

Drainage composites come in different forms, such as single-sided, double-sided, and multi-layer structures. Geotextiles and core thicknesses may be changed to suit the requirements of a particular project.

Q4: How does a drainage composite prevent clogging?

A drainage composite by the use of a geotextile is able to filter thereby the passage of water and at the same time blocking soil particles. The filtration role of the device is essential in clogging prevention and, consequently, drainage efficiency is maintained.

Q5: Is drainage composite suitable for vertical and horizontal drainage?

Certainly, drainage composites work for both vertical and horizontal drainage installations such as wall drainage, foundation drainage, slope drainage, and roof drainage systems.

Q6: What factors should be considered when selecting a drainage composite?

Among the major considerations are the drainage capacity, compressive strength, geotextile filtration performance, chemical resistance, project load conditions, and the installation environment.

Q7: Is drainage composite resistant to chemicals and environmental conditions?

Generally, drainage composites' base materials are polymers like HDPE or PP, thus they feature great resistance to chemicals, corrosion, and biological degradation, and this is why they are a good choice for long-term application in a rugged environment.

Q8: Can drainage composite be customized for specific projects?

Certainly, drainage composites can be altered as per the core thickness, geotextile type, roll size, and performance specs to fit the particular needs of different engineering projects.

About BPM GEOSYNTHETICS

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, and geogrids. Established in 2007, the company is committed to providing one-stop services in research, production, and sales, with a focus on innovation and quality. BPM's products, certified by EU CE and GLP, meet ISO 9001, ISO 14001, and OHSAS 18001 standards, ensuring performance and durability. With a manufacturing facility of over 36,000 square meters and a team of 120 technical experts, BPM serves various sectors such as aquaculture, erosion control, drainage, and municipal engineering. We look forward to partnering with you to tackle complex challenges using our high-performance geosynthetic solutions.