Guide to HDPE Geomembrane 1.5 mm and Its Applications

With the continuous improvement of people's living standards, various new materials have emerged. HDPE Geomembrane 1.5 mm, as a new type of building material, is receiving increasing application and attention. This article will explain in detail what HDPE Geomembrane 1.5 mm is, as well as its characteristics and advantages, from the following aspects.

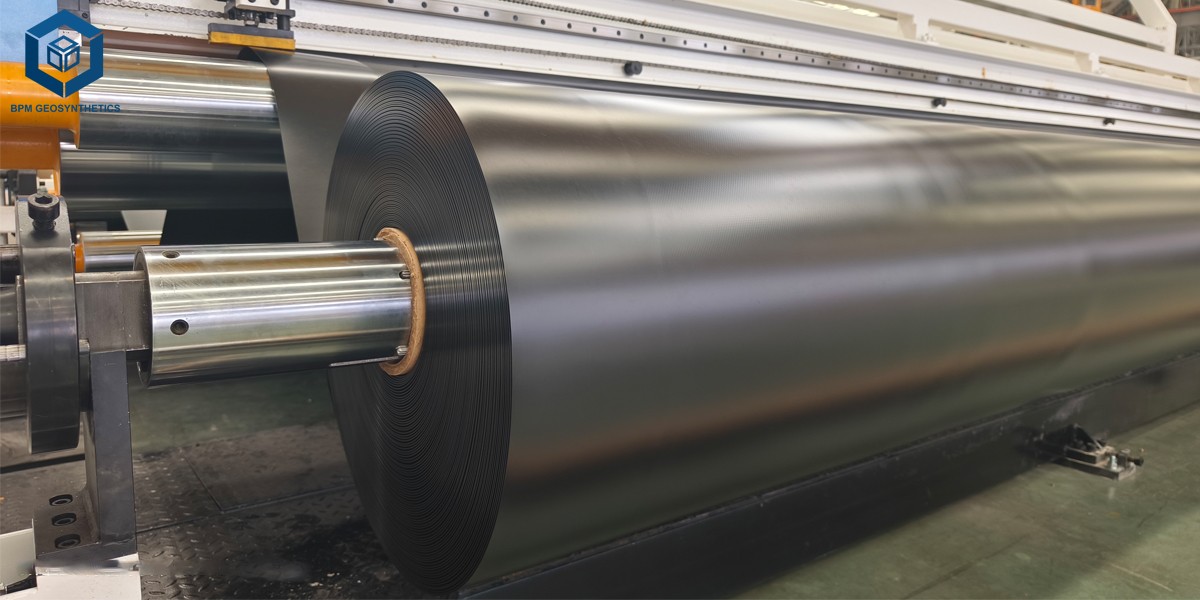

1. What Is HDPE Geomembrane 1.5 mm ?

HDPE Geomembrane 1.5 mm is a thin film material made of polymer materials, usually divided into two types: polyvinyl chloride (PVC) and polyethylene (PE). 60 mil HDPE liner has the characteristics of high strength, high corrosion resistance, high aging resistance, and leak-proofness, and is widely used in various construction projects.

Specifications of HDPE Geomembrane 1.5 mm

- Material Type

High-density polyethylene (HDPE)

Low-density polyethylene (LDPE)

Polyvinyl chloride (PVC)

- Thickness

0.2mm to 3.0mm

- Width

Common widths: 1m-8m, custom lengths available for special projects

- Length

Common lengths: 50m, 100m, 200m, custom lengths available upon request

- Color

Common colors: black, green, blue;Color selection may affect UV stability and temperature

2. What are Advantages of HDPE Geomembrane 1.5 mm? Why Use HDPE Geomembrane 1.5 mm?

2.1 High Strength

60 Mil geomembrane liner possesses high tensile and tear strength, capable of withstanding various external forces without easily deforming or being damaged.

Its robust structure makes it suitable for heavy-load environments such as landfills, mining sites, and reservoirs.Even under long-term pressure or uneven settlement, it maintains outstanding mechanical stability.

2.2 High Corrosion Resistance

Geomembrana 60 mils exhibits high corrosion resistance to various chemicals, effectively resisting the erosion of acids, alkalis, salts, and other chemicals.

This makes it ideal for industrial wastewater ponds, chemical containment areas, and hazardous waste facilities. Its strong chemical resistance ensures long-term performance even in harsh and highly reactive environments.

2.3 High Aging Resistance

Through special treatment, 1.5 mm hdpe geomembrane sheet effectively delays aging and extends its service life, maintaining its physical properties for a long period.

UV inhibitors and antioxidants help the liner resist ultraviolet radiation and environmental weathering.It can operate stably for decades under outdoor conditions without significant degradation.

2.4 Leak-proof

1.5 mm hdpe membrane has excellent leak-proof properties, effectively preventing liquid penetration and leakage, ensuring the quality and safety of construction projects.

Its low permeability design makes it a top choice for environmental protection and groundwater isolation.When properly welded and installed, the liner forms a continuous waterproof barrier with exceptional sealing performance.

2.5 Easy Construction

60 Mil HDPE geomembrane liner is simple and convenient to construct, easy to operate, and can significantly shorten the construction cycle and improve construction efficiency.

It is compatible with various welding methods, allowing for fast and reliable seam bonding.Additionally, its flexible yet durable structure reduces installation difficulty, even on irregular terrain.

3. What are Applications of HDPE Geomembrane 1.5 mm ?

3.1 Water Conservancy Projects

In water conservancy projects, 60 Mil pond lining geomembrane is widely used in reservoirs, dams, and river management projects, effectively improving the seepage prevention performance and service life of these structures.

Its strong impermeability helps maintain stable water levels and reduces water loss caused by soil infiltration.Additionally, the liner protects the foundation from erosion, ensuring long-term structural safety in harsh hydrological environments.

3.2 Environmental Protection Projects

In environmental protection projects, 1.5 mm sheet geomembrane is widely used in sewage treatment and landfill projects, effectively preventing pollution and leakage.

Its chemical-resistant properties create a reliable barrier that blocks contaminants from entering soil and groundwater.This makes it essential for modern waste management systems aiming to meet strict environmental protection standards.

3.3 Building Construction Projects

In building construction projects, 1.5mm HDPE Geomembrane is widely used in roofs, basements, parking lots, and other areas requiring waterproofing and moisture protection, improving the waterproofing performance and service life of buildings.

The geo membrane helps prevent moisture penetration, mold growth, and concrete deterioration in long-term operation.Its flexibility and durability make it suitable for complex architectural designs and varied construction conditions.

3.4 Other Applications

1500 micron geomembrane can also be widely used in the petroleum, chemical, and mining industries, providing seepage prevention and corrosion protection.

It acts as a stable containment barrier for tailings ponds, chemical storage areas, and fuel depots.Its high mechanical strength and chemical resistance ensure reliable performance even in highly aggressive industrial environments.

4. How Long is Service Life of HDPE Geomembrane 1.5 mm?

60 Mil HDPE smooth surface geomembrane is difficult to biodegrade naturally. If it's used for renovations or other purposes, it can only be cleaned up, which can be quite troublesome. However, 1.5 mm HDPE Geomembrane has virtually no environmental impact. The lifespan of 60 Mil HDPE Geomembrane mainly depends on whether the plastic film provides waterproofing.

60 Mil geomembrane hdpe liner, also known as "high-density polyethylene film," has excellent resistance to environmental stress cracking, low-temperature resistance, aging resistance, corrosion resistance, a wide operating temperature range (-60°C to +60°C), and a long service life (50 years). 60 Mil polyethylene geomembrane offers a waterproofing effect unmatched by ordinary waterproofing materials, strong tensile strength, excellent elasticity and deformability, making it suitable for short substrates with significant deformation. It also possesses excellent chemical stability and is used in wastewater treatment, chemical reaction tanks, and landfills.

High-quality 60 Mil high density polyethylene waterproofing geomembrane produced using virgin materials can meet the American standard GRIGM-13. This standard of 60 Mil geomembrane waterproofing has high acid and alkali resistance and corrosion resistance, and can be used for seepage prevention in various projects. Generally, the service life of high-quality pond geomembrane produced using virgin materials can reach more than 100 years underground and more than 20 years above ground.

5. Operating and Maintaining HDPE Geomembrane 1.5 mm

5.1 Construction of geomembrane waterproof HDPE generally involves two methods: geomembrane welding and the use of KS geomembrane-specific adhesive. The treatment of the joints in welding the 60 Mil geomembrane liner HDPE is a crucial procedure, directly affecting the service life of the project. Quality testing indicates that hot welding is the most ideal method. (A special adhesive can also be used.) The hot welding method involves heating the surfaces of the 60 Mil HDPE Geomembrane to be joined, melting them, and then fusing them together under pressure.

5.2 It is best to lay the geomembrane dam liners in a specific direction. A certain amount of PE film and PET non-adhesive layer should be reserved on both sides of the 60 Mil impermeable HDPE geomembrane. During laying, the orientation of each 60 Mil 8 m HDPE geomembrane unit should be adjusted to facilitate welding between units.

5.3 After laying the 60 Mil geomembrane 1.5mm hdpe, it should be weighed down with sandbags to prevent wind movement. The edges and joints must be free of dirt, moisture, dust, and other impurities.

5.4 Before welding, adjust the two PE single-layer films at the joint to ensure a certain overlap, flatness, and no wrinkles.

Welding should ideally be performed by experienced technicians using a dedicated welding machine. Temperature and speed must be adjusted appropriately (adhesive bonding is also possible).

5.5 Precautions:The thickness of 60 Mil hdpe geomembrane waterproofing should not be less than 0.3mm. Too thin a layer may create air pockets and is easily damaged during construction, reducing its waterproofing effect. During the construction of 60 Mil geomembrane waterproof sheet, special attention should be paid to ensuring the laying is not too tight, avoiding wrinkles, and ensuring secure joints. Strict adherence to technical specifications is essential, with rigorous quality control at five stages: preparation, laying, splicing, inspection, and backfilling.

- The laying should extend from the bottom to the top, without pulling too tight, leaving a 1.50% margin to accommodate localized settlement and stretching. Considering the actual conditions of this project, the slope will be laid from top to bottom.

- The longitudinal joints of two adjacent sections should not be on the same horizontal line; they should be staggered by more than 1 meter.

- The longitudinal joints should be at least 1.50 meters away from the dam toe and bends, and should be located on a flat surface.

- Lay the slope first, then the site bottom.

- When laying the membrane on the slope, the direction of membrane spreading should be basically parallel to the maximum slope.

Summary

As an important engineering material, 1.5 mm double smooth hdpe geomembrane plays a crucial role in environmental protection and civil engineering due to its excellent impermeability and durability. Its effective impermeability not only protects soil and water bodies from pollution but also demonstrates broad application prospects in many fields such as waste management, water resource protection, and mining development. With continuous technological advancements, the types and applications of 60 Mil pond liner hdpe geomembrane materials are constantly expanding, making it an important component of modern sustainable development and environmental protection. A deeper understanding of the performance and applications of permeable 60 Mil HDPE Geomembrane will help us better address current environmental challenges and promote ecological civilization.

For reliable quality and global supply, The Best Project Material Co., Ltd.(BPM Geosynthetics)is a trusted manufacturer of 60 Mil HDPE geomembrane solutions.