Root Barrier Membrane

The global demand for Root Barrier Membrane has risen steadily over the past decade, driven by rapid urbanization, large-scale transportation upgrades, and the expansion of sustainable landscaping initiatives. Governments and private contractors are increasingly prioritizing long-term ground stability, drainage安全, and vegetation management, especially in regions where aggressive root systems threaten underground utilities, pavements, and structural foundations.

According to industry research reports, the global geosynthetics market—within which Root Barrier Membrane forms a fast-growing segment—has surpassed USD 10 billion in annual value and is forecast to maintain a CAGR of 5–7% through 2030. Infrastructure programs in North America, the Middle East, and Southeast Asia continue to stimulate procurement, particularly for highway greenbelts, railway corridors, urban tree-lined streets, and municipal pipe network protection.

Global Demand for Root Barrier Membrane in Infrastructure and Environmental Projects

The global demand for Root Barrier Membrane has risen steadily over the past decade, driven by rapid urbanization, large-scale transportation upgrades, and the expansion of sustainable landscaping initiatives. Governments and private contractors are increasingly prioritizing long-term ground stability, drainage安全, and vegetation management, especially in regions where aggressive root systems threaten underground utilities, pavements, and structural foundations.

According to industry research reports, the global geosynthetics market—within which Root Barrier Membrane forms a fast-growing segment—has surpassed USD 10 billion in annual value and is forecast to maintain a CAGR of 5–7% through 2030. Infrastructure programs in North America, the Middle East, and Southeast Asia continue to stimulate procurement, particularly for highway greenbelts, railway corridors, urban tree-lined streets, and municipal pipe network protection.

Market Trends and Strategic Adoption Across Regions

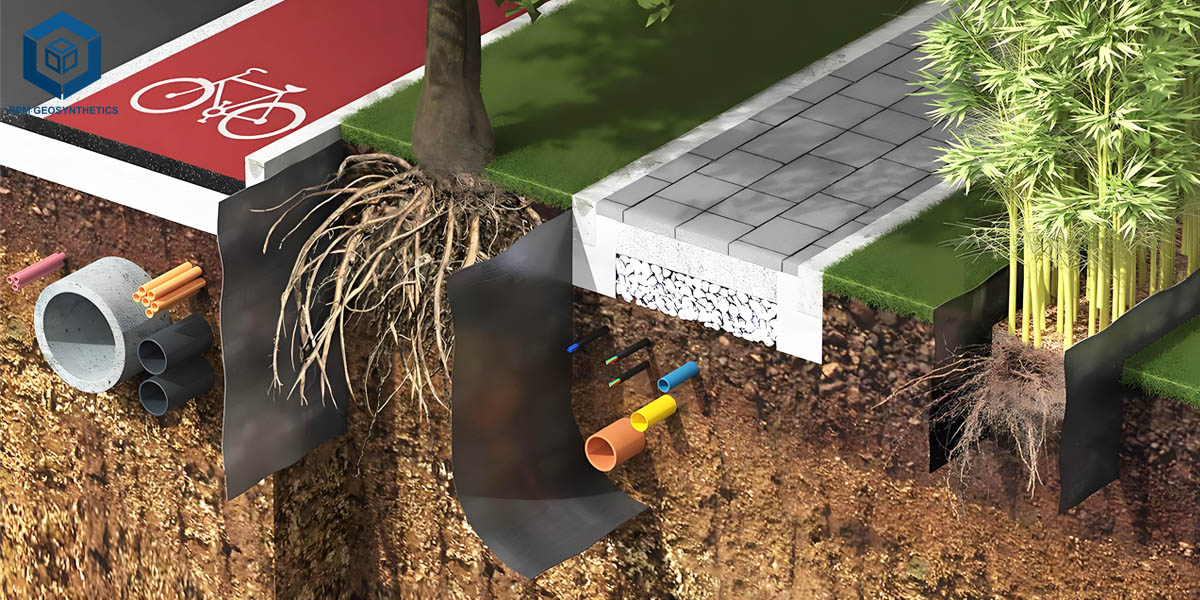

The increase in urban greening projects has elevated the strategic relevance of Root Barrier Membrane as a non-negotiable protective component. Cities are planting more deep-rooting species to improve air quality and regulate microclimates. However, without proper containment, roots can penetrate concrete slabs, damage waterproofing systems, and disrupt drainage channels.

Another key trend is the shift toward high-density polymer structures that combine tensile strength with long-term chemical resistance. Buyers are moving from traditional low-grade polyethylene sheets to engineered membranes with controlled thickness, multi-layer reinforcement, and stabilized carbon-black formulations. Sustainability has also become a priority: recyclable materials and increased membrane lifespan directly reduce replacement cycles and maintenance costs for public projects.

Technical Parameters That Define Modern Root Barrier Membrane Quality

A high-grade Root Barrier Membrane typically features precise mechanical and chemical characteristics that ensure reliable anti-intrusion performance. While specifications vary by application, most international buyers evaluate membranes using the following parameters:

• Thickness range from 0.5 mm to 2.0 mm, depending on installation depth and root aggressiveness.

• Tensile strength generally between 25–40 kN/m, allowing membranes to withstand soil stress and mechanical stretching during installation.

• Puncture resistance values exceeding 1,500–2,500 N to prevent perforation by sharp roots or debris.

• Oxidation and UV stabilization achieved through additives and controlled extrusion processes.

• Waterproof performance with<1% water absorption and seamless protection for underground waterproofing systems.

These technical metrics are also used by engineering consultants when evaluating compliance with construction codes, transportation standards, and urban landscaping guidelines. Long-tail keywords such as “HDPE root barrier sheet,” “underground root protection membrane,” and “tree root control barrier” naturally emerge within technical documentation.

Product Structure and Material Engineering

Modern Root Barrier Membrane designs increasingly rely on multi-layer composite extrusion technology. A typical structure includes:

• A high-density polyethylene (HDPE) or polypropylene base layer providing rigidity and long-term dimensional stability.

• Reinforced middle layers that enhance resistance to tearing, puncture, and deformation.

• A surface with controlled texture or embossing to improve friction with surrounding soil and prevent membrane slippage.

This engineered structure allows Root Barrier Membrane products to perform effectively in high-pressure underground environments and withstand root intrusion from species with powerful radial growth.

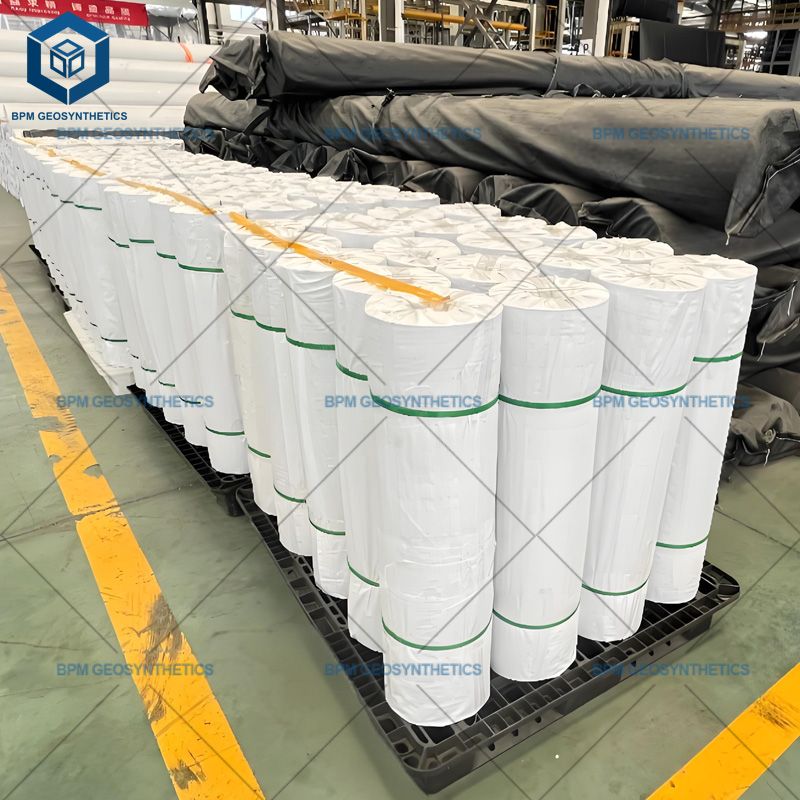

Manufacturing Process and Quality Control Standards

The manufacturing of Root Barrier Membrane follows a precision-controlled extrusion and shaping process designed for consistency. High-purity resin pellets are melted under calibrated temperatures before being extruded through dies that determine membrane thickness and width. Continuous cooling and stretching systems ensure uniform density, while online laser measurement instruments maintain tolerance accuracy.

Quality control laboratories test each batch for tensile strength, elongation, puncture resistance, thermal stability, and chemical compatibility. Many suppliers now operate under ISO-compliant systems, ensuring that Root Barrier Membrane products meet international engineering specifications and procurement standards.

Applications Across Infrastructure, Landscaping, and Utility Protection

Root Barrier Membrane solutions are widely applied across municipal and commercial environments, including:

• Roadside greenbelts and median strips, where strong root systems can lift asphalt or concrete.

• Underground pipeline corridors requiring root-free zones to protect drainage pipes, water lines, and fiber-optic cables.

• Railway and subway infrastructure, especially in regions with persistent soil moisture and invasive tree species.

• Commercial landscapes, parks, golf courses, and residences where long-term root management reduces maintenance frequency.

The ability of Root Barrier Membrane to create a controlled root-growth zone ensures that vegetation thrives while protecting essential assets.

International Buyer Preferences and Pain Points

Global buyers—particularly importers, contractors, and government project supervisors—share several procurement priorities for Root Barrier Membrane:

• Consistent mechanical strength backed by certified test data.

• Availability of wide-width rolls to reduce seam work during installation.

• Long service life (20–40 years) validated by aging and outdoor exposure testing.

• Competitive pricing and predictable delivery schedules for large project bidding.

• Clear installation guides and technical drawings for field engineers.

Common pain points include uneven quality among suppliers, membrane tearing during installation, limited chemical resistance, and insufficient documentation. Strengthening technical transparency, offering OEM customization, and providing sample evaluation help address these issues effectively.

Strategic Positioning of Root Barrier Membrane in the Global Supply Chain

In a competitive procurement environment, Root Barrier Membrane suppliers must emphasize engineering reliability, certified performance, and responsive service. For international buyers, the difference between suppliers often depends on the accuracy of technical parameters, material-grade consistency, and the ability to meet complex project specifications.

We continue to see increased demand for reinforced membranes, higher thickness options, and installation-ready accessories—reflecting the global shift toward high-longevity infrastructure materials.

Conclusion: Enhancing Project Durability with Advanced Root Barrier Membrane Solutions

As global infrastructure and landscaping projects grow in scale and complexity, Root Barrier Membrane stands out as a critical protective component. Its ability to prevent structural damage, reduce maintenance, and support sustainable urban greenery has made it an essential material for contractors and project managers worldwide.

We welcome international buyers to request detailed technical sheets, specification support, and samples for evaluation. Our engineering team provides professional guidance to help select the appropriate Root Barrier Membrane for diverse applications, ensuring long-term performance and cost efficiency.

FAQs

1. What thickness of Root Barrier Membrane is recommended for roadside or municipal applications?

Most municipal projects use membranes between 1.0–1.5 mm for optimal strength and durability, depending on soil conditions and plant species.

2. Can Root Barrier Membrane be used with aggressive tree species?

Yes. High-density membranes with strong puncture resistance and reinforced layers are designed for deep-rooting and invasive species.

3. How long does a high-quality Root Barrier Membrane last underground?

With proper installation, membranes can maintain performance for 20–40 years due to UV stabilizers and anti-aging formulations.

4. Do you provide technical drawings or installation guidance?

Yes. Engineering teams can supply installation manuals, CAD drawings, and customized specifications upon request.

For international quotations, project consultations, or sample evaluation, please contact us to begin your procurement process with professional technical support.