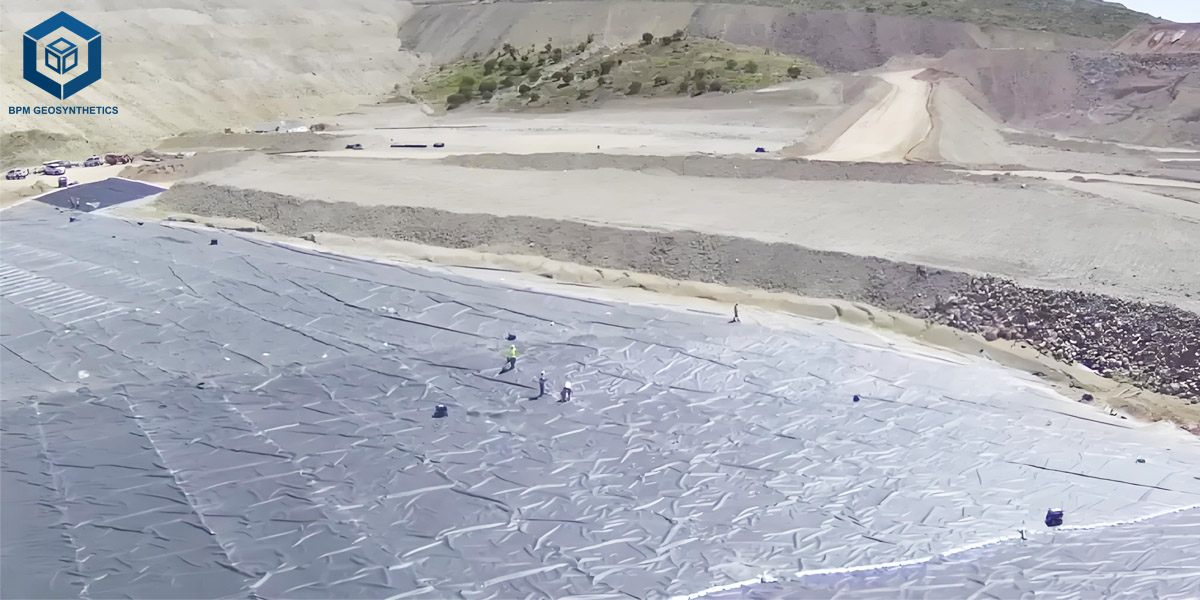

Mining Geomembrane Liner

Mining geomembrane liner is durable, flexible, and chemically resistant membranes designed to supply dependable containment options for more than a few mining applications. Made from excellent HDPE materials, these geomembrane liner make sure long-term safety in opposition to leakage and environmental illness in tailings ponds, heap leach pads, and waste containment areas.

- Thickness: 0.2 mm – 3.0 mm (customizable)

- Density: 0.94 – 0.96 g/cm³

- UV Resistance: Excellent, with stabilizers

- Chemical Resistance: Resistant to acids, alkalis, solvents, and mining chemicals

- High impermeability stopping seepage and contamination

- Superior mechanical electricity and puncture resistance

- Environmentally pleasant and compliant with mining regulations

- Easy welding and area seaming for tightly closed containment

Mining geomembrane liner is artificial impermeable geomembrane liner particularly designed to comprise beverages and forestall environmental infection in mining operations. Made from high density polyethylene (HDPE), these geomembrane liner furnish fantastic chemical resistance, excessive tensile strength, and incredible sturdiness beneath harsh mining conditions. HDPE mining geomembrane liner successfully isolate hazardous mining fluids from soil and groundwater, making sure long-term safety and compliance with environmental regulations. Their sturdy physical properties, along with resistance to UV publicity and temperature extremes, make them best for functions such as tailings ponds, heap leach pads, and waste containment areas in the mining industry.

1. Key Materials Used in Mining Geomembrane Liner

1.1 HDPE (High Density Polyethylene) Mining Geomembrane Liner :

- Renowned for its fantastic tensile strength, making it noticeably resistant to mechanical stresses such as punctures and tears in the course of mining operations.

- Exhibits extraordinary chemical resistance, correctly withstanding publicity to acids, alkalis, solvents, and a huge vary of mining chemicals.

- Superior sturdiness and long-term stability, capable of keeping overall performance beneath harsh environmental stipulations inclusive of severe temperatures and extreme UV radiation.

- Low permeability ensures an fantastic barrier to stop leakage and infection of soil and groundwater.

- Excellent dimensional stability, lowering deformation beneath load or temperature changes, which is necessary for keeping containment integrity in mining sites.

1.2 BPM Mining Geomembrane Liner Commitment to Quality:

BPM HDPE geomembrane is manufactured completely from 100% imported virgin HDPE uncooked materials, making sure the best purity and constant quality.

The use of top class imported virgin HDPE enhances the mechanical residences and chemical resistance of the liner, extending their provider existence and reliability in annoying mining applications.

Strict best manipulate in the course of the manufacturing technique ensures uniform thickness, strength, and weldability, ensuing in most desirable high density polyethylene geomembrane performance.

BPM’s dedication to the use of solely virgin HDPE uncooked substances distinguishes its merchandise in the market, presenting consumers with reliable and environmentally secure mining liner.

2. Mining Geomembrane Liner Technical Specifications and Performance Properties

2.1 Mining Geomembrane Liner Thickness Range:

Mining geomembrane liners normally vary in thickness from 0.2 mm to 3.0 mm, relying on the unique necessities of the mining application. Thicker liners supply larger mechanical energy and puncture resistance, making them appropriate for heavy-duty areas such as tailings ponds or waste containment sites. Thinner liners might also be used the place flexibility and ease of set up are prioritized. Selecting the terrific thickness is fundamental to making sure each overall performance and cost-effectiveness in mining projects.

2.2 Mining Geomembrane Liner Tensile Strength:

The tensile power of mining HDPE geomembrane sheets usually exceeds 20 MPa, permitting them to stand up to massive mechanical stresses encountered all through set up and operation. High tensile energy helps forestall tearing, stretching, or failure underneath heavy masses and soil pressures, making sure the liner continues its integrity over time, even in worrying mining environments.

2.3 Mining Geomembrane Liner Elongation at Break:

With an elongation at destroy of 700% or higher, Geomembranes pond liner showcase superb flexibility. This property approves the liner to stretch and adapt to floor movements, uneven terrain, and contract except cracking or breaking. Such flexibility is crucial for retaining a non-stop impermeable barrier, specially in mining areas susceptible to transferring or seismic activity.

2.4 Mining Geomembrane Liner Density:

HDPE geomembrane normally have a density ranging from 0.94 to 0.96 g/cm³. This distinctly excessive density contributes to the liner’s electricity and chemical resistance whilst offering a stable, long lasting barrier. The density vary ensures a balanced aggregate of sturdiness and flexibility, optimized for mining applications.

2.5 Mining Geomembrane Liner Chemical Resistance:

Impermeable geomembrane is formulated to withstand a wide spectrum of chemical compounds often discovered in mining operations, which include acids, alkalis, solvents, and a variety of mining reagents. This chemical resistance prevents degradation or weakening of the liner when uncovered to harsh substances, making sure long-term containment and environmental protection.

2.6 Mining Geomembrane Liner Temperature Resistance:

These HDPE pond liner sheet is designed to function reliably in severe temperature conditions, normally from -60°C up to +80°C. This broad temperature tolerance ensures the liner stays secure and practical in numerous climates, from freezing bloodless environments to warm wasteland mining sites, except dropping its mechanical homes or turning into brittle.

2.7 Mining Geomembrane Liner UV Resistance:

Exposure to daylight can degrade polymer substances over time, so pool liner geomembrane include UV stabilizers and antioxidants. These components considerably beautify the liner’s resistance to ultraviolet radiation, stopping untimely aging, cracking, or loss of electricity due to extended solar publicity all through storage, installation, or provider life.

3. Mining Geomembrane Liner Primary Applications

3.1 Mining Geomembrane Liner for Tailings Ponds:

Tailings ponds are engineered containment areas the place slurry— a combination of water and finely floor mining waste—is saved after mineral extraction. Mining geomembrane liners are crucial in these ponds to create an impermeable barrier that prevents the slurry from seeping into the surrounding soil and contaminating groundwater sources. The liners’ chemical resistance is necessary to face up to the corrosive nature of tailings, whilst their mechanical energy protects in opposition to punctures from sharp particles. By securely keeping apart these wastes, geo membrane liner assist mining agencies comply with environmental rules and reduce ecological risks.

3.2 Mining Geomembrane Liner for Heap Leach Pads:

Heap leach pads are large, mainly organized areas the place beaten ore is heaped and irrigated with leaching solutions, such as cyanide or acid, to extract treasured metals. Mining geomembrane liners serve as the foundational barrier below these lots to stop leachate from infiltrating the environment. The liner need to be fantastically resistant to chemical assault and bendy sufficient to conform to uneven terrain and moving loads. Its impermeability ensures that hazardous leaching fluids are safely accrued and managed, stopping soil and water infection and facilitating recuperation of the leachate for processing.

3.3 Mining Geomembrane Liner for Waste Containment:

Mining operations generate a range of hazardous wastes, together with spent ore, sludge, and contaminated soils. HDPE geomembrane sheet are broadly used to isolate these substances in specified containment areas or engineered landfills. The liners act as a shielding protect that prevents poisonous components from migrating into the environment. Their sturdiness and chemical resistance make sure long-term containment, even in difficult mining conditions. This utility now not solely protects ecosystems however additionally reduces doable liabilities and remediation charges for mining companies.

3.4 Mining Geomembrane Liner for Process Water Reservoirs:

Mining procedures require extensive quantities of water for ore processing, dirt suppression, and different operations. Process water reservoirs are designed to shop this water safely. Geomembrane Pond Liner is set up to create leak-proof reservoirs that stop water loss and illness of underground aquifers. The liners’ strong building ensures resistance to mechanical harm and environmental degradation, preserving water nice and provide reliability necessary for mining efficiency.

3.5 Mining Geomembrane Liner for Landfills and Storage Areas:

Mining websites frequently want tightly closed storage for strong wastes or brief stockpiles of materials. Smooth geomembrane supply impermeable obstacles underneath landfills or storage areas to guard soil and groundwater from infection precipitated via leachate or spills. The pond liner assist comprise hazardous substances, assisting secure waste administration practices. Their ease of set up and adaptability make them appropriate for a range of storage configurations, making sure environmental safety during the mine’s lifecycle.

4. Customer Case Studies: Mining Geomembrane Liner Applications

4.1 Mining Geomembrane Liner Case Study 1: Tailings Pond Liner for Large-Scale Copper Mine in Chile

A main copper mining organization in northern Chile chosen BPM’s geomembrane HDPE 2mm pond liner for the containment of tailings in one of their principal processing sites. The venture required a high-strength liner succesful of withstanding aggressive chemical publicity and harsh climatic conditions, which includes severe UV radiation and giant temperature fluctuations. BPM’s geomembrane, manufactured with a hundred percent imported virgin HDPE, supplied tremendous chemical resistance and mechanical durability. The liner used to be efficaciously mounted over 50,000 rectangular meters, making sure zero leakage and full regulatory compliance. This answer appreciably minimized environmental dangers and facilitated safer tailings management.

4.2 Mining Geomembrane Liner Case Study 2: Heap Leach Pad Liner for Gold Mining Operation in South Africa

A gold mining operator in South Africa deployed BPM’s geomembrane HDPE 1.5 mm to line their heap leach pad, a vital containment place the place cyanide answer is used for gold extraction. The liner’s super impermeability and chemical resistance averted poisonous answer seepage into surrounding soil and groundwater. The bendy nature of the liner accommodated the uneven terrain of the heap pad, permitting convenient set up and dependable overall performance underneath dynamic load conditions. Post-installation checking out validated seam integrity and absence of leaks, making sure long-term environmental protection.

4.3 Mining Geomembrane Liner Case Study 3: Wastewater Containment Pond in a Coal Mine, Australia

In Australia, a coal mining corporation hooked up BPM’s 3.0 mm HDPE geomembrane liner for their wastewater containment ponds. The mission demanded a liner with greatest puncture resistance due to general heavy equipment endeavor nearby. BPM’s geomembrane delivered brilliant mechanical strength, resisting injury in the course of each set up and operation. The liner additionally exhibited first-rate UV stability, necessary for the region’s robust daylight exposure. This task highlighted BPM’s potential to furnish custom-made geomembrane options tailor-made to site-specific challenges, assisting sustainable mining practices.

5. Customization Options for Mining Geomembrane Liner

At BPM Geosynthetics , we understand that each mining task has special requirements. That’s why we provide a large vary of customization choices for our mining geomembrane liner, including:

- Tailored roll sizes to suit your particular width and size needs.

- Color variants such as green, blue, white, and greater to healthy website online specs or preferences.

- Column-Point or double-textured surfaces designed to enhance slope balance and decrease slippage.

- Co-extruded multilayer geomembranes engineered for improved chemical resistance and increased durability.

- For mining initiatives with specialised layout parameters, our skilled engineering group is equipped to personalize the geomembrane formulation, making sure ideal overall performance and compliance with your genuine purposeful needs.

6. Packaging & Logistics for Mining Geomembrane Liner

BPM geosynthetics takes fantastic care in packaging each roll of our mining geomembrane liners to warranty product integrity at some stage in delivery and ease of coping with on-site. We recognize the significance of preserving product exceptional and full traceability during the logistics process.

Our popular mining geomembrane liner packaging methods include:

Rolling the geomembrane liners onto robust, moisture-resistant cardboard or plastic cores to forestall deformation and water damage.

Wrapping with UV-protected polyethylene movie or long lasting woven geotextile covers to guard in opposition to dirt, sunlight, and mechanical influences in the course of transit and storage.

Applying clear, everlasting labels that show batch numbers, product specifications, and manufacturing dates, making sure full traceability and streamlined stock administration on-site.

With an widespread export community attaining over a hundred countries, BPM presents bendy and dependable delivery alternatives by means of sea, rail, and air freight. Our expert logistics group coordinates intently with freight forwarders to make sure easy customs clearance, punctual delivery, and real-time monitoring updates for venture managers. For pressing mining projects, we additionally furnish expedited manufacturing and precedence transport offerings to meet tight deadlines.

7. Conclusion

Mining geomembrane liner is essential for achieving sustainable and environmentally safe mining operations. With outstanding chemical resistance, exceptional mechanical strength, and proven environmental protection performance, they play a critical role in securely containing mining fluids and waste. Choosing the right HDPE liner, ensuring strict quality manufacturing, and following proper installation practices are key to maximizing long-term durability and compliance with environmental regulations.

For mining projects that demand reliability, quality, and professional support, BPM offers premium mining geomembrane liners made from 100% imported virgin HDPE, backed by advanced production technology and rigorous quality control. Partner with BPM Geosynthetics to ensure the safety, efficiency, and environmental integrity of your mining operations.