HDPE Geomembrane Sheet

HDPE geomembrane sheet is a multifunctional lining made of high-density polyethylene, broadly used in a variety of functions of environmental administration and control. These boards are designed to furnish tremendous liquid and fuel barriers, making them vital substances for initiatives such as landfills, reservoirs, and industrial enclosures. Their sturdiness and reliability make sure long-term overall performance beneath a number of environmental conditions.

-UV stability:

Maintain integrity and overall performance when uncovered to daylight for prolonged intervals of time.

-Economically environment friendly solution:

Provide a stability between first-class and affordability to limit standard challenge costs.

-Easy to install:

Lightweight and flexible, handy to set up shortly and successfully on quite a number surfaces.

HDPE geomembrane sheet is an engineering lining made of high-density polyethylene, designed specially for environmental safety and the good sized use of security shells. These boards are acknowledged for their extremely good sturdiness and resistance to more than a few chemicals, making them an perfect preference for landfills, ponds, reservoirs, and mining operations. The low permeability of HDPE geomembrane sheet can forestall from passing through, successfully defending groundwater and soil from pollution. They can face up to ultraviolet radiation and make sure long-lasting overall performance even underneath out of doors conditions. In addition, HDPE geomembrane sheet boards are light-weight and flexible, simplifying the set up manner on a variety of surfaces and shapes. These geomembranes prioritize nice and environmental safety, endure rigorous testing, and meet enterprise standards, imparting dependable options for initiatives that require high quality manage and environmental management. Its cost-effectiveness in addition enhances its attractiveness, making HDPE geomembrane sheet board a famous preference for business and industrial applications.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | D1505/D792 | 90.000kg | 0.94g/cc | ||||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 5 3 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

HDPE Geomembrane Sheet Features

1. High chemical resistance:

HDPE geomembrane sheet is resistant to a range of chemicals, consisting of acids, alkalis, and natural solvents, making it appropriate for a range of industrial applications.

2. Low permeability:

These boards have extraordinarily low permeability, which can forestall liquid infiltration and defend groundwater from pollution.

3. Durability:

HDPE geomembrane sheet has excessive tensile electricity and puncture resistance, and can stand up to harsh environmental prerequisites and mechanical stress.

4. UV resistance:

Designed to withstand degradation by means of ultraviolet (UV) light, ensuring long-term overall performance in out of doors purposes except compromising structural integrity.

5. Flexibility:

The flexibility of HDPE geomembrane sheet makes it effortless to installation on uneven surfaces and complicated shapes, and can adapt properly to task requirements.

6. Cost effectiveness:

These HDPE geomembrane sheets supply dependable options at aggressive prices, assisting to limit typical assignment charges by means of minimizing upkeep and alternative needs.

7. Environmental Protection:

HDPE geomembrane sheets play a indispensable position in defending soil and water from pollution, steady with sustainability and regulatory compliance goals.

8. Easy to install:

The light-weight traits of HDPE geomembrane sheet facilitate speedy and environment friendly installation, and a number of welding strategies are regularly used to create protected joints.

Applications of HDPE Geomembrane Sheet

1. Landfill liners:

HDPE geomembrane sheet is extensively used as a liner in landfills to stop leachate from escaping and contaminating the surrounding soil and groundwater.

2. Reservoir:

These HDPE geomembrane sheets grant a dependable barrier for the water storage tank, making sure that the water stays enclosed and uncontaminated.

3. Irrigation pool:

In agricultural environments, HDPE geomembrane sheet is used for irrigating ponds, which helps to keep water and decrease evaporation.

4. Wastewater cure facilities:

The sewage cure plant makes use of HDPE geomembrane sheets to accommodate sludge and by-products, stopping detrimental materials from getting into the environment.

5. Mining applications:

In mining operations, these HDPE geomembrane sheets are used for tailings ponds and heap leaching pads to efficaciously manipulate dangerous components and guard water resources.

6. Aquaculture:

HDPE geomembrane sheet creates a managed surroundings for fish farming and aquaculture, retaining water fine and stopping pollution.

7. Flood manipulate system:

These tables are used in flood manipulate tasks to manipulate rainstorm runoff and shop water throughout heavy rainfall events.

8. Cofferdam:

HDPE geomembrane sheet can be used to assemble transient cofferdams and furnish dry working prerequisites for the duration of building or protection tasks in water bodies.

Company Profile

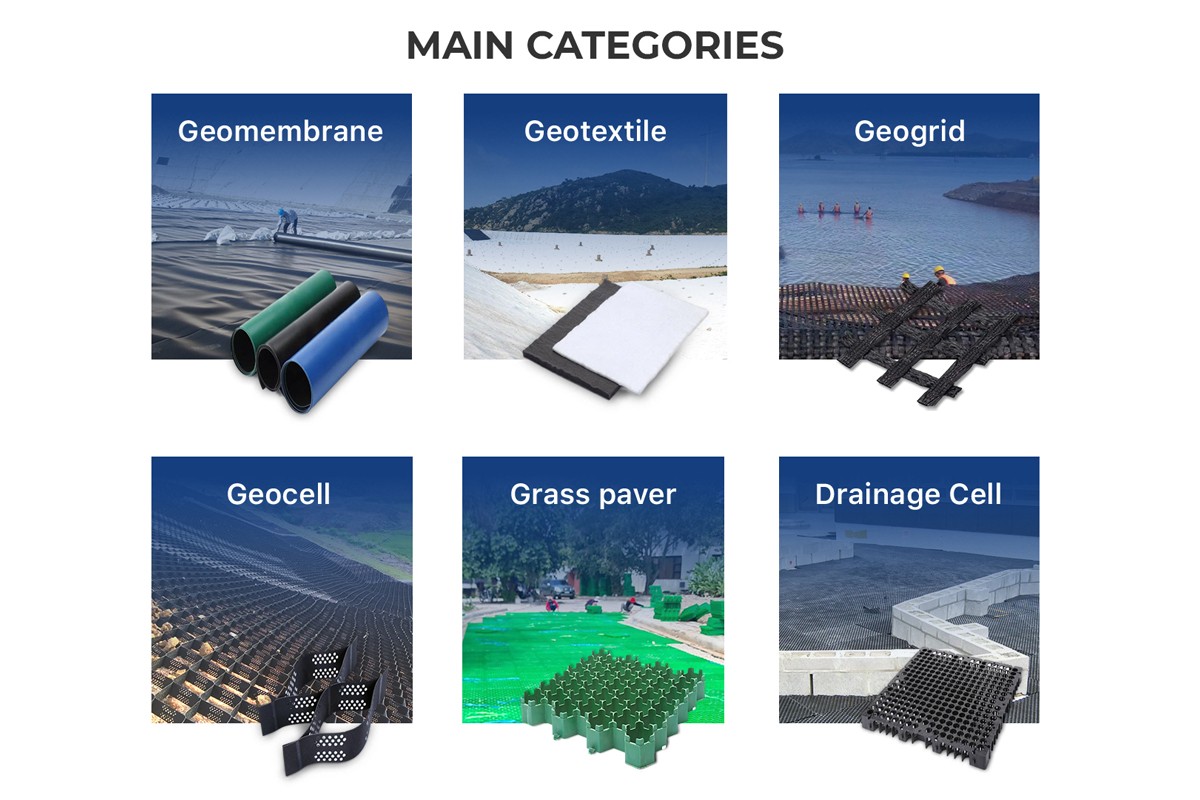

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, geogrids, geocells, and geosynthetic clay liners (GCL). Our products, certified by EU CE and GLP, have passed ISO 9001, ISO 14001, and OHSAS 18001 standards, and are recognized for their quality, performance, and durability.

BPM GEOSYNTHETICS has been committed to providing one-stop services for global customers in the research and development, production, sales, and export of geosynthetic materials since its establishment in 2007. The company has 120 senior technical talents specializing in geotechnical materials. The manufacturing factory covers an area of over 36000 square meters and is equipped with industry-leading automated production equipment and professional testing instruments. Product innovation, quality assurance, and customer satisfaction have always been BPM commitment to partners.

We're committed to innovation and quality, offering flexible cooperation and the best solutions for engineering projects worldwide. Our products are utilized in various sectors like aquaculture, erosion control, drainage systems, municipal engineering, mining, and landscaping. We look forward to partnering with you to solve complex challenges with our high-performance geosynthetic products.