HDPE Geomembrane Liner

HDPE geomembrane liner is sturdy boundaries made from high-density polyethylene, appreciably used in a fluctuate of elements for containment and environmental protection. Their remarkable sturdiness and chemical resistance make them superb for initiatives such as landfill liners, water reservoirs, and mining operations. These liners successfully stop leaks and contamination, making high-quality environmental protection and compliance with regulations.

- High Chemical Resistance:

Protects in opposition to a huge vary of chemical compounds and leachates.

- Durability:

Exceptional puncture and tear resistance for long-term use.

- Cost-Effective:

Offers a steadiness of extraordinarily excellent and affordability, reducing long-term costs.

1. HDPE Geomembrane Liner Product Overview

HDPE Geomembrane Liner is a class of advanced synthetic liners that are popular for waterproofing, containment, and environmental protection uses. In addition to being barrier materials, hdpe liner made of superior quality polyethylene resin also show exceptionally good chemical resistance, UV stability, and durability over the years. Because of these features, they are the closest picks for an array of sectors such as landfill, mining, water storage, and civil engineering.

1.1 HDPE Geomembrane Liner Key Features:

1.1.1 100% Virgin HDPE Resin

Perfectly stable in material properties, durable in the long run, and with excellent chemical resistance, the HDPE membrane produced using 100% virgin resin meets the most rugged containment and waterproofing projects requirements.

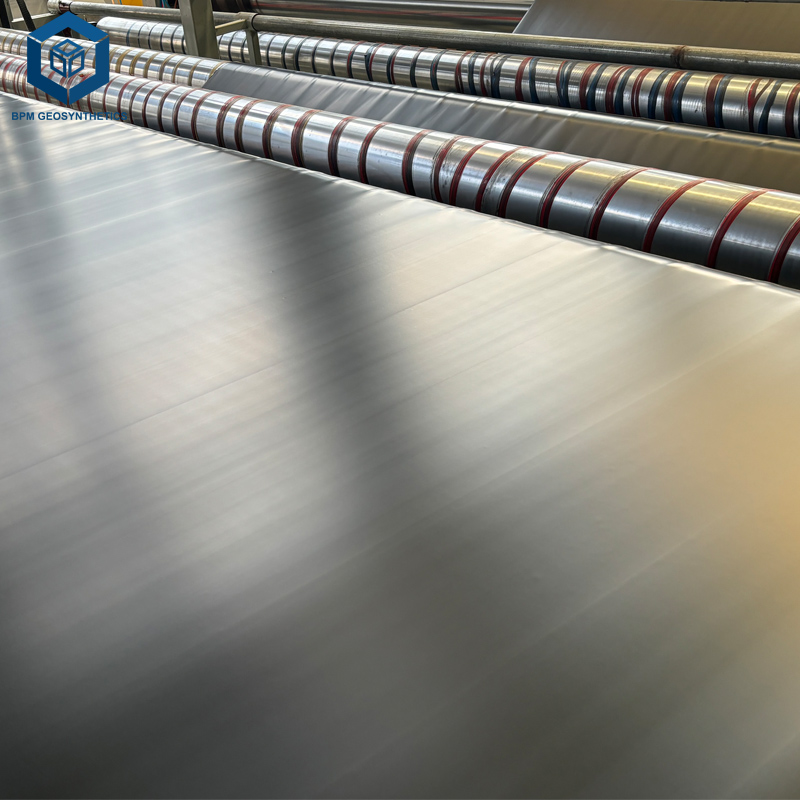

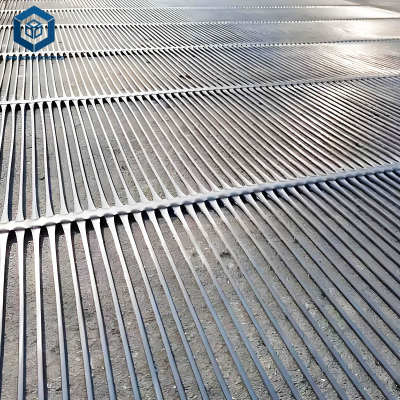

1.1.2 Smooth or Textured Surface Options

One can choose between smooth and textured surfaces to suit the different kinds of installations. In friction applications, a smooth surface is the best, while in grips and slopes textured ones make reach more stable and safer.

1.1.3 Thickness from 0.2 mm (8 mil) to 3.0 mm (120 mil) or Customized

Chooses an appropriate thickness from a very thin to a very thick product ranging to cover from light to heavy material works. In those cases where performance or regulation is a must, custom geomembrane sheet thickness is ready for you.

1.1.4 Widths up to 8 Meters (Can be changed)

Maximum width of one raw can be 8 meters, thus fewer seams and a faster pitch of the location will be possible. The width can be customized to suit the exact condition of the site and, thus, the labor and the installation time reduced will be.

1.1.5 High Tensile Strength, Puncture, and Tear Resistance

To be tough mechanically, high density polyethylene geomembrane have been built to give strong tensile strength, puncture resistance, and tear resistance. I.e., hdpe geo membrane can handle heavy loads and stay stable even in harsh weather.

1.2 Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | D1505/D792 | 90.000kg | 0.94g/cc | ||||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 5 3 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

2. HDPE Geomembrane Liner Material Composition

The ingredients of one are high-density polyethylene (HDPE) resin and a few additives such as UV inhibitors, antioxidants, and carbon black. The additives are carefully chosen, and they play a huge role in high performance and durable liners in tough applications:

2.1 UV Resistance – Long-Term Sunlight Exposure Without Degradation

Solar UV radiation is almost entirely absorbed by the stabilizers and the carbon black, and thus the source of radiation is kept away from the polymer and the ageing process is considerably retarded, so after long times in the open, the absorbed strength and the flexibility are still there.

2.2 Chemical Resistance – Protection Against Acids, Alkalis, Salts, and Hydrocarbons

Even though the chemically inert HDPE is coupled with antioxidants for the ultimate protection, the hdpe geomembrane sheet can still take on the harshest of liquids such as industrial chemicals, leachate, and petroleum products without a problem, thus, it is a perfect fit removal of pollutants from landfills, mining ponds, and the like.

2.3 Thermal Stability – Performance From -60°C to +110°CT With Same Material

Under even very low or very high temperatures, the hdpe liner sheet material retains the ability to change its dimensions minimally, it is also flexible and strong from a mechanical point of view, and this guarantees the reliability of performance in cold climates, hot regions, or temperature-fluctuating environments.

2.4 Mechanical Strength – High Tensile Strength and Low Creep Characteristics

HDPE impermeable liner have very good tensile strength, can hardly be punctured or torn, and also are somewhat resistant to creep - which means the plastic doesn't deform even when subjected to loading, thus the structures' solidity and impermeability have been ensured for a very long time.

3. HDPE Geomembrane Liner Applications

3.1 Landfill and Waste Containment

HDPE membrane sheet have become the favorite choices of bottom and side liners for landfills of both municipal and industrial sectors due to their toughness and impermeability which is what makes them ideal for preventing the contamination of the soil and groundwater. Besides them, hdpe landfill liner are perfect for leachate holding tanks and hazardous waste containment designed to ensure the environment remains safe over time, and laws are adhered to.

3.2 Mining Industry

HDPE liners in mining scenarios are generally utilized for tailing ponds, heap leach pads, and slurry ponds, thus ensuring the mining by-products are contained properly. Polyethylene geomembrane resistance to chemicals also allows for the storage of even the most corrosive (acidic or alkaline) solutions, thereby giving safety to the environment around.

3.3 Water Containment

With the help of water containment BPM geomembrane made of HDPE can be effectively used in reservoirs, canals, ponds, and irrigation channels thus water that is absorbed can be stopped and losses because of the water are reduced. Besides that, hdpe smooth geomembrane are used in water treatment lagoons and storage tanks, which guarantee clean water retention and efficient management of industrial or agricultural water resources.

3.4 Civil Engineering and Infrastructure

Among other things, HDPE lining for the civil engineering projects are the secondary containment of chemical plants which not only helps the chemical plants in the containment of the chemicals but also prevents the escape of hazardous wastes. By means of their applications, they become tunnels, reservoirs, and underground waterproofing, which offer long-lasting, and flexible solutions for difficult infrastructure installations.

3.5 Environmental Protection Projects

One of the primary functions of high density polyethylene hdpe liners is to serve as a layer in capping polluted sites, thereby helping in the isolation of pollutants and reduction of risks to the environment. Moreover, these materials find usage as erosion-control liners for the rivers, coastal projects, and embankments, thus they provide not only the stability for the long-term but also protection from erosion of soil.

4. HDPE Geomembrane Liner Installation & Welding

Hot wedge welding, extrusion welding, or specialized seaming techniques are the three methods by which HDPE geomembranes liner are linked. They pave the way for an uninterrupted, watertight sealing. The right installation of the device is very important if we want the apparatus to work for a long time, have mechanical strength, and be safe for the environment.

4.1 Seam Strength Close to the Parent Material (≥ 80% of Sheet Strength)

Correct welding methods make sure that seams can hold at least 80% of the tensile strength of the base material, thus they are prevented from breaking under heavy loads and also, they provide a stable, long-living joint during the whole life span of the material.

4.2 Resistance to Puncture and Tearing at Seams

Seams that are done properly can cope with penetrating, shear, and tearing forces, thus the membrane used as a liner will be safe from any spoil even if it is with the heavy side of the use category like in landfills, mining ponds, and civil engineering projects.

4.3 Long-Term Leak-Proof Performance

A continuous, impermeable liner is ensured through proper placement and quality-controlled welding, thus the coming of leakage is at its minimum and environmental protection is assured for a long time.

4.4 Installation Accessories

4.4.1 Geotextile Cushion Underlay

The use of a geotextile protective layer can be considered, which is put under the membrane in order not to be punctured by some sharp objects, stones, or uneven subgrade, hence extending the lifespan of the liner.

4.4.2 Anchoring Systems (Batters, Toe Trenches)

Geometry of anchors helps the membrane to stay firm on the slopes, edges, and trenches and thus the absence of movers is guaranteed together with resistance to the different kinds of agents such as the wind, pressure of the water, or the shifting named soils.

4.4.3 Testing Kits for Seam Quality (Air Channel or Vacuum Box Testing)

The use of air channel or vacuum box testing kits is done in checking the correctness of seams and through this means the testing done on welded joints without giving the welding a damage is essential in finding places from which the air leaks or are weak points prior to cover back or opening.

5. HDPE Geomembrane Liner Quality Assurance

5.1 Tensile, Tear, Puncture, and Elongation Testing

BPM hdpe membrane is tested through the full range of their mechanical properties in order to demonstrate high tensile strength, tear resistance, and puncture resistance, while also exhibiting the correct elongation. In this way, it is assured that such linings will be able to resist all kinds of mechanical forces and the heavy loads that will be applied during the installation as well as the operation in the long run.

5.2 Thickness and Density Uniformity Inspections

Each roll of hdpe geomembrana is inspected for thickness that is uniform along with density that is also uniform thus the liner is capable of providing barrier performance that is reliable over the entire area and exactly meeting the project specifications.

5.3 Seam Quality Verification

All welded seams are tested using standardized methods to confirm integrity and leak-proof performance, preventing potential failures at joints and ensuring the geomembrane functions as a continuous protective layer.

5.4 Compliance with International Standards

BPM geomembrane in HDPE fully comply with international quality and performance standards, including ASTM D5199, ASTM D6693, GRI GM13, and ISO 9001 certification. This compliance assures clients of consistent quality, durability, and regulatory acceptance for global engineering and environmental projects.

6. HDPE Geomembrane Liner Packaging & Delivery

6.1 Rolled on Durable Support, Wrapped with Protective Film

Geo membrane sheet is snugly rolled on strong supports and wrapped with durable protective film in order to keep them from being damaged, deformed, or contaminated during handling, storage, and transportation.

6.2 Standard Roll Width: 4–8 Meters, Length: up to 50–100 Meters per Roll

Normal roll sizes are planned for the easy transportation and installation, thus the number of seams and on-site labor are kept to a minimum. The dimensions of the rolls can be changed to match the installation requirements of the project.

6.3 Customizable Thickness, Width, and Roll Length Available Upon Request

In order to satisfy the variety of the engineering needs, geomembrana in hdpe may be custom-made in certain thicknesses, widths, and roll lengths so as to ensure the best use of the material and the least amount of waste from the installation.

6.4 Worldwide Shipping is Possible by Container or Bulk Delivery

BPM offers adaptable worldwide shipping methods including containerized and bulk delivery options that facilitate safe, timely, and economical transportation to project sites worldwide.

Summary

HDPE Geomembrane Liner is the perfect choice for waterproofing, environmental protection, and containment applications. Thanks to their excellent mechanical, chemical, and environmental resistance, they are ideal for projects like landfills, mining ponds, reservoirs, and civil engineering structures. The Best Project Material Co., Ltd. (BPM Geosynthetics) delivers factory-direct quality, international certifications, and technical support, thus making sure that your project reaches durable performance and safety compliance.