Geomembrana in HDPE

Geomembrana in HDPE is permeable resistant, long lasting sheet from high-density polyethylene (HDPE). The geomembrana resists chemicals very well and is also flexible and designed for long time performance, hence it is great choice for containment, waterproofing, and protective uses. Made in production from 100% virgin material under tight quality control, the product always maintains and guarantees thickness, strength, and reliability.

- Thickness Range: Generally 0.2 mm – 3.0 mm (8 mils – 120 mils) adapted to different project requirements.

- Width and Length: Standard rolls of up to 10 m wide and various lengths for convenient installation.

- Temperature Range: Can be used in a wide temperature range (-60°C to 90°C) without problems.

- Meetings: Conforms with environmentally friendly & performance requirements of international norms for geomembranes.

- Installation Advantages: Being lightweight, flexible, and easy to weld on-site, it minimizes work and installation time.

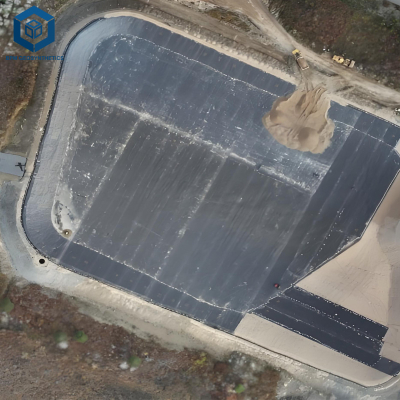

Geomembrana in HDPE is a very effective synthetic liner made from high-density polyethylene (HDPE). It is geared towards providing excellent impermeability, chemical resistance as well as long-lasting durability, thus it is a perfect solution for environmental protection, mining, water containment, and civil engineering projects.

We manufacture our geomembrane in HDPE entirely from virgin HDPE resin, thus the product is of steady quality, flexible, and has resistance to UV radiation. Every single roll is subjected to rigorous quality control wherein it is checked for tensile strength, puncture, elongation, and thickness consistency tests, in which the tests used are at a level of standard or beyond the international standards.

1. Geomembrana in HDPE Key Features and Benefits

1.1 High Impermeability

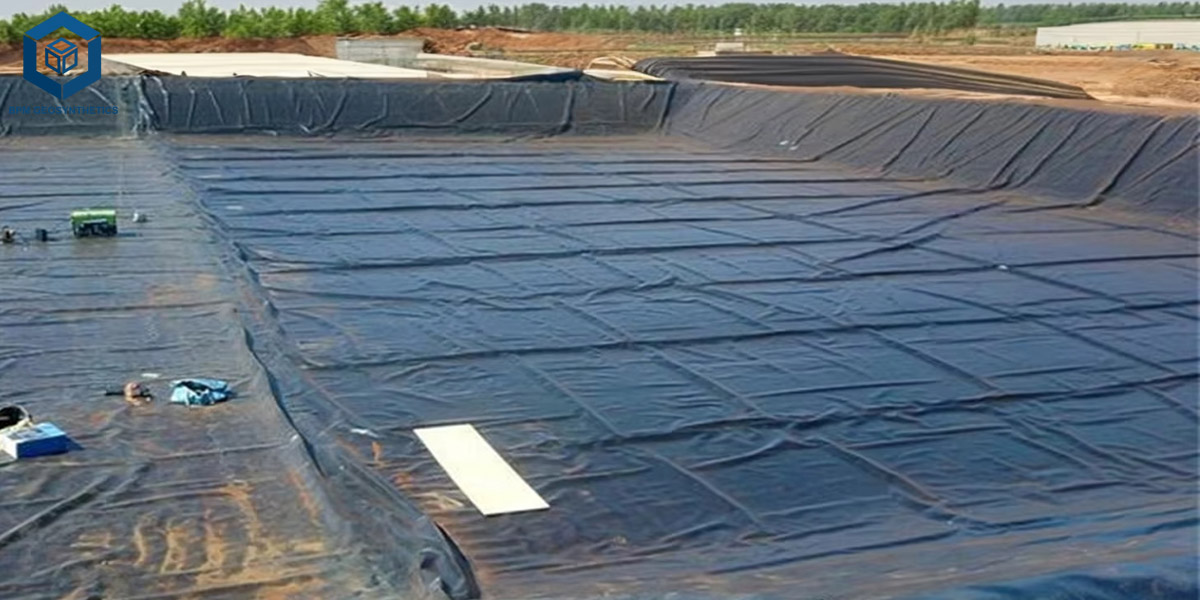

HDPE geomembrane offers a very high level of impermeability that goes a long way to preventing leakages and thus protecting both soil and groundwater from pollution. Due to this feature, the geomembrane product is highly recommended when used as landfill liners, water reservoirs, and chemical containment systems. By functioning as dependable barriers, the products will guarantee safety and environment protection for a long period of time, even for those projects that involve the containment of liquid or gaseous materials.

1.2 Chemical Resistance

The HDPE geomembrane we supply is very tough against acids, alkalis, salts and most of the industrial chemicals, therefore it is suitable for highly demanding mining, chemical storage, and hazardous waste containment applications. Thanks to this chemical resistance, the geomembrane liner will keep its shape and function for a long time even after chemical attacks, which in turn reduces the chances of the material breaking down and further environmental pollution.

1.3 UV Resistance

The hdpe membrane retains the strength and the flexibility after being continually exposed to the sun due to the fact that it is very good in resisting UV. The product thus prevents from cracking, losing of the initial character, and becoming over aged before time, hence the product performance will be trusted in outdoor installations such as reservoirs, canals or landfill covers. By being UV stabilized, the hdpe geomembrane liner will tolerate harsh weather conditions by keeping intact its properties.

1.4 Durability

HDPE geomembrane sheet is made to be highly durable; in fact, the duration of a normal-life-cycle can last more than 20–30 years. Thanks to its barrier to outside influences, resistance to punctures, and abrasion, it is quite rare for the product to fail and moreover no costly maintenance or replacement repairs will be required. Such an outstanding performance over a long period makes this product a financially viable and a reliable plan for civil, industrial, and environmental projects.

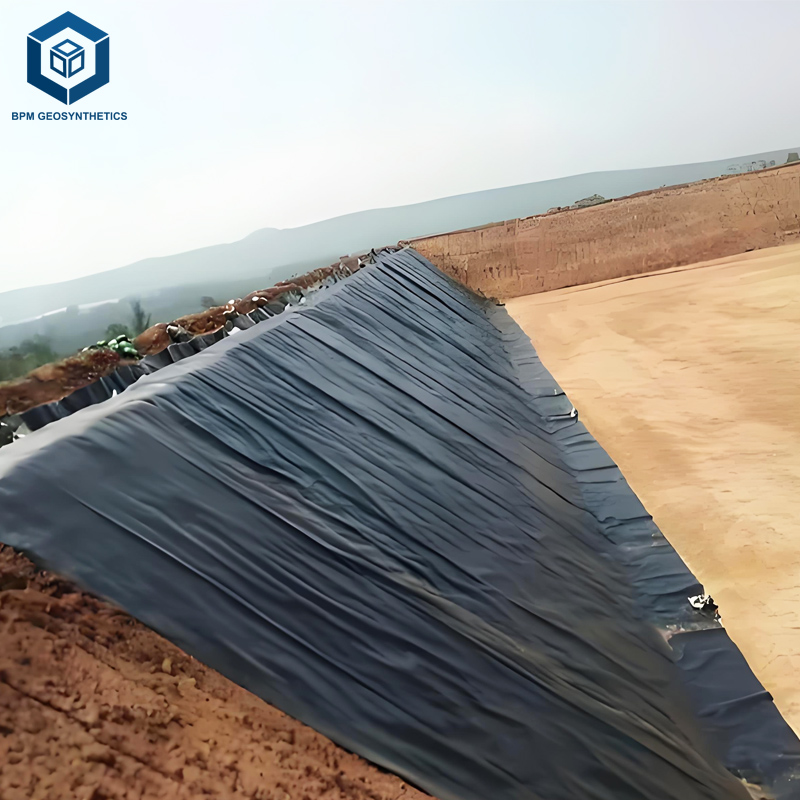

1.5 Flexibility

The capability the product has of bending easily without breaking is what helps it to change shape as per the ground slopes, surface irregularities, ponds and canals, etc. Hence, impermeable geomembrane can be welded or joined seamlessly, which makes it easy to cover large areas or difficult terrains. Such versatility of the product helps the installation of the product in various civil, mining, and hydraulic engineering projects smoothly and precisely and without compromising the quality.

1.6 Environmentally Friendly

Geomembrane sheet is crafted from 100% recyclable material. Additionally, it does not contain any harmful additives, thus offering an environmentally-friendly option. Its green characteristics make it a great fit for sustainable building, water resource management, and waste containment safety. By opting for this geomembrane liner, the endeavor can not only deliver the top-class results but also stay environmentally compliant.

2. Geomembrana in HDPE Product Advantages

2.1 Manufactured with Full Virgin HDPE Resin

Our product hdpe liner sheet is made from 100% virgin HDPE resin, assuring an excellent quality of raw materials that are reflected in the product's performance consistency. The use of first-grade raw materials exclusively resulted in the geomembrane's outstanding strength, high flexibility, and resistance to chemicals, which will be a guarantee of the product's long lifespan and reliability for multiple environmental, civil, and industrial cases.

2.2 Customizable Dimensions

To best match the diversity of project needs, our HDPE geomembrana can be customized in width, length, and thickness. Such flexibility gives the engineer and the project manager freedom to choose the optimal dimensions for their specific cases, whether that be huge water tanks, landfills, mining tailing ponds, or installations on uneven ground, thus ensuring an exact and efficient fit.

2.3 Consistent Thickness

Minimal variance in thickness characterizes each roll of hdpe impermeable liner and thus provides for safe installation and performance. The thickness uniformity removes the danger of leak occurrence and failure, so the layer is trustworthy to hold liquids, protect the slope, and perform other vital functions.

2.4 ISO 9001 Certified Production Process

Being ISO 9001 certified means that from the selection of raw materials to the inspection of the final product, strict quality control is observed at every phase. Through the awarding of this certificate, it is certain that the performance, durability, and safety standards of each roll conform to the internationally recognized ones thereby ensuring that the clients can have assurance in the quality and dependability of the material.

2.5 Professional Technical Support

From giving local guidance to performing on-site supervision – we cover every aspect of technical support for a project. Our very skilled engineers provide help with planning, welding, seaming, maintenance, etc., thus making certain that the installation is correct and the performance is the highest. This professional help leads to lower mistakes, decreased project risks, and the impermeable geomembrane liner's long-lasting ability and effectiveness.

3. Geomembrana in HDPE Ordering Process

3.1 Inquiry

The ordering process is initiated by the client's inquiry which should be detailed and should include the project specifications, such as the needed thickness, width, length, and use of the product. Most of the time, the details of a project are the key to the whole solution, so when you provide a very accurate specification, it is like the team can already see through the project in detail and the result will be a better-quality service at a reasonable cost.

3.2 Quotation

We send a competitive, clear, and detailed quote back as soon as we received your request. This includes prices, the time it will take to deliver the goods, as well as any add-on services that you might wish to consider, ultimately enabling you to take your decision with all the required information at hand. The offer does not contain any hidden charges and is therefore reliable for everyone, hence there is no doubt that good communication and trust are already established even at the very start of the process.

3.3 Sample Approval

Clients may request samples of HDPE geomembrane, which are given to them optionally, for the purpose of checking the quality. This way, project owners and engineers can (before ordering the full quantity) evaluate the product for such parameters as thickness, flexibility, overall quality, thus gaining confidence that the impermeable sheet is exactly what they need.

3.4 Production

Production goes into full gear once the order is confirmed and the contract signed. Every roll is custom-made strictly according to the customer's needs for thickness, width, length, and color. Our production line is very efficient to ensure not only quality but also compliance with international standards.

3.5 Quality Inspection

Each individual roll is thoroughly checked and tested for quality before it is dispatched. This is to ensure that features such as thickness, tensile strength, puncture resistance, and overall quality are of a very high standard. Hence, we really are giving the customers a high-quality, reliable product that will perform well.

3.6 Shipping

The finished hdpe membrane sheet rolls are basically ready for shipment after production, packaging, and storage. There are various modes of transportation available for the shipment, i.e., by sea, air, or land, and each can be chosen in accordance with the project requirement and location. Packaging and handling are done with utmost care so that the hdpe geomembrana is delivered in perfect condition and installation can directly commence.

4. Geomembrana in HDPE Customer Services

4.1 Technical Consultation

Our technical experts provide guidance and assistance to clients in selecting the best geomembrane for their projects. They also help clients to decide on the thickness, width, length, and method of installation based on the project requirements. By collaborating with our team, our customers can count on solutions that suit their needs in terms of performance and cost, thus minimizing errors and increasing overall project efficiency.

4.2 Custom Manufacturing

If your project is somewhat different, no problem, we can custom-make the high density polyethylene geomembrane rolls just for you. You tell us your desired dimensions, thicknesses, and colors, and we make the rolls accordingly. By doing this, your project will have a perfect coverage, the product will have the peak performance for the purpose, and the aesthetic requirements will be met without compromising on the quality and durability of the products we manufacture.

4.3 Installation Support

In order to guarantee the successful installation of the membrane HDPE, our highly skilled team is always ready to provide you with installation support of the highest quality. We are more than just a geomembrane supplier - we are your installation partner, helping you every step of the way through heat-welding, extrusion welding, seaming, and anchoring. Our on-site assistance will certainly help you avoid the most common installation mistakes, create leak-proof lap joints, and increase the service life of your geomembrane.

4.4 Delivery & Logistics

We understand well that timely and safe delivery of geo membranes rolls rightly forms the basis of the success in a project. We will take utmost care of the products prior to transit so as to ensure no damage occurs and the products are delivered in perfect condition. Besides that, we offer flexible shipment options, including sea, air, and land transportation, to suit your convenience. Thus, your project will be able to adhere to the scheduled timeline and you will not have to worry about any delays due to material handling.

4.5 After-Sales Support

Our service does not stop at delivering a product to the client. We are always here to provide full after-sales support to our clients. We offer guidance on how to keep using the product, how to take care of it, and what to do in case of problems. We want to make sure the work gets done without a hitch and the geo membrane sheet always performs well during its entire service life.

5. Geomembrana in HDPE Frequently Asked Questions (FAQ)

5.1 What is the expected service life of geomembrana in HDPE?

BPM geomembrane is designed with longevity in mind and so it can last for two to three decades or even longer if the environmental conditions are quite normal. The lifespan can be shortened or lengthened depending on how the material is exposed to UV rays, chemicals, mechanical forces, and how well it has been installed, respectively. To get the maximum life out of your polyethylene geomembrane, installation, maintenance, and protection are all very important.

5.2 Can geomembrana in HDPE be used in very cold or very hot conditions?

The answer is yes. HDPE geomembrane can be used over a very wide range of temperatures, generally from -60°C to +80°C (-76°F to +176°F). It is able to keep its flexibility and strength under both cold and warm conditions, which is why it is a perfect material for desert/arctic/industrial applications with frequent temperature changes.

5.3 What are the methods of installation and joining of the geomembrana in HDPE?

The joining of HDPE geomembranes to achieve a leak-proof barrier is typically done using heat welding or extrusion welding methods. The rolls are carefully unrolled and anchored before the overlap areas are welded to ensure that the barrier along the entire surface is continuous. Our technical support team is always ready to assist you with proper installation procedures such as surface preparation, welding temperature, and seam inspection.

5.4 Does geomembrana in HDPE have a negative impact on the environment?

Of course not. HDPE geomembrane is produced from 100% virgin, recyclable polyethylene and does not contain any hazardous additives. Consequently, it is extensively utilized in landfills, water reservoirs, and industrial containment facilities to prevent the pollution of soil and water, thus supporting environmentally friendly and sustainable construction methods.

5.5 What measures can I take to ensure the proper maintenance of the geomembrana in HDPE?

It is a must to carry out regular inspection and maintenance. Looking for punctures, checking the seams, and monitoring any signs of UV degradation are some of the routine checks that should be done, especially after extreme weather conditions. Minor damages must be repaired immediately with the use of approved methods for welding or patching. You may refer to our technical team for a detailed maintenance manual to help you extend the geomembrane's life.

5.6 Can you describe the after-sales support provided?

We offer comprehensive after-sales services, such as installation instruction, troubleshooting, advice on maintenance, and warranty support, to name a few. Our staff is always ready to answer your questions, help with problem-solving, and guarantee that HDPE geomembrane will keep performing at its best during its lifetime.

Conclusion

Due to its impermeability, chemical resistance, durability, and flexibility, the geomembrana in HDPE is an excellent product for environmental protection, water containment, mining, and civil engineering projects. By offering customizable sizes, rigorous quality control, and expert technical support, the product guarantees dependable and long-lasting performance. If you want to have the best quality products and be worry-free, then we strongly recommend The Best Project Material Co., Ltd.(BPM Geosynthetics)geomembrana in HDPE - the best partner you can rely on for high performance and eco-friendly solutions.