High Density Polyethylene Geomembrane

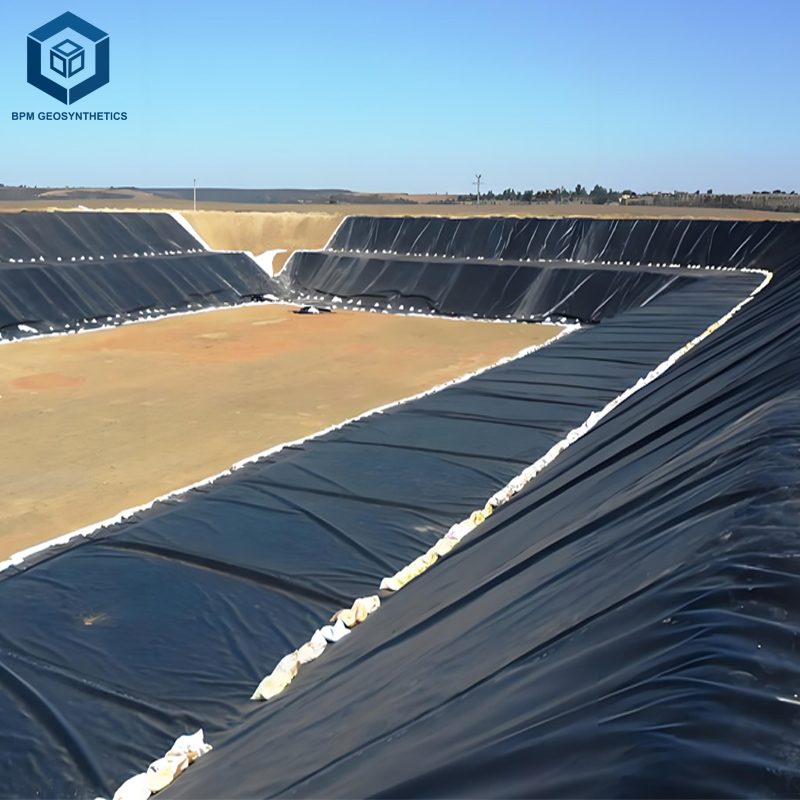

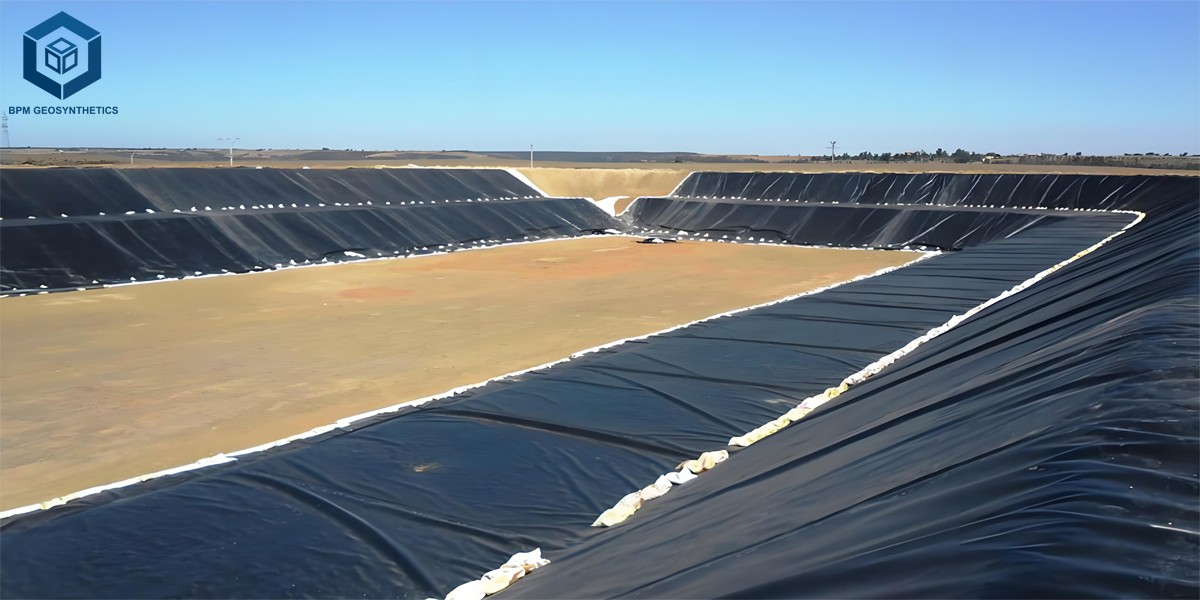

High density polyethylene geomembrane is a robust and versatile synthetic liner used in a differ of applications, consisting of water containment, waste management, and environmental protection. It is viewed for its pinnacle notch chemical resistance, durability, and impermeability, making it an brilliant want for many engineering projects.

- Chemical Resistance: Effectively withstands a big range of chemical factors and hazardous materials.

- UV Stability: Resistant to ultraviolet radiation, prolonging the lifespan of the membrane.

- Cost-Effective: Offers a steadiness of everyday primary universal overall performance and affordability, lowering common project costs.

- Environmental Protection: Prevents pollution of soil and groundwater, merchandising sustainability.

High density polyethylene geomembrane is a pretty lengthy lasting and versatile synthetic liner that performs a crucial role in a quantity applications, which encompass landfill projects, water reservoirs, and environmental containment systems. Constructed from high-density polyethylene, this geomembrane is engineered to grant first-rate resistance to a extensive fluctuate of chemicals, making it gorgeous for every industrial and agricultural uses. Its incredible functionality to face up to UV radiation ensures that it continues its integrity and average overall performance even under prolonged publicity to sunlight, which is essential for outdoor applications.

The puncture resistance of high density polyethylene geomembrane is essential for resisting physical damage in certain factors during installation and service life. Its anti-seepage performance effectively prevents the leakage of water and pollutants, protects the surrounding environment, and contributes to environmental protection work. Overall, high density polyethylene geomembrane stands out as a imperative problem in sustainable engineering practices, providing reliable typical overall performance that helps a vary of environmental protection initiatives while making positive the long-term steadiness and reliability of containment systems.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | D1505/D792 | 90.000kg | 0.94g/cc | ||||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 5 3 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

High Density Polyethylene Geomembrane Features

1. Chemical resistance: High density polyethylene geomembrane can resist various chemicals, as well as acids, alkalis, and herbal solvents, making it a top material in landfills and industrial waste control.

2. UV stability: The formula of this high density polyethylene geomembrane can resist the degradation of ultraviolet (UV) radiation, ensuring its lifespan and durability in outdoor environments with severe sunlight exposure.

3. Anti puncture and tear : The sturdy material of high density polyethylene geomembrane provides the highest resistance to notch puncture and tear, enabling it to successfully withstand harsh regulations and minimize the risk of injury in certain aspects of installation and use.

4. Impermeability : It has the most super impermeable characteristic, effectively preventing water and pollutants from penetrating into the material, which is a typical feature of protecting soil and groundwater.

5. Lightweight and flexible: The lightweight characteristics of high density polyethylene geomembrane make them easy to handle and install, while their flexibility allows them to adapt to various ground contours and shapes.

6. Cost effectiveness: High density polyethylene geomembrane provides an economical solution to curb projects, reducing daily expenses through its durability, low storage requirements, and extended tissue life.

7. Environmental Protection : By preventing the leakage of harmful substances, this high density polyethylene geomembrane performs excellently in environmental protection, making it fully compliant with legal regulations for sustainability.

8. Easy to install : The material can be welded or connected for quick installation, which is crucial for meeting the task schedule.

These factors simultaneously enhance the normal overall performance and reliability of high density polyethylene geomembrane, which are widely and regularly used in engineering and environmental applications.

Applications of High Density Polyethylene Geomembrane

1. Landfill liner : High density polyethylene geomembrane is broadly used as a liner for landfills to stop leachate from contaminating the surrounding soil and groundwater, making sure environmental safety and compliance with regulations.

2. Reservoirs: They play an impermeable lining position in water storage and reservoirs, stopping water loss thru leakage and preserving splendid water exceptional by means of isolating from pollutants.

3. Mining operations: High density polyethylene geomembranes are used in tailings storage amenities and heap leaching mats to comprise poisonous elements and stop environmental pollution.

4. Agricultural applications: These high density polyethylene geomembranes are used for agricultural pond and irrigation building to restrict water loss and manipulate wastewater, contributing to environmentally pleasant water aid management.

5. Environmental remediation : High density polyethylene geomembrane is used for remediation work to incorporate hazardous waste and to end the unfold of pollution in the course of cleansing operations.

6. Aquaculture: They are used for fish farming and aquaculture to create lined ponds and water tanks that provide a reliable management environment for the survival of aquatic organisms even in the event of environmental pollution.

7. Rainwater administration : High density polyethylene geomembrane is used for rainwater retention and retention in structures to manipulate runoff and flood control, and enhance city drainage solutions.

8. Civil engineering tasks : They are integral in a range of civil engineering projects, such as avenue and bridge construction, which require impermeable boundaries to manipulate water float and defend infrastructure.

These points spotlight the multifunctionality and effectiveness of high-density polyethylene geomembranes in addressing big fluctuations in environmental and engineering challenges.

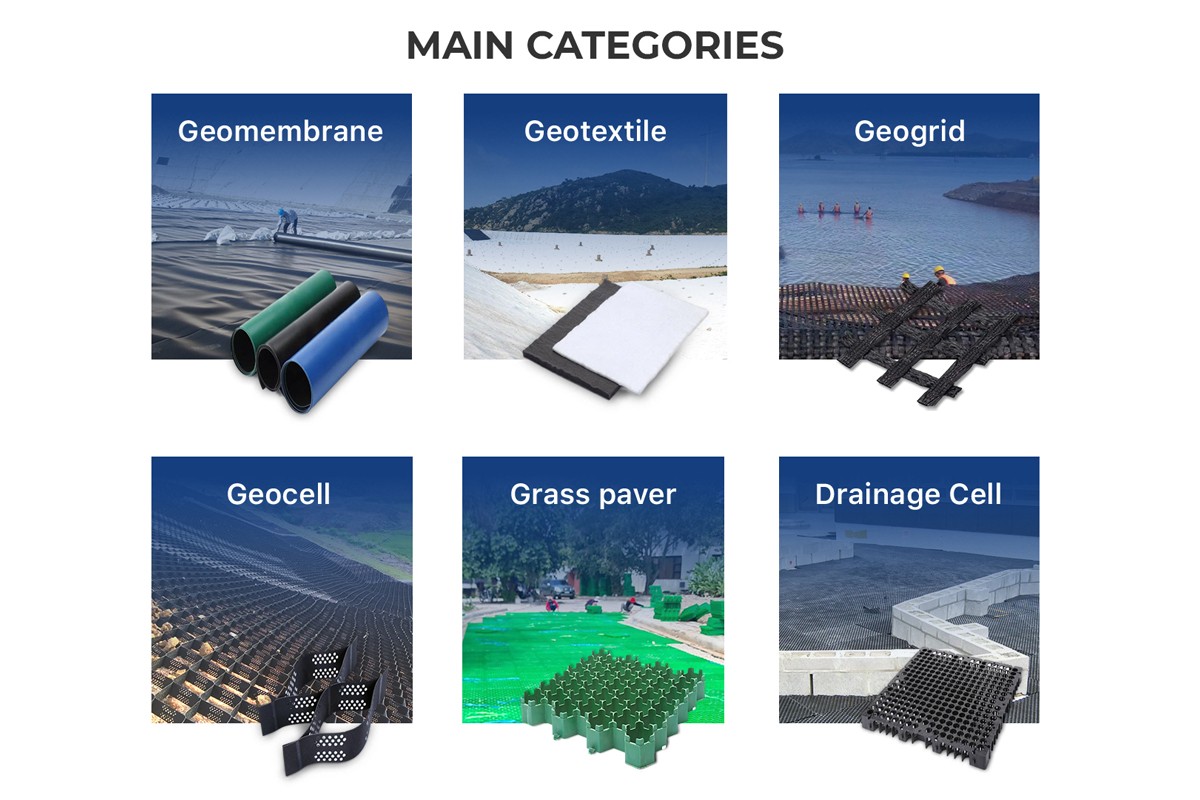

Company Profile

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, geogrids, geocells, and geosynthetic clay liners (GCL). Our products, certified by EU CE and GLP, have passed ISO 9001, ISO 14001, and OHSAS 18001 standards, and are recognized for their quality, performance, and durability.

BPM GEOSYNTHETICS has been committed to providing one-stop services for global customers in the research and development, production, sales, and export of geosynthetic materials since its establishment in 2007. The company has 120 senior technical talents specializing in geotechnical materials. The manufacturing factory covers an area of over 36000 square meters and is equipped with industry-leading automated production equipment and professional testing instruments. Product innovation, quality assurance, and customer satisfaction have always been BPM commitment to partners.

We're committed to innovation and quality, offering flexible cooperation and the best solutions for engineering projects worldwide. Our products are utilized in various sectors like aquaculture, erosion control, drainage systems, municipal engineering, mining, and landscaping. We look forward to partnering with you to solve complex challenges with our high-performance geosynthetic products.