PE Geomembrane

PE Geomembrane is a flexible, impermeable artificial liner made from polyethylene, designed to grant long-lasting containment in a extensive vary of environmental and civil engineering projects. Whether used for water storage, waste management, or mining, BPM’s PE Geomembrane provides extraordinary overall performance and protection.

- High Impermeability: Excellent barrier towards liquids, gases, and chemicals

- UV & Chemical Resistance: Withstands harsh climate and aggressive substances

- Flexible and Durable: Maintains power beneath stress, deformation, and settlement

- Wide Thickness Range: Available from 0.2mm to 3.0mm to swimsuit numerous needs

- Smooth or Textured Surface: For more suitable friction or welding requirements

- Easy Installation: Compatible with thermal welding and customized panel fabrication

PE Geomembrane is a flexible, impermeable artificial liner made from incredible polyethylene (PE) resin. Known for its awesome chemical stability, durability, and waterproofing properties, PE is broadly used as a dependable cloth for containment options in a number of engineering fields.

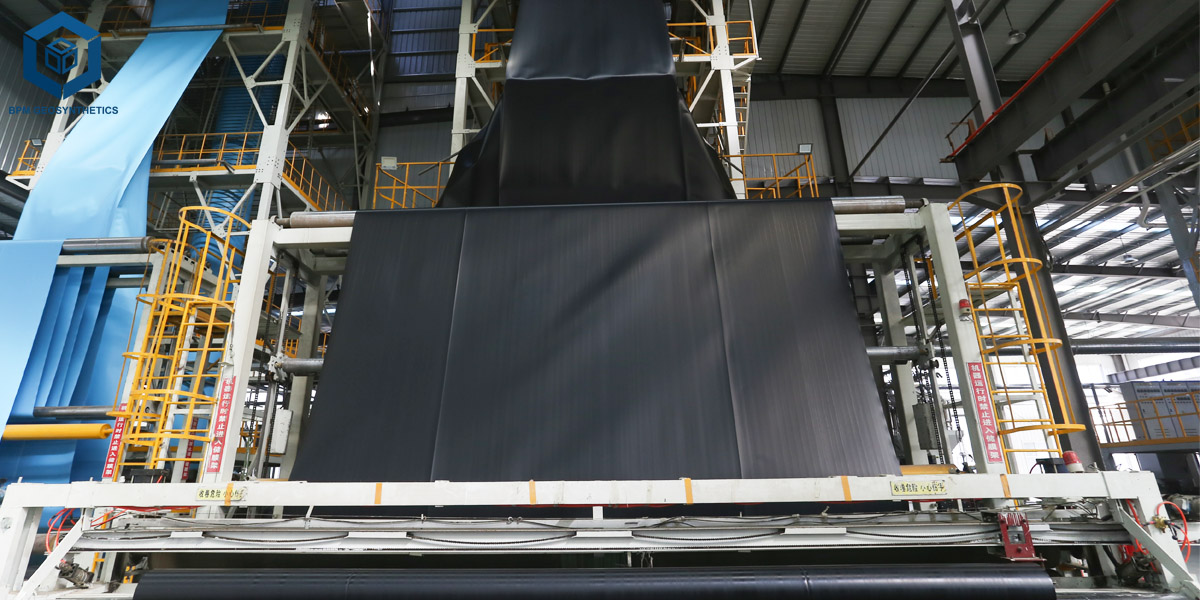

Produced thru superior extrusion or blow molding processes, PE geomembrane supply most appropriate chemical resistance, UV protection, and mechanical strength, making them best for each above-ground and below-ground applications. They are in many instances used in environmental protection, civil construction, agriculture, mining, and industrial initiatives to stop seepage, defend soil and water, and beautify normal machine integrity.

1. PE Geomembrane – Key Features & Advantages

PE Geomembrane gives a vary of high-performance elements that make it an perfect answer for a huge range of containment and environmental safety applications. Manufactured with precision and fantastic control, BPM PE geomembrane supply reliable, long-term overall performance below worrying website conditions.

1.1 PE Geomembrane Excellent Impermeability

PE geomembranes structure a extraordinarily superb barrier towards liquids, gases, and vapors, stopping seepage and leakage into surrounding soil and groundwater. This impermeable layer is critical for purposes such as landfills, ponds, reservoirs, and waste lagoons, the place containment of water or hazardous supplies is critical.

1.2 PE Geomembrane UV and Weather Resistant

Engineered for outside use, PE geomembranes are stabilized with UV-resistant components that guard in opposition to degradation triggered via extended solar exposure, ozone, temperature fluctuations, and intense weather. They keep their integrity and overall performance even in warm barren region environments or bloodless alpine conditions.

1.3 PE Geomembrane High Chemical Resistance

PE well-knownshows extraordinary resistance to a huge vary of acids, alkalis, salts, and natural compounds. This makes it in particular appropriate for use in chemically aggressive environments such as industrial waste containment, mining leachate ponds, and chemical processing facilities.

1.4 PE Geomembrane Tensile Strength and Puncture Resistance

PE geomembranes are designed to suffer excessive mechanical stress, along with tensile loading, impact, and puncture from sharp or angular substrates. This electricity ensures structural balance at some stage in set up and for the duration of their provider life, even beneath heavy masses and agreement conditions.

1.5 PE Geomembrane Smooth and Textured Surface Options

Available in each smooth and textured finishes, PE geomembranes can be chosen to suit precise challenge needs. Textured geomembranes beautify frictional resistance when used on steep slopes or embankments, enhancing balance and stopping slippage between layers.

1.6 PE Geomembrane Environmentally Safe

Made from non-toxic, inert polyethylene resin, PE geomembranes are protected for use in environmental and agricultural applications. They do now not leach unsafe elements and are appropriate for lining potable water reservoirs, fish ponds, and irrigation canals except impacting water fine or ecosystems.

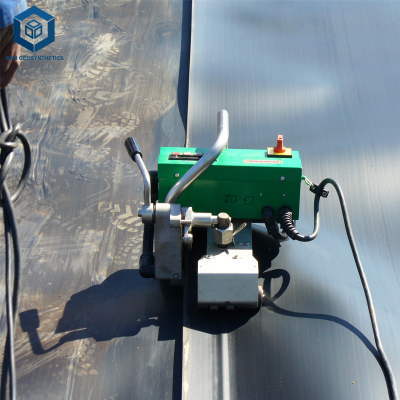

1.7 PE Geomembrane Easy to Weld and Install

PE geomembranes are like minded with all fashionable thermal welding techniques, consisting of warm wedge, warm air, and extrusion welding. This makes on-site seaming environment friendly and reliable. BPM additionally affords prefabricated panels to limit subject welding and pace up installation.

1.8 PE Geomembrane Wide Thickness Range

BPM PE geomembranes are handy in a vary of thicknesses from 0.2 mm to three mm, supplying flexibility for light-duty to heavy-duty applications. Thinner membranes are perfect for transient covers or smaller water features, whilst thicker membranes grant strong protection in stressful infrastructure projects.

1.9 PE Geomembrane Long Service Life

With acceptable set up and minimal maintenance, PE geomembranes are designed to operate successfully for over 30 years, even when uncovered to harsh environmental or chemical conditions. This long-term sturdiness helps minimize lifecycle charges and ensures dependable overall performance over time.

2. PE Geomembrane Available Specifications

| Parameter | Range |

Thickness | 0.2 mm – 3.0 mm |

Width | Up to 10 meters (customizable) |

Length | Up to 100 meters per roll (depends on thickness) |

Color | Black (standard), White, Green, or custom |

Surface Type | Smooth / Single-side textured / Double-side textured |

Material Types | HDPE, LDPE, LLDPE |

All BPM PE geomembrane conform to international standards such as ASTM D7495, GM13, and ISO 9001.

3. PE Geomembrane Material Types Explained – Why Choose HDPE Geomembrane?

When choosing a PE geomembrane, perception the variations between HDPE, LDPE, and LLDPE substances is crucial. Each kind provides special bodily homes that go well with precise applications, however HDPE (High-Density Polyethylene) stands out as the most extensively used and depended on cloth for large-scale, long-term containment solutions.

3.1 HDPE Geomembrane – High-Density Polyethylene PE Geomembrane

HDPE Geomembrane is the enterprise fashionable for necessary containment functions thanks to its first-rate chemical resistance, UV stability, and mechanical strength. Its excessive molecular density offers it a rigid, challenging structure, making it perfect for harsh environments and long-term projects.

3.1.1 Key Advantages:

- Superior Chemical Resistance: Resists acids, alkalis, hydrocarbons, and industrial waste, making it best for landfills, chemical plants, and mining leach pads.

- Excellent UV Resistance: Withstands long-term publicity to daylight except degradation, best for uncovered installations.

- High Tensile & Puncture Strength: Maintains structural integrity beneath heavy loads, differential settlement, and sharp substrates.

- Long Lifespan: Proven overall performance of 30+ years, even in uncovered or chemically aggressive environments.

- Cost-Effective for Large Projects: Lower fee per unit region due to sturdiness and minimal preservation needs.

3.1.2 HDPE geomembrane Best for:

HDPE geomembrane is first-rate suitable for annoying purposes such as landfills, mining operations (including heap leach pads and tailings dams), industrial waste containment, reservoirs, canals, and oil and fuel containment basins, the place long-term sturdiness and excessive chemical resistance are essential.

3.2 LDPE Geomembrane – Low-Density Polyethylene PE Geomembrane

LDPE Geomembrane is greater bendy than HDPE and gives less complicated handling, in particular in tight or irregular spaces. However, it has lower tensile power and decreased chemical and UV resistance, making it higher appropriate for light-duty or momentary applications.

Key Traits:

LDPE geomembrane is characterised by means of its low-density molecular structure, which makes it notably greater bendy and less difficult to fold or form in contrast to HDPE. This flexibility approves for quicker set up in restricted or irregular areas and reduces the hazard of cracking at some stage in placement. LDPE gives reasonable impermeability and mechanical strength, making it appropriate for purposes that do no longer contain excessive structural stress or chemical exposure. However, due to its decrease tensile power and decreased resistance to UV radiation and aggressive chemicals, LDPE geomembrane is high-quality used in temporary or light-duty applications—such as ornamental ponds, landscaping, transient containment covers, and small-scale liners—where ease of dealing with is prioritized over long-term durability. It is commonly now not endorsed for use in fundamental containment structures requiring prolonged provider existence or publicity to harsh environmental conditions.

3.3 LLDPE Geomembrane – Linear Low-Density Polyethylene PE Geomembrane

LLDPE Geomembrane gives a stability between flexibility and strength. It has higher elongation than HDPE, making it appropriate for purposes the place floor motion or contract is expected. However, it commonly presents decrease UV and chemical resistance than HDPE and is now not best for extraordinarily aggressive environments.

Key Traits:

LLDPE geomembrane is recognised for its great flexibility and excessive elongation properties, making it an brilliant preference for tasks involving uneven terrain or subgrades inclined to settlement. Its adaptability approves it to conform without difficulty to complicated surfaces, decreasing stress concentrations and the chance of injury throughout or after installation. While it gives average resistance to weathering and chemical exposure—slightly decrease than that of HDPE—it performs reliably in a range of environments. LLDPE is best for purposes such as canals, irrigation ponds, floating covers, agricultural water containment, and aquaculture facilities, the place floor motion is predicted and flexibility is crucial to long-term performance.

While LDPE and LLDPE have their niches, HDPE geomembrane is the most reliable solution for critical, high-risk containment. Its unmatched durability, chemical resistance, and longevity make it the top choice for engineers, contractors, and environmental professionals worldwide.

4. PE Geomembrane Typical Applications

4.1 PE Geomembrane for Landfills

Used as base liners to stop leachate seepage into the ground, capping layers for closure systems, and leachate containment boundaries to manipulate and isolate hazardous waste and liquid by-products.

4.2 PE Geomembrane for Mining

Essential for heap leach pads that extract precious metals, tailings dams to safely save mining residues, and evaporation ponds for the managed evaporation of system water and chemicals.

4.3 PE Geomembrane for Ponds & Lakes

Applied in aquaculture ponds to preserve water quality, ornamental ponds for panorama aesthetics, and stormwater basins to manipulate runoff and decrease flood risks.

4.4 PE Geomembrane for Agriculture

Utilized in irrigation canals to decrease water loss, reservoirs for long-term water storage, and manure lagoons for secure containment of animal waste and natural by-products.

4.5 PE Geomembrane for Water Treatment

Lined in wastewater cure plant life for impenetrable containment, and in chemical containment basins to stop environmental infection from industrial effluents.

4.6 PE Geomembrane for Energy Projects

Deployed in biogas digesters for gas-tight sealing, photo voltaic pond liners for thermal strength collection, and coal ash containment structures to stop the launch of poisonous by-products.

4.7 PE Geomembrane for Tunnel and Foundation Waterproofing

Used as anti-seepage barrier structures under tunnels, basements, and constructing foundations to guard in opposition to groundwater infiltration and make sure structural integrity.

5. About BPM Geosynthetics

With over 20 years of trip in geosynthetics manufacturing, BPM Geosynthetics has set up itself as a dependable and expert provider of geomembrane liner and a huge vary of geotechnical materials, along with geotextile, geogrid, geocell, GCL, and drainage composite.

Our current manufacturing facility is geared up with superior computerized machinery, enabling high-efficiency output and constant product quality. All merchandise are manufactured underneath strict first-class administration structures and validated via our in-house trying out laboratory, making sure compliance with worldwide requirements such as ISO 9001, CE, and GRI-GM13.

BPM’s sturdy world logistics community and skilled export crew enable us to supply substances shortly and reliably to tasks in over one hundred nations throughout six continents. We help customers with technical consultation, product customization, and on-site set up guidance, making us a depended on companion for environmental, mining, civil engineering, and agricultural tasks worldwide.