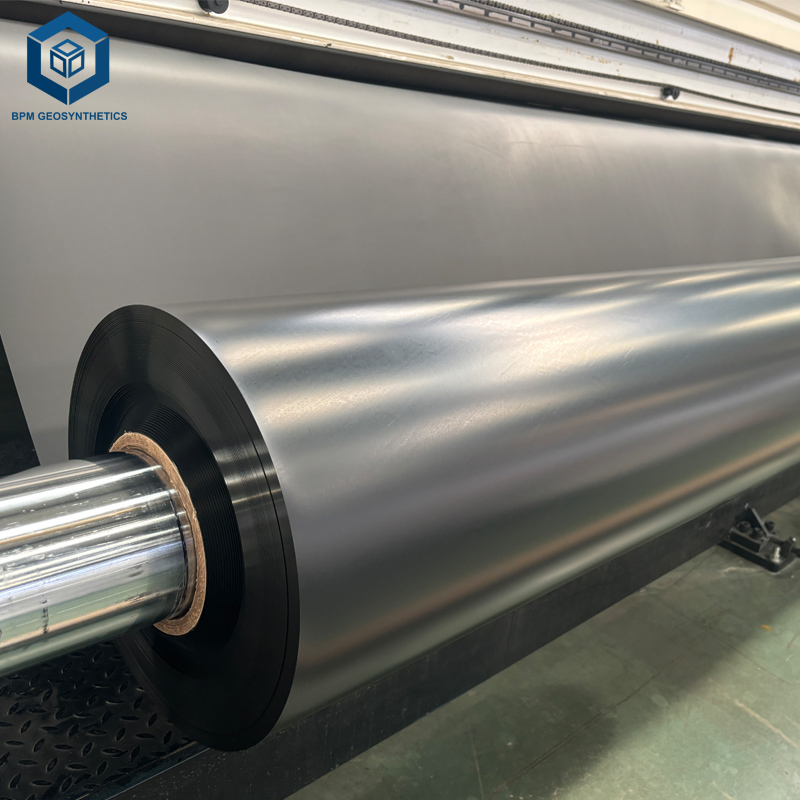

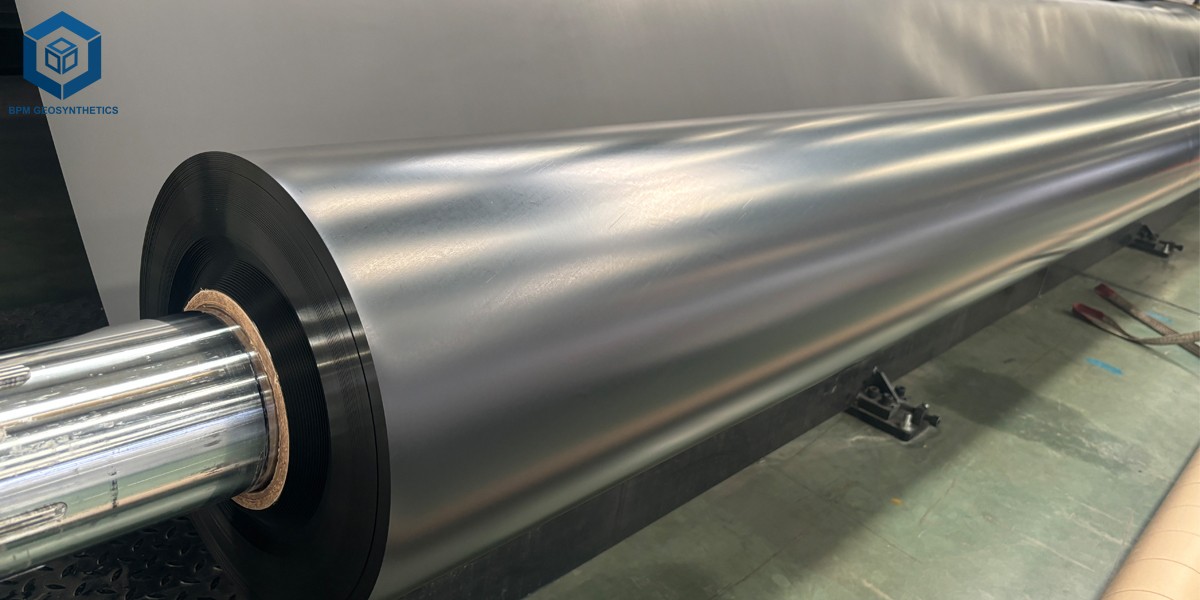

HDPE Geomembrane Sheet Price

HDPE geomembrane sheet price is versatile and long lasting water-resistant limitations used in a variety of applications, along with landfill liners, pond liners, and environmental containment. Known for their amazing chemical resistance and strength, these HDPE sheets provide an nice answer for stopping water and chemical leakage.

-Excellent Chemical Resistance: Withstand a extensive vary of chemicals, making them perfect for waste containment and chemical storage.

-High Strength: Designed to face up to heavy hundreds and severe climate conditions, making sure long-lasting performance.

-Superior Waterproofing: Supply wonderful waterproofing, defending the surroundings and groundwater from contamination.

Choosing HDPE geomembrane sheets ensures a dependable and environment friendly answer for your containment needs.

HDPE geomembrane sheet price are critical substances in a range of applications, specifically in environmental protection, civil engineering, and waste management. These HDPE geomembrane sheets are manufactured from exceptional polyethylene resin, which gives top notch chemical resistance, UV stability, and durability. HDPE geomembrane sheets are generally handy in a range of thicknesses, ranging from 0.2 mm to 3 mm, permitting for customization based totally on precise undertaking requirements. Their foremost feature is to act as a water resistant barrier, efficiently stopping the migration of liquids, such as water and hazardous chemicals, into surrounding soil and groundwater. This makes them best for use in landfill liners, pond liners, and containment structures for industrial waste. Additionally, HDPE geomembrane sheets are light-weight and flexible, facilitating effortless transportation and set up thru methods like fusion welding. Their dazzling tensile energy ensures they can face up to heavy hundreds and harsh environmental conditions, presenting long-lasting performance. As a sustainable option, HDPE geomembrane sheets are additionally recyclable, contributing to eco-friendly practices in development and environmental management. Overall, these sheets are a dependable desire for initiatives requiring fine containment options and environmental protection.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | D1505/D792 | 90.000kg | 0.94g/cc | ||||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 5 3 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

HDPE Geomembrane Sheet Price Features

1. Chemical Resistance: HDPE geomembrane sheet showcase fantastic resistance to a vast vary of chemicals, such as acids, bases, and solvents. This makes them appropriate for functions involving hazardous waste containment and chemical storage.

2. Durability: These HDPE sheets are designed to stand up to harsh environmental conditions, together with excessive temperatures and UV exposure. Their strong development ensures long-term overall performance and reliability.

3. Waterproofing Capabilities: HDPE geomembrane sheets furnish optimum waterproofing, efficaciously stopping water infiltration and defending the surrounding environment from contamination. This characteristic is indispensable for functions such as landfill liners and pond liners.

4. High Tensile Strength: The excessive tensile power of HDPE geomembrane sheets approves them to face up to deformation and hold integrity below heavy loads. This attribute is indispensable for making sure steadiness in a number of applications.

5. Lightweight and Flexible: HDPE geomembrane sheets are lightweight, making them convenient to transport and install. Their flexibility permits for adaptation to a variety of surfaces and shapes, facilitating environment friendly set up processes.

6. Ease of Installation: Installation techniques such as fusion welding and mechanical fastening make it simple to set up HDPE geomembrane sheets, lowering labor charges and assignment timelines.

7. Eco-Friendly: Being recyclable, HDPE geomembrane sheets make contributions to sustainable practices in building and waste management, minimizing their environmental footprint.

8. Cost-Effectiveness: The lengthy lifespan and low protection necessities of HDPE geomembrane sheets make them a reasonably priced answer for a number of projects, offering super price over time.

These points together make HDPE geomembrane sheet prices a favored desire for many industries requiring positive containment and environmental safety solutions.

Applications of HDPE Geomembrane Sheet Price

1. Landfill Liners: HDPE geomembrane sheets are generally used as liners in landfills to forestall leachate from contaminating the surrounding soil and groundwater. Their impermeability ensures that poisonous substances are contained.

2. Pond Liners: These HDPE geomembrane sheet serve as nice liners for ponds and reservoirs, stopping water loss due to seepage and defending the water exceptional from exterior contaminants.

3. Wastewater Treatment: In wastewater cure plants, HDPE geomembrane sheets are used to line lagoons and basins, offering a barrier that prevents the get away of hazardous supplies whilst facilitating environment friendly remedy processes.

4. Agricultural Applications: HDPE geomembrane sheets are utilized in agricultural settings for irrigation ponds, water storage, and as liners for aquaculture systems, making sure water retention and quality.

5. Mining Operations: In the mining industry, these HDPE geomembrane sheets are employed in tailings ponds and heap leach pads to incorporate hazardous substances and forestall environmental pollution.

6. Chemical Storage: HDPE geomembrane sheets are perfect for lining storage tanks and containment areas for chemicals, making sure protection and compliance with environmental regulations.

7. Green Roof Systems: In inexperienced constructing applications, HDPE geomembrane sheets are used in inexperienced roofs to supply waterproofing whilst permitting for drainage and water retention for plant growth.

8. Environmental Remediation: HDPE geomembrane sheets play a quintessential function in environmental remediation projects, assisting to isolate contaminated web sites and forestall similarly pollution.

These numerous functions spotlight the versatility and effectiveness of HDPE geomembrane sheets in imparting dependable containment and environmental safety throughout a variety of industries.

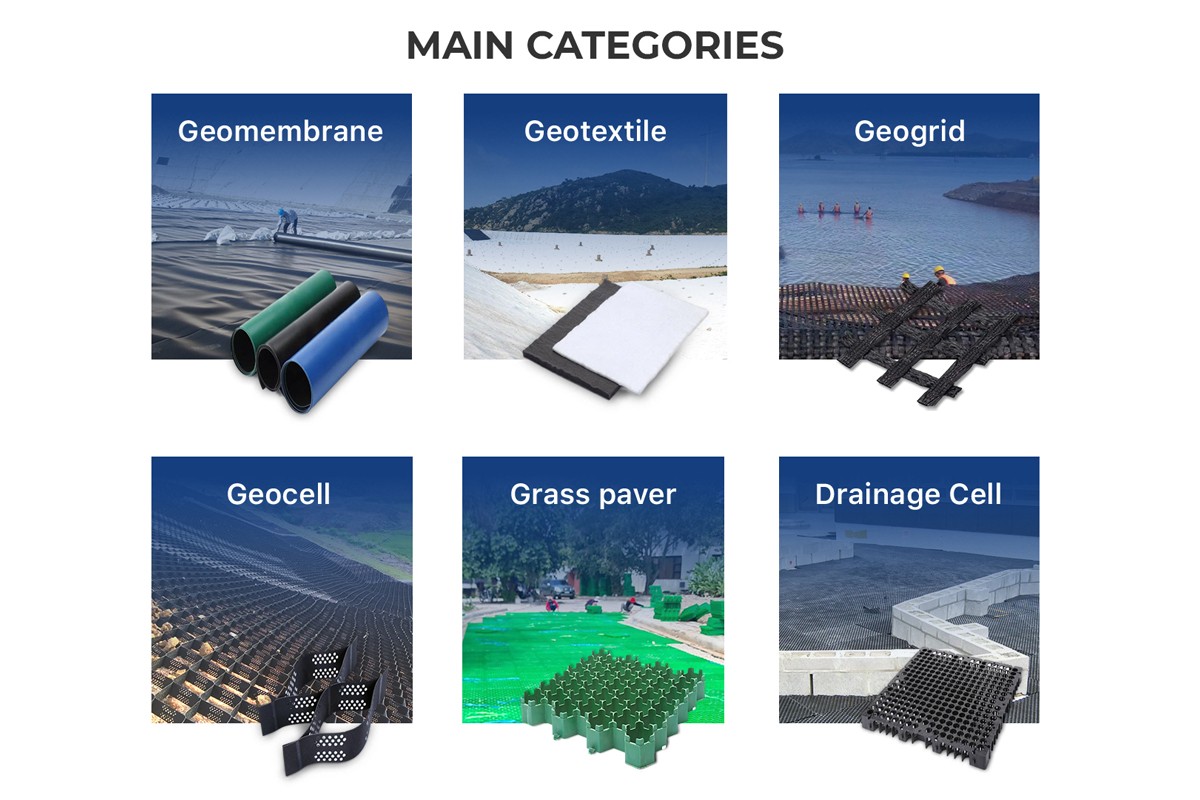

Company Profile

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, geogrids, geocells, and geosynthetic clay liners (GCL). Our products, certified by EU CE and GLP, have passed ISO 9001, ISO 14001, and OHSAS 18001 standards, and are recognized for their quality, performance, and durability.

BPM GEOSYNTHETICS has been committed to providing one-stop services for global customers in the research and development, production, sales, and export of geosynthetic materials since its establishment in 2007. The company has 120 senior technical talents specializing in geotechnical materials. The manufacturing factory covers an area of over 36000 square meters and is equipped with industry-leading automated production equipment and professional testing instruments. Product innovation, quality assurance, and customer satisfaction have always been BPM commitment to partners.

We're committed to innovation and quality, offering flexible cooperation and the best solutions for engineering projects worldwide. Our products are utilized in various sectors like aquaculture, erosion control, drainage systems, municipal engineering, mining, and landscaping. We look forward to partnering with you to solve complex challenges with our high-performance geosynthetic products.