LLDPE Pond Liner

With increasing global awareness of water conservation, aquaculture development, and environmental protection, the demand for LLDPE pond liner solutions has surged across multiple industries. From agricultural reservoirs and fish ponds to mining tailing storage and industrial wastewater containment, LLDPE liners provide long-term impermeability, durability, and environmental safety.

Introduction: Why LLDPE Pond Liners Dominate Modern Containment Projects

With increasing global awareness of water conservation, aquaculture development, and environmental protection, the demand for LLDPE pond liner solutions has surged across multiple industries. From agricultural reservoirs and fish ponds to mining tailing storage and industrial wastewater containment, LLDPE liners provide long-term impermeability, durability, and environmental safety.

Recent reports show the geomembrane market, especially LLDPE pond liner materials, is growing at 6%–7% CAGR from 2024 to 2030. The shift from traditional clay or concrete containment systems toward flexible geomembranes is driven by reduced installation costs, high chemical resistance, and optimized field performance in harsh conditions.

What Is an LLDPE Pond Liner?

LLDPE pond liner is a flexible geomembrane manufactured from Linear Low-Density Polyethylene. Its molecular structure offers exceptional elongation, toughness, and crack resistance. Compared with HDPE liners, LLDPE provides greater flexibility, making it easier to install in irregular ponds, slopes, or complex containment structures.

Key Functions

Leak prevention

Water conservation

Chemical and UV resistance

Terrain adaptability

Long-term environmental protection

Because of its excellent balance between strength and flexibility, LLDPE pond liner is widely used in aquaculture, stormwater basins, decorative landscaping ponds, mining, and industrial containment.

Technical Specifications of LLDPE Pond Liners

International buyers typically request the following performance parameters when sourcing LLDPE pond liners:

● Thickness Range

Common options include 0.5mm, 0.75mm, 1.0mm, 1.5mm, and 2.0mm, depending on project requirements.

● Tensile Strength and Elongation

LLDPE geomembranes offer higher elongation—often 600%+—making them suitable for uneven or shifting subgrades.

● Tear and Puncture Resistance

Enhanced resistance to rocks, debris, and construction tools ensures higher safety during installation.

● Chemical Stability

Effective against fertilizers, salts, mild acids, and alkalis, widely used in agriculture and industrial containment.

● UV and Oxidation Resistance

Stabilized with UV additives to withstand extended outdoor exposure.

● Standard Roll Dimensions

Typical rolls: 5.8m–8m width, 50–100m length, customizable upon request.

These specifications align with global project standards such as water retention, aquaculture pond construction, and waste containment engineering.

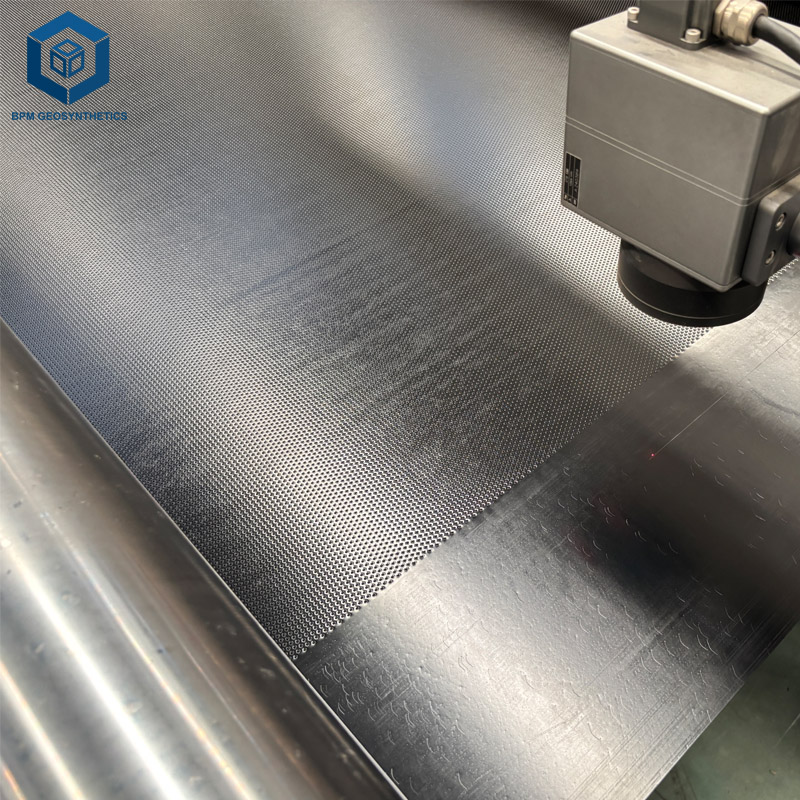

How LLDPE Pond Liners Are Manufactured

LLDPE pond liner production involves several technical steps designed to ensure consistency, strength, and long-term performance:

1. Raw Material Processing

High-grade LLDPE resin is melted and compounded with antioxidants, UV stabilizers, and carbon black.

2. Extrusion Process

Using blown film or cast extrusion, molten polymer is formed into a uniform geomembrane sheet.

3. Cooling and Surface Treatment

Advanced cooling systems stabilize the membrane and enhance adaptability.

4. Thickness and Property Testing

Quality tests include:

Tensile strength

Tear resistance

Puncture resistance

Permeability testing

Carbon black dispersion

UV resistance testing

5. Cutting, Welding, and Packaging

Rolls are trimmed, welded (if necessary), and packaged for global shipment.

We follow strict testing procedures to ensure the final LLDPE pond liner meets international standards across various applications.

Global Market Outlook for LLDPE Pond Liners

● Strong Growth in Aquaculture

Asia-Pacific and Africa are seeing rapid increases in fish farming and shrimp cultivation, significantly boosting demand.

● Mining and Industrial Expansion

LLDPE pond liners are widely used in heap leaching, process water basins, and chemical storage ponds.

● Water Scarcity Driving Adoption

Worldwide drought conditions encourage farmers and municipalities to construct lined reservoirs and retention basins.

● Regulatory Requirements

Environmental regulations require reliable containment systems, leading to higher use of certified geomembranes.

● Landscaping and Commercial Construction

Hotels, resorts, and real estate developments rely on LLDPE liners for decorative water features and artificial lakes.

Given these trends, the LLDPE pond liner market is expected to remain strong through the next decade.

Key Applications of LLDPE Pond Liners

1. Aquaculture Ponds

Ideal for fish farms, shrimp ponds, and hatcheries due to their clean, antibacterial performance.

2. Agricultural Water Reservoirs

Used in irrigation ponds, rainwater harvesting, and farm storage.

3. Mining Operations

Provides safe containment for leachate and chemical process fluids.

4. Landfill and Wastewater Treatment

LLDPE geomembranes help protect soil and water from contamination.

5. Landscape and Decorative Ponds

Widely used in artificial lakes, golf course ponds, and commercial fountains.

6. Stormwater and Retention Basins

Ensures reliable containment during heavy rainfall.

Why Global Buyers Choose LLDPE Over Other Materials

● Superior Flexibility

Ideal for projects requiring easy installation in irregular shapes.

● Cost-Effective

Lower installation cost due to reduced subgrade preparation.

● Environmentally Stable

Resistant to UV, chemicals, and biological degradation.

● Long Service Life

Expected lifespan of 15–25 years depending on thickness and exposure.

● Efficient Logistics

Lightweight rolls reduce transportation and handling costs.

Buyer Guide: Selecting the Right LLDPE Pond Liner

Before purchasing, consider the following:

Application type (aquaculture, mining, landscaping)

Required thickness

Soil conditions and subgrade quality

Expected exposure to sunlight and chemicals

Preferred roll size for installation efficiency

Budget and long-term durability requirements

We provide technical recommendations for different environmental and engineering conditions.

FAQ: Common Questions from International Buyers

1. What thickness of LLDPE pond liner should I choose?

0.5–1.0mm suits landscaping and small ponds; 1.0–1.5mm is common for aquaculture; 2.0mm is recommended for mining and industrial containment.

2. Can LLDPE liner be used in extreme hot or cold climates?

Yes. LLDPE maintains flexibility in low temperatures and resists thermal cracking in high-temperature regions.

3. How long does LLDPE pond liner last?

Typically 15–25 years, depending on UV exposure, installation quality, and project type.

4. Is LLDPE safe for fish and drinking water storage?

LLDPE is food-grade and non-toxic, making it suitable for aquaculture and potable water applications when properly certified.

Conclusion: LLDPE Pond Liner as a Sustainable and Reliable Containment Solution

The increasing need for efficient water management, environmental safety, and industrial containment has positioned LLDPE pond liner as a leading geomembrane solution internationally. Its balance of flexibility, chemical resistance, and cost-effectiveness makes it ideal for projects requiring long-term durability across varied environments.

Professional Call-to-Action

If you are sourcing LLDPE pond liner for aquaculture, landscaping, industrial containment, or large reservoir construction, our technical team can provide customized specifications, engineering support, samples, and competitive export pricing. Contact us for professional guidance and reliable supply solutions for your global projects.