HDPE Geomembrana

HDPE geomembrana is an impermeable liner of high-density polyethylene that is very effective and largely used for water containment, waterproofing and environmental protection. After a long time of chemical resistance, ultraviolet stability, and service life, HDPE geomembrane liner will still control leakage in cases of ponds, landfills, mining and agricultural applications.

- High Impermeability: It is a reliable solution that totally isolates water in the containment area.

- Excellent Chemical Resistance: It is able to endure contact with the most corrosive chemicals such as acid, alkali, salt, and industrial effluent.

- UV & Weather Resistance: Outdoor exposure is not a problem since it will not deteriorate.

- Strong Mechanical Properties: Includes a high level of resistance to tensile strength, tear and puncture.

- Thermal Weldable Seams: Heat welding ensures that the seams are leak-proof and continuous.

- Long Service Life: With very little maintenance, it can still remain in good condition for decades.

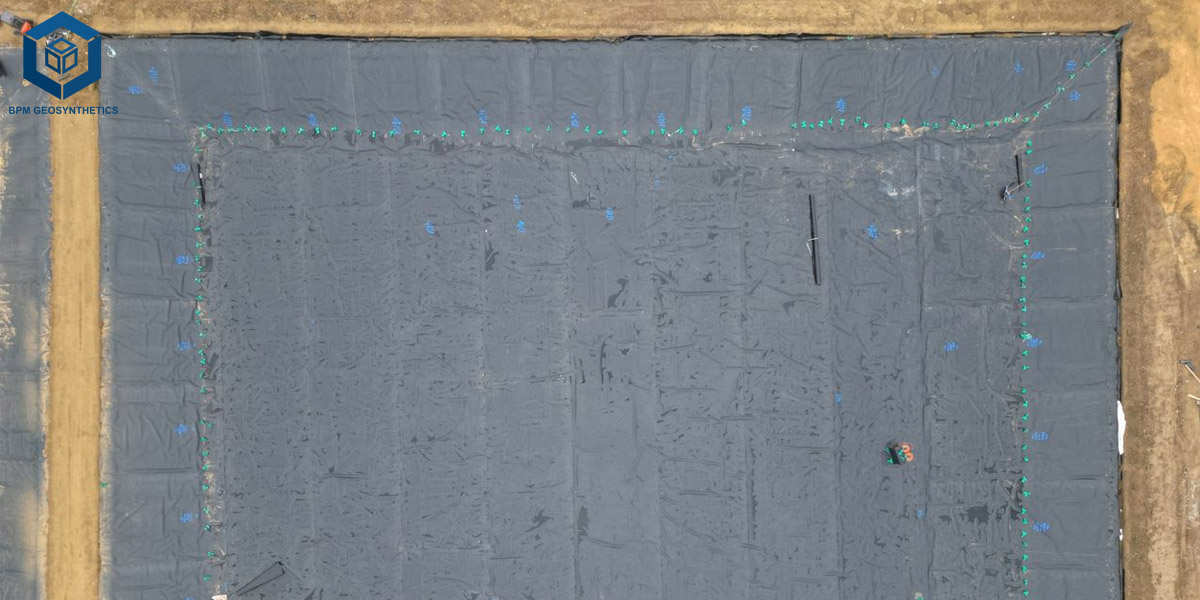

HDPE Geomembrana is a premium lining material made of high-density polyethylene and designed for outstanding waterproofing, containment, and environmental protection. Geomembrana is a very versatile product that is installed in all types of projects wherever there is a need for civil, industrial, agricultural, and environmental engineering. It is the best solution in tough and rugged environments that require long term containment, seepage control, and structural protection.

1. HDPE Geomembrana Key Features & Technical Advantages

1.1 High Impermeability

Being a highly impermeable material, HDPE liner can be used as a barrier to prevent leakage and seepage and also to stop groundwater contamination. Low permeability has the benefit of keeping water, chemicals, and industrial effluents safely contained thereby reducing environmental hazards.

1.2 Chemical Resistance

The product is chemically resistant to a wide range of dangerous chemicals such as acids, alkalis, salts, hydrocarbons, and mining effluents. This feature gives HDPE geomembrana a great potential to be used in landfills, tailings ponds, chemical storage, and wastewater containment.

1.3 UV & Weather Resistance

This polymer can keep intact its mechanical properties and flexibility even when it is continuously exposed to sunlight, temperature extremes, and severe weather changes. This capability is possible only if the UV resistance is in the material which subsequently results in a long outdoor service life.

1.4 Mechanical Strength

The geomembrane liner material can resist high tensile forces, tears, and punctures, as it also has a degree of flexibility that accounts for these capabilities. In addition to this, it can be expected to perform well in uneven terrain, slopes, and high-stress environments where, during both installation and operation, it will be less likely to get damaged.

1.5 Thermal Weldability

Cold welding of the hdpe geomembrane can be performed by using different welding methods that include heat welding or extrusion welding. After the welding process, a seam that is strong and leak-proof, that is, a joint that is so tight, is formed, and this leads to maximum containment efficiency. Besides, this characteristic facilitates the installation process while the user is assured that the geomembrane will maintain its integrity throughout its lifetime.

1.6 Wide Thickness Options

Geomembrana sheet can be customized in terms of its thicknesses that range from 0.5 mm to 3 mm (or higher) so as to meet different project requirements.

1.7 Longevity & Reliability

The performance of the hdpe membrane material has been tested and it is shown to be sufficient for potential use over 20-30 years in a majority of cases. HDPE geomembrane liner is an inexpensive, low-maintenance product that will last for the long haul.

1.8 Lightweight & Flexible

HDPE geomembrane sheet is not only a lightweight product but also flexible that it could be considered a great helper when it comes to transport, handling, and installation even at locations that are complex or have challenging terrains. Its flexibility allows it to be adapted to irregular shapes without losing the ability to contain.

1.9 Eco-Friendly & Safe

Impermeable geomembrane is manufactured from materials that are non-toxic and inert, and these materials can be recycled at the end of the product life- cycle. HDPE geomembrana is chemical containment compatible, safe for the environment, and complies with international sustainability standards.

2. HDPE Geomembrana Expanded Applications

2.1 Water Storage & Irrigation:

Reservoirs, ponds, canals, artificial lakes, aquaculture ponds, and irrigation channels. HDPE liner sheet is a tough, sealed barrier that keeps water from leaking out, thus enabling more effective irrigation and water storage.

2.2 Mining & Industrial Uses:

Tailings ponds, leachate containment, process water ponds, chemical containment ponds, and industrial wastewater management. Impermeable geomembrane liner is resistance to chemicals and strong tensile strength allow it to be used for hazardous liquid containment and mining and industrial site environmental protection.

2.3 Landfill & Environmental Protection:

Landfill liners and caps, leachate collection systems, hazardous waste containment, slope stabilization, and soil protection.The hdpe dam liners acts as a barrier preventing the spread of contaminants to the soil and groundwater, thus meeting the requirements of environmental safety regulations.

2.4 Civil Engineering & Infrastructure:

Dam lining, canal lining, tunnel and bridge waterproofing, foundation protection, and flood control reservoirs.The product's resilience and adjustability allow it to be utilized on rough and angled surfaces, as well as in highly stressed civil engineering structures.

2.5 Agriculture & Aquaculture:

Fish ponds, shrimp farms, livestock water ponds, and irrigation retention ponds.The hdpe impermeable liner not only helps to save water but also stops the water from soaking into the ground and keeps the livestock and aquaculture water clean and fresh.

2.6 Special Projects:

Stormwater retention basins, artificial wetlands, water treatment plants, and environmental remediation projects.HDPE geomembranas are a good choice to guarantee containment and protection of water management and ecological restoration projects that are experimental or state-of-the-art.

3. HDPE Geomembrana Installation & Maintenance

3.1 Installation Methods

HDPE geomembrana may be joined by heat welding, extrusion welding, or adhesive bonding, which are all capable of producing strong and leak-proof seams. It may be fixed on uneven surfaces, slopes, and difficult terrain, thus it has a wide application range including civil, industrial, and agricultural projects. Adequate welding is essential for the material's longevity and leak prevention.

3.2 Site Preparation

High density polyethylene geomembrane is recommended to have a flat and clean basis before placing the material so as to avoid the liner getting punctured or damaged. This might involve clearing out sharp stones, gradient leveling, and soil compaction, thus ensuring that the geomembrane retains its impermeability as well as mechanical strength.

3.3 Maintenance

HDPE geomembrana is characterized by a long service life during which it hardly requires any maintenance. Membrane hdpe is a good practice to do periodical checks for the condition of the seams, look for any punctures or damages caused by accidents, especially in high traffic or mechanical stress areas. Using heat welding or patching, even minor repairs can be made quite conveniently.

3.4 Custom Fabrication

Reinforced polypropylene geomembrane rolls may be cut, prefabricated, or formed in order to correspond to the dimensions and layouts of particular projects. When custom fabrication is used, the installation is completed more quickly, less welding is done on-site, and a perfect fitting is obtained for odd-shaped and large-scale applications, thus the total efficiency and reliability aspects become better.

4. HDPE Geomembrana Specifications & Customization

4.1 Thickness

0.2 mm – 3 mm (custom thickness on request).

The hdpe geo membrane material is available in a very wide range of thicknesses that serve various purposes. For instance, one purpose may be just to line a pond, while another extremely heavy-duty one would be used in landfills and mining. Moreover, special thickness can be produced to correspond to special situations of engineering and load requirements in case the need arises.

4.2 Width

6–10 meters standard; custom widths on request.

Having so few seams due to rolls of standard width makes the work of installation go faster. Furthermore, if desired, rolls with widths different from the standard ones can be made so as to reduce welding at the site and fit large or irregular layouts.

4.3 Color

Black (standard), other colors available for UV and heat reflection.

Black high density polyethylene geomembrane offers excellent UV resistance and durability. Other colors can be provided to enhance heat reflection, visibility, or meet specific environmental and project design requirements.

4.4 Standards Compliance

ASTM, GRI-GM13, ISO, or project-specific standards.

Manufactured under strict quality control, membrane HDPE complies with major international standards. Project-specific technical requirements and third-party testing can be supported upon request.

5. HDPE Geomembrana Advantages Over Other Liners

5.1 Superior Chemical Resistance

HDPE Impervious Geomembrane has much better resistance to chemicals than the PVC or EVA liners. Its successful experiments with chemical solutions such as acids, alkalis, salts, hydrocarbons, and industrial effluents are its competitive advantages. Therefore, geomembrane material is the best pick for landfills, mining, and wastewater projects among other applications.

5.2 Longer Service Life & Higher Durability

When comparing a clay or concrete liner to a geomembrana in hdpe, one naturally hesitates to stand on clay or concrete because the latter has a shorter service life and more risk of cracks, erosion, or wear. Thanks to its ability against environmental stress and weathering, BPM geomembrane is the best choice to maintain containment performance over a long period of time.

5.3 Flexible & Lightweight Design

HDPE geomembrane waterproofing being flexible and lightweight makes it very portable, easy to handle, and install on the irregular surfaces, slopes, and complex terrains. The flexibility factor here contributes not only to the time saved during installation but to the reduced labor costs as well, without losing the structure of the product.

5.4 Cost-Effective for Large-Scale Projects

If it is a medium-sized or a large-scale water reservoir, a landfill, or a waste containment site then geomembrane in hdpe is the most capable lining in terms of cost-efficiency. It is confirmed by the relatively long lifespan, the need for minimum maintenance, and the quick installation of the product which altogether give rise to the total expenses of the project being lower than in case of the alternative lining solutions.

6. HDPE Geomembrana – Product FAQ

Q1: What are the different sizes of HDPE Geomembrana available?

A:HDPE Geomembrana comes in various thickness options, usually ranging from 0.3mm to 3.0mm (12 mil to 120 mil). The most popular thicknesses are 0.5mm, 1.0mm, 1.5mm, and 2.0mm.

Q2: What standards are met by HDPE Geomembrana?

A:HDPE Geomembrana is made to meet international standards like ASTM GRI-GM13. Hence, the product has a guaranteed high standard and performance reliability.

Q3: How long can the HDPE Geomembrana material last?

A:With proper handling, correct installation, and in normal conditions, the lifetime of an HDPE Geomembrana could be 30 to 50 years. The performance lifespan will vary depending on the weather and the way it is used.

Q4: Will HDPE Geomembrana be tailored?

A:Of course. HDPE Geomembrana can be changed in:

- Thickness

- Width and length of the roll

- Surface type (smooth or textured)

- Color (black, white, green, etc.)

Q5: What factors should I consider to get the right HDPE Geomembrana for my project?

A:The selection of a product should be based on the requirements of the project, e.g. chemical exposure, load conditions, climate, and design life. Our technicians are available for you to discuss your project and receive advice based on your application.

Summary

The Best Project Material Co., Ltd.(BPM Geosynthetics)HDPE Geomembrana is a dependable, efficient, and long-lasting lining material that can handle the most stringent requirements of containment and waterproofing projects. We accept requests for free samples, technical support, and competitive quotations. For detailed specifications, pricing, and professional advice on your project, please get in touch with us.