Dam Lining

Dam lining is a shielding barrier mounted on dam surfaces to stop seepage, erosion, and structural harm brought on by using water infiltration. It enhances the sturdiness and security of dams whilst minimizing protection costs.

High Impermeability – Effectively prevents water leakage thru dam structures.

Durable Materials – Made from bolstered geomembrane for lengthy carrier life.

UV & Weather Resistance – Withstands extended daylight exposure, temperature fluctuations, and heavy rainfall.

Chemical Resistance – Suitable for dams uncovered to various water pH tiers or industrial effluents.

Easy Installation – Designed for environment friendly on-site utility with minimal downtime.

Environmental Protection – Prevents water loss and protects surrounding ecosystems.

Dam lining is a specialised defensive layer utilized to dam surfaces to make certain structural integrity, stop water leakage, and prolong the operational lifespan of the dam. It performs a crucial position in water conservation, flood control, and hydroelectric energy era by means of keeping reservoir steadiness and effectivity even below difficult environmental conditions.

Our Dam Lining Solutions are engineered with superior substances and manufacturing methods to supply notable impermeability, great durability, and dependable environmental protection. Suitable for a large range of dam kinds and sizes, they efficaciously guard in opposition to seepage, erosion, and long-term structural injury precipitated by way of water pressure, chemical exposure, and climate extremes. By lowering preservation desires and improving operational safety, our options make certain your dam continues to function at height overall performance for decades, imparting a impervious and sustainable water useful resource administration system.

1. Dam Lining Purpose and Function

The foremost reason of dam lining is to create a strong, continuous, and impermeable barrier that minimizes seepage via each the dam physique and its foundation. This shielding layer serves as a essential protect for the long-term stability, efficiency, and protection of the complete dam structure. By reaching this, dam lining affords a number of key functions:

1.1 Dam Lining Protects Against Erosion and Internal Structural Weakening

Dam buildings are continuously uncovered to hydraulic pressure, fluctuating water levels, and environmental forces that can erode soil, concrete, or rock surfaces over time. Without ample protection, water infiltration can steadily wash away best particles inside the dam body, main to inner voids, cracks, or slope instability. A extremely good dam plastic lining prevents water penetration, lowering inner erosion and retaining the dam’s core energy for decades.

1.2 Dam Lining Reduces Water Loss from Reservoirs

Even minor seepage can end result in extensive cumulative water loss, particularly in large-scale reservoirs. This no longer solely affects the dam’s operational effectivity however additionally reduces on hand water for downstream makes use of such as irrigation, industrial supply, and municipal needs. Plastic dam liner ensures near-total impermeability, assisting to hold most water storage capacity, enhance water aid management, and assist constant furnish in the course of dry seasons.

1.3 Dam Lining Enhances the Dam’s Overall Performance in Water Storage and Management

By retaining reservoir ranges and stopping structural degradation, dam lining material immediately contributes to the dam’s potential to supply steady overall performance over its supposed lifespan. It ensures environment friendly water waft control, supports dependable hydroelectric energy generation, and improves flood administration capabilities. Moreover, through decreasing preservation interventions and structural repairs, dam liner helps operators optimize operational prices and limit downtime.

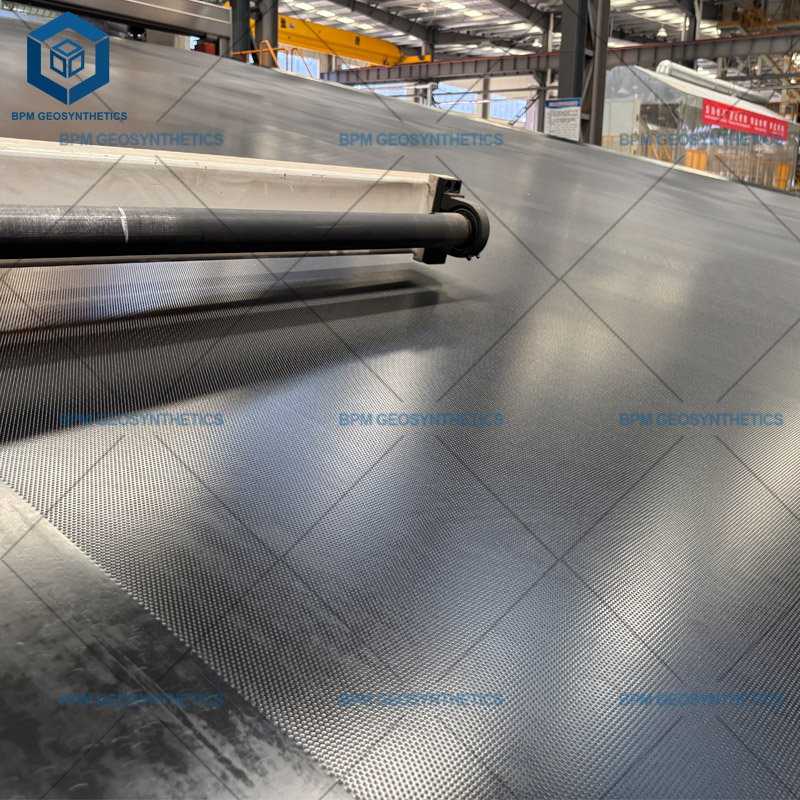

2. Dam Lining – Premium Geomembrane Materials for Superior Performance

We use solely high-grade geomembrane liner to make sure most protection, reliability, and provider lifestyles in dam lining applications. Our impermeable geomembrane liner options are engineered to function below the most traumatic environmental and operational conditions, turning in unmatched impermeability and durability.

2.1 Dam Lining - Exceptional Impermeability

High Density Polyethylene HDPE and Low-Density Polyethylene LDPE geomembrane create an impermeable barrier that certainly eliminates water seepage via dam partitions and foundations. This ensures highest quality reservoir capability and water conservation.

2.2 Dam Lining - UV and Weather Resistance

Specially formulated to stand up to extended publicity to sunlight, severe temperatures, and seasonal climate changes, our geomembranes pond liner preserve their structural integrity except becoming brittle or degraded over time.

2.3 Dam Lining - Outstanding Mechanical Strength

With excessive tensile energy and puncture resistance, these geomembranes withstand tearing and deformation underneath hydraulic pressure, sediment load, and viable affects from particles or equipment.

2.4 Dam Lining - Chemical Stability

Impermeable geomembrane stay unaffected through editions in water pH, mineral content, or publicity to chemical compounds and industrial effluents, making them best for each freshwater and industrial water storage dams.

2.5 Dam Lining - Flexible Installation Options

LLDPE geomembranes provide highest quality flexibility, making them simpler to set up over complicated dam geometries, slopes, and irregular surfaces except compromising performance.

2.6 Dam Lining - Long Service Life

Designed for many years of dependable operation, our geomembranes considerably decrease the want for maintenance, repairs, and replacements, reducing whole lifecycle costs.

2.7 Dam Lining - Environmentally Responsible

Manufactured with eco-friendly approaches and entirely recyclable at the cease of their provider life, high density polyethylene geomembrane grant a sustainable answer for dam lining projects.

3. Our Dam Lining Delivers Reliable, Long-Term Protection

3.1 Dam Lining - Zero Compromise on Impermeability

Our HDPE dam liner structures are engineered to acquire near-perfect impermeability, making sure that even the smallest leaks are prevented. This now not solely safeguards the dam’s structural integrity however additionally maximizes water retention, assisting preserve reservoir ranges and decreasing operational water loss over time.

3.2 Dam Lining - Extreme Weather Resistance

Designed to operate in the most harsh environments, our dam linings face up to excessive heat, freezing cold, heavy rainfall, and extended drought barring warping, cracking, or dropping effectiveness. This ensures constant overall performance year-round, regardless of local weather conditions.

3.3 Dam Lining - Chemical Stability for Diverse Water Conditions

Whether the water has excessive mineral content, fluctuating pH levels, or achievable industrial contaminants, our plastic dam liners stay unaffected. Their chemical resistance ensures long-term sturdiness in each herbal and industrial water storage applications.

3.4 Dam Lining - Fully Tailored to Your Project Requirements

We provide personalized dam lining options with variable thickness, sheet sizes, and set up techniques to flawlessly fit your web site conditions, mission design, and overall performance goals. This flexibility ensures superior safety and price efficiency.

3.5 Dam Lining - Proven Global Track Record

Our options are depended on by using engineers and operators in hydropower plants, irrigation networks, flood manipulate systems, and industrial water reservoirs around the world. This confirmed overall performance file highlights our dedication to quality, safety, and long-term reliability.

4. Dam Lining Maintenance and Longevity

Although dam lining is engineered for a long time of dependable service, ordinary inspection is indispensable to make certain they proceed to operate at their best. Scheduled opinions permit operators to discover early symptoms of wear, bodily damage, or environmental stress earlier than they improve into extra serious issues. Factors such as sediment buildup, intense climate events, or extended UV publicity can progressively have an effect on the lining’s condition. By addressing minor repairs straight away and following encouraged protection practices, operators can extensively prolong the lifespan of the lining HDPE, keep its impermeability, and keep the average security and effectivity of the dam structure.

5. Dam Lining - Hassle-Free Installation & Support

From the preliminary venture diagram section to post-installation maintenance, our BPM skilled engineering group offers complete technical guide each and every step of the way. We work carefully with customers to check web site conditions, advocate the most appropriate lining materials, and strengthen a tailor-made set up graph that minimizes downtime. Our professional set up crews make certain unique application, desirable sealing, and thorough exceptional checks, guaranteeing a flawless finish. Even after completion, we provide ongoing upkeep coaching and inspection offerings to make sure long-term reliability and most reliable overall performance of your dam lining system.

6. Dam Lining Applications

Dam lining is a versatile answer extensively used throughout a range of sorts of dams and water storage projects. Its adaptability and shielding features make it integral in more than one industries, making sure operational safety, water conservation, and environmental protection.

6.1 Dam Lining for Hydroelectric Power Dams – Ensuring Energy Generation Efficiency

In hydroelectric energy plants, preserving reservoir integrity is necessary for regular water drift and power production. Dam linings forestall seepage that ought to minimize water ranges and disrupt turbine operation. For example, the Hoover Dam in the USA makes use of superior geomembrane lining in spillways and reservoir edges to guard in opposition to leakage and erosion, assisting preserve its large power output reliably.

6.2 Dam Lining for Irrigation Reservoirs – Conserving Water for Agricultural Use

Agriculture relies upon closely on environment friendly water storage and distribution. Geomembranes pond liner in irrigation reservoirs stop steeply-priced water loss due to seepage, specially in arid areas the place each and every drop counts. The Indira Gandhi Canal Project in India comprises impermeable liner to decrease seepage in its giant reservoirs, drastically improving water availability for farming communities.

6.3 Dam Lining for Flood Control Dams – Maintaining Operational Safety During Extreme Weather Events

Flood manage dams need to undergo fast water degree adjustments and intense climate barring compromising their structure. Lining substances assist defend towards erosion and seepage at some point of heavy rains or floods, maintaining dam balance and stopping downstream hazards. The Three Gorges Dam in China, one of the world’s greatest flood manage structures, employs superior lining structures in indispensable sections to stand up to seasonal flooding effectively.

6.4 Dam Lining for Industrial Water Storage – Protecting Against Contamination and Leakage

Many industrial techniques require massive volumes of saved water, regularly uncovered to chemical compounds or pollutants. Dam lining in these reservoirs acts as a barrier, stopping illness of groundwater and surrounding ecosystems whilst containing probably hazardous fluids safely. For instance, mining operations in Australia use pond liner membrane tailings dams to securely save water blended with mining residues, minimizing environmental risks.

7. Summarize

Dam lining is a quintessential element in defending dam structures, stopping water loss, and making sure long-term operational protection throughout a number applications, from hydroelectric strength to irrigation and flood control. To obtain the absolute best requirements of durability, impermeability, and environmental protection, we advise BPM Geosynthetics is superior dam lining solutions. Our confirmed substances and understanding supply dependable performance, tailor-made set up support, and sustainable effects for each dam project.