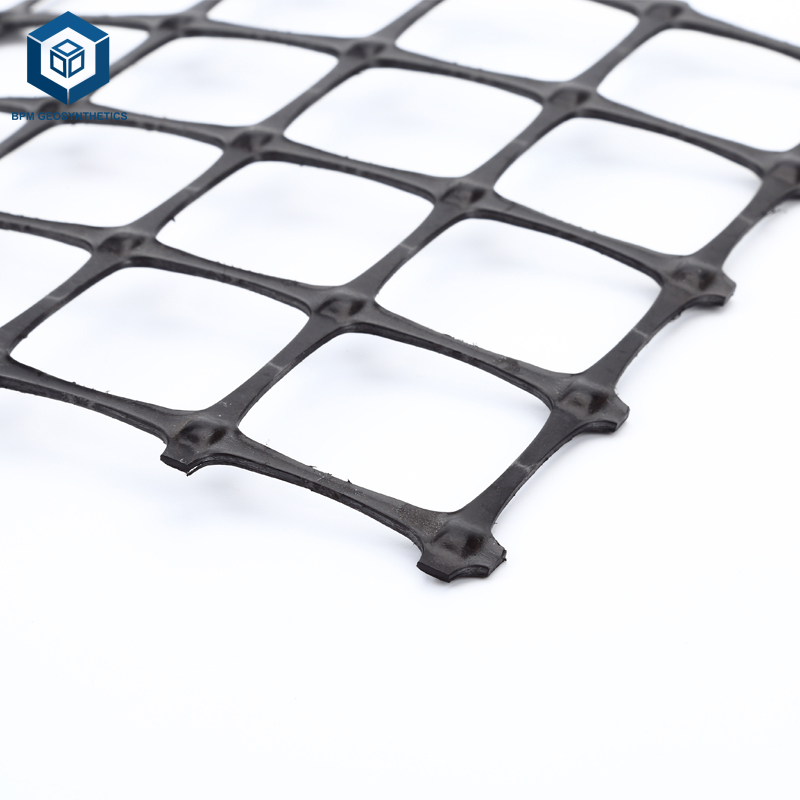

Biaxial Plastic Geogrid

Biaxial plastic geogrid is a excessive power geosynthetic fabric. Designed with a grid-like shape and evenly dispensed apertures, it offers first-rate tensile electricity in each longitudinal and transverse directions. This makes it best for soil stabilization, roadbed reinforcement, and load distribution in more than a few civil engineering applications.

- Biaxial Plastic Geogrid Material: Polypropylene (PP) or High Density Polyethylene (HDPE)

- Tensile Strength: Typically 15–50 kN/m (in each directions)

- Roll Size: Common widths: 1–4 meters; Lengths: 50–100 meters

- Structure: Rigid grid with uniform apertures for interlocking with soil

- Durability: UV-resistant, chemical-resistant, and corrosion-free

- Application: Suitable for roads, driveways, parking lots, conserving partitions

Biaxial plastic geogrid is a high performance geosynthetic material engineered to furnish soil reinforcement and subgrade stabilization in civil engineering and infrastructure projects. Manufactured from polypropylene (PP) or high-density polyethylene (HDPE), it elements a rigid, grid-like shape with excessive tensile power in each the longitudinal and transverse directions. This dual-direction reinforcement functionality makes it perfect for a number load-bearing and ground-support applications.

1. Biaxial Plastic Geogrid Key Features and Benefits

1.1 Biaxial Plastic Geogrid - Biaxial Strength

Provides balanced tensile energy in each laptop and transverse directions, making sure uniform load distribution and efficaciously stopping rutting, differential settlement, and structural deformation.

1.2 Biaxial Plastic Geogrid - Durable and Weather-Resistant

Made from UV-stabilized and chemically inert materials, the geogrid withstands extended publicity to sunlight, acids, alkalis, and harsh environmental prerequisites besides degradation.

1.3 Biaxial Plastic Geogrid - Lightweight and Easy to Install

The bendy and light-weight diagram simplifies transportation, handling, and set up processes, decreasing building time and reducing labor costs.

1.4 Biaxial Plastic Geogrid - Corrosion-Free

Unlike metal reinforcements, biaxial geogrid face up to corrosion, rust, and organic attack, making sure long-lasting overall performance in buried applications.

1.5 Biaxial Plastic Geogrid - Cost-Effective Solution

Reduces the want for thick granular base layers and immoderate fill materials, saving on fabric and transportation prices whilst extending pavement lifespan and decreasing protection expenses.

2. Biaxial Plastic Geogrid Technical Specifications

| Property | Value Range |

Material | Polypropylene / HDPE |

Tensile Strength (MD/TD) | 15–50 kN/m |

Elongation at Break | <13% |

Aperture Size | 25–40 mm |

Roll Width | 1–4 meters |

Roll Length | 50–100 meters |

Color | Black (UV-stabilized) |

Durability | >20 years in buried soil |

3. BPM Biaxial Plastic Geogrid Manufacturing Process and Quality Control

BPM geosynthetics's biaxial plastic geogrid is produced via a meticulous manufacturing method that combines superior extrusion and stretching technologies. High-quality polypropylene (PP) or high-density polyethylene (HDPE) resin is first extruded into smooth, uniform flat sheets. These sheets are then automatically punched to create a unique grid pattern, observed with the aid of a bi-directional stretching process—in each the laptop and transverse directions. This enhances the tensile houses of the cloth and varieties a geogrid shape with uniform apertures, sturdy node bonding, and first-rate dimensional stability.

To make certain constant product exceptional and excessive performance, BPM geosynthetics implements a complete first-rate manipulate device at each stage of production:

3.1 BPM Biaxial Plastic Geogrid Raw Material Inspection

Only virgin-grade HDPE or PP resins are used. All incoming substances are carefully examined to confirm polymer purity, molecular weight, and additive content, making sure long-term sturdiness and strength.

3.2 BPM Biaxial Plastic Geogrid Dimensional Accuracy Testing

Aperture size, grid thickness, and sheet width are exactly measured and managed to meet format tolerances. This ensures suited interlock with soil and aggregates in the course of application.

3.3 BPM Biaxial Plastic Geogrid Tensile Strength Testing

Each manufacturing batch is subjected to tensile energy assessments in accordance to ASTM D6637 standards, confirming that the geogrids meet or exceed the exact mechanical overall performance for reinforcement applications.

3.4 BPM Biaxial Plastic Geogrid UV and Aging Resistance Test

Accelerated weathering checks are performed to consider resistance to ultraviolet degradation, thermal aging, and oxidation, making BPM polypropylene geogrid appropriate for long-term outside use.

3.5 BPM Biaxial Plastic Geogrid Third-Party Certifications and Audits

To enhance credibility and international compliance, BPM merchandise are generally audited and licensed through unbiased laboratories such as SGS, BV (Bureau Veritas), and Intertek. These certifications validate that BPM geogrid conform to global requirements for strength, environmental safety, and consistency.

Thanks to these strict manufacturing and best manage practices, BPM ensures that each roll of biaxial geogrid provides dependable performance, lengthy carrier life, and engineering-grade consistency, making it a relied on answer for soil reinforcement and floor stabilization worldwide.

4. Biaxial Plastic Geogrid Compatibility with Other BPM Geosynthetics

Biaxial plastic geogrid is enormously versatile and regularly used in conjunction with different geosynthetic substances to structure built-in structures that supply better structural performance, durability, and functionality. This compatibility permits engineers and contractors to format robust, in your price range options tailor-made to complicated website stipulations and venture demands.

4.1 Biaxial Plastic Geogrid + Nonwoven Geotextile

When used together, geogrid and nonwoven geotextiles provide most advantageous stabilization. The geotextile gives fundamental filtration, drainage, and separation functions—preventing fines from migrating into the mixture base—while the geogrid reinforces the soil and distributes masses evenly.

4.2 Biaxial Plastic Geogrid + Geomembrane

In environmental and waste containment initiatives such as landfills, ponds, and leachate series systems, geogrids are positioned above or under geomembranes to supply mechanical protection, decorate slope stability, and stop puncture or geomembrane liner displacement due to subgrade movement.

4.3 Biaxial Plastic Geogrid + Geocell

For slope reinforcement, channel protection, and erosion control, biaxial geogrid act as a steady base layer that improves the load-bearing potential of geocells. This mixture presents confinement, stability, and erosion resistance, specifically on steep or gentle terrain.

4.4 Biaxial Plastic Geogrid + Drainage Layer and Composite Drain

Geogrids assist hold the integrity and separation of drainage layers by means of stopping mixing of soil and combination whilst retaining free-flowing water paths. This is vital in roadways, holding walls, and green roof structures the place water administration is essential.

By integrating biaxial geogrids with complementary geosynthetics, engineers can optimize soil behavior, enlarge bearing capacity, prolong infrastructure lifespan, and tackle more than one format challenges simultaneously. Such hybrid options are specifically precious in transportation, environmental, and civil engineering initiatives with variable or susceptible subgrade conditions.

5. Biaxial Plastic Geogrid Applications and Case Studies

Biaxial plastic geogrid from BPM are broadly utilized throughout a vary of civil, industrial, and environmental projects. Their strength, durability, and ease of set up make them perfect for soil reinforcement and floor stabilization in difficult web page conditions. Typical software areas include:

5.1 Biaxial Plastic Geogrid Applications

- Biaxial Plastic Geogrid for Roadway and Highway Base Reinforcement

Improves load-bearing capacity, reduces base thickness, and extends pavement provider life.

- Biaxial Plastic Geogrid for Driveways and Parking Lot Stabilization

Minimizes rutting, cracking, and floor deformation underneath repeated visitors loads.

- Biaxial Plastic Geogrid for Railway Track Bed Support

Enhances lateral confinement and reduces ballast degradation underneath cyclic loading.

- Biaxial Plastic Geogrid for Retaining Wall and Embankment Reinforcement

Provides tensile resistance and improves the steadiness of soil structures.

- Biaxial Plastic Geogrid for Landfill and Mining Infrastructure

Strengthens base layers, improves drainage, and enhances containment machine integrity.

- Biaxial Plastic Geogrid for Construction Site Ground Improvement

Stabilizes smooth soils, enables get right of entry to roads, and reduces agreement risks.

5.2 Biaxial Plastic Geogrid Case Studies and Project References

BPM biaxial plastic geogrids have demonstrated overall performance in real-world initiatives throughout various climates and soil conditions. Below are a few consultant case studies:

5.2.1 Biaxial Plastic Geogrid for Highway Subgrade Stabilization – Southeast Asia

In a main infrastructure project, BPM geogrids had been used to make stronger a gentle clay subgrade. The layout enabled a 40% discount in granular base thickness and decreased ordinary building expenses through 25%, barring compromising overall performance or safety.

5.2.2 Biaxial Plastic Geogrid for Retaining Wall Support – South America Mining Project

A 6-meter-high conserving wall developed on a mining website was once strengthened the use of more than one layers of BPM biaxial geogrids. The set up carried out a security component above two and delivered long-term steadiness underneath seismic and dynamic load conditions.

5.2.3 Biaxial Plastic Geogrid for Parking Lot Reinforcement – Eastern Europe

For a massive business complex, geogrids have been hooked up under permeable pavers. The gadget avoided rutting, elevated drainage, and appreciably prolonged pavement lifespan whilst decreasing future renovation needs.

BPM Biaxial Geogrid has accomplished lots of comparable initiatives in over one hundred countries. Additional references, technical data, and case-specific options are reachable upon request.

6. Contact Us for Technical Support or a Free Quote

Whether you’re reinforcing a driveway or designing a large-scale toll road project, BPM’s biaxial plastic geogrids provide unmatched performance, efficiency, and value. Contact our BPM geosynthetics team nowadays for free samples, pricing, or customized technical specs tailor-made to your project.