PP Biaxial Geogrid

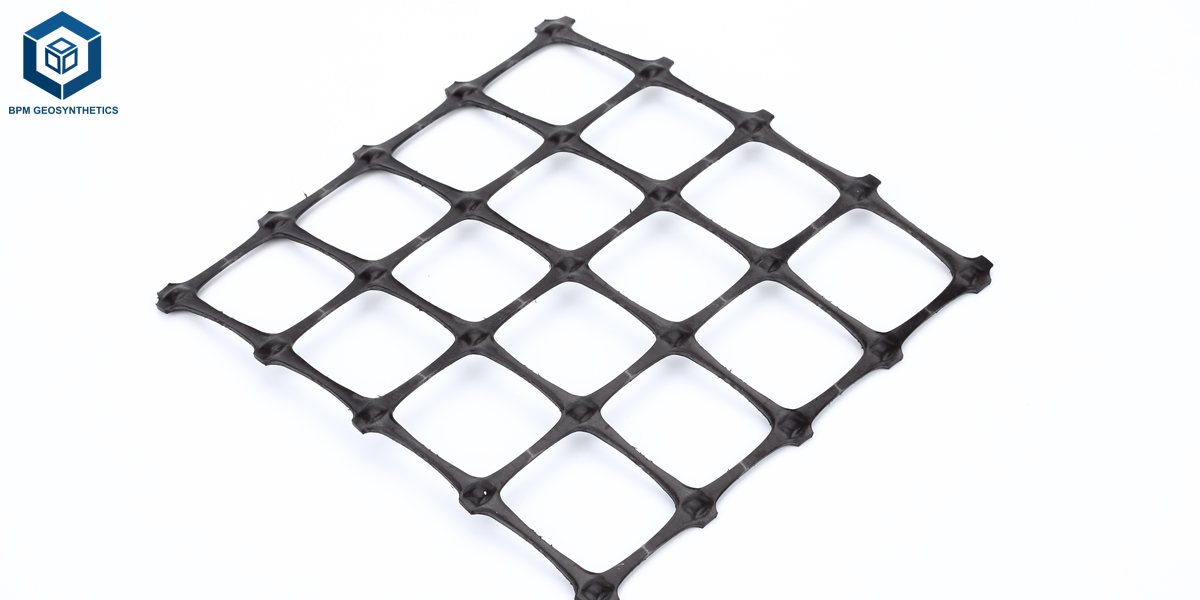

PP Biaxial Geogrid is a high-strength polypropylene geogrid manufactured via extrusion and biaxial stretching. It affords tremendous tensile strength, durability, and chemical stability. Widely used in street reinforcement, slope stabilization, soil strengthening, and railway projects, it correctly improves floor bearing capability and extends the provider existence of infrastructure.

- High-Strength Material: Made from top class polypropylene, providing most fulfilling tensile electricity and long-lasting durability.

- Biaxial Load-Bearing: Provides robust reinforcement in each longitudinal and transverse instructions for better soil stability.

- Corrosion and Aging Resistant: Resistant to UV radiation and chemical attack, appropriate for harsh environmental conditions.

- Easy Installation: Lightweight and flexible, effortless to reduce and lay, lowering building time and labor.

PP biaxial geogrid is top class geosynthetic substances designed for soil reinforcement, stabilization, and structural support. These biaxial geogrid is engineered to improve the mechanical overall performance of soil in civil engineering, street construction, slope stabilization, and different applications. Manufactured with superior extrusion and biaxial stretching technology, PP biaxial geogrids supply excessive tensile energy in each longitudinal and transverse directions, ensuring uniform reinforcement underneath heavy loads.

1. PP Biaxial Geogrid Composition and Manufacturing Process

1.1 PP Biaxial Geogrid Material Selection

High-quality polypropylene (PP) is cautiously chosen as the important cloth for manufacturing biaxial geogrids. Biaxial polypropylene geogrid is chosen for its notable chemical resistance, light-weight nature, and long-term durability. This thermoplastic polymer can stand up to publicity to acids, alkalis, and different soil contaminants besides degrading, making it perfect for reinforcing soil over many years. Its inherent electricity and steadiness make sure that the geogrid keeps structural integrity even underneath heavy loads, whilst its light-weight residences facilitate handy transport and installation. In addition, PP geogrid is environmentally friendly, recyclable, and appropriate for sustainable civil engineering projects.

1.2 PP Biaxial Geogrid Extrusion Process

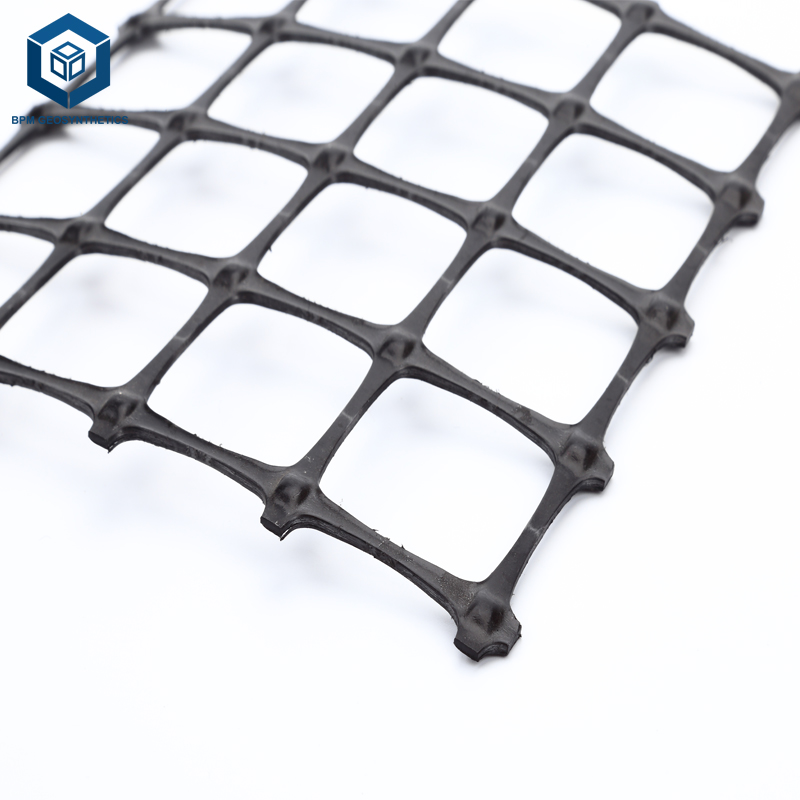

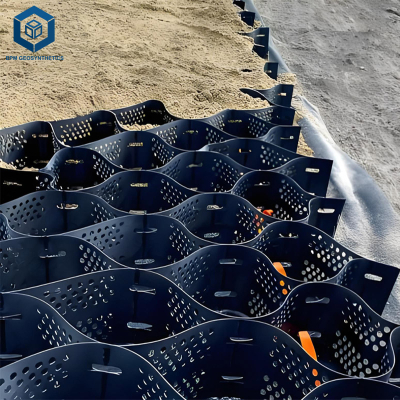

The manufacturing technique starts offevolved with melting the polypropylene and extruding it into uniform sheets. These biaxial plastic geogrid is then punched with precision to create a regular grid of apertures, which later structure the spine of the geogrid’s structural strength. The managed punching manner ensures uniform aperture sizes, vital for steady soil interlock and mechanical performance. This stage additionally lets in for changes in thickness and aperture spacing, relying on the particular load necessities of the remaining product.

1.3 Biaxial Stretching

Once the polypropylene geogrid is punched, they bear biaxial stretching, a manner that stretches the material each longitudinally and transversely. This dual-axis alignment of the polymer chains effects in more desirable tensile electricity and steadiness in each directions. The biaxial orientation ensures that the geogrid can evenly distribute loads, forestall deformation, and enhance soil interlock. It additionally lets in the geogrid to function reliably in functions the place stresses are utilized in a couple of directions, such as street subgrades, embankments, and conserving wall reinforcement.

1.4 PP Biaxial Geogrid Surface Treatment

To further beautify performance, some PP biaxial geogrids bear floor cure or texturing. This may additionally encompass making use of coatings or embossing patterns that enhance friction and adhesion between the geogrid and surrounding soil or aggregates. The elevated interface reduces slippage and ensures that the bolstered soil behaves as a unified structural layer, maximizing the geogrid’s effectiveness. Surface therapy additionally affords an extra layer of safety in opposition to abrasion throughout set up and in-service use.

1.5 PP Biaxial Geogrid Quality Control

Each roll of biaxial polypropylene geogrid is subjected to rigorous best manage strategies to warranty regular performance. Testing consists of measuring tensile strength, elongation at break, thickness, and junction efficiency. High junction effectivity is critical, as it ensures that the intersections between longitudinal and transverse ribs can switch hundreds correctly except failure. Only geogrids that meet strict specs are authorized for shipment, making sure that clients get hold of a product succesful of performing reliably in stressful civil engineering projects. Quality manage additionally helps stop versions between batches, keeping the consistency and reliability wanted for large-scale building applications.

2. PP Biaxial Geogrid Key Specifications

2.1 PP Biaxial Geogrid Material

PP Biaxial Geogrids are manufactured from premium-grade polypropylene (PP), a thermoplastic polymer acknowledged for its brilliant chemical resistance, durability, and light-weight characteristics. The cloth is UV-stabilized, which approves the geogrid to stand up to extended publicity to daylight besides big degradation. Its chemical resistance ensures overall performance even in soils with excessive acidity, alkalinity, or publicity to industrial contaminants. The aggregate of outstanding PP and UV stabilization presents long-term sturdiness and reliability, making it appropriate for out of doors and heavy-duty civil engineering projects.

2.2 PP Biaxial Geogrid Tensile Strength

The tensile electricity of PP biaxial geogrid mesh generally degrees from 10 kN/m × 10 kN/m to 50 kN/m × 50 kN/m, relying on the mannequin and manufacturer. This dual-axis energy ensures that the geogrid can withstand anxiety in each longitudinal and transverse directions, supplying uniform load distribution throughout strengthened soil layers. Lower-strength fashions are best for landscaping or light-duty avenue reinforcement, whilst higher-strength fashions are appropriate for highways, railways, conserving walls, and landfill stabilization. The excessive tensile electricity additionally minimizes the hazard of deformation or failure beneath heavy loading, making sure long-term structural integrity.

2.3 PP Biaxial Geogrid Elongation at Break

Elongation at wreck generally reaches up to 13%, which approves the geo grid mesh to take in stress and adapt to minor soil motion barring compromising its mechanical performance. This flexibility ensures that the geogrid continues appropriate soil interlock and structural balance even beneath various environmental conditions, such as settlement, temperature fluctuations, or water infiltration. The managed elongation offers a stability between stress and adaptability, which is fundamental for purposes in avenue bases, embankments, and different civil engineering structures.

2.4 PP Biaxial Geogrid Roll Dimensions

PP Biaxial Geogrids are furnished in rolls with widths ranging from 1 meter to 6 meters and lengths of up to 50 meters, permitting for handy transport, handling, and installation. For large-scale projects, customized roll dimensions can be produced to optimize fabric utilization and reduce onsite splicing. The beneficiant roll lengths decrease the wide variety of seams in the installation, making sure regular overall performance and simplified construction. The aggregate of width and size flexibility makes these geo grid ground grid appropriate for functions ranging from small landscaping initiatives to giant highways and industrial sites.

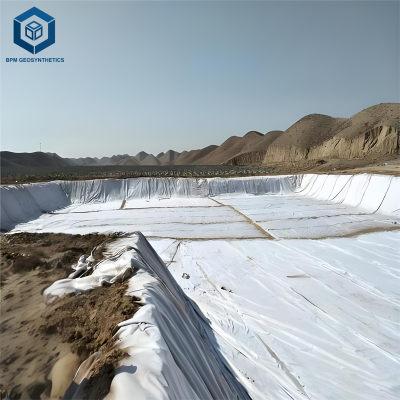

2.5 PP Biaxial Geogrid Color Options

Geogrids are accessible in numerous colors, which includes black, green, and white. Black is the most frequent colour due to its most excellent UV steadiness and established versatility. Green or white variations can also be chosen for aesthetic motives or particular undertaking requirements. The shade is regularly correlated with UV stabilization additives, which assist lengthen the material’s lifespan in outside applications. Choosing the fabulous colour ensures each overall performance and visible integration with the surrounding environment.

2.6 PP Biaxial Geogrid Certifications

High-quality PP Biaxial Geogrids are licensed to meet worldwide requirements such as CE, ISO 9001, and SGS. These certifications warranty regular product quality, manufacturing excellence, and compliance with rigorous checking out protocols. Certification ensures that the geogrid performs reliably underneath described mechanical and environmental stipulations and meets the expectations of engineers, contractors, and regulatory authorities.

2.7 PP Biaxial Geogrid Junction Efficiency

Junction effectivity refers to the power of the intersections the place longitudinal and transverse ribs meet. In PP Biaxial Geogrids, junction effectivity exceeds 90%, which capacity that the junctions can switch nearly the full tensile load besides considerable slippage or separation. High junction effectivity ensures that the geogrid continues structural integrity beneath heavy loads, reduces plausible failure points, and improves soil interlock. This is in particular vital for keeping walls, embankments, and different load-bearing purposes the place regular reinforcement overall performance is required.

3. PP Biaxial Geogrid Structural Characteristics

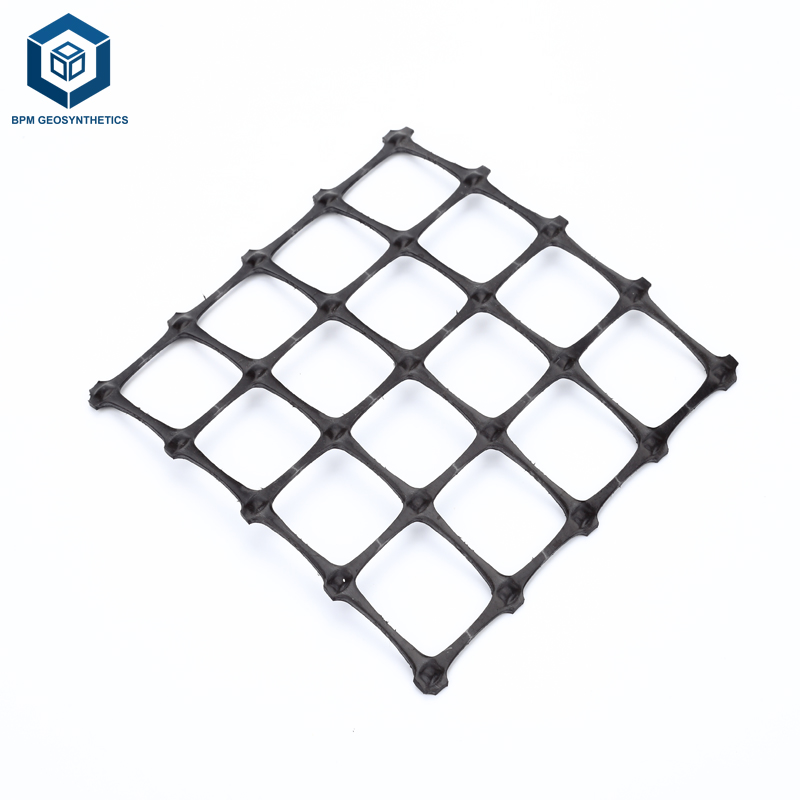

3.1 PP Biaxial Geogrid - Uniform Aperture Size

PP Biaxial Geogrids characteristic uniformly spaced apertures, which play a essential function in reaching regular soil interlock and high-quality load distribution. The everyday grid sample ensures that stress utilized to the strengthened soil is transmitted evenly, minimizing vulnerable factors and stopping localized deformation. This uniformity approves the soil and aggregates to characteristic collectively as a single structural unit, improving typical steadiness and lowering the danger of agreement or rutting below heavy loads.

3.2 PP Biaxial Geogrid - High Junction Strength

The intersections the place the longitudinal and transverse ribs meet are cautiously engineered to furnish excessive junction strength. Strong welded junctions stop slippage or separation beneath heavy or repetitive loading, preserving the dimensional steadiness of the geogrid. High junction effectivity is indispensable for functions such as maintaining walls, embankments, and highways, the place regular reinforcement and dependable overall performance are critical. By retaining structural integrity at these junctions, the geogrid ensures long-term reliability even underneath difficult environmental conditions.

3.3 PP Biaxial Geogrid - Flexural Rigidity

PP Biaxial Geogrids showcase flexural pressure ranging from 250,000 mg·cm to 4,800,000 mg·cm, relying on the product model. This attribute gives enough structural power to assist hundreds whilst nevertheless permitting the geogrid to flex and conform to uneven subgrade surfaces. Adequate flexural pressure ensures that the grid can adapt to minor floor irregularities except compromising its reinforcement function, making it appropriate for each flat and sloped applications.

3.4 PP Biaxial Geogrid - Mechanical Interlock

The aperture diagram of PP Biaxial Geogrids is mainly engineered to maximize mechanical interlock with surrounding soil or mixture particles. This interlock enhances load switch efficiency, improves soil stability, and reduces lateral motion of the strengthened layer. By securely anchoring the soil inside the grid structure, mechanical interlock prevents displacement and keeps the integrity of the bolstered soil over time.

3.5 PP Biaxial Geogrid - Aperture Stability

Apertures in geogrid erosion control is designed to continue their structure even beneath sustained hundreds and environmental stress, such as temperature changes, moisture variations, and freeze-thaw cycles. Stable apertures make sure that the geogrid continues to function efficiently over its complete provider life, retaining soil reinforcement and stopping deformation or grid collapse. This steadiness is specially necessary for long-term civil engineering projects, consisting of avenue bases, embankments, and keeping structures, the place reliability over a long time is required.

4. PP Biaxial Geogrid for Applications

PP biaxial geogrids are fairly versatile geosynthetic materials, extensively utilized throughout civil engineering and development tasks due to their high-quality tensile strength, durability, and soil reinforcement capabilities. Their multi-directional energy and structural balance make them appropriate for a range of difficult environments:

4.1 PP Biaxial Geogrid for Road Construction

Geogrid material is notably used to strengthen unbound base layers in street construction. By offering extra tensile strength, they assist distribute hundreds greater evenly, decreasing stress on underlying soil layers. This reinforcement minimizes rutting, cracking, and protection charges over time. They are perfect for highways, rural roads, airport runways, and industrial pavements, the place heavy visitors masses are common.

4.2 PP Biaxial Geogrid for Railway Embankments

Rail song beds and embankments require steady aid to preserve alignment and stop settlement. Plastic geogrid enhance the bearing potential of the soil, stabilizing song beds and minimizing differential settlement. This ensures smoother teach operation, reduces preservation requirements, and enhances standard security alongside the railway corridor.

4.3 PP Biaxial Geogrid for Retaining Walls

When used in the back of holding walls, PP biaxial geogrids enhance the soil, enhancing wall steadiness and lowering the danger of erosion or collapse. They assist distribute lateral earth strain and grant long-term structural integrity, making them perfect for terraced landscapes, dual carriageway cuttings, and city holding wall projects.

4.4 PP Biaxial Geogrid for Landfills

In landfill construction, geogrids are used to separate layers of waste, stabilize the subgrade, and stop differential settlement. They additionally enhance the balance of overlying layers, minimize lateral motion of waste material, and beautify the average lifespan and overall performance of the landfill liner system.

4.5 PP Biaxial Geogrid for Slope and Embankment Stabilization

PP biaxial geogrids assist stop soil erosion and slope disasters via reinforcing embankments and riverbanks. Their use is especially fantastic in reclaimed land, coastal areas, and hillside slopes, the place soil can be unstable and susceptible to landslides or washouts.

4.6 PP Biaxial Geogrid for Foundations

Geogrids fortify susceptible or tender soils underneath constructing foundations, growing their load-bearing capacity. This reduces differential contract and improves structural balance for residential, commercial, and industrial buildings.

4.7 PP Biaxial Geogrid for Industrial Platforms

For areas that help heavy machinery, storage yards, or loading zones, PP biaxial geogrids enhance subgrade overall performance and stop uneven settlement. They assist keep flat, secure surfaces succesful of withstanding repeated heavy hundreds over time.

5. PP Biaxial Geogrid Installation Guidelines

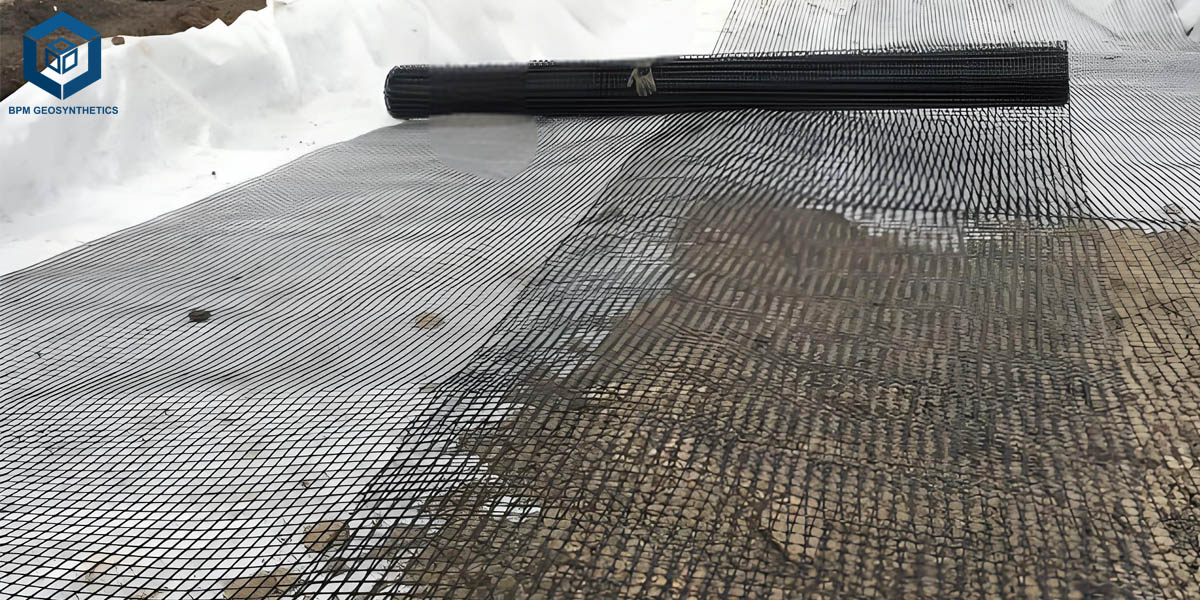

Proper set up of PP biaxial geogrids is indispensable to make certain most reinforcement and long-term performance. Following these quality practices ensures sturdiness and structural reliability:

- Subgrade Preparation: The floor have to be true prepared, making sure it is clean, level, and free of sharp stones or particles that ought to puncture or injury the geogrid. Minor irregularities must be smoothed out to permit full contact with the soil.

- Roll Placement: Rolls of geogrid have to be unrolled carefully, preserving the cloth flat and wrinkle-free. Avoid dragging the geogrid throughout tough surfaces to forestall abrasion.

- Overlap: Adjacent rolls must overlap through 20–30 cm to furnish non-stop load transfer. In high-stress areas, overlap might also be multiplied to beautify reinforcement and make sure seamless coverage.

- Anchoring: Secure the edges the use of pins, stakes, or soil nails to forestall motion at some point of set up and mixture placement. Proper anchoring continues alignment and ensures the geogrid stays taut.

- Aggregate Placement: Place soil, gravel, or different mixture substances steadily and compact uniformly to keep away from transferring or adverse the geogrid. Layering need to be performed cautiously to preserve constant contact and mechanical interlock between the soil and geogrid.

- Inspection: Before last covering, investigate the geogrid for tears, punctures, or misalignment. Any broken areas need to be repaired or changed to preserve finest performance. Correct set up practices are critical to maximize the geogrid’s reinforcement functionality and longevity.

6. Conclusion

PP biaxial geogrids are superior geosynthetic substances that mix excessive tensile strength, long-term durability, and dependable flexibility to meet the needs of contemporary civil engineering projects. By developing a sturdy and uniform soil interlock, they efficiently enhance load distribution, stabilize vulnerable floor conditions, and stop erosion. These facets make them critical in a vast vary of applications, which includes avenue construction, railway embankments, preserving walls, landfill reinforcement, slope stabilization, basis improvement, and heavy-duty industrial platforms.

For tasks that demand quality, reliability, and worldwide requirements compliance, selecting a relied on producer is essential. The Best Project Material Co., Ltd(BPM Geosynthetics) is a main provider with massive trip in producing high-performance geogrids and different geosynthetic solutions. With strict best control, world certifications, and expert technical support, BPM ensures that each and every mission advantages from validated sturdiness and reasonably priced reinforcement solutions.

By partnering with BPM Geosynthetics, you can be assured in reaching safe, sustainable, and environment friendly engineering results.