Bentonite Liner Cost

Bentonite liners, additionally acknowledged as Geosynthetic Clay Liners (GCLs), provide a exceedingly most economical answer for environmental containment and waterproofing projects. Compared to ordinary compacted clay liners or concrete sealing systems, bentonite liners supply superb overall performance at drastically decrease set up and cloth costs. Their efficiency, ease of installation, and long-term reliability make them a desired preference in landfill, mining, and pond lining applications.

- Lower Material Costs:BPM factory-manufactured rolls decrease the want for sourcing and transporting massive volumes of compacted clay.

- Reduced Installation Time:Simple roll-out and overlap graph cuts down labor and equipment expenses.

- Self-Sealing Properties:Reduces danger of leaks and high-priced post-installation repairs.

- Long-Term Durability:Decreases upkeep and alternative prices over the liner’s lifetime.

1. Bentonite Liner Cost

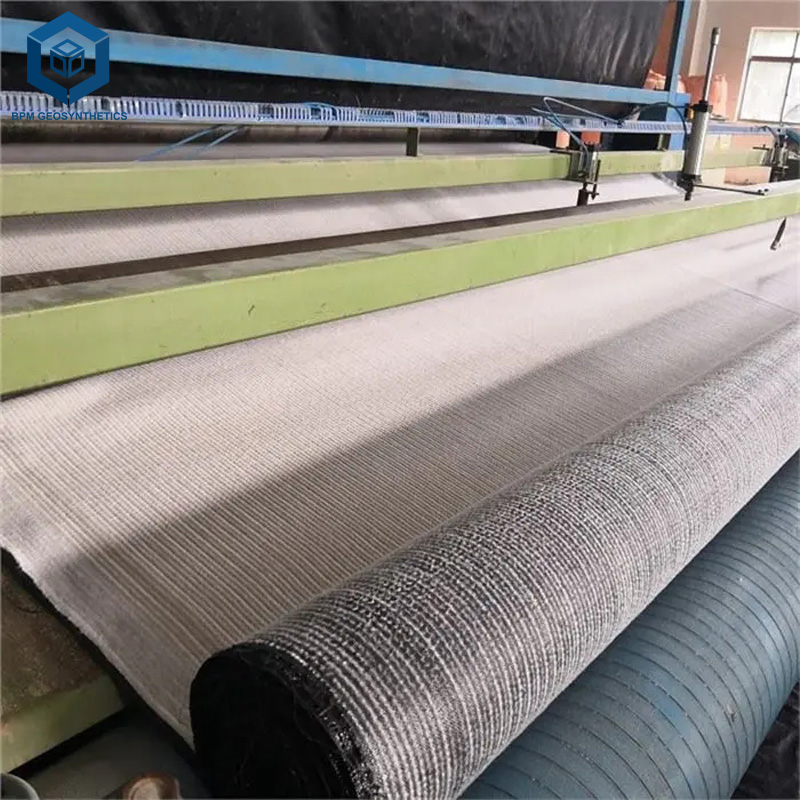

A Bentonite liner, frequently referred to as a Geosynthetic Clay Liner (GCL), is a composite product used for containment applications. It usually consists of a layer of natural sodium bentonite sandwiched between two geotextiles (woven and non-woven fabrics). These liners swell upon contact with water to structure a low-permeability barrier.

2. Choose BPM Bentonite Liner Cost

2.1 Superior Sealing Properties: Swells when hydrated to structure an impermeable barrier.

2.2 Environmental Protection: Used in landfills, ponds, and wastewater remedy to stop leachate leakage.

2.3 Cost-Effective Alternative: Often less expensive and less complicated to installation than compacted clay liners or HDPE membranes.

2.4 Self-Healing Capability: Bentonite’s swelling conduct approves it to self-seal small punctures or tears.

3. Bentonite Liner Cost

3.1 Price Range

- Material Cost: Typically degrees from \$4 to \$10 per rectangular meter, relying on quantity, brand, and specifications.

- Installation Cost: Around \$2 to \$5 per rectangular meter, primarily based on website conditions, labor, and equipment.

- Total Installed Cost: Generally between \$6 to \$15 per rectangular meter.

3.2 Key Cost Factors

- Project Scale: Bulk purchases limit per-unit cost.

- Bentonite Quality: Higher sodium content material improves overall performance however will increase cost.

- Carrier Geotextiles: Woven vs. non-woven combos have an effect on sturdiness and price.

- Location & Shipping: Transport and neighborhood market versions influence complete cost.

- Installation Complexity: Sloped terrain or irregular shapes elevate labor expenses.

4. Main Applications of Bentonite Liner Cost

Bentonite Liner, additionally recognized as Geosynthetic Clay Liners (GCL), are affordable and notably dependable barrier structures broadly used throughout a number of industries for environmental safety and containment solutions. Thanks to their self-sealing properties, robust chemical resistance, and ease of installation, they provide huge blessings in each overall performance and challenge price control. Below are the key software areas of bentonite liners:

4.1 Bentonite Liner Cost - Waste Management

Bentonite liners are significantly used in stable waste containment structures to shield the surrounding surroundings from contamination.

- Landfill Base and Cover Liners: Serve as a integral barrier layer at the backside and pinnacle of landfills to forestall leachate from seeping into the ground.

- Leachate Collection Systems: Installed under the waste layer to accumulate and direct leachate for suited treatment, making sure compliance with environmental regulations.

4.2 Bentonite Liner Cost - Water Containment

These liners furnish a herbal and bendy sealing answer for a number water storage and manage applications.

- Artificial Lakes and Ponds: Used to line man-made water bodies, making sure water retention and minimizing seepage losses.

- Stormwater Detention Basins: Offer a dependable answer for controlling and quickly storing stormwater runoff, supporting stop flooding and erosion.

4.3 Mining & Industrial

Bentonite liners are perfect for tasks requiring chemical resistance and long-term sealing overall performance in harsh conditions.

- Tailings Dams: Prevent seepage of poisonous mining byproducts, safeguarding surrounding land and groundwater.

- Chemical Storage Facilities: Used as an impermeable layer below industrial storage tanks to comprise unintended leaks and spills.

4.4 Environmental Protection

GCLs play a key function in sustainable infrastructure by means of offering reliable containment and air pollution prevention.

- Secondary Containment: Deployed below gasoline tanks or chemical drums as a backup barrier device in case of important containment failure.

- Groundwater Safety Barriers: Installed to isolate contaminated zones or stop hazardous chemical compounds from migrating into easy groundwater sources.

Bentonite liners provide a practical, most economical answer across these sectors through decreasing set up time, minimizing renovation needs, and making sure long-term environmental protection.

5. Technical Specifications of Bentonite Liner Cost

| Parameter | Typical Value |

Bentonite Mass/Area | 4 – 5 kg/m² |

Swell Index | ≥ 24 mL/2g |

Permeability Coefficient | ≤ 5 × 10⁻¹¹ m/s |

Tensile Strength | ≥ 500 N/50 mm |

Thickness (Dry) | ~6 mm |

Peel Strength | ≥ 360 N/m |

6. Bentonite Liner Cost Installation

6.1 Installation Steps

- Surface Preparation: Level and easy the subgrade.

- Unroll the Liner: Lay down panels with overlap (typically 15–30 cm).

- Seal the Joints: Overlaps are sealed by way of herbal swelling or the use of bentonite powder/granules.

- Covering Layer: Apply a protecting soil layer (minimum 30 cm) earlier than publicity to visitors or UV.

6.2 Installation Tips

- Avoid putting in at some point of rain or moist conditions.

- Store in dry stipulations prior to use.

- Minimize foot and tools visitors immediately on the liner.

7. Bentonite Liner VS Other Liners, Advantages

Feature | Bentonite Liner | HDPE Liner | Compacted Clay |

Self-Healing | Yes | No | Limited |

Ease of Installation | High | Medium | Low |

Flexibility | Flexible | Flexible | Rigid |

Permeability | Very Low | Very Low | Moderate |

Cost Efficiency | Competitive | Higher | High Labor Cost |

8. Common Questions About Bentonite Liners

Q1: Can Bentonite Liners Be Used in Harsh Chemical Environments?

Yes, however solely sodium bentonite modified GCLs are appropriate for chemical resistance. Always take a look at chemical compatibility.

Q2: How Long Do Bentonite Liners Last?

With perfect set up and covering, they can closing 50+ years besides sizeable degradation.

Q3: Do They Require Maintenance?

Minimal renovation is required. Monitoring for erosion or cowl damage is recommended.

9. Bentonite Liner for Your Project

If your undertaking needs an effective, low-cost, and environmentally friendly barrier system, a Bentonite Liner is a pinnacle choice. It combines ease of use with proven performance, specifically in landfill, water containment, and environmental safety projects.

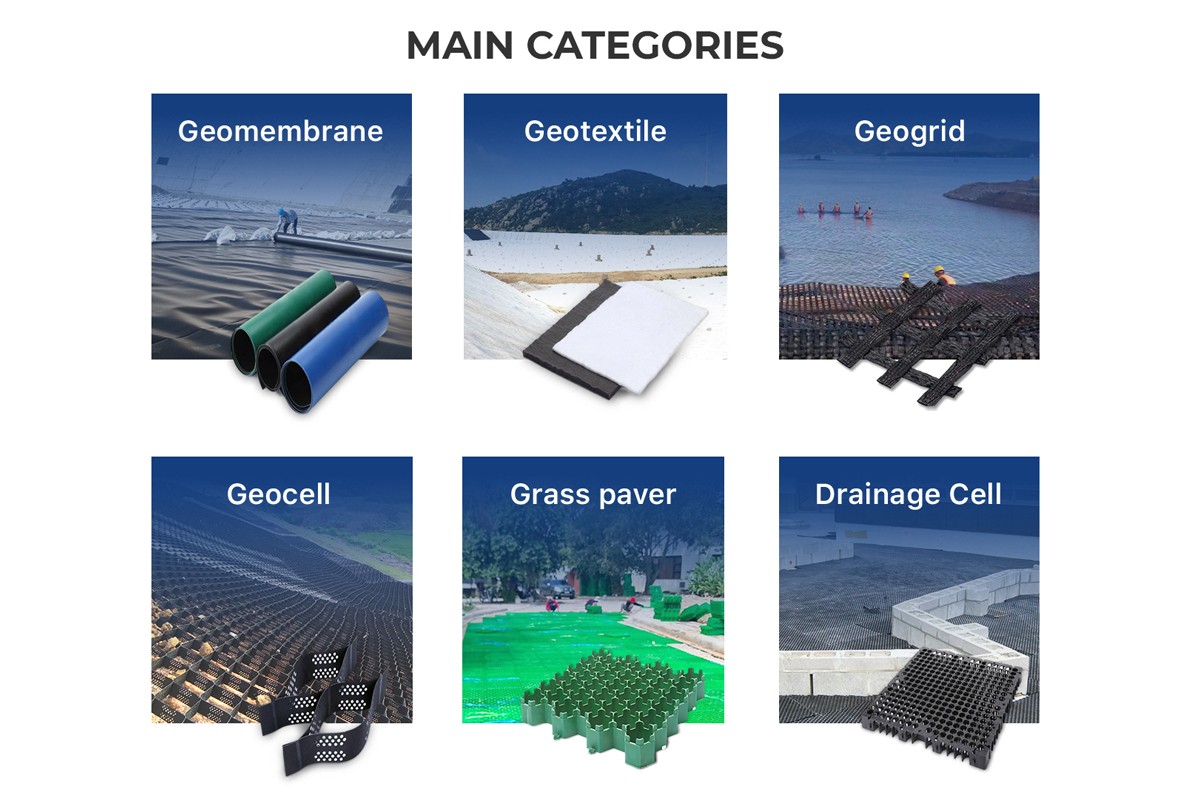

About BPM GEOSYNTHETICS

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, and geogrids. Established in 2007, the company is committed to providing one-stop services in research, production, and sales, with a focus on innovation and quality. BPM's products, certified by EU CE and GLP, meet ISO 9001, ISO 14001, and OHSAS 18001 standards, ensuring performance and durability. With a manufacturing facility of over 36,000 square meters and a team of 120 technical experts, BPM serves various sectors such as aquaculture, erosion control, drainage, and municipal engineering. We look forward to partnering with you to tackle complex challenges using our high-performance geosynthetic solutions.