Drainage Sheet

With tested overall performance in a broad vary of environmental and structural conditions, BPM drainage sheet provide a cost-effective, long-lasting answer for environment friendly water manage and waterproofing protection. Let us assist you diagram smarter, greater resilient building systems—contact BPM today for samples, technical specifications, or custom-made drainage solutions.

Drainage Sheet - Customization & Support for Your Project Needs:

- Available Heights & Profiles:Dimple heights from 6mm to 20mm to suit drainage quantity requirements

- Roll Sizes: Standard and project-specific roll widths and lengths for decreased waste

- Composite Options: Can be mixed with nonwoven geotextiles for built-in filtration and drainage

- Colors: Black, white, or green—custom colours reachable for particular functions or branding

- OEM Services: Logo printing, packaging customization, and bulk provide options available

1. BPM Geosynthetic Drainage Sheet

A drainage sheet is a high-performance geosynthetic layer designed to manipulate water round constructed environments. It serves as each a drainage conduit and a defensive layer in opposition to hydrostatic pressure, soil movement, and structural damage.

It is extensively used in present day building to substitute standard gravel-based drainage layers. By making sure perfect subsurface water flow, drainage sheets:

- Protect underground buildings from water infiltration,

- Reduce the hazard of dampness and mold,

- Minimize basis shifts due to water buildup.

Drainage sheets are necessary in waterproofing systems, making sure that moisture is channeled away from quintessential areas like basements, podium decks, tunnels, and panorama installations.

2. BPM Uses Imported Raw Materials to Manufacture High-Quality Drainage Sheet

The overall performance of a drainage sheet relies upon generally on the composition and format of its layers. Key substances include:

2.1 High-Density Polyethylene (HDPE)

High-Density Polyethylene (HDPE) gives the drainage sheet with tremendous tension and toughness, making sure structural balance at some point of and after installation. Its top of the line resistance to corrosion, salts, and a large vary of chemical compounds makes it in particular well-suited for use in aggressive soil environments the place long-term sturdiness is critical. Additionally, HDPE presents excessive compressive strength, usually exceeding 250 kPa, which approves the sheet to hold its structure and drainage ability even below the strain of heavy soil backfill or concrete slabs.

2.2 Polypropylene (PP)

Polypropylene (PP) is a bendy and UV-stabilized material, making it notably appropriate for outside environments and vertical installations such as protecting partitions or basis exteriors. Its composition ensures low moisture absorption and gorgeous resistance to organic degradation, permitting it to operate reliably in damp or buried prerequisites besides deteriorating over time.

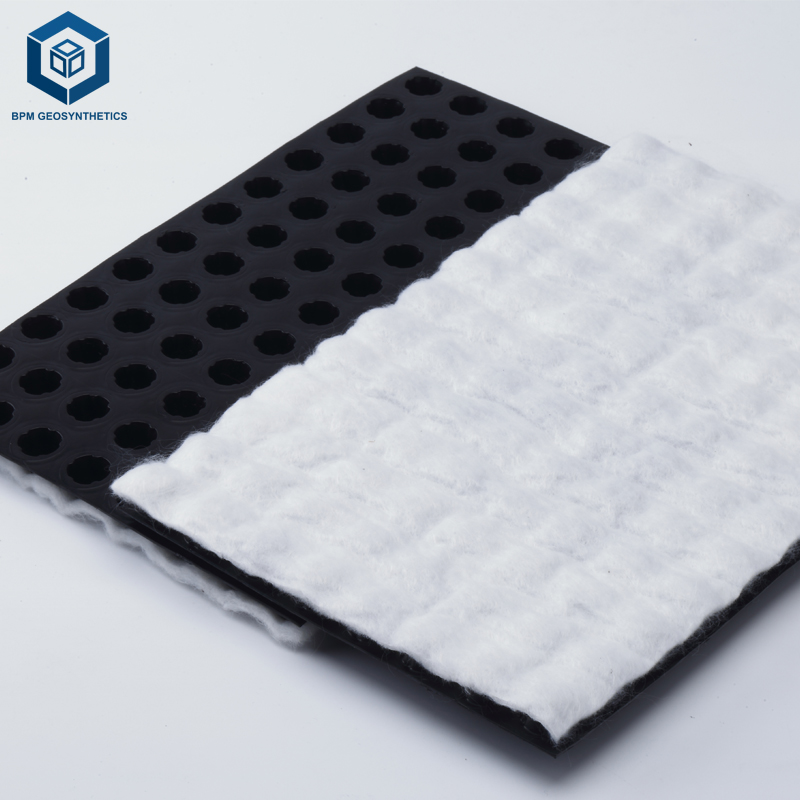

2.3 Nonwoven Geotextile Fabric

The nonwoven geotextile fabric, both thermally bonded or needle-punched, is laminated onto the dimpled core of the drainage sheet to feature as an superb filtration layer. It lets in water to ignore thru freely whilst conserving great soil particles, thereby stopping sediment from coming into and clogging the drainage channels. This diagram substantially enhances long-term filtration performance, making sure regular water float and keeping the effectivity of the drainage device over time.

3. Application Principle of Drainage Sheet

Drainage sheets work by way of developing a void area that allows speedy motion of water away from the structure. Their operation can be damaged down into three layers:

3.1 Dimpled or Cuspated Core

The dimpled core is the coronary heart of the drainage sheet system, offering a third-dimensional shape that creates non-stop air gaps to facilitate water flow. It successfully helps each vertical and horizontal drainage, even below sizable soil pressure. Depending on the required drainage capacity, the dimples are reachable in a range of heights, usually ranging from eight mm to 20 mm, to accommodate exclusive mission needs.

3.2 Geotextile Filtering Layer

The geotextile layer performs a vital position with the aid of stopping soil particles from clogging the core, making sure the drainage machine stays wonderful over time. It is engineered to keep excessive permeability, generally higher than 0.1 cm/s, even after extended publicity to soil and moisture, supplying dependable long-term performance.

Water getting into thru the soil or shape interface is directed thru the sheet to drain retailers or series systems, assisting keep the integrity of concrete, masonry, and water resistant membranes.

4. Key Features of a Drainage Sheet

Drainage sheets are designed for high-performance water administration and structural protection. Their standout facets include:

4.1 High Drainage Flow Rate

Drainage sheets successfully control water float by way of developing non-stop air channels that enable rainwater and groundwater to pass freely. The dimpled core, frequently paired with a nonwoven geotextile, gives a fast drainage course that reduces hydrostatic strain on constructing elements. This characteristic is mainly quintessential for basis walls, inexperienced roofs, and protecting buildings that have to continue to be dry and structurally sound.

4.2 Durability Under Load

Engineered from high-strength substances like HDPE or PP, drainage sheets showcase awesome compressive resistance. They can assist the weight of soil backfill, paving, or concrete slabs except deforming or collapsing. This ensures the integrity of the drainage layer stays intact, even underneath long-term structural masses in underground or high-traffic installations.

4.3 Dimensional Stability

The sheets maintain their bodily structure and drainage potential below various conditions, consisting of temperature modifications and mechanical pressures. Whether uncovered to intense bloodless or excessive heat, the fabric does now not warp, shrink, or lose performance. This dimensional steadiness is vital for preserving a steady drainage layer throughout seasons and website conditions.

4.4 UV and Chemical Resistance

UV-resistant polymers shield the sheets from degradation triggered via extended publicity to sunlight—an essential consideration for uncovered purposes such as podiums or inexperienced roofs. Additionally, their chemical inertness lets in them to operate in environments containing aggressive elements like avenue salts, acidic soils, or industrial runoff besides breaking down over time.

4.5 Root Resistance

When hooked up in panorama or inexperienced roofing environments, the sheet acts as a barrier to root intrusion. This prevents plant roots from achieving waterproofing membranes or structural joints, accordingly lowering the hazard of damage, leaks, or device failure. Some versions encompass anti-root components or coatings to in addition decorate this defensive feature.

5. Sizes and Specifications for Drainage Sheet

| Property | Range / Value |

Dimple/Core Height | 8 mm, 10 mm, 12 mm, 20 mm |

Sheet Thickness | 0.5 mm to 2.0 mm |

Roll Width | 1 m to 3 m |

Roll Length | 10 m to 30 m |

Compressive Strength | Up to 400 kPa |

Flow Rate | 5 to 10 L/m²·s |

Geotextile Type | 100–150 g/m² (nonwoven, needle-punched) |

6. Environmentally Friendly Drainage Sheet

Yes, drainage sheets are developed with sustainability and environmental duty at their core. Their sketch and cloth decision aid each ecological desires and modern-day development standards. Here’s how:

6.1 Made from Recyclable Materials

Most drainage sheets are manufactured from recyclable thermoplastics, such as High-Density Polyethylene (HDPE) or Polypropylene (PP). These substances no longer solely furnish long-term sturdiness and performance however additionally make a contribution to environmental conservation by means of permitting reuse or recycling at the quit of the product’s carrier life. This reduces landfill waste and helps round development practices.

6.2 Non-Toxic and Chemically Stable

Drainage sheets are chemically inert and free from dangerous additives, which capacity they do now not leach toxins or contaminants into the surrounding soil or groundwater. Their steadiness makes them appropriate for use in environmentally touchy areas, such as close to wetlands, agriculture zones, or potable water infrastructure. This ensures the safety of neighborhood ecosystems at some stage in the product’s lifespan.

6.3 Root-Resistant and Green Infrastructure Compatible

Designed to face up to root penetration, these sheets grant a shielding barrier for waterproofing membranes in inexperienced roofs, planter boxes, and different vegetated systems. Their compatibility with eco-projects makes them perfect for use in sustainable city design, assisting vegetation whilst managing extra water via built-in drainage channels.

6.4 Lightweight and Efficient in Transport

Unlike regular gravel-based drainage systems, drainage sheets are lightweight, compact, and convenient to transport, which appreciably reduces carbon emissions related with shipping and handling. Their roll-form packaging lets in greater environment friendly storage and shipping, in addition contributing to decreased gas consumption and greenhouse gasoline output.

6.5 Supports Green Building Certifications

When used in conjunction with sustainable constructing practices, drainage sheets can assist earn credit in inexperienced constructing certification structures such as LEED (Leadership in Energy and Environmental Design) or BREEAM. Their roles in stormwater management, cloth useful resource efficiency, and ecosystem upkeep make them a key aspect in environmentally licensed building and infrastructure projects.

BPM GEOSYNTHETICS – Drainage Sheet

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a globally diagnosed producer and exporter of top rate geosynthetic products, along with drainage sheets, geomembranes, geotextiles, geogrids, and associated systems. Since its institution in 2007, BPM has targeted on turning in comprehensive one-stop services masking product research, manufacturing, technical support, and world sales—with a dedication to non-stop innovation, licensed quality, and purchaser satisfaction.

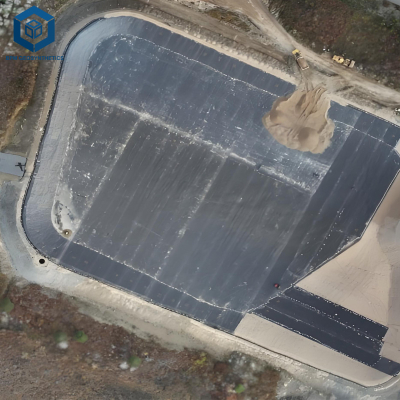

BPM’s drainage sheets are produced the usage of high-quality imported uncooked materials, such as HDPE and PP, making sure brilliant durability, water administration performance, and long-term resistance to chemicals, soil pressure, and environmental exposure. These sheets are extensively used in basements, tunnels, conserving walls, inexperienced roofs, plaza decks, and basis systems, the place fine subsurface drainage and waterproofing safety are critical.

Strong Manufacturing Capabilities

- Over 36,000 rectangular meters of modern-day manufacturing facilities

- Equipped with advanced extrusion and thermoforming lines for drainage sheet production

- Annual ability exceeding 10 million rectangular meters of geosynthetic materials

- Backed via a crew of 120+ professional engineers and technical experts

- Rigorous quality manipulate system and in-house trying out lab to make sure each roll meets worldwide standards

Certified Quality & Global Reach

BPM’s drainage merchandise are certified through EU CE, GLP, and wholly comply with ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and OHSAS 18001 (Occupational Health & Safety) standards. Our geosynthetic options have been exported to over 100 countries, serving industries such as civil construction, landscaping, mining, infrastructure, environmental protection, and municipal drainage projects.

With a long time of ride and a recognition for reliable quality, quickly delivery, and professional service, BPM GEOSYNTHETICS is your relied on accomplice for high-performance drainage sheet solutions. Whether you’re managing a small-scale panorama plan or a large-scale infrastructure project, BPM offers validated geosynthetic structures to beautify durability, drainage efficiency, and building success.