Geogrid for Roads

Geogrid for roads is an superior reinforcement answer aimed at enhancing the structural integrity and lifespan of street systems. This geogrid is made of high-strength polymer, efficiently distributing loads, minimizing avenue deformation, and extending street life. Its special grid shape additionally helps correct drainage, stopping erosion and structural injury prompted with the aid of water accumulation, making it an best desire for a number of street building applications.

-High bearing ability : Uniform distribution of load, decreasing roadbed stress, and stopping deformation.

-Durability : Resistant to UV radiation and environmental degradation, making sure long-lasting performance.

-Improve drainage: Enhance water flow, stop erosion, and keep street stability.

-Easy to set up : Lightweight, handy to operate, simplifies the building process, and reduces labor costs.

Geogrid for roads is a present day reinforcement material in particular designed to decorate the structural integrity and sturdiness of avenue systems. This geogrid for roads is made of high-strength polymer and has a special grid sample that can efficiently distribute hundreds over a large area. This load distribution substantially reduces the stress on the roadbed, thereby minimizing the hazard of deformation and cracking of the avenue floor underneath heavy traffic.

The modern diagram of geogrid for roads no longer solely improves the bearing capacity, however additionally enhances the drainage capacity. By merchandising fine water flow, it can stop water accumulation, which can lead to soil erosion and possible structural injury to roads. This is in particular essential in areas inclined to heavy rainfall or floods, the place superb drainage is integral for retaining street integrity.

Overall, street geogrid for roads are a multifunctional and reasonably-priced answer in cutting-edge street construction, assisting to improve safer and extra sustainable infrastructure to meet modern-day transportation needs. The mixture of strength, durability, and effectivity makes it an vital factor in enhancing avenue overall performance and lifespan.

Parameter

Properties | Unit | Product Specification | |||||||

BGUG25 | BGUG35 | BGUG50 | BGUG80 | BGUG110 | BGUG120 | BGUG150 | |||

Width | m | 1.0-2.0m | |||||||

Length/Roll | m | 50 | |||||||

Tensile Strength | HDPE | kN/m2 | ≥25 | ≥35 | ≥50 | ≥80 | ≥110 | ≥120 | ≥150 |

PP | kN/m2 | ≥25 | ≥35 | ≥50 | ≥80 | ≥110 | ≥120 | ≥150 | |

Elongation | HDPE | % | 11-16 | ||||||

PP | % | 10 | |||||||

Strength At 2%Elongation | HDPE | kN/m | ≥6 | ≥9 | ≥10 | ≥23 | ≥30 | ≥35 | ≥46 |

PP | kN/m | ≥7 | ≥10 | ≥12 | ≥26 | ≥32 | ≥38 | ≥48 | |

Strength At 5% Elongation | HDPE | kN/m | ≥12 | ≥18 | ≥25 | ≥44 | ≥60 | ≥70 | ≥87 |

PP | kN/m | ≥14 | ≥20 | ≥28 | ≥48 | ≥64 | ≥75 | ≥93 | |

Geogrid for Roads Features

-High bearing capacity: The special grid shape of geogrids correctly distributes masses over a wider area, appreciably decreasing the stress on the roadbed and minimizing street deformation to the biggest extent possible.

-Durability: Geogrids are made of high-strength polymers that can face up to UV radiation and environmental degradation, making sure long-lasting overall performance even in harsh climate conditions.

-Improving drainage: This plan is really helpful for properly drainage, stopping water accumulation from inflicting soil erosion and structural damage, thereby improving street stability.

-Lightweight and effortless to install: The light-weight traits of geogrids simplify coping with and installation, making tasks quicker and lowering labor costs.

-Multi useful utility : Suitable for a range of street types, consisting of highways, nearby roads, and get entry to roads, making it a bendy answer for engineers.

-Economically efficient: By lowering the want for extra substances and maintenance, geogrids supply an economically environment friendly answer that improves usual assignment efficiency.

-Erosion manipulate : Helps stabilize soil and forestall erosion, and contributes to the long-term protection and integrity of street structures.

-Sustainability: Supporting environmentally pleasant building practices through enhancing soil steadiness and lowering the ecological have an effect on of roads.

Applications of Geogrid for Roads

-Highway construction: Geogrids beautify the structural integrity of highways by using distributing heavy visitors loads, decreasing deformation, and extending pavement life.

-Local roads: Geogrids are used in nearby street building to stabilize the roadbed, forestall ruts, make sure sturdiness of the street surface, and stand up to every day traffic.

-Access road: Geogrid is an best preference for transient or everlasting get right of entry to roads, which can enhance bearing capability and stability, facilitate development and preservation operations.

-Parking Lot: Geogrids fortify the floor of the parking lot to stop cracking and deformation underneath car loads, thereby lowering preservation expenses and enhancing aesthetics.

-Existing street repair: In street restore projects, geogrids can be used to fortify present avenue surfaces, enhance their load-bearing capacity, and lengthen their carrier life.

-Slope stability: Geogrids are used in slope balance tasks to assist forestall soil erosion and landslides, making sure safer roads in hilly or unstable areas.

-Railway embankment: Geogrids are used in railway building to supply integral aid for embankments, enhance music stability, and decrease settlement.

-Green infrastructure: In environmentally sustainable projects, geogrids assist control rainwater runoff and soil conservation, and make a contribution to environmentally pleasant street design.

These functions spotlight the multifunctionality and effectiveness of geogrids in avenue construction, making them an necessary fabric for improving the overall performance and protection of more than a few avenue systems.

Company Profile

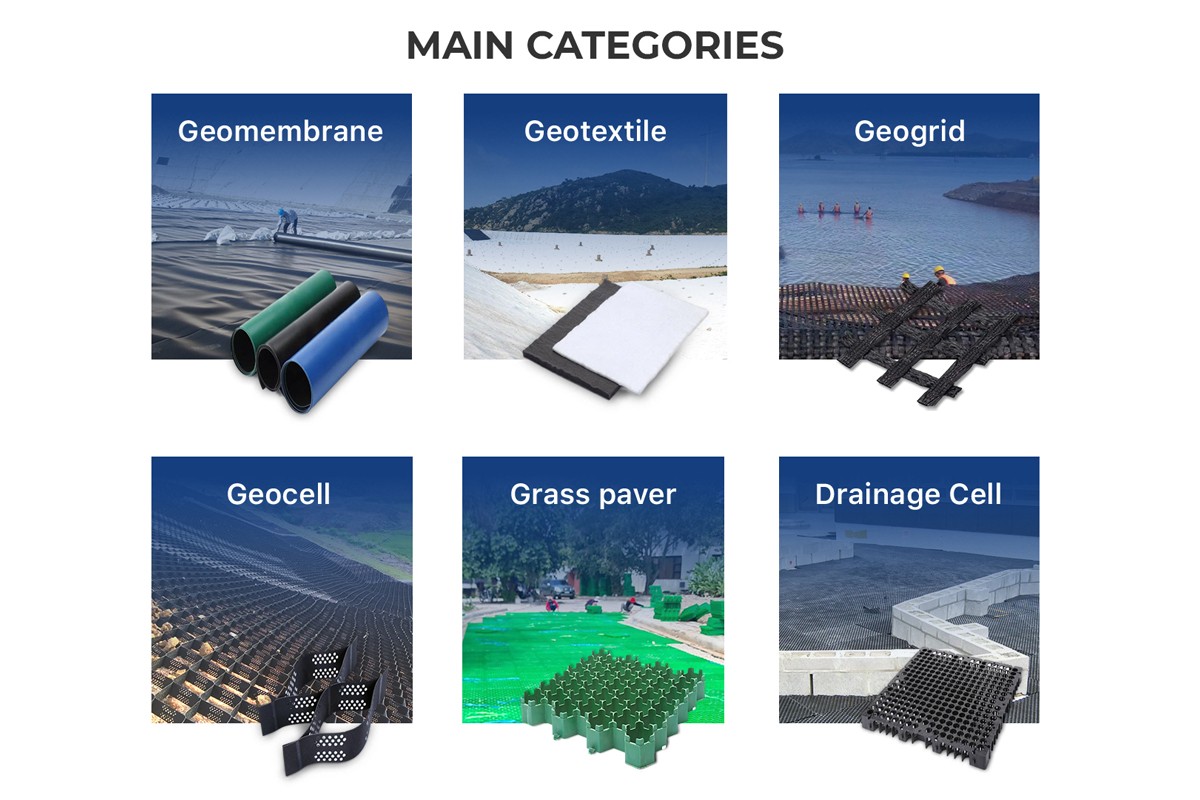

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, geogrids, geocells, and geosynthetic clay liners (GCL). Our products, certified by EU CE and GLP, have passed ISO 9001, ISO 14001, and OHSAS 18001 standards, and are recognized for their quality, performance, and durability.

BPM GEOSYNTHETICS has been committed to providing one-stop services for global customers in the research and development, production, sales, and export of geosynthetic materials since its establishment in 2007. The company has 120 senior technical talents specializing in geotechnical materials. The manufacturing factory covers an area of over 36000 square meters and is equipped with industry-leading automated production equipment and professional testing instruments. Product innovation, quality assurance, and customer satisfaction have always been BPM commitment to partners.

We're committed to innovation and quality, offering flexible cooperation and the best solutions for engineering projects worldwide. Our products are utilized in various sectors like aquaculture, erosion control, drainage systems, municipal engineering, mining, and landscaping. We look forward to partnering with you to solve complex challenges with our high-performance geosynthetic products.