Erosion Control Geomat

Erosion control has become a critical component in modern civil engineering, environmental remediation, and large-scale infrastructure development. As extreme rainfall and construction activities accelerate surface degradation, demand for erosion control geomat products continues to rise across global markets. This article provides an in-depth overview of erosion control geomats, including market trends, material technology, manufacturing insights, and application guidelines for international B2B buyers seeking reliable geosynthetic solutions.

Erosion Control Geomat: A High-Performance Solution for Slope Protection and Soil Stabilization

Erosion control has become a critical component in modern civil engineering, environmental remediation, and large-scale infrastructure development. As extreme rainfall and construction activities accelerate surface degradation, demand for erosion control geomat products continues to rise across global markets. This article provides an in-depth overview of erosion control geomats, including market trends, material technology, manufacturing insights, and application guidelines for international B2B buyers seeking reliable geosynthetic solutions.

Global Market Background and Industry Demand

In recent years, large infrastructure programs—such as road expansion, mining operations, riverbank protection, and agricultural modernization—have significantly increased the use of geosynthetics for environmental protection. According to industry data, the global erosion control materials market is estimated to exceed USD 2.5 billion by 2027, driven by stricter environmental regulations and the demand for long-lasting slope protection systems.

Within this market, erosion control geomat products stand out due to their lightweight structure, flexible installation, and strong compatibility with vegetation growth. These factors make them an effective alternative to traditional methods like concrete slope coverage or stone pitching.

What Is an Erosion Control Geomat?

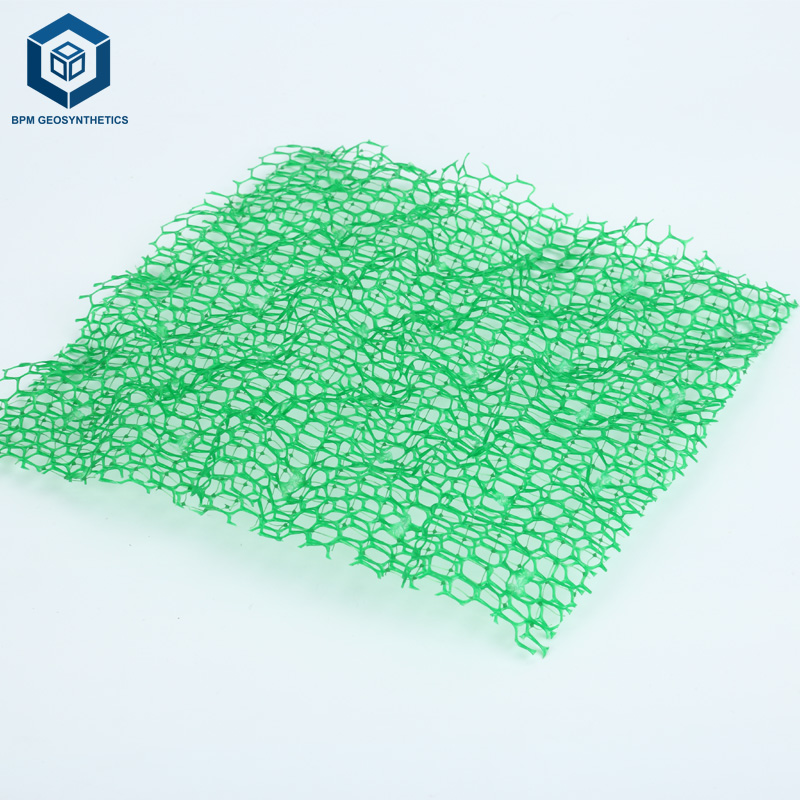

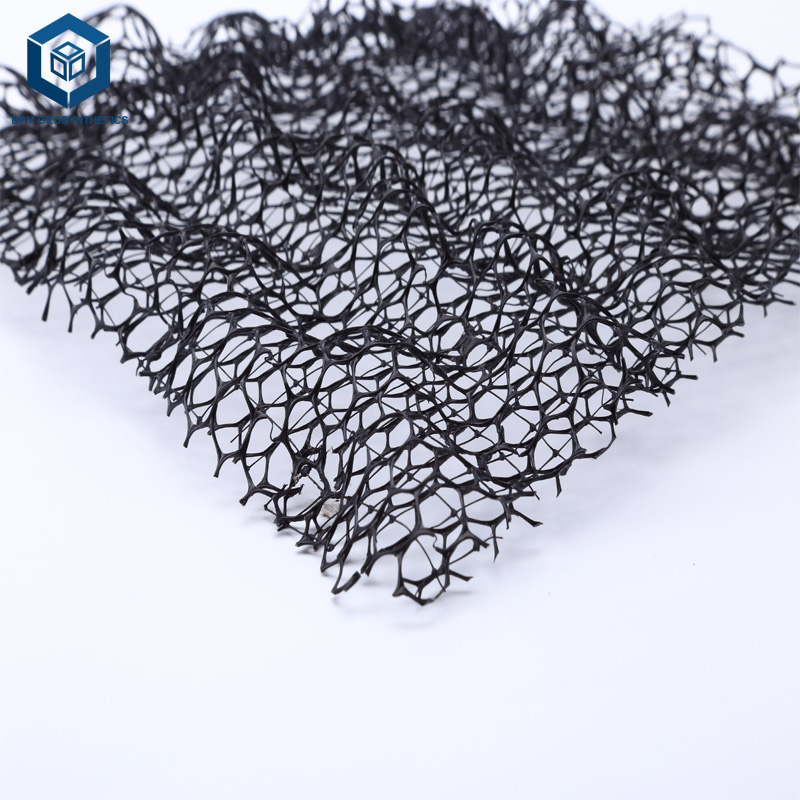

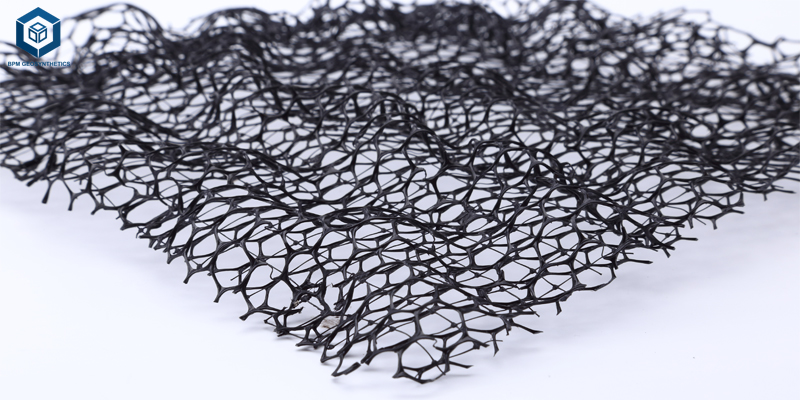

An erosion control geomat is a three-dimensional, polymer-based synthetic mat designed to reinforce soil, protect slopes, and prevent surface erosion. It is typically manufactured using high-density polyethylene (HDPE), polypropylene (PP), or a combination of polymer fibers bonded into a multi-layer mesh structure.

Key Functions

Stabilizing soil on steep or unstable slopes

Reducing rainfall-induced erosion

Enhancing vegetation rooting and long-term ecological restoration

Improving surface water drainage to minimize soil displacement

Protecting riverbanks, channels, and landfill caps

Thanks to its open-mesh design, the geomat provides a stable environment for grass roots to anchor, forming a composite system of soil + geomat + vegetation that significantly increases surface resistance.

Material Technology and Manufacturing Overview

High-quality erosion control geomats are typically produced using extrusion and bonding processes that form a uniform, interwoven network of polymer filaments. The most commonly used material, HDPE, offers exceptional chemical resistance and durability, making it suitable for long-term outdoor exposure.

Manufacturing Steps (Simplified)

Polymer extrusion — Base resin is melted and extruded into filaments.

Layer bonding — Multiple layers are thermally bonded to form a multi-dimensional structure.

Cooling & shaping — The geomat is set to ensure uniform pore size and thickness.

Rolling & packaging — The finished product is rolled for easy transport and deployment.

Modern production lines allow customization in thickness, density, tensile strength, and UV stabilization, enabling buyers to select geomats that match specific project requirements such as slope gradient or rainfall intensity.

Applications of Erosion Control Geomat in Engineering Projects

H2: Slope Protection in Road and Railway Construction

Infrastructure projects often involve high-cut slopes that are vulnerable to erosion. An erosion control geomat significantly improves soil cohesion and forms a natural green surface that supports long-term ecological restoration.

H2: Riverbank and Canal Protection

In water management projects, geomats prevent scouring and wash-out. The porous structure maintains hydraulic function while safeguarding soil stability.

H2: Mining and Landfill Environmental Covers

Mining tailings and landfill closure systems require erosion-resistant top layers. Geomats provide an efficient barrier against rainfall and surface runoff.

H2: Agricultural and Landscape Engineering

In farmlands and landscaping zones, geomats control erosion, support vegetation, and reduce maintenance costs for exposed slopes.

Market Trends: Why Buyers Are Increasingly Choosing Geomats

Rising Environmental Compliance

Countries in Asia, the Middle East, Europe, and Latin America have tightened soil protection guidelines, directly boosting demand for geosynthetic erosion control systems.

Optimization of Construction Costs

Compared with concrete or rock revetment, geomats significantly lower transportation and installation expenses while maintaining sufficient engineering strength.

Growth in Green Engineering Concepts

The concept of “soil bio-engineering” favors solutions like geomats that combine mechanical stability with vegetation growth.

Increasing Demand for Lightweight Products

Contractors now prefer lightweight, roll-packaged erosion control materials for easier logistics in remote or mountainous regions.

Performance Advantages of Erosion Control Geomat

Excellent UV resistance and long outdoor service life

High tensile strength due to multi-layer polymer bonding

Easy installation and minimal technical requirements

Resistance to chemicals, microorganisms, and natural weathering

Superior vegetation compatibility compared with other polymers

These performance characteristics make erosion control geomats ideal for large-scale, cost-efficient environmental protection projects.

FAQ: Common Questions from B2B Buyers

1. What thickness or type of erosion control geomat should I choose?

Selection depends on slope gradient, rainfall intensity, soil conditions, and project specifications. Standard choices range from 10 mm to 20 mm in thickness.

2. How long can an erosion control geomat last outdoors?

With UV-stabilized HDPE materials, geomats can achieve service lives exceeding 8–10 years, depending on climate conditions.

3. Can the geomat support vegetation growth in harsh environments?

Yes. The three-dimensional mesh encourages root penetration and stabilization, helping vegetation establish even on poor or thin soils.

4. Are geomats environmentally friendly?

Most HDPE and PP geomats are considered environmentally safe, non-toxic, and recyclable, aligning with global green engineering trends.

Conclusion and Professional Call to Action

As global infrastructure development accelerates, erosion control geomat solutions offer unmatched efficiency, cost-effectiveness, and ecological benefits for slope and soil stabilization. Whether you are sourcing for road construction, water conservancy, mining rehabilitation, or landscaping projects, choosing the right geomat can significantly enhance long-term performance and reduce environmental risks.

If you require technical data sheets, customized product specifications, or engineering consultation for upcoming projects, We welcome professional inquiries from international buyers. Contact us to obtain detailed solutions tailored to your erosion control needs.