Composite Geomembrane Liner

Strong and Durable: Combines HDPE and geotextiles for enhanced resistance.

Improved Water Management: Boosts filtration and drainage while preventing erosion.

Lightweight and Easy to Install: Cuts transport and labor costs.

Flexible Customization: Adapts to various project needs.

Eco-Friendly Protection: Shields soil and groundwater from pollution.

Wide Application: Used in landfills, mining, water control, and remediation.

Composite geomembrane liner mix the strengths of more than one substances to create an tremendously positive barrier gadget for quite a number applications. These liners commonly consist of a high-density polyethylene (HDPE) layer bonded to a geotextile or any other material, supplying better sturdiness and versatility. One of the major benefits of composite geomembrane liners is their best puncture resistance, which makes them especially appropriate for installations in difficult environments the place sharp objects or abrasive substances may also pose a risk. Additionally, the geotextile layer gives awesome filtration and drainage properties, permitting for environment friendly water administration whilst stopping soil migration. This function is specifically recommended in purposes such as landfill liners and water containment systems, the place controlling leachate and seepage is crucial. The composite shape additionally enables effortless set up and welding, making sure sturdy seams that beautify the universal integrity of the system. Furthermore, these liners show off super chemical resistance, making them perfect for containing a broad vary of hazardous substances barring chance of degradation. Overall, the aggregate of strength, flexibility, and superior overall performance traits makes composite geomembrane liners an ideal desire for engineers and environmental authorities looking for dependable options for containment, protection, and environmental sustainability throughout various applications.

Parameter

Test ltem | Test Properties | Unit | BCM4 | BCM5 | BCM6 | BCM7 | BCM8 | BCM9 | BCM10 |

Unit Weight | g/㎡ | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | |

Film Thickness | mm | 0.25-0.35 | 0.30-0.50 | ||||||

Mechanical Properties | Break Strength | kN/m | 5.0 | 7.5 | 10.0 | 12.0 | 14.0 | 16.0 | 18.0 |

Break Elongation | % | 30-100 | |||||||

CBR Burst Strength | KN | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | |

Tear Resistance | KN | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | |

Peel Resistance | KN | ≥6 | |||||||

Hydrostatic Pressure | Film Thickness | Mm | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 |

One cloth one film | Mpa | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | |

Two cloth one film | Mpa | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | |||

Composite Geomembrane Liner Features

1. Enhanced Puncture Resistance: The aggregate of substances in composite geomembranes gives most appropriate puncture resistance, making them appropriate for installations in environments with sharp or abrasive materials.

2. Excellent Chemical Resistance: These liners can face up to publicity to a large vary of chemicals, making sure they stay intact and nice in containing hazardous components except degradation.

3. Filtration and Drainage Properties: The geotextile layer lets in for wonderful filtration and drainage, stopping soil migration whilst managing water float and lowering hydrostatic pressure.

4. Strong Seam Integrity: Composite geomembranes can be effortlessly welded, growing sturdy seams that beautify the universal integrity and reliability of the barrier system.

5. Flexibility and Adaptability: The composite shape permits for flexibility, enabling the liners to conform to a variety of shapes and contours of the set up site, which simplifies the set up process.

6. UV and Weather Resistance: These geomembranes are designed to face up to UV radiation and harsh climate conditions, making sure long-term overall performance and durability.

7. Lightweight Design: Composite geomembranes are quite lightweight, facilitating simpler coping with and transportation, which speeds up the set up technique on site.

8. Cost-Effective Solution: By combining the advantages of exclusive materials, composite geomembrane liners supply a budget friendly solution, decreasing the want for regular replacements and repairs.

9. Environmental Protection: They efficaciously stop leachate and contaminants from migrating into the surrounding environment, contributing to environmental safety and regulatory compliance.

10. Versatile Applications: Due to their special properties, composite geomembranes are appropriate for a huge vary of applications, together with landfill liners, pond liners, and mining operations, amongst others.

Applications of Composite Geomembrane Liner

1. Landfill Liners: Composite geomembranes are considerably used as liners in landfills to forestall leachate from contaminating surrounding soil and groundwater, making sure environmental security and compliance with regulations.

2. Water Containment: These liners are best for water reservoirs, retention ponds, and irrigation canals, correctly stopping water loss due to seepage whilst retaining water quality.

3. Mining Operations: In the mining industry, composite geomembranes are utilized for tailings storage, heap leach pads, and waste containment, assisting to manipulate hazardous substances and defend the environment.

4. Wastewater Treatment: Composite geomembranes are employed in wastewater remedy services to create impermeable boundaries that incorporate sludge and forestall the get away of contaminants into the surrounding area.

5. Agricultural Applications: They are used in agricultural settings for lining irrigation ditches and ponds, merchandising environment friendly water use and stopping soil erosion.

6. Aquaculture: Composite geomembranes are indispensable in fish farming and aquaculture systems, offering impenetrable environments for aquatic lifestyles whilst stopping illness from exterior sources.

7. Oil and Gas Industry: These liners are used in secondary containment structures for storage tanks and pipelines, efficiently stopping leaks and spills that ought to damage the environment.

8. Civil Engineering Projects: Composite geomembranes are utilized in a number of civil engineering tasks for slope stabilization, erosion control, and as limitations in building web sites to control water flow.

9. Green Roof Systems: They are utilized in inexperienced roofing functions to create water-proof barriers, helping vegetation whilst permitting for tremendous drainage.

10. Recreational Applications: Composite geomembranes are used in artificial turf fields and leisure ponds, supplying dependable drainage and retaining most advantageous stipulations for sports activities and enjoyment activities.

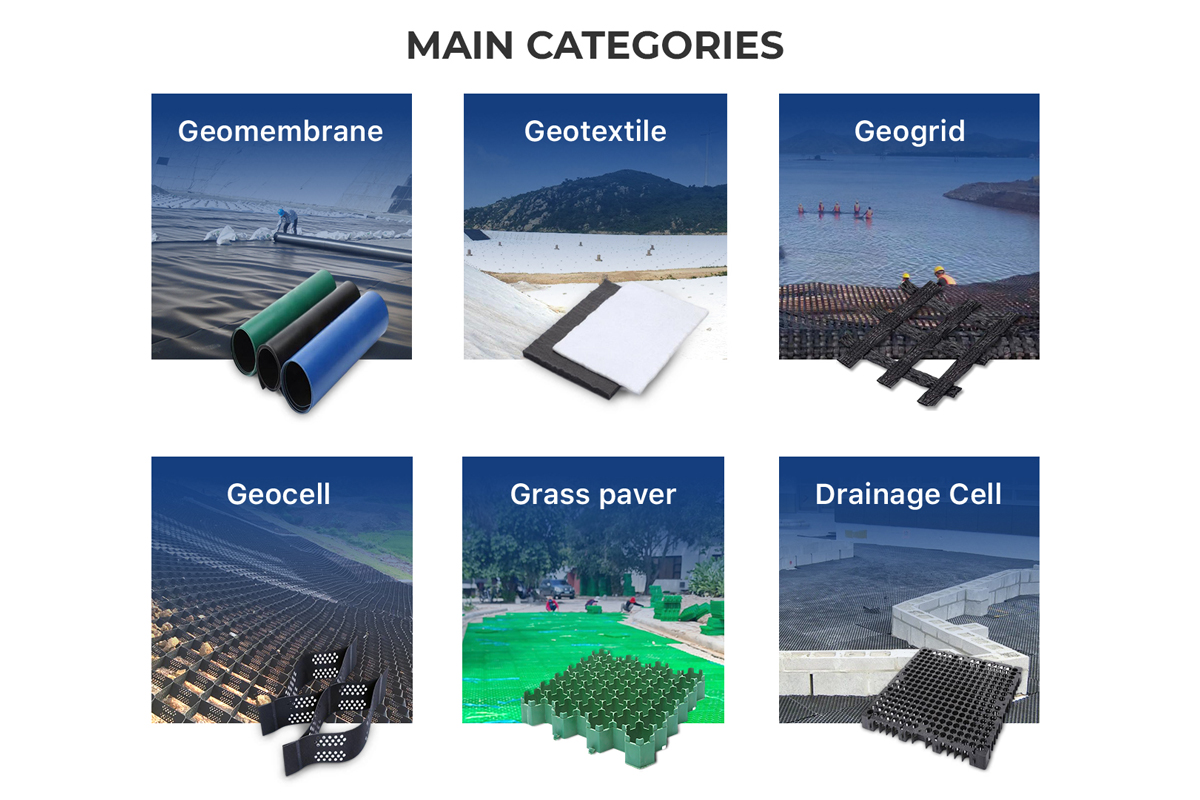

Company Profile

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, geogrids, geocells, and geosynthetic clay liners (GCL). Our products, certified by EU CE and GLP, have passed ISO 9001, ISO 14001, and OHSAS 18001 standards, and are recognized for their quality, performance, and durability.

BPM GEOSYNTHETICS has been committed to providing one-stop services for global customers in the research and development, production, sales, and export of geosynthetic materials since its establishment in 2007. The company has 120 senior technical talents specializing in geotechnical materials. The manufacturing factory covers an area of over 36000 square meters and is equipped with industry-leading automated production equipment and professional testing instruments. Product innovation, quality assurance, and customer satisfaction have always been BPM commitment to partners.

We're committed to innovation and quality, offering flexible cooperation and the best solutions for engineering projects worldwide. Our products are utilized in various sectors like aquaculture, erosion control, drainage systems, municipal engineering, mining, and landscaping. We look forward to partnering with you to solve complex challenges with our high-performance geosynthetic products.