GCL Membrane

BPM Geosynthetics is a relied on producer and provider of super Geosynthetic Clay Liner (GCL Membrane) designed for most advantageous impermeability, environmental protection, and long-term performance. Our GCL liner mix herbal sodium bentonite and high-strength geotextiles to create a long lasting hydraulic barrier best for landfills, ponds, mining, and wastewater containment.

- High Impermeability: Sodium bentonite types a self-sealing barrier when hydrated, stopping leakage effectively.

- Strong Bonding & Stability: Needle-punched shape ensures shear energy and dimensional balance below quite a number website online conditions.

- Chemical & Thermal Resistance: Performs properly in harsh environments, which includes acidic and high-temperature applications.

- Customized Solutions: BPM Geosynthetics offers GCL membranes tailor-made for unique assignment needs, making sure the proper stability of overall performance and cost.

- Certified Quality: Manufactured beneath ISO9001 and GRI standards, making sure constant best and lengthy provider life.

1. What is a GCL Membrane?

A Geosynthetic Clay Liner (GCL Membrane) is an superior impermeable barrier gadget composed of herbal sodium bentonite sandwiched between two layers of geotextile fabric. It serves as a high-performance choice to normal compacted clay liners, imparting dependable waterproofing, chemical resistance, and environmental protection. When hydrated, the bentonite clay swells and types a dense, low-permeability gel layer that successfully blocks water and contaminants.

BPM Geosynthetics produces premium-grade GCL membrane that mix innovation, quality, and sustainability — making them perfect for civil, environmental, and industrial engineering projects.

2. GCL Membrane Structure and Composition

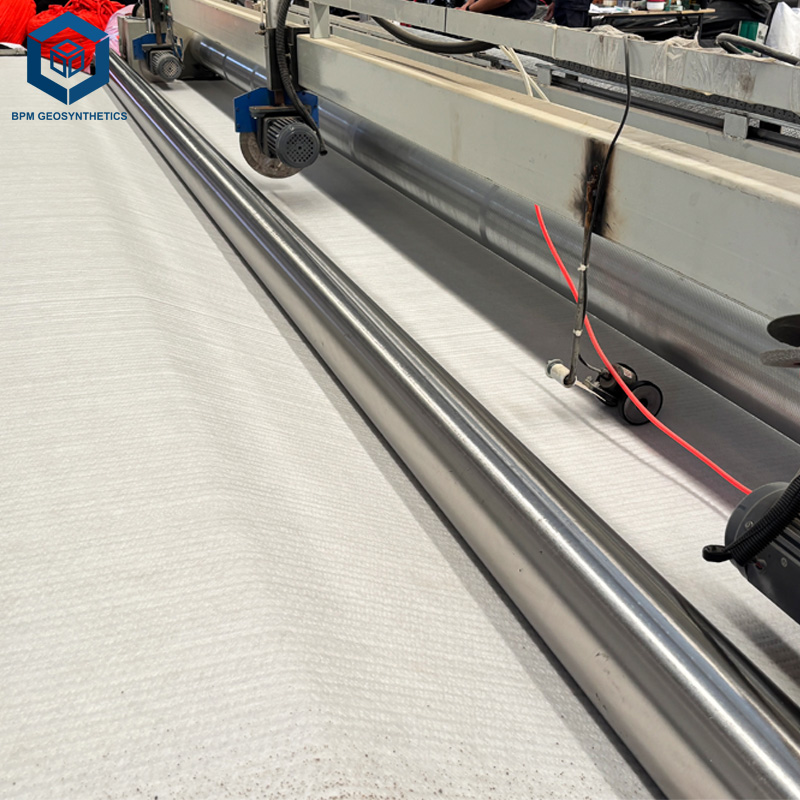

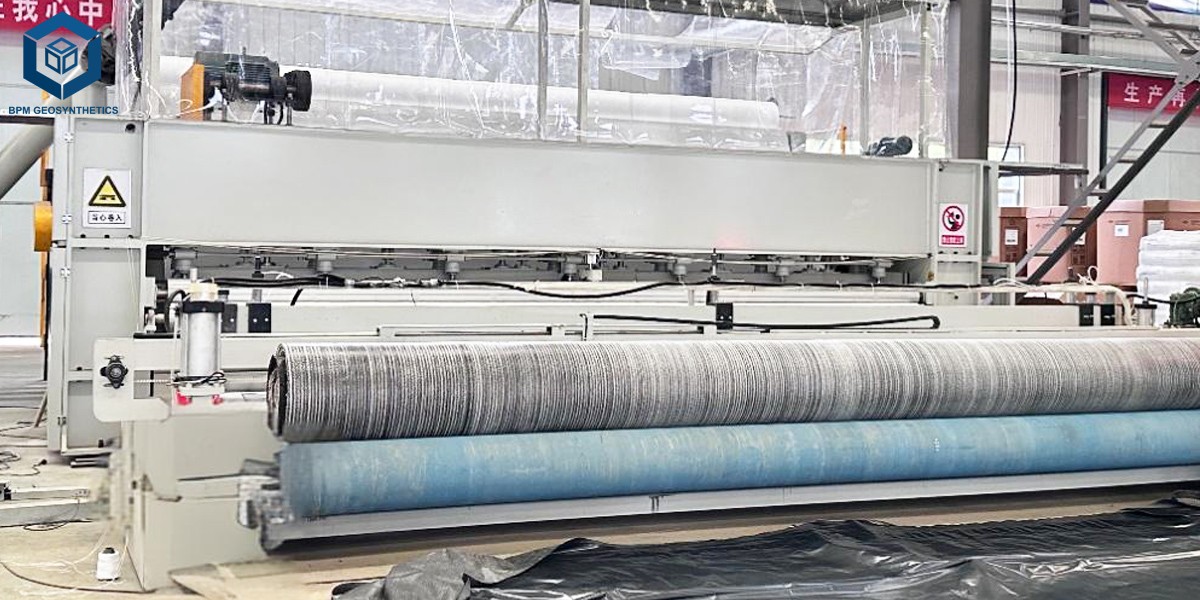

BPM’s GCL membrane is manufactured the usage of a needle-punched lamination process, which robotically interlocks the layers to furnish most fulfilling interior stability, strength, and long-term performance. This superior approach ensures that the bentonite core stays evenly allotted and securely bonded between the geotextile layers, stopping interior slippage and keeping steady hydraulic overall performance even beneath excessive pressure, uneven settlement, or variable environmental conditions.

2.1 Structure Layers:

2.1.1 Upper Layer – Non-Woven Geotextile

Enhances tensile strength, protects the bentonite core at some stage in dealing with and installation, and improves interface friction with soil or overlying geomembrane, making sure slope balance and long-term performance.

2.1.2 Core Layer – Natural Sodium Bentonite

Provides extraordinary self-sealing and waterproofing capabilities. Upon hydration, the bentonite swells to shape a low-permeability barrier, efficaciously blockading water, leachate, and chemical migration.

2.1.3 Bottom Layer – Woven Geotextile or Geomembrane

Offers structural integrity and dimensional stability, supporting stop deformation at some point of set up and presenting superior friction with basis soils for impervious placement on slopes or uneven surfaces.

This multilayer layout now not solely combines strength, flexibility, and impermeability however additionally lets in for simplified set up in contrast to standard compacted clay liners. Lightweight rolls, ease of unrolling, and minimal tools necessities limit labor fees and speed up assignment timelines. In real-world applications, BPM GCL have confirmed steady overall performance in landfills, ponds, mining containment, and wastewater management, keeping structural and hydraulic integrity even below difficult environmental conditions.

3. GCL Membrane Key Technical Advantages

3.1 Superior Impermeability

The herbal sodium bentonite core in BPM’s geosynthetic clay liner varieties a noticeably tremendous hydraulic barrier. When hydrated, it swells to create a dense, low-permeability layer that extensively reduces water and contaminant flow. BPM’s gcl liner can attain permeability coefficients as low as 1.0×10⁻¹¹ cm/s, imparting overall performance related to various meters of compacted clay, making them perfect for landfill liners, ponds, and industrial containment systems.

3.2 Self-Sealing and Self-Healing Properties

Small punctures or minor tears in the geosynthetic liner do now not compromise its performance. Once uncovered to moisture, the bentonite core swells and naturally fills gaps, correctly resealing the broken area. This self-healing characteristic reduces renovation necessities and ensures long-term waterproofing except the want for general repairs or exterior intervention.

3.3 Excellent Chemical Resistance

BPM bentonite clay liner is distinctly resistant to a broad vary of chemical contaminants, consisting of acids, alkalis, heavy metals, and natural compounds. This chemical balance permits them to be used safely in hazardous waste containment, mining tailings dams, industrial wastewater ponds, and different environments the place publicity to aggressive chemical substances should compromise much less sturdy liners.

3.4 High Shear Strength

The needle-punched lamination manner automatically interlocks the geotextile layers with the bentonite core, improving the membrane’s inside shear strength. This prevents layer separation underneath strain or stress and ensures slope steadiness on steep or uneven surfaces. It additionally improves resistance to contract or soil movement, making BPM clay liner noticeably dependable in annoying geotechnical applications.

3.5 Temperature and Aging Resistance

BPM gcl pond liner is designed to function correctly throughout a vast vary of temperatures. They withstand UV degradation, oxidation, microbial activity, and thermal cycling, making sure long-term sturdiness even in harsh climates. This ageing resistance extends the carrier existence of the membrane, lowering alternative fees and offering dependable containment for decades.

4. Applications of GCL Membrane

BPM Geosynthetics’ geocomposite clay liner is broadly used in a number geotechnical, environmental, and industrial containment structures due to their finest impermeability, chemical resistance, and ease of installation. Key functions include:

4.1 GCL Membrane for Landfill Liners and Caps

Geo clay liner is appreciably used in municipal and industrial landfill tasks to forestall leachate seepage and shield surrounding groundwater. The low-permeability bentonite layer ensures that hazardous drinks and chemical compounds do no longer contaminate soil or close by water sources, whilst the robust geotextile layers furnish mechanical steadiness for long-term operation.

4.2 GCL Membrane for Ponds, Lagoons, and Reservoirs

Ideal for aquaculture, irrigation, and water storage, BPM gcl clay liner make sure long-term water containment. They stop seepage and loss of precious water resources, helping sustainable fish farming, shrimp ponds, and agricultural irrigation systems. Their flexibility permits them to conform to irregular pond shapes and uneven terrain.

4.3 GCL Membrane for Mining and Tailings Dams

In mining operations, gcl geosynthetic clay liners grant chemical resistance in opposition to acidic or poisonous mining effluents, defending the surrounding soil and groundwater. They are broadly utilized in tailings dams and heap leach pads, forming an fine barrier that consists of hazardous beverages and reduces environmental risks.

4.4 GCL Membrane for Tunnel and Underground Waterproofing

Geotextile clay liner is fantastic for subsurface waterproofing in tunnels, underground structures, and basements. They stop water infiltration from groundwater and soil moisture, making sure structural integrity and long-term sturdiness in underground building projects.

4.5 GCL Membrane for Industrial Wastewater Treatment Plants

BPM geosynthetic liner is appropriate for wastewater containment, inclusive of industrial effluents and hazardous liquids. They supply a dependable barrier that prevents leakage, making sure compliance with environmental policies and minimizing the hazard of soil and water contamination.

4.6 GCL Membrane for Environmental Remediation Projects

In contaminated land and remediation projects, clay liner can isolate hazardous soil or waste materials, stopping the unfold of pollutants. Their self-sealing houses and chemical resistance make them best for long-term containment in environmental cleanup efforts.

5. Why Choose BPM Geosynthetics GCL Membrane?

BPM Geosynthetics stands out as a international chief in geosynthetic products, presenting unmatched expertise, fine assurance, and customer-focused service.

- Advanced Production Technology: State-of-the-art tools ensures constant product excellent and uniform bentonite distribution.

- Strict Quality Control: Every roll undergoes laboratory trying out for permeability, tensile strength, and mass per unit area.

- Global Standards Compliance: Manufactured in accordance with ASTM D5887, GRI-GCL3, and ISO9001 certifications.

- Custom Solutions: Available in more than a few thicknesses, roll sizes, and cloth kinds to meet particular challenge requirements.

- On-site Technical Support: BPM Geosynthetics affords set up training and education to make sure ideal performance.

- Sustainability Commitment: BPM Geosynthetics makes use of eco-friendly substances and methods to minimize environmental affect whilst turning in ideal engineering results.

6. GCL Membrane Installation and Handling

BPM Geosynthetics’ gcl geosynthetic clay liners are designed for handy and environment friendly installation, requiring much less labor and gear than standard clay liners. Correct set up ensures long-term impermeability and structural stability.

6.1 Site Preparation

Prepare a smooth, stage floor free of sharp objects and debris. Fill minor irregularities with sand or soil to supply uniform aid and forestall damage.

6.2 Unrolling

Carefully unroll the membrane flat, fending off wrinkles or folds. Maintain at least 30 cm overlap between panels for applicable seam bonding.

6.3 Seaming

Seal overlaps with a skinny layer of bentonite powder or adhesive to make sure a continuous, impermeable barrier.

6.4 Anchoring

Secure edges in anchor trenches or with ballast to stop shifting, specifically on slopes.

6.5 Protection Layer

Cover the membrane with soil, sand, or geomembrane to shield in opposition to UV, mechanical damage, and erosion, whilst distributing hundreds evenly.

Proper set up ensures long lasting hydraulic overall performance and long-lasting containment for landfills, ponds, mining, and industrial projects.

7. BPM Geosynthetics Technical Specifications (Typical Values)

Property | Unit | Typical Value | Test Standard |

Bentonite Mass | g/m² | 4000–5000 | ASTM D5993 |

Permeability Coefficient | cm/s | ≤ 1.0×10⁻¹¹ | ASTM D5084 |

Peel Strength | N/100mm | ≥ 400 | ASTM D6496 |

Tensile Strength | kN/m | ≥ 8 | ASTM D6768 |

Swell Index | mL/2g | ≥ 24 | ASTM D5890 |

Conclusion

The GCL membrane by way of BPM Geosynthetics grants a superior, cost-effective, and eco-friendly answer for current waterproofing and containment systems. Its mixture of excessive impermeability, chemical stability, and ease of set up makes it the desired preference for engineers and contractors worldwide.

Whether used in landfills, mining projects, ponds, or industrial applications, The Best Project Material Co., Ltd.(BPM Geosynthetics)’s GCL membranes make sure long-term safety, performance, and sustainability — making BPM Geosynthetics a relied on international associate in geosynthetic innovation.