HDPE Geomembrane Welding Machine

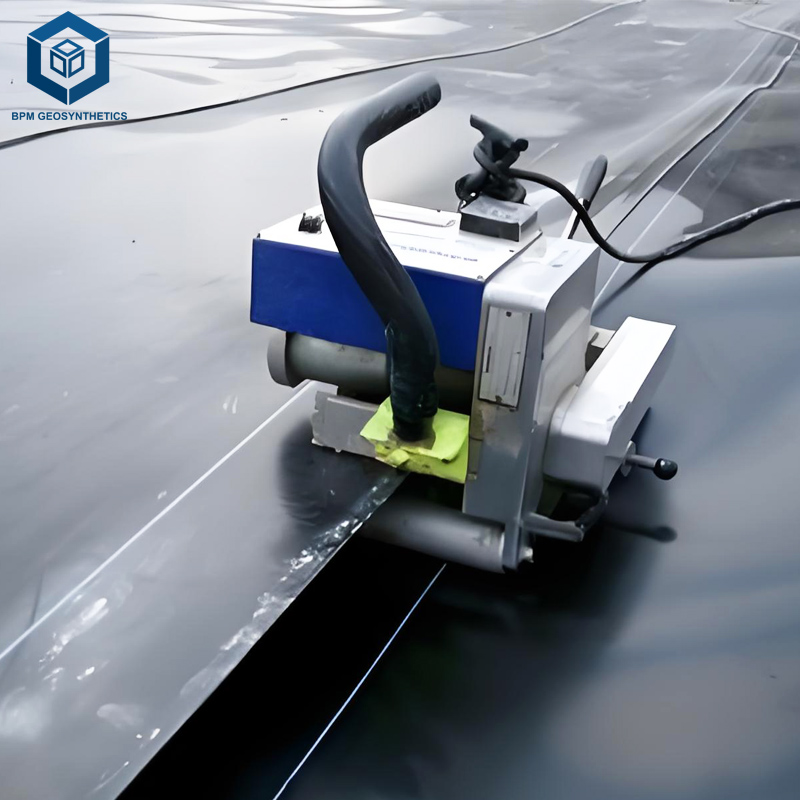

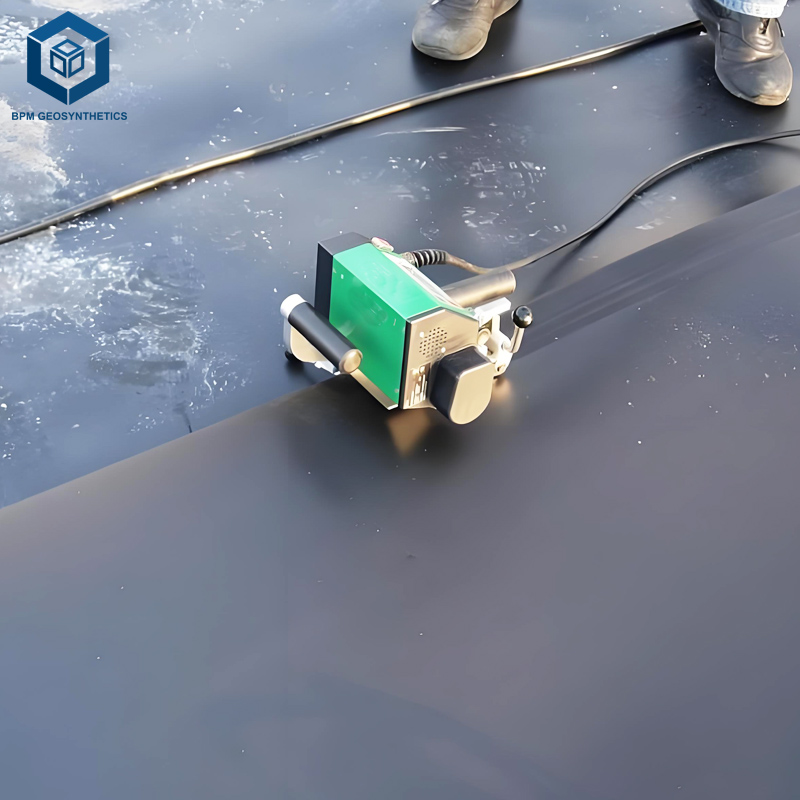

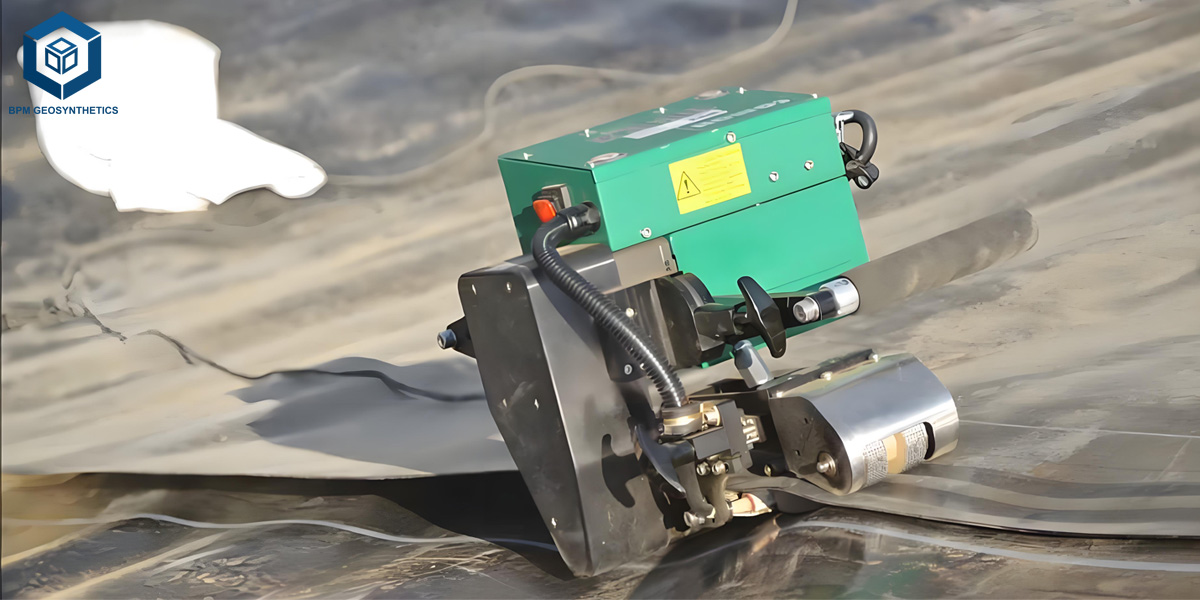

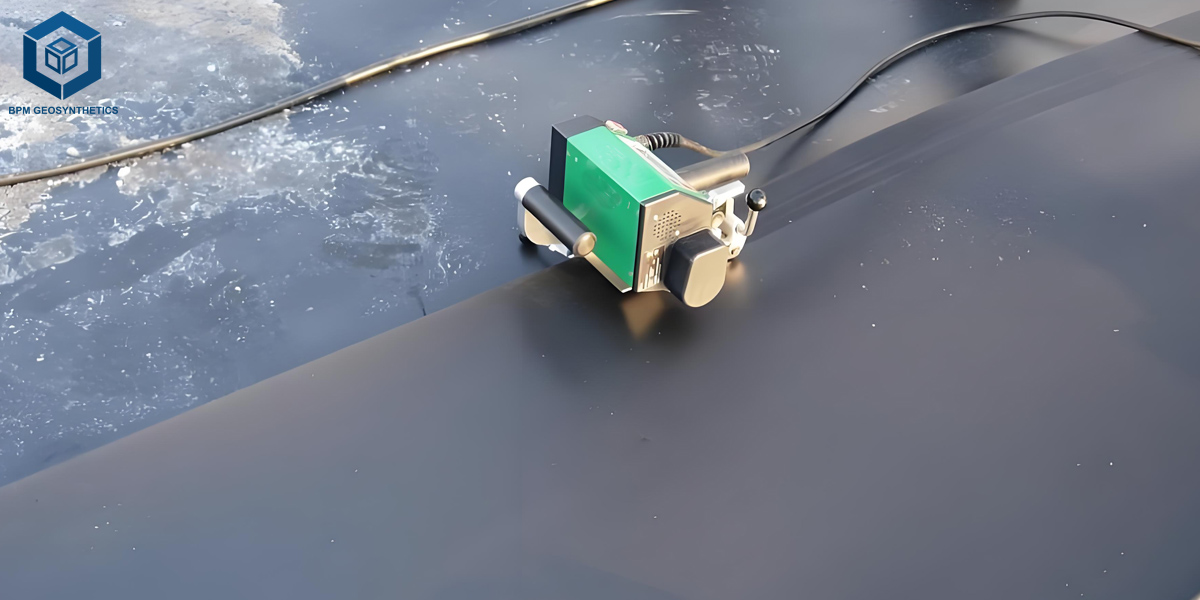

HDPE Geomembrane Welding Machine is a specialised device designed for becoming a member of HDPE liner with precision and durability. It is broadly used in landfills, ponds, reservoirs, and industrial containment projects. The computing device ensures strong, leak-proof seams, enhancing the reliability and lifespan of geomembrane installations.

- High Precision Welding: Intelligent temperature manage and adjustable stress furnish consistent, super seams.

- Versatile Operation: Suitable for a range of HDPE liner thicknesses, together with 20 mil, 40 mil, 60 mil, and 80 mil.

- User-Friendly Design: Digital manipulate panel, convenient adjustment, and ergonomic setup for discipline use.

- Durable Heating System: Fast-heating factors allow non-stop operation besides downtime.

- Quality Assurance: Ensures clean seams with most reliable tensile energy and hermetic joints.

This welding laptop is an fundamental answer for engineers and contractors looking for efficient, reliable, and long-lasting geomembrane installations.

HDPE Geomembrane Welding Machine is a high-performance, precision-engineered device designed for the dependable welding of HDPE liners in a large vary of applications, together with landfills, ponds, reservoirs, canals, mining projects, and wastewater containment systems. Built for durability, ease of use, and particular temperature and strain control, it can provide consistent, leak-proof seams, most excellent tensile strength, and long-lasting impermeability. With its sturdy diagram and undemanding operation, the laptop ensures high-quality, environment friendly installations, making it an fundamental answer for civil, environmental, and industrial engineering initiatives that demand reliability, safety, and long-term performance.

1. HDPE Geomembrane Welding Machine Key Features and Advantages

1.1 High-Precision Welding

Equipped with shrewd temperature control, adjustable pressure, and digital velocity regulation, this welding computer grants consistent, fantastic seams appropriate for a range of HDPE liner thicknesses (from 20 mil to 120 mil) and surface textures (smooth, embossed, reinforced).

1.2 Durable Heating System

Advanced fast-heating factors enable non-stop operation except temperature drop, making sure uniform welds even in large-scale installations.

1.3 Adjustable Pressure System

Dual-roller or hot wedge mechanisms ensure uniform pressure along the seam, improving tensile strength and reducing defects.

1.4 Versatile Compatibility

Works correctly with special sorts of geomembrane liner, inclusive of smooth, textured, or strengthened HDPE sheets.

1.5 User-Friendly Design

Ergonomic handles, clear digital manipulate panels, and easy-to-read warning signs make the laptop perfect for each on-site and manufacturing facility use.

2. HDPE Geomembrane Welding Machine Accessories and Additional Services

2.1 Welding Machine Accessories Included

Hot wedge tips, extruder nozzles, spare heating elements, rollers, and stress wheels are furnished to make sure easy operation.

2.2 Maintenance Kits

BPM components fundamental preservation equipment and coaching for long-term computing device performance.

2.3 Extended Service and Support

Customers acquire session for task planning, welding parameter selection, and troubleshooting, making sure most effectivity and quality.

2.4 Optional Add-Ons

Extended curler sets, digital seam testers, and welding tables for large-scale projects.

2.5 Consumables Support

Recommended welding rods, sealants, and adhesives well matched with HDPE liner.

3. Why Choose BPM Geosynthetics HDPE Geomembrane Welding Machine

3.1 Reliable Performance

High-quality aspects and strict manufacturing requirements assurance long-term operation.

3.2 Comprehensive Support

From pre-sale session to after-sale technical assistance, BPM ensures operators gain consistent, tremendous welds.

3.3 Cost-Effective Solution

Includes vital add-ons and specialist guidance, minimizing downtime and set up blunders while maximizing the lifespan of geomembrane projects.

In summary, the BPM Geomembrane Welding Machine is a whole answer for engineers and contractors who require precision, durability, versatility, and specialist assist in geomembrane sheet set up projects.

4. HDPE Geomembrane Welding Machine Service and Customer Support

4.1 Pre-Sale Consultation

BPM gives complete technical preparation to assist clients select the most appropriate welding computing device mannequin primarily based on task requirements, hdpe membrane liner thickness, and website conditions. Our professionals additionally suggest on the pleasant welding methods, operational parameters, and add-ons wished for most excellent performance, making sure clients make knowledgeable choices earlier than purchase.

4.2 Project Planning Assistance

For large-scale or complicated installations, BPM affords guide in desktop allocation, workflow optimization, and seam approach planning. This consists of pointers on tools placement, operational sequencing, and seam plan to maximize efficiency, minimize downtime, and make sure constant weld great throughout the complete project.

4.3 After-Sale Service

BPM ensures lifetime technical support, inclusive of troubleshooting, renovation guidance, and substitute section supply. Our group works carefully with clients to optimize computer performance, tackle problems promptly, and keep long-term operational reliability, supporting initiatives remain on agenda and inside budget.

4.4 Training Programs

To make sure incredible welds and secure operation, BPM offers complete coaching programs. These consist of on line courses, special manuals, and on-site workshops for engineers, technicians, and operators. Training covers welding techniques, computer maintenance, seam inspection methods, and security procedures, equipping groups with the capabilities to gain consistent, expert results.

5. HDPE Geomembrane Welding Machine Installation and Operation Support

5.1 Step-by-Step Instructions

BPM Geosynthetics affords targeted manuals, video tutorials, and digital courses masking all components of setup, calibration, and welding procedures.

5.2 On-Site Training

Professional engineers are reachable for on-site guidance, making sure right welding parameters, seam inspection, and operational safety.

5.3 Welding Quality Verification

Machine helps quite a number inspection methods, consisting of air channel and vacuum container testing, to assurance leak-proof seams.

5.4 User Safety Features

Overheat protection, emergency cease functions, and ergonomic plan decrease operator danger in the course of lengthy welding sessions.

6. HDPE Geomembrane Welding Machine Quality Assurance

6.1 Strict Manufacturing Standards

Each high density polyethylene geomembrane Welding Machine is manufactured beneath rigorous excellent manipulate techniques to make sure regular performance, durability, and reliability for all industrial and environmental applications.

6.2 Standards Compliance

The machines totally comply with ASTM, GRI, and ISO requirements for geo membrane sheet welding equipment, guaranteeing that each and every unit meets worldwide safety, performance, and operational benchmarks.

6.3 Comprehensive Testing

Before shipment, each and every welding laptop undergoes thorough trying out for temperature stability, strain accuracy, and electrical safety, making sure dependable operation on-site and minimizing the threat of set up mistakes or downtime.

7. HDPE Geomembrane Welding Machine Key Considerations for Users

7.1 Match Machine Type to Liner Thickness and Surface Type

Selecting the right welding mannequin is vital to gain excellent seams. Consider the HDPE liner thickness (e.g., 40 mil, 60 mil, 80 mil) and whether or not the floor is smooth, textured, or bolstered to make certain desirable warmness distribution and constant weld strength.

7.2 Ensure Operator Training for Optimal Seam Performance

Proper coaching is crucial to attaining durable, leak-proof seams. Operators need to be acquainted with desktop operation, welding speed, strain adjustment, and seam inspection strategies to preserve regular first-rate and decrease errors.

7.3 Plan for Accessories and Spare Parts for Uninterrupted Field Operation

Always put together crucial accessories, spare parts, and upkeep kits on-site to forestall downtime. This consists of substitute warm wedge tips, extruder nozzles, rollers, and heating factors for seamless operation throughout giant or long-term projects.

7.4 Use Recommended Welding Rods and Tools to Maintain Warranty Compliance

Adhering to producer tips for welding rods, adhesives, sealants, and well matched equipment ensures suited seam integrity and protects assurance coverage. Using non-recommended substances might also compromise weld electricity and computer performance.

8. Applications and Use Environments of HDPE Geomembrane Welding Machine

The hdpe geo membrane Welding Machine is a precision-engineered device designed for developing durable, leak-proof seams in HDPE liners. Its versatility, reliability, and excessive welding excellent make it appropriate for a large range of functions and environmental conditions.

8.1 HDPE Geomembrane Welding Machine for Landfills and Waste Containment

Geomembrane welder ideal for municipal and industrial landfills, stopping leachate from contaminating soil and groundwater.

Performs reliably below heavy soil stress and chemical exposure, making sure long-term containment.

8.2 Water Storage: Ponds, Reservoirs, and Canals

Pond liner welding machine used in aquaculture ponds, irrigation reservoirs, ingesting water storage, and canals.

Prevents water seepage, continues water quality, and helps environment friendly water administration in each small and large-scale projects.

8.3 HDPE Geomembrane Welding Machine for Mining and Industrial Applications

Essential for tailings ponds, chemical storage areas, and hazardous waste containment.

HDPE liners welded with the laptop face up to chemical corrosion and abrasion, making sure environmental protection and regulatory compliance.

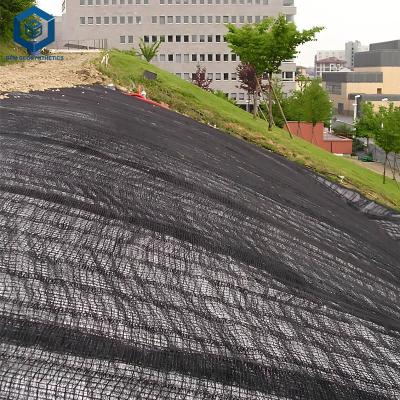

8.4 HDPE Geomembrane Welding Machine for Civil Engineering Projects

Applied in slopes, embankments, maintaining walls, and drainage channels to stop seepage, erosion, and structural weakening.

Suitable for complicated terrains and uncovered environments, keeping integrity beneath harsh climate conditions.

8.5 HDPE Geomembrane Welding Machine for Wastewater Treatment and Environmental Protection

Used in sewage remedy plants, oil pits, and chemical processing facilities.

Ensures long-lasting impermeable barriers, safeguarding surrounding soil and water sources.

8.6 HDPE Geomembrane Welding Machine for Large-Scale Infrastructure Projects

Supports sizable development initiatives the place uniform weld exceptional and excessive operational effectivity are critical.

Handles non-stop welding duties in environments ranging from open-air websites to semi-enclosed industrial facilities.

8.7 HDPE Geomembrane Welding Machine for Diverse Environmental Conditions

Dam liner welding machine operates reliably below excessive temperatures, excessive humidity, or dusty/abrasive work sites.

Compatible with smooth, textured, or strengthened HDPE liners, making it adaptable to diverse assignment specifications.

Summary

The Best Project Material Co., Ltd.(BPM Geosynthetics)HDPE Geomembrane Welding Machine is a complete, high-performance answer for engineers, contractors, and environmental professionals. With precision welding, sturdy design, full-size accessories, and full technical support, it ensures durable, leak-proof geomembrane installations, whilst bettering challenge effectivity and cost-effectiveness.