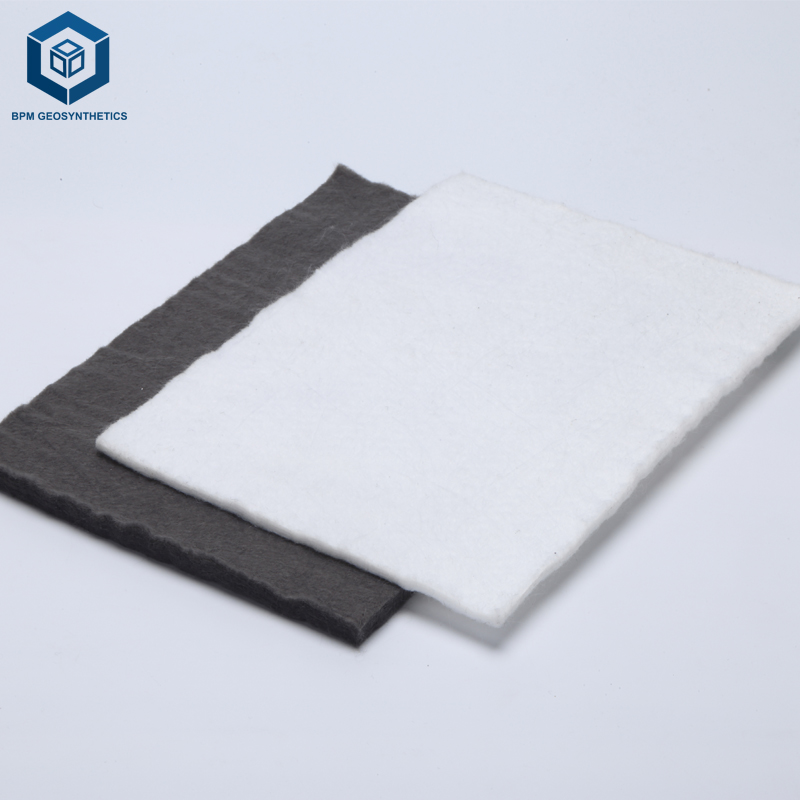

Geotextile Nonwoven Fabric

BPM Geosynthetics offers high-quality Geotextile Nonwoven Fabric designed for most useful filtration, separation, and drainage applications. Manufactured with precision and sturdiness in mind, our fabric meet global requirements and supply long-lasting overall performance for civil engineering and environmental projects.

- Premium Material Quality: Made from 100% high-strength polypropylene fibers for tremendous sturdiness and resistance to UV and chemical degradation.

- Enhanced Filtration & Drainage: Optimized fiber shape ensures most advantageous water permeability whilst stopping soil migration.

- Consistent Performance: Strict pleasant manipulate ensures uniform thickness, weight, and tensile electricity for dependable engineering outcomes.

- Trusted by means of Professionals: Over 20 years of BPM Geosynthetics ride in geosynthetics ensures validated overall performance and technical assist for each project.

BPM Geosynthetics proudly provides our Geotextile Nonwoven Fabric, engineered to furnish magnificent overall performance in civil engineering, environmental protection, and infrastructure projects. Designed for filtration, separation, reinforcement, and drainage applications, our nonwoven fabric provide long-term durability, reliability, and cost-effectiveness. Leveraging over 20 years of industry expertise, BPM Geosynthetics ensures each and every roll meets the very best requirements of quality and performance.

1. Key Features of BPM Geotextile Nonwoven Fabric

1.1 Geotextile Nonwoven Fabric High-Quality Material

BPM Nonwoven Geotextile is manufactured from 100% virgin polypropylene fibers, making sure great strength, durability, and dimensional stability. This top class non woven geotextile fabric offers long-term resistance to UV exposure, chemical attack, and environmental aging, making it appropriate for each temporary and long-term engineering applications. The extraordinary fibers additionally enable the material to preserve its shape and performance even underneath heavy hundreds or severe climate conditions, making sure dependable overall performance all through the lifestyles of the project.

1.2 Superior Filtration & Drainage

The special nonwoven needle-punched shape of BPM geotextile material approves water to skip thru efficaciously whilst protecting best soil particles. This makes it perfect for purposes requiring soil separation and water filtration, such as street bases, embankments, retention ponds, and drainage layers. By stopping soil clogging, the material ensures long-term drainage effectivity and protects structural layers from erosion, lowering protection necessities and prolonging infrastructure lifespan.

1.3 Enhanced Mechanical Strength

BPM geo fabric reveals high tensile strength, tear resistance, and elongation properties, which reduce the chance of harm all through set up and in-service conditions. The geotech fabric’s steady weight, thickness, and density make certain uniform overall performance throughout giant areas, stopping susceptible spots and bettering standard assignment reliability. This mechanical robustness makes it appropriate for heavy-duty functions such as highways, railways, and strengthened embankments the place steadiness is critical.

1.4 Versatility Across Applications

BPM non woven geotextile is engineered to serve a vast vary of engineering and environmental purposes:

- Road Construction & Pavements: Separates subgrade soil from combination layers to forestall contamination, limit rutting, and enhance pavement lifespan.

- Slope Stabilization & Erosion Control: Protects soil on slopes or embankments, helps vegetation growth, and lets in water to drain safely barring inflicting erosion.

- Drainage & Water Management: Ensures environment friendly water glide in subdrains, conserving walls, and stormwater structures whilst stopping soil migration and clogging.

- Landfill & Waste Containment: Functions as a defensive filtration and cushioning layer above geomembranes, improving landfill balance and decreasing puncture risk.

1.5 Eco-Friendly & Sustainable

Made from recyclable polypropylene, BPM non woven landscape fabric helps environmentally accountable development practices. Its use in inexperienced infrastructure, such as stormwater administration structures and erosion manipulate projects, contributes to sustainable water and soil management. The non woven geotextile membrane’s lengthy lifespan reduces substitute frequency, decreasing the environmental footprint of development and preservation activities.

2. Advantages of Choosing BPM Geotextile Nonwoven Fabric

2.1 Geotextile Nonwoven Fabric Precision Manufacturing

BPM geotextile drainage fabric is produced the usage of superior needle-punching and fiber bonding technology, making sure that fibers are evenly disbursed in the course of the fabric. This precision manufacturing ensures constant thickness, uniform weight, and dependable tensile strength, which are integral for reaching ultimate overall performance in large-scale engineering projects. The managed manufacturing procedure minimizes defects and variations, offering engineers with self assurance in cloth reliability throughout each installation.

2.2 Reliable Quality Assurance

Every batch of BPM geotextile filter fabric undergoes rigorous pleasant manipulate trying out to make sure it meets or exceeds global requirements such as ASTM, ISO, and different regional certifications. Tests encompass tensile strength, elongation, permeability, puncture resistance, and UV stability. This strict fine assurance ensures that the material performs as predicted in worrying applications, lowering the danger of undertaking delays or material failure.

2.3 Technical Support & Expertise

BPM offers complete technical instruction for all projects. Our skilled engineers aid in deciding on the proper film geotextile type, identifying best set up methods, and addressing site-specific challenges. This ensures that the material is utilized efficaciously and effectively, maximizing overall performance and durability. Clients gain from BPM’s 20+ years of geosynthetics experience, assisting to limit errors, set up costs, and long-term upkeep issues.

2.4 Cost-Effective & Durable

BPM geo cloth is designed for lengthy provider life, with extraordinary resistance to UV degradation, chemical exposure, and mechanical wear. Its sturdiness reduces the frequency of preservation and replacement, reducing typical lifecycle costs. By supplying excessive overall performance over time, BPM geotech cloth supply a low in cost answer for infrastructure, environmental, and industrial initiatives except compromising pleasant or reliability.

2.5 Global Project Experience

BPM Geosynthetics geotextile drainage has been efficaciously utilized in infrastructure, transportation, environmental, and industrial tasks worldwide. Our geotextile filter cloth is depended on in highways, railways, landfills, stormwater systems, and slope stabilization initiatives throughout numerous climates and terrains. This world journey demonstrates verified overall performance beneath various conditions, giving consumers self assurance that BPM Geosynthetics merchandise are engineered to meet the needs of each neighborhood and worldwide projects.

3. Geotextile Nonwoven Fabric Specifications

Property | Typical Value (Example) | Test Standard |

Weight | 100 – 500 g/m² | ASTM D3776 |

Tensile Strength | 10 – 50 kN/m | ASTM D4595 |

Elongation | 50 – 100% | ASTM D4595 |

Thickness | 1 – 10 mm | ASTM D5199 |

Water Permeability | 50 – 500 L/m²/s | ASTM D4491 |

(Values may vary depending on project requirements. Custom specifications available.)

4. Geotextile Nonwoven Fabric Applications in Detail

4.1 Geotextile Nonwoven Fabric for Road & Highway Construction

In street and motorway projects, BPM geo fabric material acts as a essential separation layer between subgrade soil and mixture base layers. This prevents soil contamination, reduces rutting, and improves the structural integrity of the pavement. The nonwoven geotextile fabric additionally helps evenly distribute site visitors loads, minimizing differential agreement and prolonging the lifespan of roads and highways. Its sturdiness ensures regular overall performance below repeated heavy traffic, making it perfect for highways, city roads, and airport pavements.

4.2 Geotextile Nonwoven Fabric for Slope & Erosion Protection

Applied to slopes, embankments, or keeping structures, BPM Nonwoven geotextile fabric under gravel helps stabilize soil and limit erosion, even at some point of heavy rainfall or excessive climate events. The geotextile landscape fabric approves water to drain safely whilst protecting soil particles, defending in opposition to landslides and floor washouts. Additionally, it helps vegetation boom by way of preserving soil shape and moisture, bettering the ecological and aesthetic fee of slopes and embankments in infrastructure and landscaping projects.

4.3 Geotextile Nonwoven Fabric for Drainage & Water Management

BPM non woven filter fabric is fantastically wonderful in stormwater administration systems, subdrain layers, and conserving wall drainage. Its excessive water permeability approves environment friendly water float whilst stopping soil particles from clogging drains, pipes, or gravel layers. This ensures long-term drainage effectivity in purposes such as inexperienced roofs, sports activities fields, preserving wall backfills, and parking areas, lowering protection wants and defending surrounding buildings from water damage.

4.4 Geotextile Nonwoven Fabric for Environmental & Landfill Engineering

In environmental engineering projects, consisting of landfills and waste containment sites, BPM non woven geotextile drainage fabric serves as a shielding filtration and cushioning layer above geomembranes. It reduces the threat of punctures or tears in liners, enhances leachate filtration, and helps hold structural integrity. By enhancing steadiness and minimizing harm to geomembranes, it contributes to safer and greater environmentally sustainable waste management solutions.

4.5 Geotextile Nonwoven Fabric for Landscape & Green Infrastructure

For parks, golf courses, city inexperienced spaces, and different landscaping projects, BPM geotextile road fabric gives soil stabilization, erosion prevention, and water management. It promotes sustainable increase of vegetation with the aid of retaining soil shape and moisture balance, whilst stopping soil displacement in high-traffic areas or steep terrains. Its use helps environmentally pleasant city infrastructure, reduces maintenance, and enhances the durability of panorama installations.

Choose BPM Geosynthetics Geotextile Nonwoven Fabric

At BPM Geosynthetics, we mix superior technology, optimum materials, and a long time of knowledge to supply high-performance geosynthetics solutions. Our nonwoven fabric are designed to stand up to harsh conditions, decrease protection costs, and grant long-term reliability. By selecting The Best Project Material Co., Ltd.(BPM Geosynthetics), you acquire no longer simply a product however a depended on associate for your engineering tasks worldwide.

BPM Geosynthetics Geotextile Nonwoven Fabric – Engineered for Strength, Filtration, and Durability.