Geotech Fabric

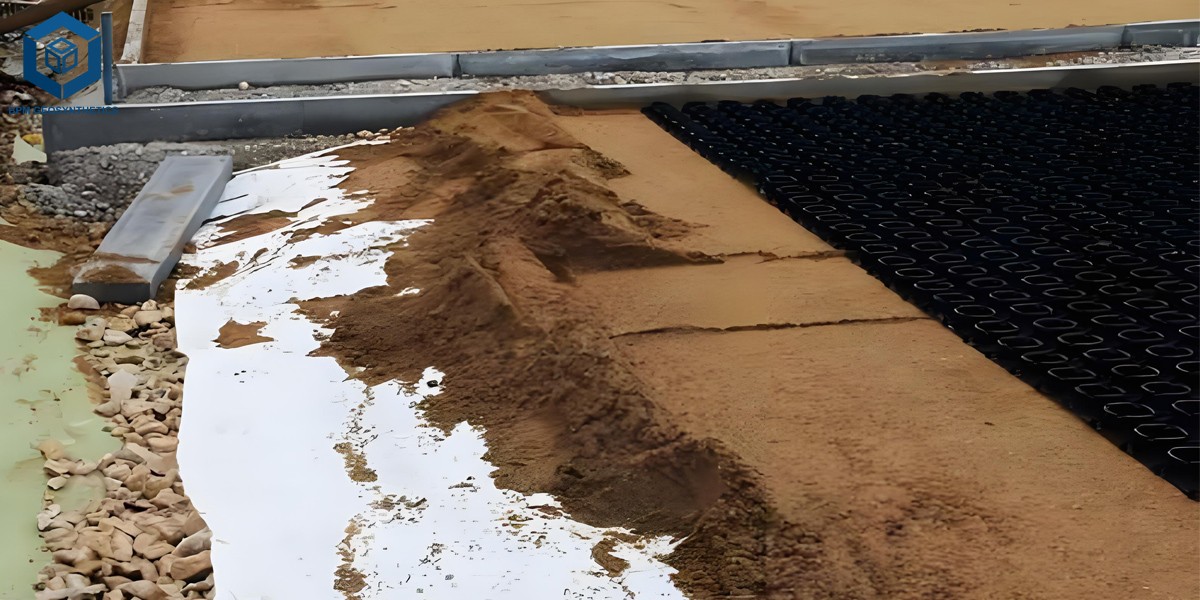

Geotech fabric, additionally recognized as geotextile, is a permeable fabric fabric used in civil engineering and development to decorate soil stability, drainage, and universal mission performance. Geotech fabrics are made of fibers designed to separate, filter, reinforce, and defend soil structures, making them quintessential for a number functions which includes avenue construction, panorama beautification, and erosion control.

-Effective filtration : permits water waft to ignore via whilst keeping soil particles, stopping erosion and retaining soil integrity.

-Durability:Resistant to UV radiation, chemicals, and biodegradation, making sure long-lasting overall performance in a variety of environments.

-Multi purposeful software : Suitable for quite a number purposes, such as roads, keeping walls, and drainage systems, to meet a number engineering needs.

Geotech fabric is an vital device in contemporary architecture, can enhance the sturdiness and sustainability of engineering projects.

Geotech fabric, additionally recognized as geotextile, is a fabric used in civil engineering and building purposes to decorate soil steadiness and help a number of structures. Typically made from polypropylene or polyester, Geotech fabric serves more than one functions, which includes separation, filtration, drainage, and reinforcement. When positioned between soil layers, it prevents the mixing of special soil types, thereby retaining the integrity of the underlying materials. Additionally, it approves water to skip thru whilst conserving soil particles, bettering drainage and lowering erosion.

Geotech fabric is extensively used in purposes such as street construction, embankment stabilization, maintaining walls, and landfills. Its sturdiness and resistance to environmental elements make it an best preference for long-term projects. The geotech fabric can be woven, non-woven, or knitted, with particular designs tailor-made to meet various engineering requirements. The use of geotech fabric no longer solely improves the overall performance of soil constructions however additionally contributes to sustainable development practices by way of minimizing fabric use and decreasing environmental impact. Overall, geotech fabric performs a integral function in contemporary engineering, supplying advantageous options for soil administration and infrastructure development.

Parameter

ltem | Unit | BTS10 | BTS15 | BTS20 | BTS25 | BTS30 | BTS35 | BTS40 | BTS45 | BTS50 | BTS60 | BTS80 |

Mechanical Properties (MD=Machine Direction Strength/CD=Cross Machine Direction Strength) | ||||||||||||

Weight | g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 |

Weight Variation | % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

Thickness | mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3 | 3.3 | 3.6 | 4.1 | 5 |

Width Variation | % | -0.5 | ||||||||||

Break Strength (MD and XMD) | KN/m | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 12.5 | 14 | 16 | 19 | 25 |

Break Elongation | % | 25-200 | ||||||||||

CBR Burst Strength ≥ | kn | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4 |

Tear Strength(MD and XMD)≥ | Kn | 0.08 | 0.12 | 0.16 | 0.2 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 |

Hydraulic Properties | ||||||||||||

Sieve Size 090 | mm | 0.07-0.02 | ||||||||||

Permeability Coefficient | cm/s | (1.0-9.9)x(10-1~10-3) | ||||||||||

Geotech Fabric Features

- Separation: Geotech fabric prevents the mixing of distinct soil layers, preserving the integrity of every layer and bettering usual stability.

- Filtration: The geotech fabric permits water to omit via whilst filtering out soil particles, which helps in drainage functions and reduces clogging.

- Drainage: Geotech fabric facilitate environment friendly water movement, assisting to control extra water in soil and lowering the threat of erosion.

- Reinforcement: By imparting extra power to soil structures, Geotech fabric enhances their load-bearing potential and stability, making it appropriate for embankments and keeping walls.

- Durability: Made from artificial materials, Geotech fabric is resistant to environmental elements such as UV rays, moisture, and degradation, making sure long-lasting performance.

- Versatility: Available in a number types, consisting of woven, non-woven, and knitted fabrics, Geotech fabric can be tailor-made to meet particular assignment requirements.

- Cost-Effectiveness: By enhancing soil overall performance and lowering the want for extra materials, Geotech fabric can lead to huge value financial savings in development projects.

- Sustainability: Its use contributes to environmentally pleasant practices by means of minimizing aid consumption and improving the toughness of infrastructure.

Applications of Geotech Fabric

- Road Construction: Geotech fabric is used in avenue establishing to separate subgrade soil from combination materials, improving load distribution and decreasing avenue deformation.

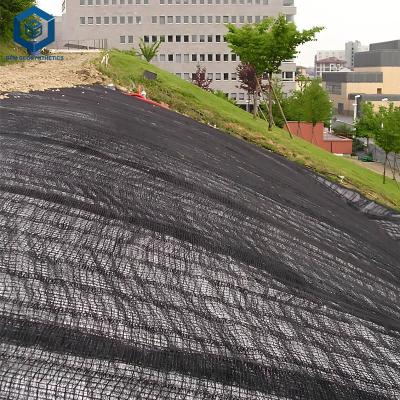

- Embankment Stabilization: In embankment projects, Geotech fabric enhances the stability of slopes through skill of reinforcing the soil and stopping erosion.

- Retaining Wall: It provides greater assist for retaining partitions via capacity of reinforcing the soil at the lower back of the wall, bettering common structural integrity.

- Landfills: Geotech fabric is employed in landfill constructing to separate waste resources from the underlying soil, facilitating drainage and stopping contamination.

- Drainage Systems: The geotech fabric is used in drainage functions to filter water at the same time as enabling it to drift freely, helping to manipulate groundwater and prevent flooding.

- Erosion Control: Geotech fabric performs a quintessential function in erosion manipulate duties via stabilizing soil on slopes and stopping sediment runoff.

- Pavement Design: In pavement applications, it enhances the average overall performance of the pavement structure thru imparting more electricity and reducing cracking.

- Slope Protection: Geotech fabric is utilized in slope security measures to improve soil and stop landslides or soil action in inclined areas.

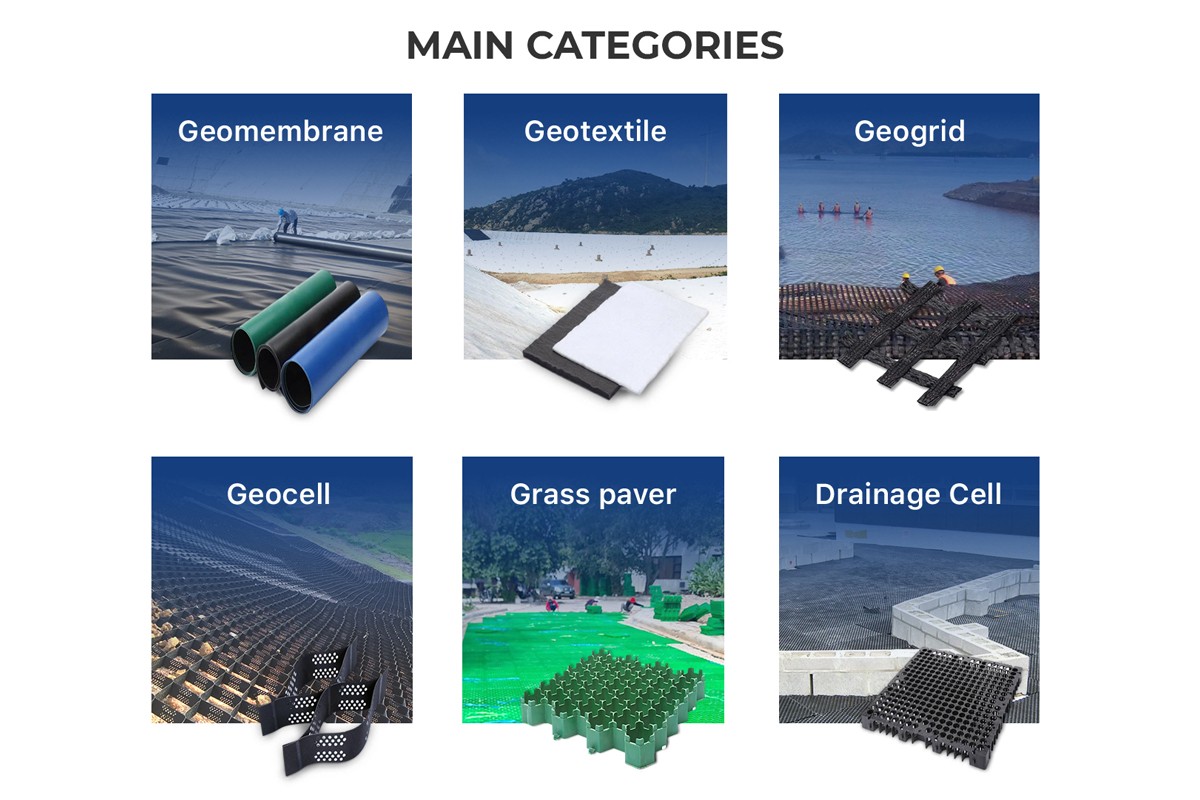

Company Profile

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, geogrids, geocells, and geosynthetic clay liners (GCL). Our products, certified by EU CE and GLP, have passed ISO 9001, ISO 14001, and OHSAS 18001 standards, and are recognized for their quality, performance, and durability.

BPM GEOSYNTHETICS has been committed to providing one-stop services for global customers in the research and development, production, sales, and export of geosynthetic materials since its establishment in 2007. The company has 120 senior technical talents specializing in geotechnical materials. The manufacturing factory covers an area of over 36000 square meters and is equipped with industry-leading automated production equipment and professional testing instruments. Product innovation, quality assurance, and customer satisfaction have always been BPM commitment to partners.

We're committed to innovation and quality, offering flexible cooperation and the best solutions for engineering projects worldwide. Our products are utilized in various sectors like aquaculture, erosion control, drainage systems, municipal engineering, mining, and landscaping. We look forward to partnering with you to solve complex challenges with our high-performance geosynthetic products.