Geonet Drainage

Geonet drainage is a high-performance geosynthetic cloth designed mainly for environment friendly underground drainage in civil engineering, environmental, and building projects. Geonet drainage has a special three-d shape that gives non-stop glide paths for drinks and gases, stopping soil saturation and improving structural stability.

-High drainage capacity: Approves water and fuel to float hastily in each horizontal and vertical directions.

-Excellent compressive strength: Keeps shape below soil and load pressure.

-Chemical and UV resistance: Durable in harsh environments and long-term out of doors use.

-Lightweight and handy to install: Reduces labor expenses and set up time.

-Wide utility range: It is an perfect desire for landfills, maintaining walls, tunnels, highways, and inexperienced roofs.

-Long carrier life: Steady underneath aging, weathering, and organic conditions.

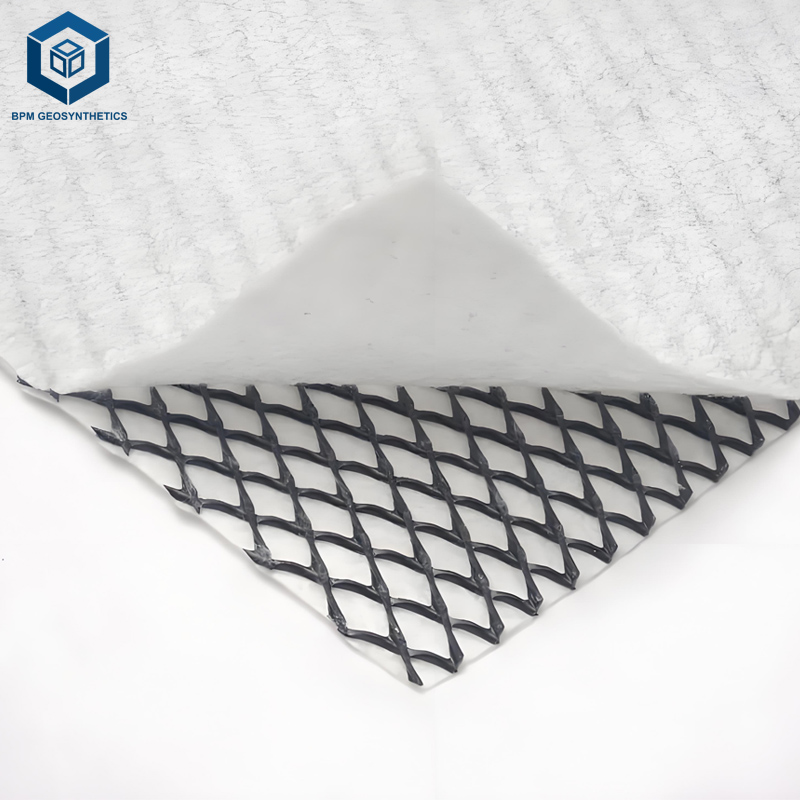

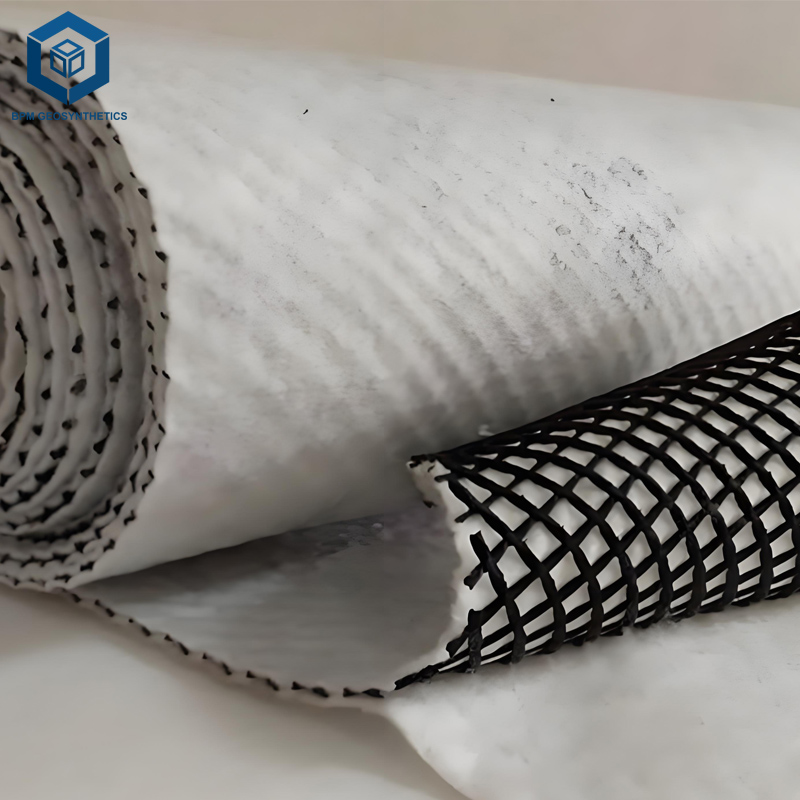

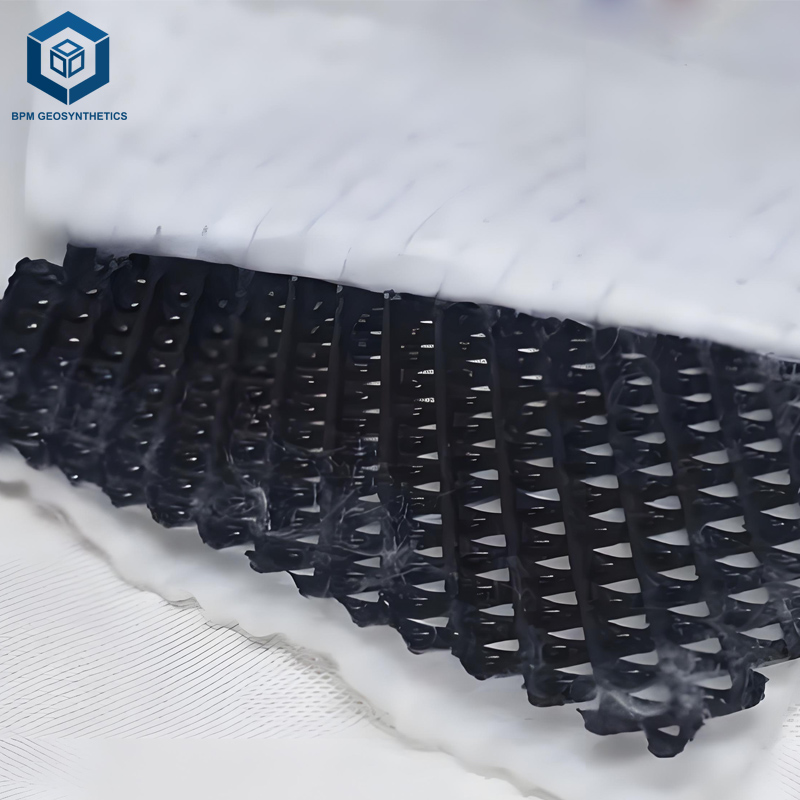

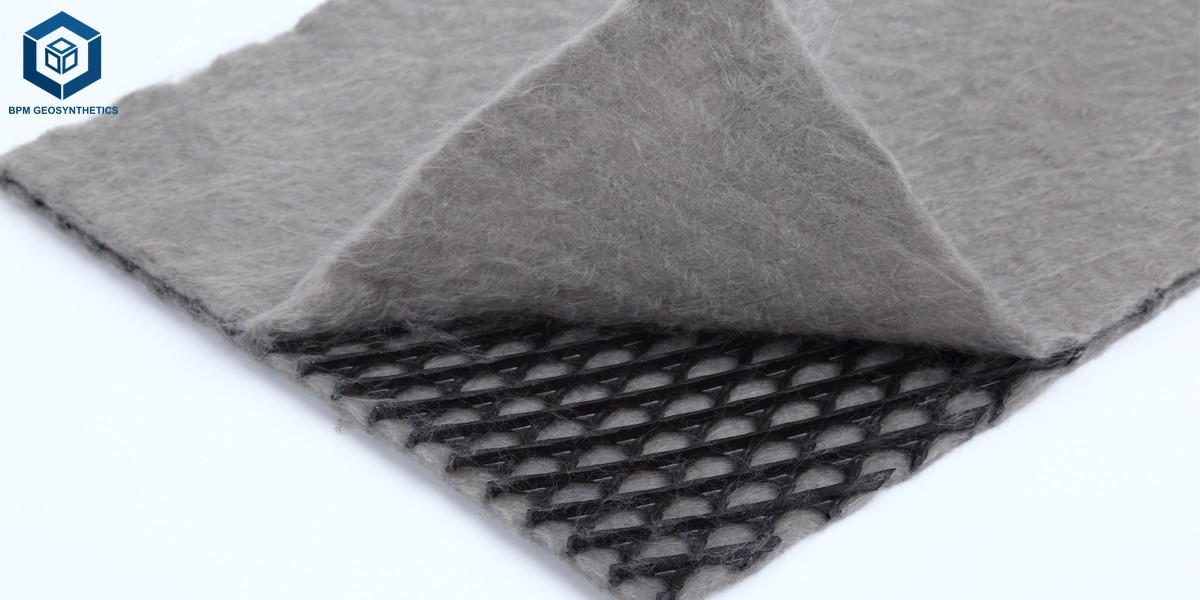

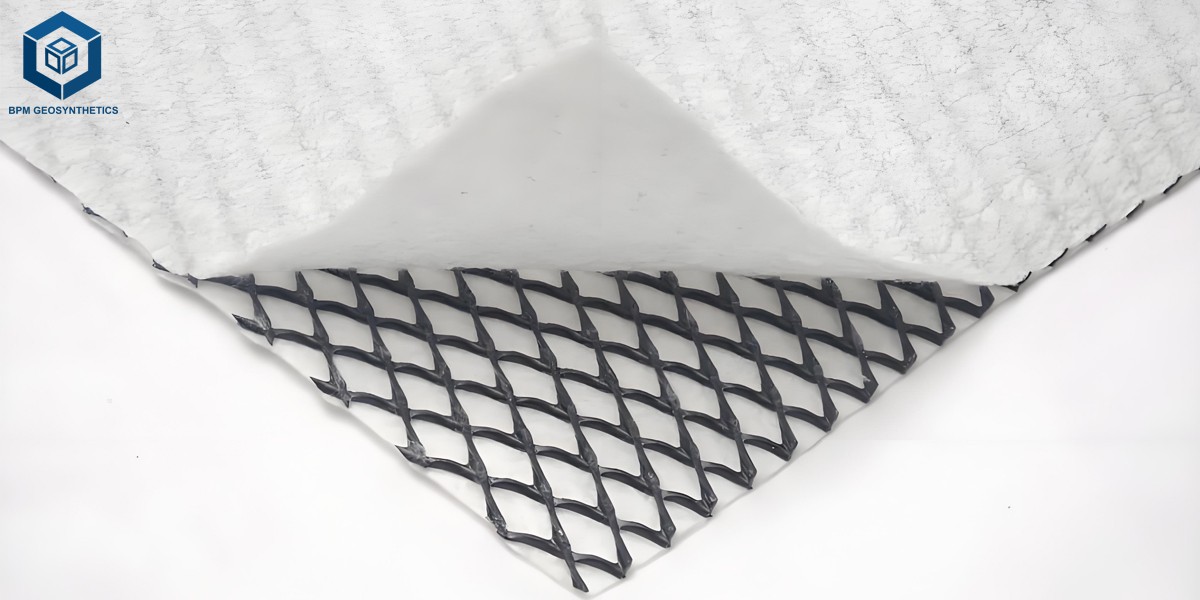

Geonet drainage is a type of geosynthetic material composed of high-density polyethylene (HDPE) with a unique bi-planar or tri-planar net-like structure. It is designed to manage water and gasoline waft beneath the surface, in unique in soil or waste containment systems. By imparting continuous glide paths, geonet assist stop water accumulation, soil saturation, and hydrostatic strain buildup. They are extensively used in landfills, street construction, conserving walls, and tunnel drainage systems, offering environment friendly and long-lasting water administration solutions. The excessive tensile electricity and chemical resistance of HDPE additionally make certain steady overall performance even below excessive masses and harsh environmental conditions.

1. Geonet Drainage Functions

Geonet drainage feature as a relatively environment friendly drainage core positioned between layers of soil or in the back of engineered structures. Typically, they are hooked up in mixture with geotextile filter layers, which enable water or different fluids (such as gases or leachate) to skip thru whilst blockading soil particles and debris. Once the fluid reaches the geonet, it flows hastily via its structured, open channels — both laterally, vertically, or each — relying on the set up perspective and design.

1.1 Rapid Lateral and Vertical Drainage

The different tri-dimensional or biplanar structure of the geonet approves for high-quality drift capacity, enabling fluids to be transported shortly throughout the floor or away from the structure. This environment friendly drainage helps preserve the balance of surrounding soils and prevents the accumulation of water that can weaken foundations. In large-scale engineering initiatives such as highways or landfill systems, this function ensures constant drainage overall performance even beneath heavy hundreds and long-term operation.

1.2 Prevention of Waterlogging and Structural Stress

By constantly getting rid of extra water, geonet drainage prevents hydrostatic strain build-up, which ought to in any other case compromise the integrity of maintaining walls, landfill caps, tunnel linings, and roadbeds. This characteristic is integral for extending the carrier existence of civil buildings and minimizing the danger of cracking or agreement triggered by using trapped moisture. In addition, it helps preserve dry and steady conditions, decreasing renovation fees and enhancing usual task safety.

1.3 Reduction of Pore Water Stress and Erosion Risk

Lower pore water strain in the soil enhances normal steadiness and reduces the chance of slope failures, floor erosion, or subsurface heaving in saturated floor conditions. By enhancing drainage efficiency, geonets promote quicker soil consolidation and limit deformation beneath load. This makes them an perfect answer for slope protection, embankment reinforcement, and different geotechnical functions uncovered to fluctuating groundwater levels.

2. Advantages of Geonet Drainage Over Traditional Gravel Drains

Geonet drainage offers a modern, environment friendly choice to gravel drains, supplying clear advantages in construction, performance, and durability.

2.1 Lightweight & Easy Installation

Made from HDPE or comparable polymers, geonet drainages are a whole lot lighter than gravel, lowering transport fees and enabling quick, equipment-free set up — best for far flung or limited areas. Their flexibility and roll-form diagram make them effortless to deal with on-site, permitting contractors to cowl massive areas with minimal manpower and time.

2.2 Stable Drainage Under Load

Geonet drainage layer keeps structured waft channels below pressure, in contrast to gravel which can shift or compact. This ensures regular drainage for essential infrastructure. Even beneath heavy masses or long-term stress, the geonet’s inflexible geometry preserves its permeability, guaranteeing dependable overall performance all through the project’s lifespan.

2.3 Less Excavation, Faster Work

Geonet composite require minimal digging and no heavy fill material, rushing up development and decreasing labor and fabric costs. This streamlined system now not solely shortens mission timelines however additionally minimizes environmental disturbance and web page restoration needs.

3. Geonet Drainage Key Applications

Geonet drainage structures are extensively used in civil, environmental, and geotechnical engineering. Their versatility, durability, and excessive drainage effectivity make them appropriate for a range of traumatic applications:

3.1 Landfills – For leachate series and fuel venting

Geonet drainages are used below landfill caps and liners to efficaciously accumulate and transport leachate whilst additionally venting decomposition gases like methane. They make certain environmental safety and comply with strict waste containment regulations.

3.2 Retaining Walls – To relieve water strain at the back of structures

Installed at the back of maintaining walls, geonets stop water build-up by using draining it laterally, decreasing hydrostatic stress that can compromise structural stability.

3.3 Tunnels and Subways – As phase of waterproofing and drainage layers

In underground constructions, Geonet drainages are used at the back of shotcrete or membrane layers to direct seepage away from tunnel linings, stopping water ingress and prolonging infrastructure life.

3.4 Road and Railway Embankments – To stabilize slopes and control runoff

Used inside embankments and slopes, geonets assist stop erosion, put off extra moisture, and enhance long-term balance of transportation infrastructure, particularly in heavy rain or flood-prone areas.

3.5 Green Roofs and Planters – For environment friendly drainage besides soil loss

Geonet drainages create a subsurface drainage layer that prevents waterlogging whilst conserving sufficient moisture for vegetation. With geotextile filters, they keep away from soil erosion and make sure root fitness in city landscaping.

3.6 Sports Fields – Keeps surfaces dry and playable year-round

Beneath artificial or herbal turf, Geonet drainage swiftly channel extra water away, stopping puddles and permitting regular use even after rainfall, which is fundamental for expert and leisure fields.

4. Geonet Drainage Durable Reason

4.1 Excellent Chemical Resistance – Ideal for landfills and contaminated sites

HDPE resists degradation from a large vary of chemicals, inclusive of acids, bases, solvents, and leachate. This makes geonets appropriate for aggressive environments such as municipal landfills, mining sites, and industrial waste areas, the place long-term chemical publicity is a concern.

4.2 UV Resistance – Suitable for uncovered applications

HDPE geonets comprise UV stabilizers that shield them from daylight degradation, permitting them to be used in brief floor installations or uncovered prerequisites except speedy getting older or loss of performance.

4.3 Thermal and Biological Stability – Unaffected via warmness or microbial activity

Geonets made from HDPE are dimensionally secure over a extensive temperature range, and they do now not help organic boom such as mold, fungi, or bacteria. This ensures they continue their drainage potential even in heat climates or organic-rich soils.

4.4 High Compressive Strength – Maintains drainage below heavy loads

HDPE geonets are designed with structured, multi-directional channels that stand up to excessive compressive masses besides give way or deformation. They proceed to grant uninterrupted drainage even when buried below roads, embankments, or thick landfill caps.

5. Technical Specifications

Property | Specification |

Material | High-Density Polyethylene (HDPE) |

Structure | Bi-planar or Tri-planar |

Thickness | 5 mm – 10 mm (depending on model) |

Tensile Strength | > 10 kN/m |

Flow Capacity (Gradient 1) | Up to 3 L/m·s (varies by model) |

Temperature Resistance | -30°C to +85°C |

UV Resistance | Yes |

Chemical Resistance | Excellent against acids, alkalis, leachate |

Standard Widths | 2–4 meters |

Roll Length | 30–100 meters (customizable) |

6. Geonet Drainage Main Advantages

Geonet drainage structures mix engineering precision, fabric performance, and set up efficiency, making them best for modern-day infrastructure and environmental safety projects. Here are their key advantages:

6.1 Efficient Drainage – High waft ability in each directions

Geonets are designed with interconnected, multi-directional channels that permit fast water or fuel go with the flow horizontally and vertically. This ensures dependable drainage in multi-layer systems, such as landfills, tunnels, or inexperienced roofs, even below various stress conditions.

6.2 Compression Resistant – Maintains structure beneath heavy backfill

Unlike typical drainage substances that may additionally deform or cave in beneath pressure, geonets preserve their structural geometry and drainage effectivity when subjected to the weight of overlying soil, roads, or buildings.

6.3 Durable and Long-Lasting – Withstands harsh environments

Made from HDPE or comparable polymers, geonets face up to chemical attack, UV degradation, thermal extremes, and organic activity. Their strong development ensures a long time of maintenance-free overall performance even in aggressive or buried environments.

6.4 Lightweight and Easy to Install – Saves time and cost

Geonets are lots lighter and thinner than gravel or different typical drainage layers, making them effortless to transport, handle, and install, even in restrained or far flung locations. This reduces labor requirements, set up time, and undertaking costs.

6.5 Environmentally Friendly – Reduces use of herbal aggregates

By changing thick gravel layers, geonets minimize the want for mining, transporting, and putting herbal materials. This now not solely minimizes environmental have an impact on however additionally helps initiatives meet inexperienced constructing or sustainability goals.

6.6 Versatile Applications – From waste containment to inexperienced infrastructure

Geonet drainage can be used in landfills, roadbeds, tunnels, holding walls, sports activities fields, and inexperienced roofs, demonstrating flexibility throughout each heavy-duty industrial and eco-sensitive city projects.

About BPM GEOSYNTHETICS

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, and geogrids. Established in 2007, the company is committed to providing one-stop services in research, production, and sales, with a focus on innovation and quality. BPM's products, certified by EU CE and GLP, meet ISO 9001, ISO 14001, and OHSAS 18001 standards, ensuring performance and durability. With a manufacturing facility of over 36,000 square meters and a team of 120 technical experts, BPM Geosynthetics serves various sectors such as aquaculture, erosion control, drainage, and municipal engineering. We look forward to partnering with you to tackle complex challenges using our high-performance geosynthetic solutions.