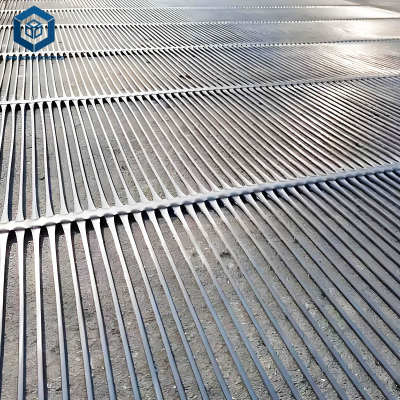

PET Filament Geotextile

PET Filament Geotextile is a high-performance geosynthetic fabric made of 100% polyester non-stop filaments. Through superior needle-punching technology, it varieties a strong, durable, and permeable fabric that ensures long-term soil stabilization, separation, filtration, and drainage performance. Widely used in street construction, embankments, railways, landfills, and hydraulic engineering, it affords dependable reinforcement and safety in worrying environments.

- Excellent Filtration & Drainage – Allows water to skip whilst efficiently holding soil particles.

- Resistance to Chemical & Biological Degradation – Stable in soil environments, resistant to acids, alkalis, and microorganisms.

- UV & Weather Resistance – Ensures balance and overall performance even beneath outside exposure.

- Cost-Effective Engineering Solution – Reduces building charges by way of extending infrastructure life.

PET Filament Geotextile, manufactured by way of BPM Geosynthetics, is a high-performance geosynthetic cloth engineered from one hundred percent virgin polyester (PET) non-stop filaments. These filaments are cautiously aligned and bonded collectively the usage of superior needle-punching technology, ensuing in a extraordinarily uniform and steady cloth structure. The special manufacturing procedure ensures outstanding tensile strength, dimensional stability, and long-term durability, even beneath heavy masses and harsh environmental conditions.

In addition to its mechanical strength, the PET filament geotextile fabric presents super permeability and filtration capabilities, permitting water to bypass whilst successfully holding soil particles. This makes it perfect for a broad vary of functions consisting of street and railway construction, slope stabilization, drainage systems, landfill protection, and water conservancy projects.

Designed to stand up to publicity to UV radiation, chemical agents, and severe climate conditions, PET filament geotextile cloth gives reliable overall performance for each momentary building initiatives and long-term civil engineering applications. With its mixture of strength, flexibility, and filtration efficiency, it meets the stringent necessities of modern-day civil engineering, infrastructure development, and environmental safety projects.

1. PET Filament Geotextile Product Functions

1.1 PET Filament Geotextile Separation

PET Filament geotextile membrane acts as a strong barrier between special soil layers, efficiently stopping intermixing of subgrade and mixture materials. This ensures the structural integrity and durability of roads, embankments, railways, and different civil engineering initiatives through keeping the designed soil layer houses and stopping contract or deformation.

1.2 PET Filament Geotextile Filtration

The special shape of the filament material offers top notch permeability whilst keeping satisfactory soil particles, permitting water to skip via except inflicting soil erosion. Non woven geotextile fabric makes it perfect for drainage systems, maintaining walls, landfills, and slope protection, the place managed water drift and soil steadiness are critical.

1.3 PET Filament Geotextile Drainage

Acting as a high-efficiency drainage medium, PET geo fabric enables the easy go with the flow of water alongside development layers. It helps minimize hydrostatic strain at the back of protecting walls, prevents water accumulation in subgrades, and ensures long-term balance in roadbeds, railway foundations, landfill capping layers, and different water-sensitive structures.

1.4 PET Filament Geotextile Reinforcement

By distributing masses over a large area, the non woven geotextile enhances soil power and improves load-bearing capacity, lowering contract and deformation. This feature is imperative in street construction, embankments, railway tracks, and slope stabilization, presenting long-term structural help below heavy visitors and dynamic loading conditions.

1.5 PET Filament Geotextile Protection

PET Filament non woven landscape fabric serves as a cushioning and shielding layer, protective geomembranes, geomembrane liners, and different touchy substances from punctures, tearing, or mechanical damage. This is specifically essential in landfill liners, water containment systems, and drainage layers, the place geofabric integrity is crucial for environmental safety and assignment safety.

2. PET Filament Geotextile Key Features

2.1 High Strength and Durability

Manufactured from one hundred percent virgin polyester (PET) non-stop filaments, this non woven geotextile membrane famous gorgeous tensile strength, tear resistance, and dimensional stability. It continues its structural integrity underneath heavy loads, dynamic pressure, and long-term environmental stress, making sure dependable overall performance and prolonged provider existence in stressful civil engineering and infrastructure projects.

2.2 Excellent Permeability

The cautiously engineered filament community approves managed water glide whilst efficaciously keeping soil particles, offering environment friendly filtration besides compromising drainage. This characteristic is specially precious for street subgrades, drainage layers, holding walls, and landfill systems, the place water administration and soil steadiness are critical.

2.3 Chemical Resistance

PET filament geotextile drainage fabric is extraordinarily resistant to acids, alkalis, and common development chemicals, making it appropriate for use in environments uncovered to industrial or herbal chemical agents. This ensures long-term sturdiness and minimal degradation, even in chemically aggressive soils or waste containment applications.

2.4 UV and Weather Resistance

Designed for outside applications, the geotextile filter fabric withstands extended publicity to ultraviolet (UV) radiation, excessive temperatures, and climate fluctuations. Geotextile filter cloth resilience prevents speedy degradation and ensures that the film geotextile performs constantly at some stage in development and for the duration of its lifecycle.

2.5 Wide Roll Widths

Available in a range of huge roll sizes, the geotextile drainage approves for quicker set up with fewer seams, lowering labor and building time. Large rolls are less difficult to handle, transport, and lay on-site, enhancing normal effectivity for large-scale infrastructure, road, and environmental safety projects.

3. Advantages of Choosing BPM Geosynthetics PET Filament Geotextile

3.1 Trusted Manufacturer

With over 20 years of trip in the geosynthetics industry, BPM Geosynthetics has set up a robust popularity for reliability, consistency, and innovation. Their significant information ensures that each and every geo fabric material product meets rigorous engineering requirements, supplying purchasers with self assurance in long-term venture performance.

3.2 Certified Quality

All merchandise are manufactured in compliance with ISO, CE, and different worldwide engineering standards, making sure excessive quality, consistency, and safety. Rigorous first-rate manage tactics all through manufacturing assurance that every roll of geotechnical cloth performs reliably in civil engineering, infrastructure, and environmental safety applications.

3.3 Global Projects

BPM Geosynthetics merchandise have been efficiently utilized in over eighty countries, masking numerous climates and terrains. This international song document demonstrates the adaptability and effectiveness of their nonwoven geotextile fabric in initiatives ranging from avenue construction, railway subgrades, and landfill safety to slope stabilization and water administration systems.

3.4 Technical Support

Beyond imparting excellent geotextile fabric under gravel, BPM Geosynthetics presents complete technical support, along with project-specific plan consultation, set up guidance, and expert after-sales service. Clients gain from specialist recommendation on fabric selection, set up techniques, and long-term maintenance, making sure optimized overall performance and decreased chance at some point of the venture lifecycle.

4. PET Filament Geotextile Applications

4.1 Road and Railway Construction

Geotextile landscape fabric is substantially used for subgrade stabilization, separation of soil layers, and reinforcement of roadbeds and railway foundations. By distributing masses evenly and stopping soil intermixing, it enhances structural integrity, reduces settlement, and extends the carrier existence of transportation infrastructure below heavy visitors and dynamic loading conditions.

4.2 Water Conservancy Projects

Ideal for canal lining, embankment reinforcement, and dam protection, this non woven filter fabric affords filtration, drainage, and reinforcement. It helps manage water flow, forestall soil erosion, and preserve structural stability, making sure long-term overall performance in irrigation systems, reservoirs, and flood manage projects.

4.3 Landfill Engineering

Serving as a shielding and filtration layer, non woven geotextile drainage fabric safeguards geomembranes and different containment liners in landfills. It prevents punctures and mechanical injury whilst preserving high quality drainage, contributing to environmental security and compliance with waste administration regulations.

4.4 Coastal and Riverbank Protection

The geotextile road fabric is broadly utilized in erosion manage and slope stabilization alongside coastlines, rivers, and lakes. By preserving soil steadiness and permitting managed water flow, it prevents soil loss, reduces hydraulic pressure, and protects infrastructure from herbal erosion processes.

4.5 Drainage Systems

Non woven geotextile landscape fabric features efficaciously in protecting walls, tunnels, and underground facilities, appearing as a filtration and drainage layer. It allows the elimination of extra water, reduces hydrostatic pressure, and protects constructions from water-related damage, making sure long-term sturdiness and safety.

5. PET Filament Geotextile Maintenance & Service Life

5.1 Durability underneath Normal Use

PET geo textile material is manufactured from one hundred percent virgin polyester (PET) non-stop filaments, giving it excellent mechanical strength, dimensional stability, and resistance to environmental degradation. Under fashionable set up conditions, the non woven geotextile filter fabric can keep its structural integrity and practical overall performance for decades, making it appropriate for long-term civil engineering, infrastructure, and environmental projects.

5.2 Inspection and Maintenance

While geo tech fabric is pretty durable, ordinary inspections are endorsed for the duration of building and periodic exams in a while to make sure that the material stays intact, specifically in areas uncovered to heavy mechanical stress, sharp objects, or erosion. Any seen harm or displacement must be addressed without delay to keep most reliable performance.

5.3 Extending Service Life

To maximize sturdiness and longevity:

- Proper Installation – Follow producer pointers for laying, overlapping, and securing the geotextile. Avoid stretching or folding unnecessarily.

- Protection from Mechanical Damage – Use defensive layers, such as sand or gravel, when masking the geotextile to stop punctures.

- Avoid Direct UV Exposure – While the cloth is UV-resistant, minimizing extended direct daylight publicity earlier than protecting can in addition prolong carrier life.

- Chemical Considerations – Ensure the geotextile is no longer uncovered to fantastically aggressive chemical compounds outdoor its targeted tolerance.

By adhering to ideal set up and upkeep practices, PET Filament Geotextile can supply long-lasting performance, making sure that infrastructure and environmental safety structures continue to be safe, stable, and superb over time.

Conclusion

As a main geosynthetic product, PET Filament Geotextile by way of The Best Project Material Co., Ltd.(BPM Geosynthetics)combines strength, filtration, and sturdiness to supply dependable overall performance for a huge vary of engineering applications. Its validated quality, alongside with BPM Geosynthetics’s world understanding and support, makes it the favored preference for engineers, contractors, and environmental professionals worldwide.