High Density Polyethylene HDPE Liners

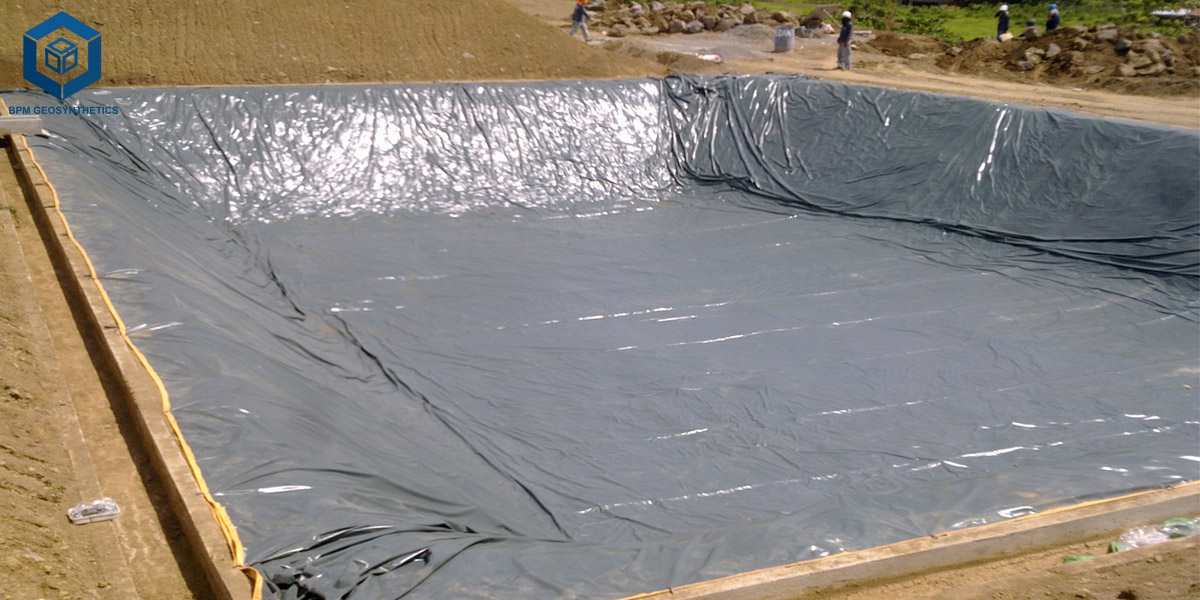

High Density Polyethylene HDPE Liners are particularly long lasting geomembranes designed to furnish gold standard impermeability and chemical resistance for a vast vary of civil, environmental, and geotechnical applications. With first-rate long-term performance, HDPE Liners are the most extensively used answer for containment and waterproofing projects.

- Superior Impermeability: Acts as a dependable barrier towards water, chemicals, and waste materials, making sure long-lasting containment.

- Flexible Applications: Suitable for landfills, mining tailings, reservoirs, ponds, canals, tunnels, and wastewater therapy facilities.

- Cost-Effective & Eco-Friendly: Long provider lifestyles reduces renovation charges whilst helping environmental safety goals.

- Customizable Options: Available in a variety of thicknesses, widths, and roll sizes to meet project-specific requirements.

High Density Polyethylene HDPE Liners are top rate geomembrane sheets manufactured via extrusion or calendering of specifically formulated HDPE resin. Engineered for most desirable impermeability, these HDPE liner create a long-lasting barrier towards liquids, gases, and chemicals, making them one of the most dependable options for environmental safety and containment. With delivered carbon black and stabilizers, HDPE pond liner provide remarkable resistance to UV radiation, weathering, and oxidation, making sure sturdiness even underneath harsh outside conditions. They are broadly utilized in engineered landfills, mining tailings ponds, reservoirs, canals, wastewater cure facilities, and a number of secondary containment systems. By combining excessive tensile strength, puncture resistance, and top notch chemical compatibility, HDPE geomembrane supply long-term overall performance and shield tasks towards leakage, contamination, and environmental risks.

1. High Density Polyethylene HDPE Liners — Material Composition & How They’re Made

1.1 Base Resin

- Virgin HDPE: Manufactured exceptionally from 100% virgin high-density polyethylene resin, making sure steady performance, excessive purity, and absence of recycled contaminants.

- Density: The resin is formulated to acquire a minimal sheet density of ≥ 0.940 g/cm³, presenting rigidity, chemical resistance, and mechanical strength.

- Molecular structure: High molecular weight with high-quality crystallinity, giving the liners low permeability and lengthy provider life.

1.2 Additives

- Carbon Black: Incorporated at about 2.0–3.0% with the aid of weight to supply high-quality UV protection, limit photo-oxidation, and prolong sturdiness in uncovered environments.

- Antioxidants / Anti-agers: Enhance thermal steadiness and extend polymer degradation at some stage in each manufacturing and long-term service.

- Processing Aids: Improve soften drift at some point of extrusion or calendaring, making sure uniform thickness and easy surfaces.

- Optional Slip or Anti-stick Agents: Reduce floor tackiness, enhance handling, and facilitate subject set up barring compromising barrier performance.

1.3 High Density Polyethylene HDPE Liners Manufacturing Process

- Extrusion / Blown Film: HDPE pellets are melted and extruded thru a die to structure non-stop sheets; blown movie strategies produce seamless rolls with high uniformity.

- Flat-Die Extrusion / Calendaring: Resin soften is extruded via a large die, then pressed and cooled by polished rollers to manipulate thickness precisely.

- Cooling & Trimming: After forming, geomembrane pond liner sheets are cooled beneath managed conditions, trimmed to genuine widths, and inspected for uniformity.

- Winding & Packaging: Finished sheets are wound into rolls, generally with widths up to 7–10 meters and various lengths relying on thickness (thinner geomembrane sheet permit longer rolls).

- Surface Finish: Liners can be produced as smooth (easy to clean, excessive impermeability) or textured (engineered for greater friction attitude and slope stability).

1.4 High Density Polyethylene HDPE Liners Quality Control

Each stage consists of tests for thickness consistency, floor defects, carbon black dispersion, and mechanical energy to make certain compliance with global requirements such as ASTM and GRI GM13.

2. High Density Polyethylene HDPE Liners Typical Physical & Mechanical Performance

- Thickness: many times 0.2 mm – 3.0 mm (10–120 mil); general business preferences consist of 0.5, 0.75, 1.0, 1.5, 2.0 and 3.0 mm.

- Density: ≈ 0.94 g/cm³ (formulated sheet density).

- Tensile electricity (break): roughly 20 – 80 kN/m relying on thickness (example: ~27 kN/m for 1.0 mm).

- Elongation at break: very excessive (typical ≈ 700% reported).

- Tear resistance: will increase with thickness (example vary ≈ 93 – 374 N for 0.75–3.0 mm).

- Puncture resistance: instance vary ≈ 240 – 960 N (0.75–3.0 mm).

- Carbon black content: ~2.0–3.0% (for UV safety and long-term stability).

- Oxidative Induction Time (OIT): wellknown and high-pressure OIT values are used to decide antioxidant package deal and long-term overall performance (typical OIT minimums suggested by using manufacturers; e.g., fashionable OIT ≈ 100 min, HP OIT ≈ 500 min in consultant product data).

3. High Density Polyethylene HDPE Liners Chemical & Environmental Resistance

3.1 Chemical Resistance

HDPE geomembrane liner provide fantastic resistance to a vast vary of chemicals, which include acids, alkalis, salts, hydrocarbons, and many industrial leachates.

Ideal for environments the place chemical publicity is expected, such as industrial containment ponds, mining tailings, and wastewater cure facilities.

For tasks involving particular chemical compounds or excessive concentrations, it is encouraged to seek advice from chemical-resistance tables and observe HDPE liner manufacturers education to make sure long-term performance.

3.2 Temperature Range

HDPE geomembrane sheet function reliably throughout a wide temperature spectrum, keeping structural integrity from nicely beneath freezing up to expanded web page temperatures.

The actual allowable working temperature relies upon on the HDPE components and challenge design; BPM geomembrane manufacturing facility gives specified specs for every product grade to fit undertaking conditions.

3.3 UV / Weathering Resistance

The addition of carbon black and antioxidant applications presents robust resistance to ultraviolet radiation, oxidation, and established weathering.

Textured or black HDPE liners gain the first-rate overall performance underneath direct daylight exposure.

BPM manufacturing unit conducts OIT (Oxidative Induction Time) checking out and long-term weathering research to predict anticipated discipline existence and make sure durability.

4. High Density Polyethylene HDPE Liners Welding, Seams & Quality Assurance

4.1 Seaming Methods

Standard thermal welding techniques consist of hot-wedge welding, extrusion welding (using extrusion guns), and hot-air welding.

All seams ought to be carried out by means of certified operators skilled in BPM Geosynthetics factory-approved welding procedures.

Seam locations, welding parameters, and operator data are documented in seam logs for traceability.

4.2 Seam Testing

Non-destructive trying out strategies consist of vacuum field checking out for textured sheets, air lance testing, and spark trying out for conductive liners.

Destructive trying out includes peel and shear exams on sample seams to affirm weld power in accordance to challenge QA procedures.

Detailed document retaining of all seam tests, along with weld maps and discipline check reports, is fashionable practice.

4.3 Factory Quality Assurance

BPM manufacturing unit performs rigorous pleasant manage at each and every stage of production, together with exams for sheet thickness, density, carbon black dispersion, tensile strength, tear and puncture resistance, and OIT values.

Visual inspection ensures steady floor fantastic and absence of defects.

For most important projects, unbiased third-party inspection can be organized to affirm compliance with worldwide standards.

5. Typical Applications & Why High Density Polyethylene HDPE Liners Are Chosen

5.1 High Density Polyethylene HDPE Liners for Sanitary Landfills

Used as important and cap liners, as nicely as for leachate series and containment systems.

Provides first-rate chemical and puncture resistance, mixed with very low permeability to stop environmental contamination.

5.2 High Density Polyethylene HDPE Liners for Mining Tailings Ponds & Process Water Containment

HDPE geomembrane sheet is sturdy in harsh, chemically aggressive environments.

Properly certain high density polyethylene pond liner make sure long-term steadiness and containment in mining and industrial operations.

5.3 High Density Polyethylene HDPE Liners for Reservoirs, Irrigation Ponds, Fish Farms & Canals

Widely utilized in water containment for agricultural and aquaculture purposes.

Protects water assets via stopping seepage and retaining structural integrity below various conditions.

5.4 High Density Polyethylene HDPE Liners for Wastewater Lagoons, Sludge Ponds & Industrial Secondary Containment

Ideal for municipal and industrial wastewater storage, sludge ponds, and secondary containment at flora and terminals.

Provides chemical resistance, puncture strength, and long-term sturdiness for environmental safety.

5.5 Design & Thickness Guidance

Small ponds or aquaculture ponds commonly use 0.5–1.0 mm HDPE liners.

Landfills, mining tailings, and closely loaded containment areas frequently require 1.5–3.0 mm, relying on web page aggressiveness, chemical exposure, and subgrade conditions.

5.6 Why High Density Polyethylene HDPE Liners is Chosen?

HDPE liner sheet Combines low permeability, chemical resistance, puncture strength, UV stability, and lengthy provider life, making it the most dependable desire for a vast vary of containment applications.

6. High Density Polyethylene HDPE Liners Design & Installation Considerations

6.1 Subgrade Preparation

Prior to hdpe dam liners installation, the subgrade need to be cautiously organized by means of eliminating sharp objects, debris, and massive stones.

Compaction and leveling of the floor assist stop punctures and make certain uniform support.

In areas the place rocks or heavy gear can also be present, a cushion geotextile or protecting layer need to be established to protect the liner.

6.2 Textured vs Smooth Surfaces High Density Polyethylene HDPE Liners

Textured geomembrane liners extend interface friction and are endorsed for slopes or places the place slope steadiness is critical.

Smooth geomembrane liners are simpler to handle, weld, and clean, making them appropriate for horizontal surfaces and water containment applications.

6.3 Anchoring & Terminations

Proper anchoring at the top, bottom, and round structural small print such as concrete curbs is essential.

Manufacturer-approved termination structures must be used, and uncovered edges have to be protected with soil or ballast to tightly closed the liner and forestall movement.

6.4 Temporary Protection During Installation

Minimize foot and equipment visitors without delay on uncovered liners to stop damage.

Use transient defensive layers such as geotextiles, sandbags, or timber planks when necessary, specifically in high-traffic areas.

6.5 Leak Detection Systems

For high-risk sites, conductive hdpe impermeable liner or composite structures with built-in leak detection layers (such as conductive scrim or geonet) can be specified.

These structures enable early detection of manageable leaks, bettering long-term security and environmental protection.

7. High Density Polyethylene HDPE Liners Repair & Maintenance

7.1 Minor Damage

Small punctures or tears can be repaired the use of welded patches, both by way of extrusion welding or hot-wedge welding, following the manufacturer’s encouraged patching procedures.

Ensure that the location round the harm is smooth and dry earlier than making use of the patch to obtain a impervious and long-lasting seal.

7.2 Major Damage or Seam Issues

For widespread tears, seam failures, or broken panels, the affected hdpe membrane sheet part must be removed, re-welded, or changed as necessary.

Post-repair testing, inclusive of damaging or non-destructive seam tests, have to continually be carried out to affirm the integrity of the repair.

7.3 Inspection Frequency

Conduct visible inspections after predominant climate activities such as heavy rain, wind, or flooding.

Schedule everyday periodic QA inspections in accordance to the project’s Operations & Maintenance (O&M) layout to screen liner circumstance and forestall long-term damage.

Pay one-of-a-kind interest to high-stress areas, anchors, seams, and exposed edges the place injury is greater possibly to occur.

8. High Density Polyethylene HDPE Liners Advantages vs Common Alternatives

8.1 High Density Polyethylene HDPE Liners Compared with PVC / EPDM

HDPE liner supply most fulfilling chemical resistance in opposition to acids, alkalis, salts, and industrial leachates, making them perfect for aggressive chemical environments.

Polyethylene pond liners additionally provide greater puncture and tear strength, bettering sturdiness in heavy-duty purposes such as landfills, mining ponds, and industrial containment.

However, HDPE geomembrane pond liner is stiffer and much less bendy than elastomeric substances like PVC or EPDM, which might also be a consideration for complicated details, tight corners, or very low-temperature applications.

8.2 High Density Polyethylene HDPE Liners Compared with LDPE / LLDPE

HDPE liner pond has greater density, rigidity, and chemical resistance, offering long-term overall performance in disturbing environments.

LLDPE or LDPE geomembrane can also be desired in initiatives requiring more flexibility, such as bloodless climates, fairly irregular surfaces, or areas with prevalent motion and settling.

Geomembrane material resolution need to reflect onconsideration on a stability of chemical exposure, slope angles, mechanical loads, subgrade conditions, and set up constraints to make certain most suitable overall performance and longevity.

8.3 Key Advantages of High Density Polyethylene HDPE Liners Overall

Excellent long-term sturdiness and low permeability.

High resistance to puncture, tear, chemical attack, and UV exposure.

Proven overall performance throughout landfills, mining, water containment, and industrial applications, making high density polyethylene liner the favored preference the place reliability and environmental safety are critical.

9. Summarize

High Density Polyethylene HDPE Liners are high-performance geomembrane sheets imparting superb impermeability, chemical resistance, UV stability, and long-term durability. Suitable for landfills, mining ponds, reservoirs, irrigation canals, and industrial containment, they furnish bendy thickness and floor picks for slopes and high-stress areas. Compared with PVC, EPDM, LDPE, or LLDPE, HDPE gives most useful chemical and puncture resistance.

For dependable great and technical support, The Best Project Material Co., Ltd.(BPM Geosynthetics)HDPE Liners are rather recommended, with licensed manufacturing and full undertaking guidance.